Method for determining rock crack stress threshold value based on full-field strain measurement

A strain measurement and threshold value technology, which is applied in the measurement device, the preparation of test samples, and the use of stable tension/pressure to test the strength of materials, etc. It can solve the microstructure heterogeneity of rock materials, unsatisfactory test results, Due to the limited number of strain gauges and other problems, it can achieve the effect of low test environment requirements, convenient results and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, below in conjunction with the accompanying drawings and specific embodiments, further elaborate how the present invention is implemented.

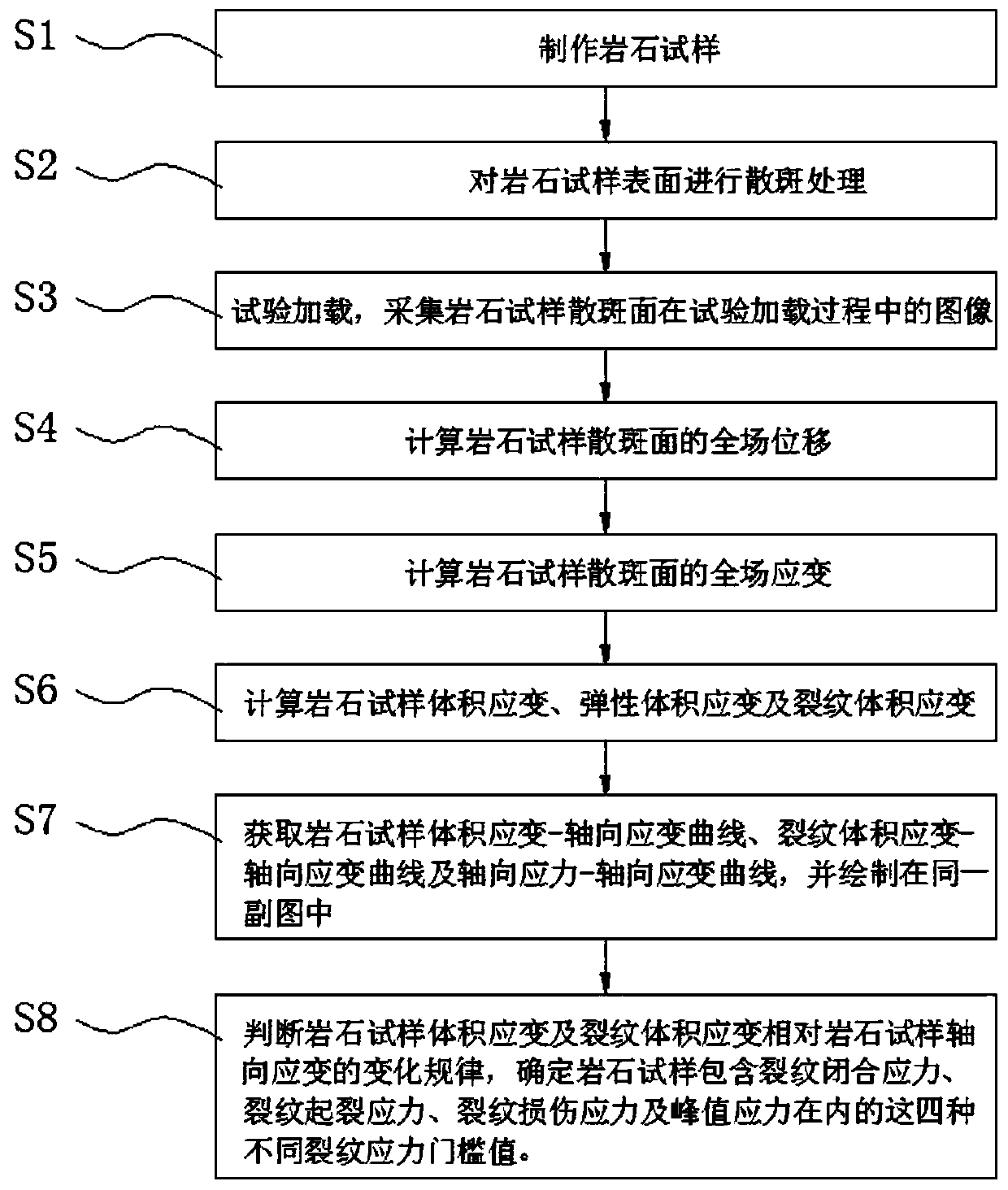

[0053] refer to figure 1 As shown, a kind of method that the present invention provides is based on full-field strain measurement to discriminate rock crack stress threshold value, comprises the following steps:

