Small device for load bending fatigue testing and method

A bending fatigue and testing device technology, applied in the field of fatigue testing, can solve the problems of poor test accuracy, low bending frequency, long test time, etc., and achieve the effect of reasonable structure design, convenient operation and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

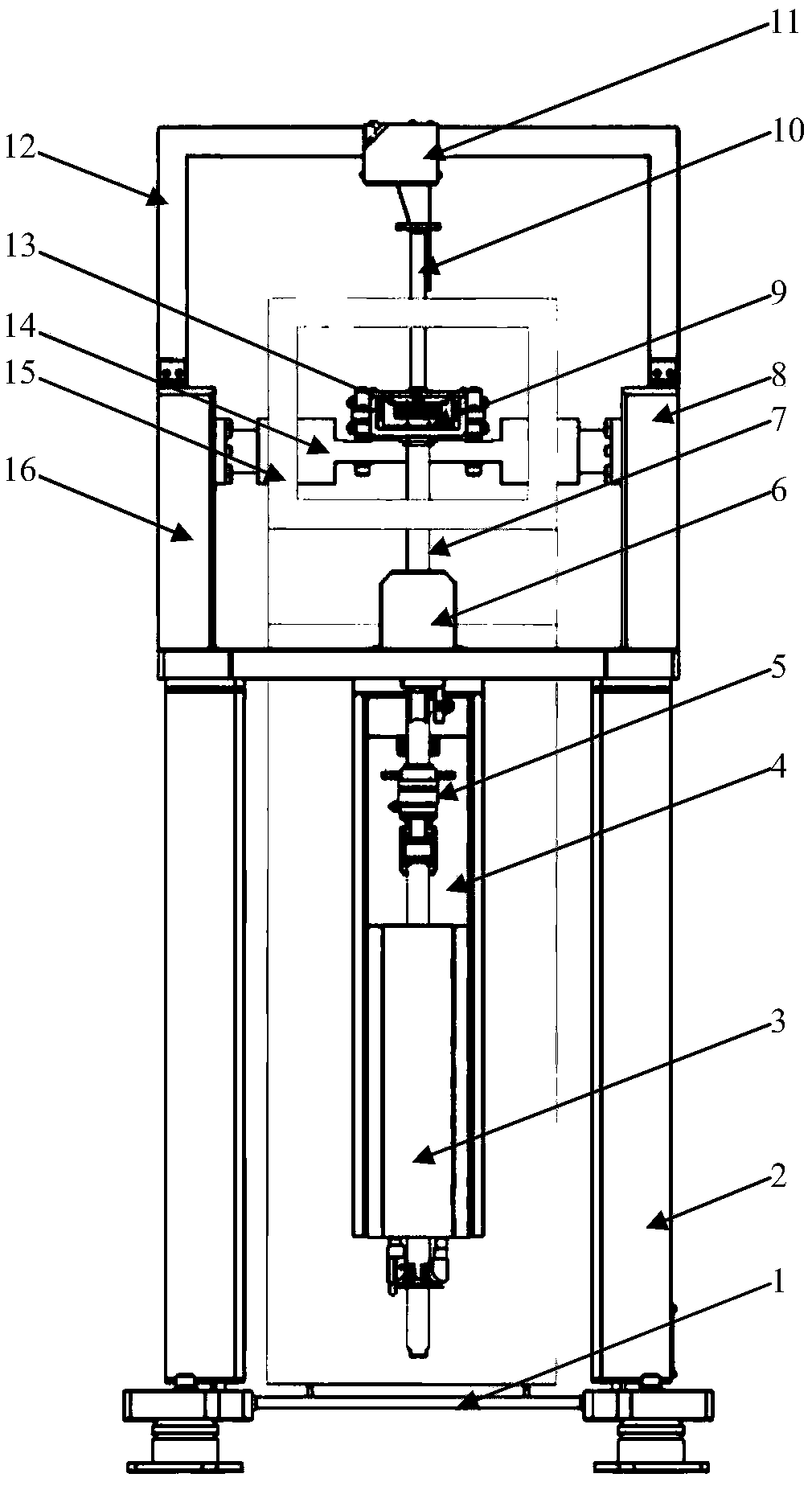

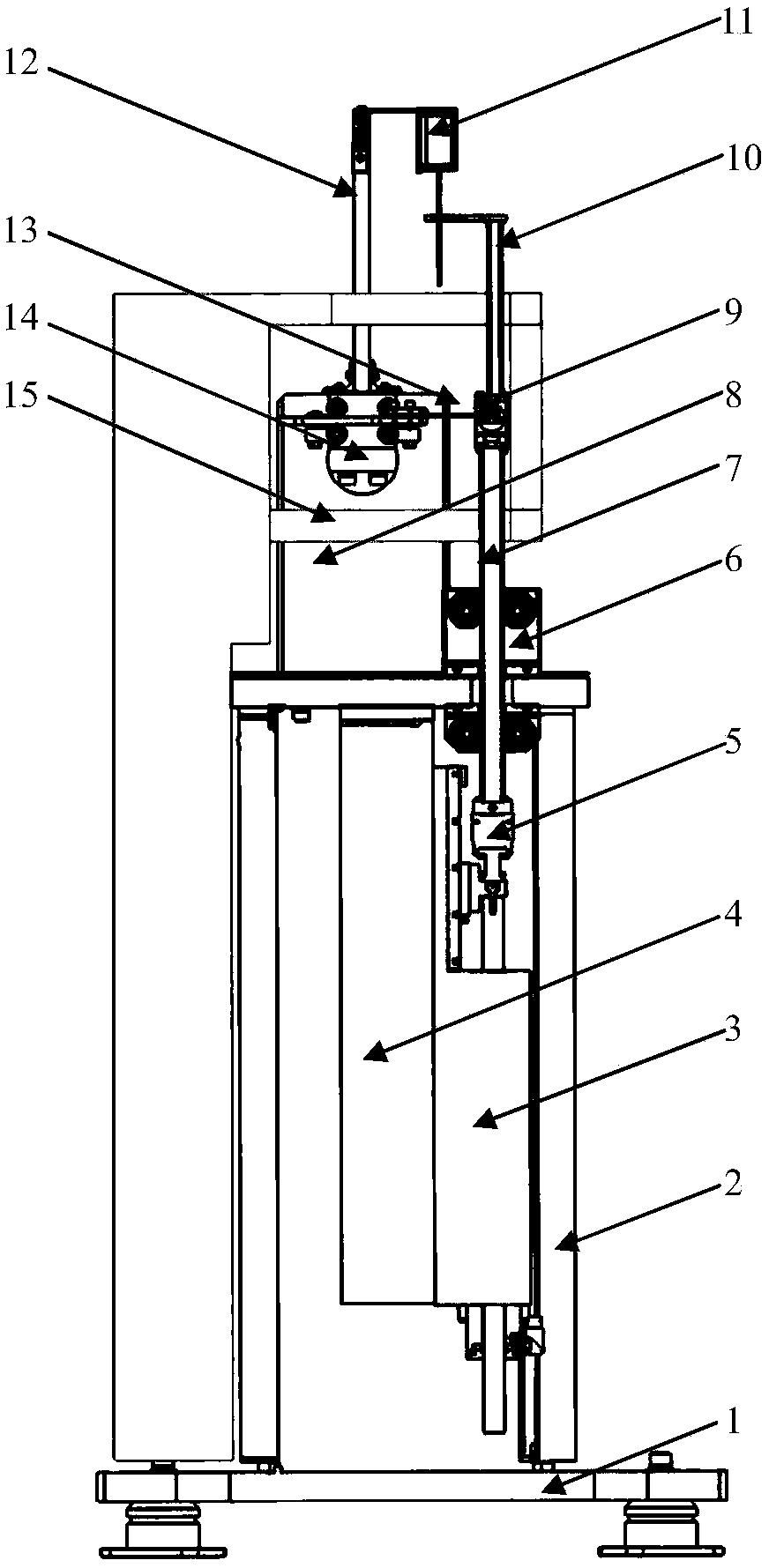

[0020] The small load bending fatigue testing device and method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

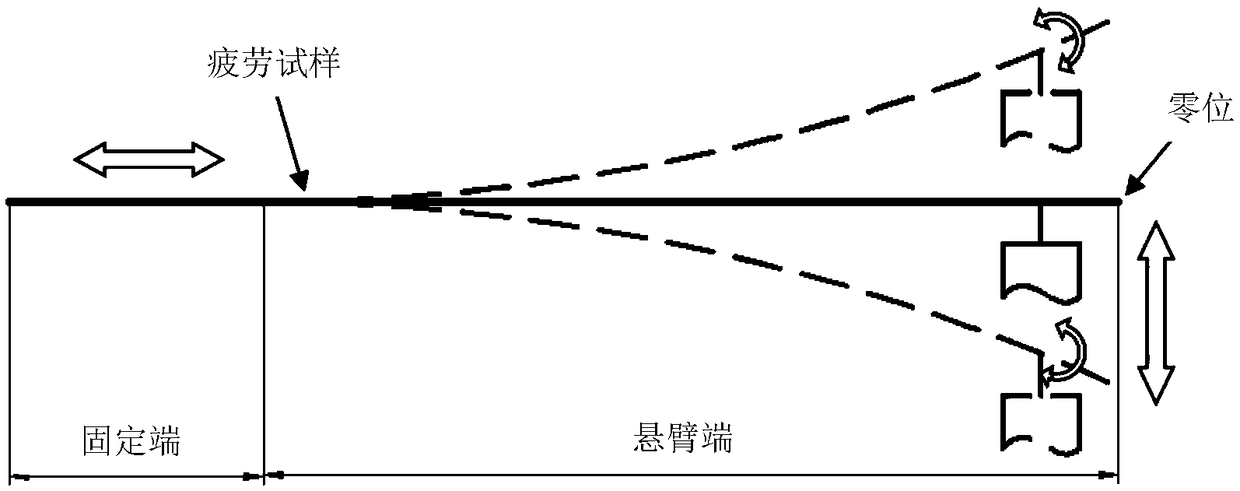

[0021] like figure 1 As shown, the present invention adopts the cantilever beam method to carry out the bending fatigue test. The driving device is a linear motor module, and the motion directly acts on the cantilever end of the fatigue sample, so that the cantilever end of the fatigue sample can move up and down. The bearing in the fixture assembly overcomes the tensile / compressive stress generated by the fatigue specimen during the test, and overcomes the torsional stress generated by the cantilever end of the fatigue specimen through the bearing integrated in the specimen cantilever end fixture assembly, so that the fatigue specimen is tested Only bear cyclic bending stress or strain during the process; by setting the zero position and displacement stroke of the linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com