Method for predicting fatigue life of friction stir welding joint based on grain size and microhardness

A technology for friction stir welding and microhardness, which is used in measuring devices, strength characteristics, instruments, etc., and can solve problems such as being unsuitable for predicting the fatigue life of friction stir welded joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

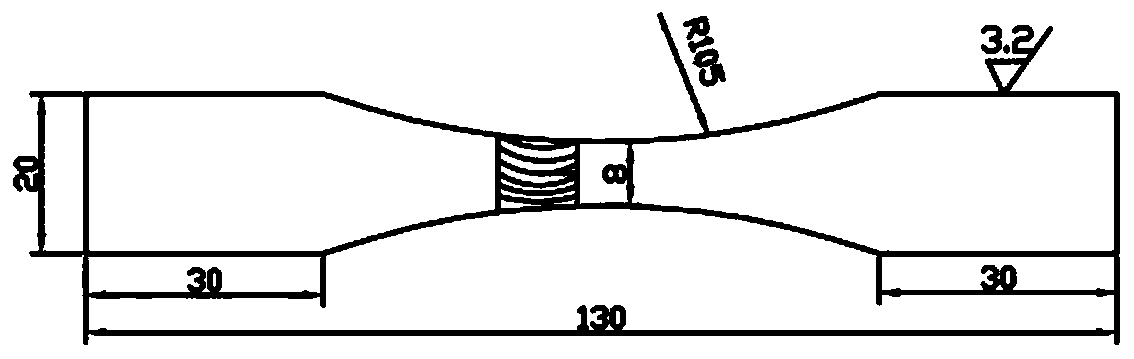

[0039] The sample size and shape described in step 1) are as follows figure 2 shown.

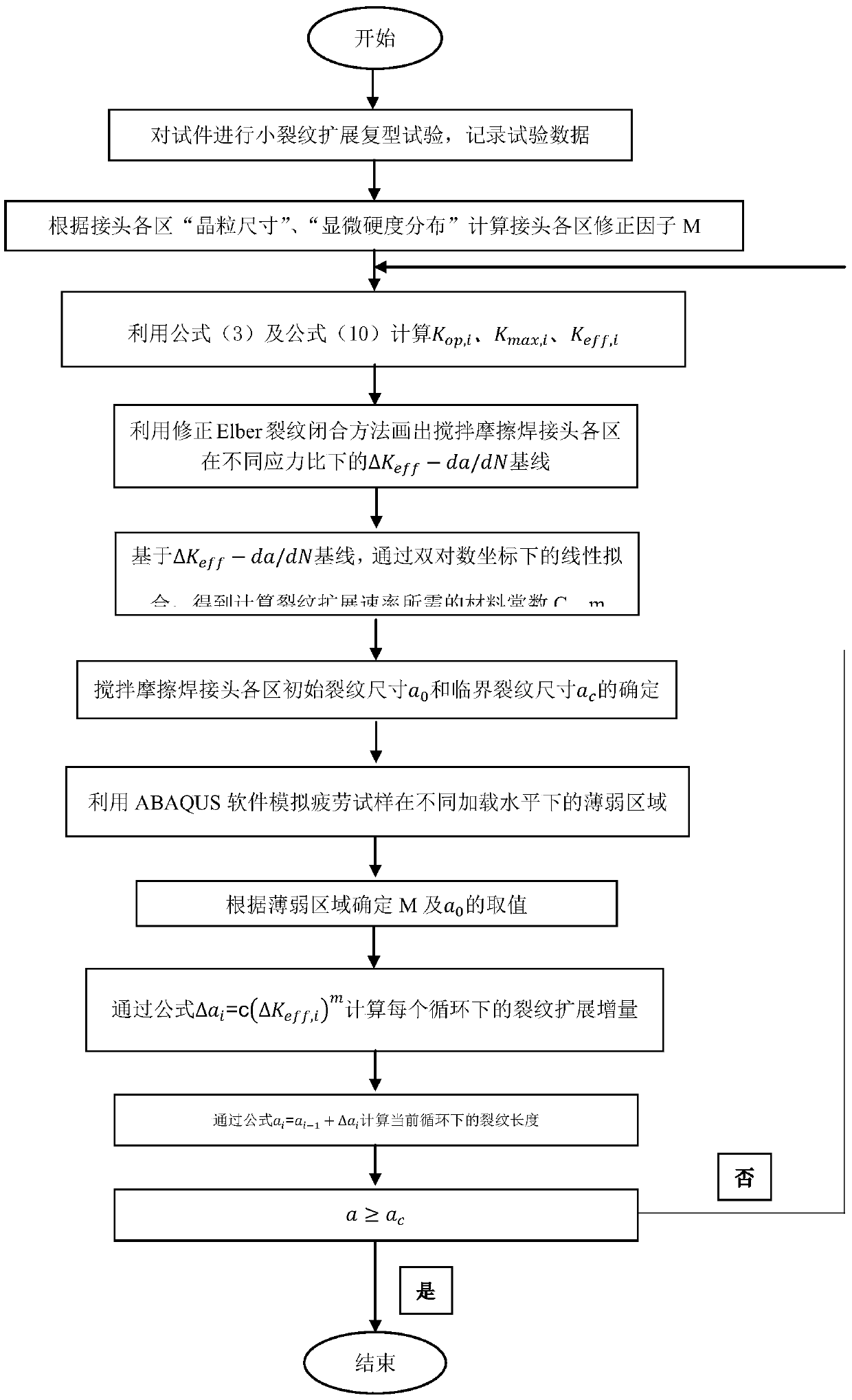

[0040] Such as figure 1 As shown, the specific implementation of a method for predicting the fatigue life of friction stir welded components based on grain size and microhardness is as follows:

[0041] Step 1): Prepare samples according to the partition characteristics of the friction stir welded joint. The middle part of the fatigue sample is arc-shaped. A total of four batches of samples are prepared, each batch of samples is more than 3, and the smallest cross-section of each batch of samples corresponds to The nugget zone (NZ), thermo-mechanical affected zone (TMAZ), heat-affected zone (HAZ) and base metal zone (BM) of fatigue samples are used to make the fracture position of each batch of samples correspond to the minimum cross section. Each batch of samples is loaded under different stress levels, and the small fatigue cracks are replicated with a film. The secant method is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com