[0054] S1, making rock samples;

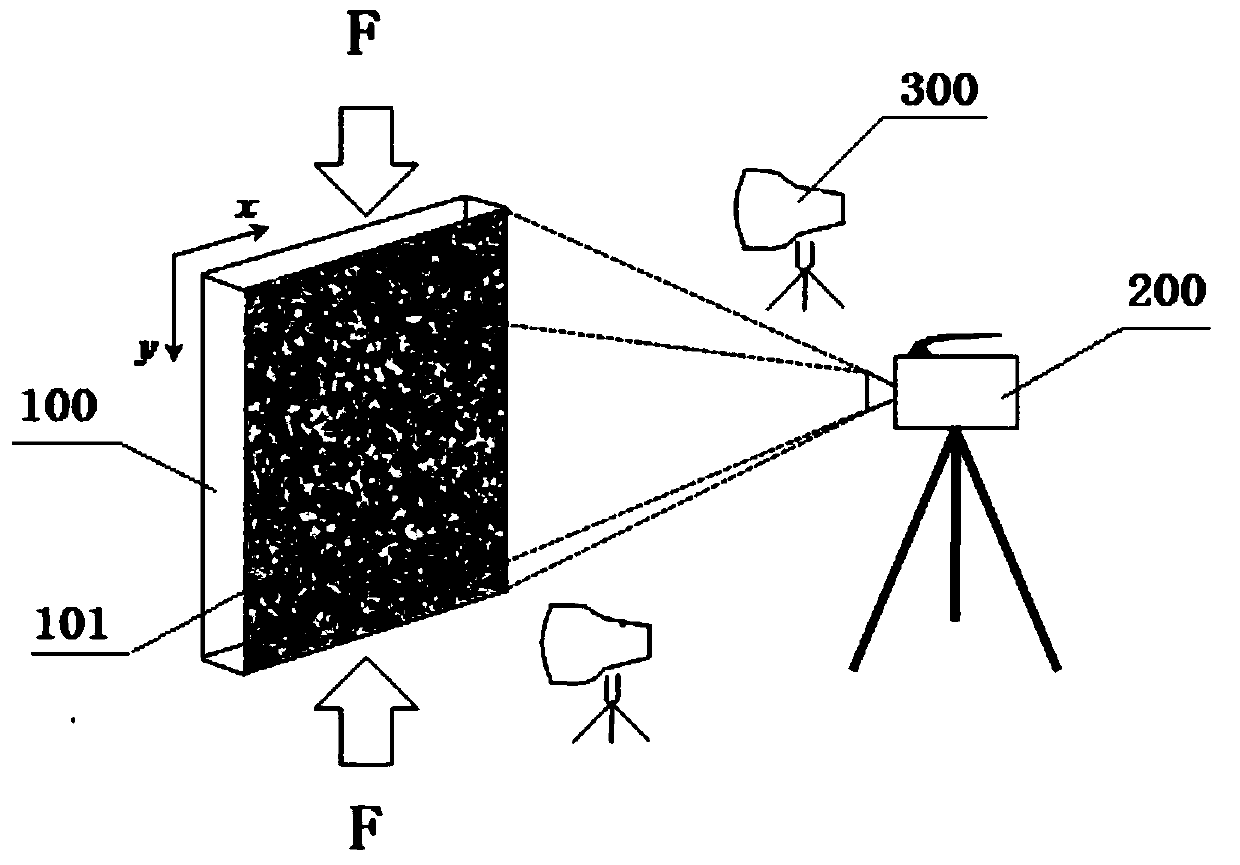

[0055] S2, performing speckle processing on the surface of the rock sample;

