Method for predicting variable-amplitude fatigue life of friction stir welding component

A technology of friction stir welding and components, which is applied in the direction of measuring devices, testing material strength by applying repetitive force/pulsation force, instruments, etc., and can solve problems such as crack propagation hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

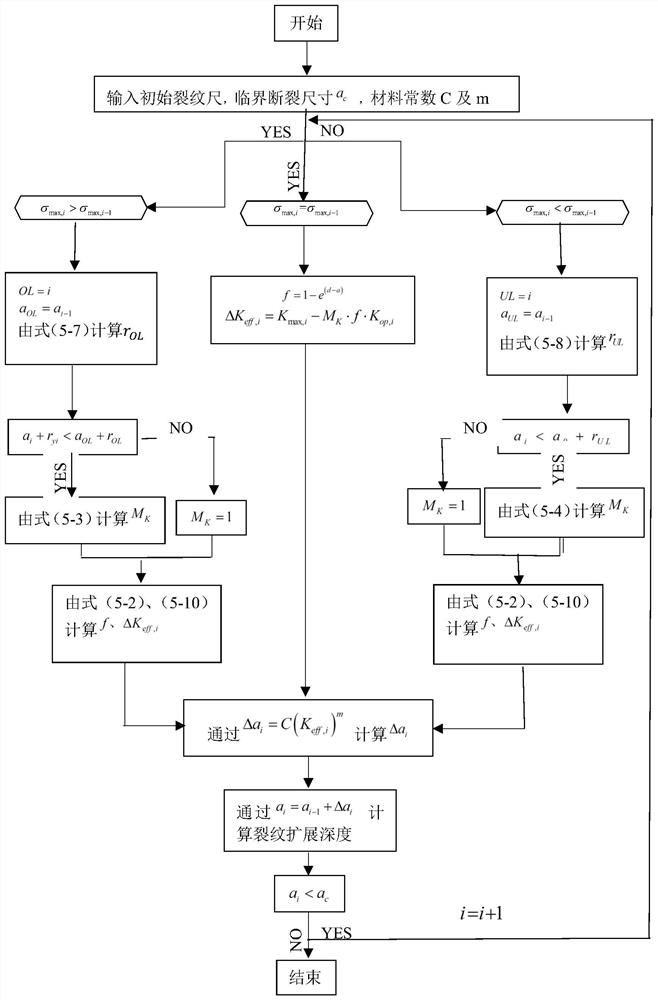

[0058] Such as figure 1 As shown, the specific implementation of the fatigue life prediction method for friction stir welded components based on the load sequence and the performance of each zone of the joint is as follows:

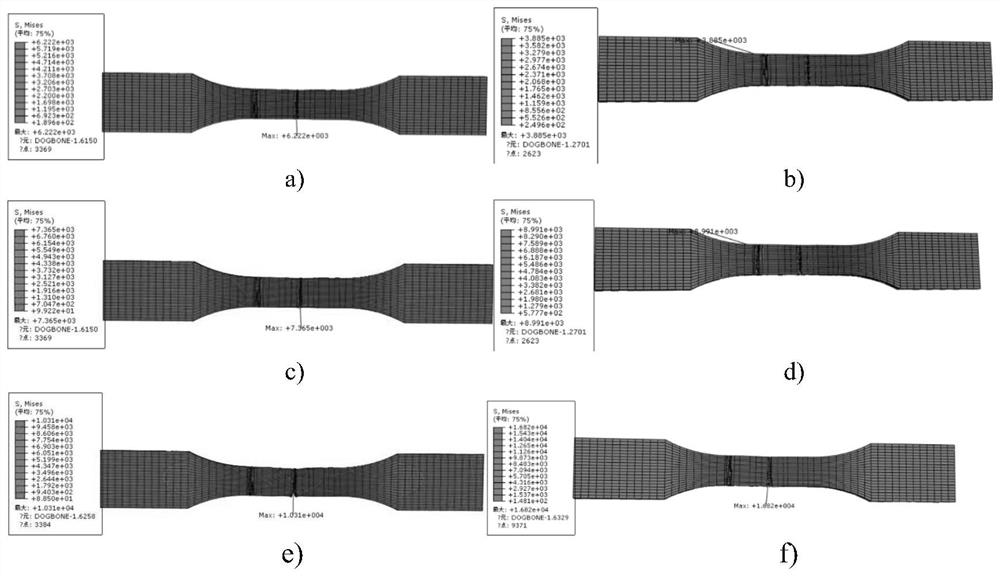

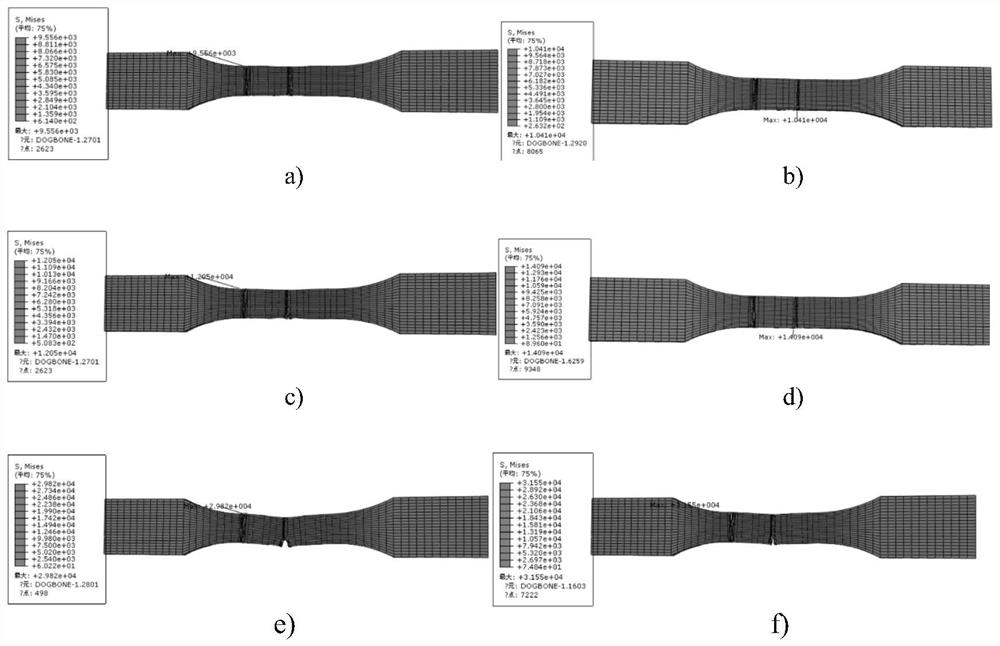

[0059] Step 1): Use finite element software (for example: ABAQUS) to simulate the change of the weak area of the friction stir welded member under different load levels, and model the model according to the characteristics of different material properties in different regions of the friction stir welded member, It is mainly divided into four areas: weld nugget (NZ), heat engine (TMAZ), heat effect (HAZ), and base metal (BM). The material properties of each area are obtained through micro-tensile test data, including stress-strain data and elastic modulus of each area of the joint. , apply different loads, and take the area of maximum stress under different loading levels as the weak area under this loading level;

[0060] Step 2): According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com