[0056] S3, test loading, collecting images of the speckle surface of the rock sample during the test loading process;

[0057] S4, calculating the full-field displacement of the speckle surface of the rock sample;

[0058] S5, calculating the full-field strain of the speckle surface of the rock sample;

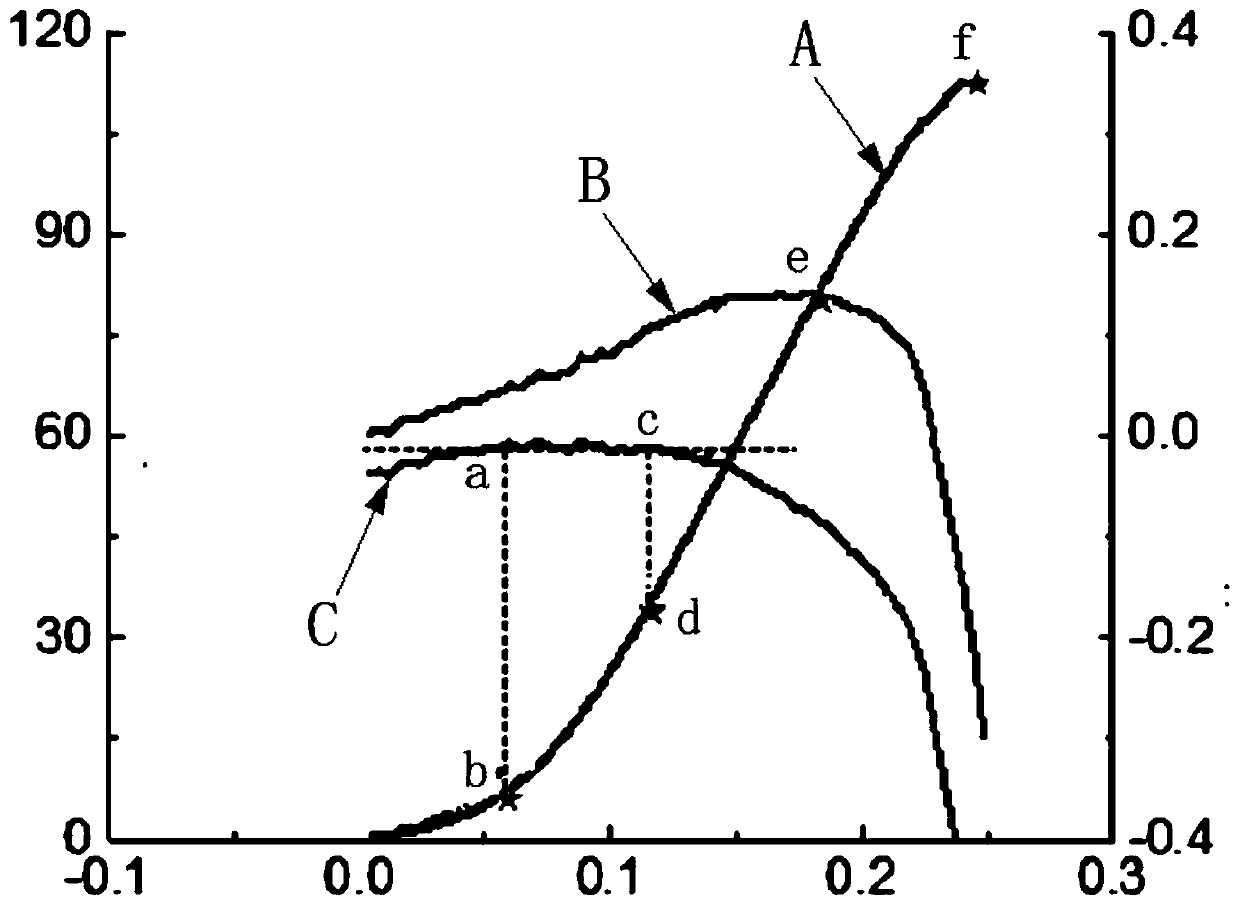

[0059] S6, calculating the rock sample volume strain, elastic volume strain and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com