Method for preparing solid core rod of one-step molded high-voltage composite insulator

A composite insulator, high-voltage technology, applied in the direction of insulators, circuits, electrical components, etc., can solve the problems of slow speed, low success rate, pultrusion, etc., and achieve the effect of firm overall structure, dense products, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

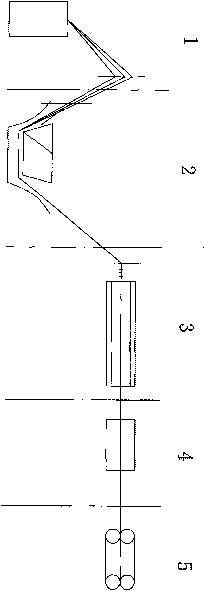

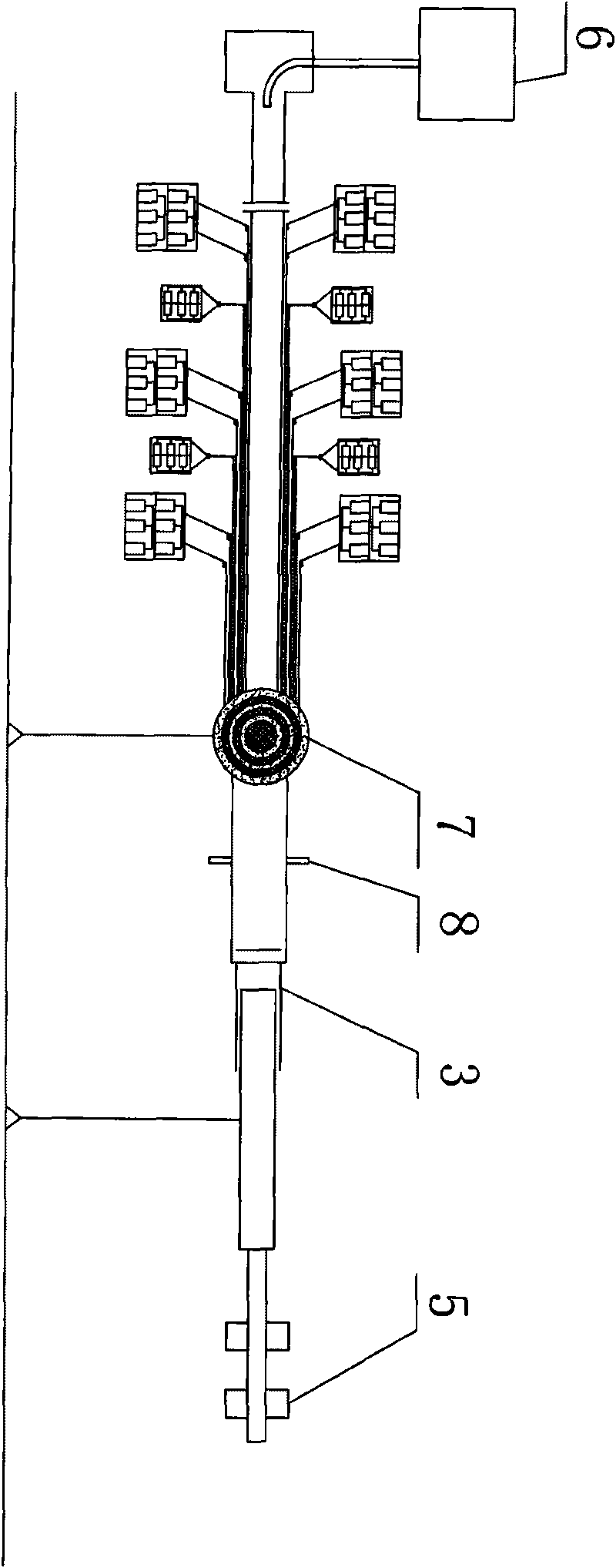

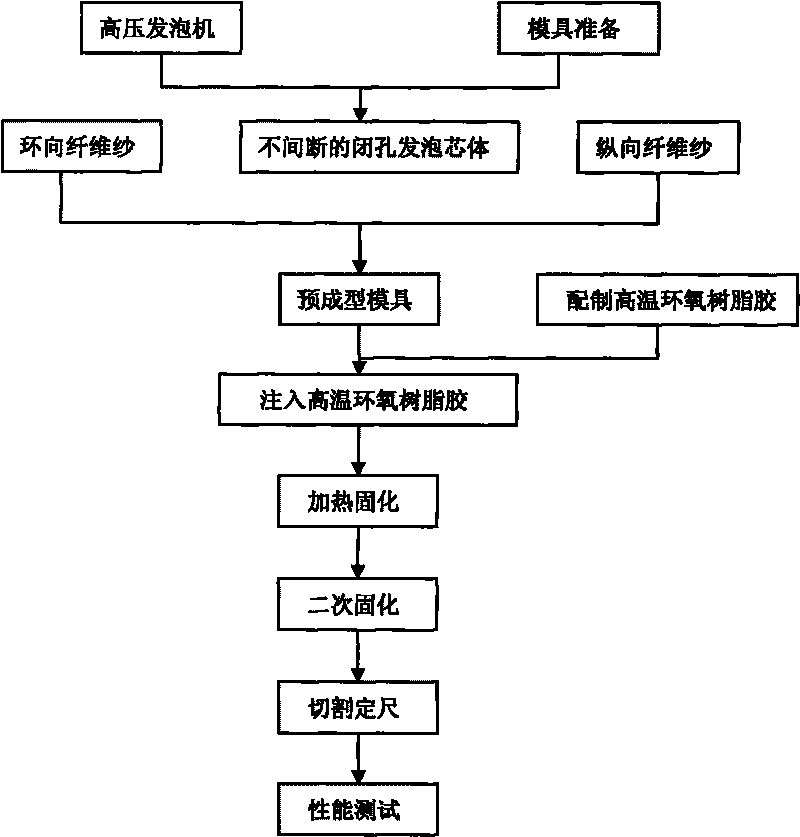

[0035] see figure 1 , ordinary pultrusion equipment, the glass fiber is placed on the yarn creel through the yarn guide mechanism 1, impregnated with epoxy resin glue through the dipping tank 2, squeezes out the excess resin glue through the scraping device at the entrance of the mold, and enters the heating wire The heated forming mold 3 is solidified and formed, and then further solidified and formed through the secondary curing zone 4. The traction device 5 is the basic mechanical part of the pultrusion equipment, which ensures that the product is pulled out at a certain speed.

[0036] The fiber distribution of ordinary pultrusion equipment is arranged longitudinally, so the hoop strength is poor. Therefore, on the basis of ordinary pultrusion equipment, pultrusion technology and winding technology are organically combined to overcome the low transverse strength of pultrusion profiles and the low production efficiency of winding pipes. , Waste and other disadvantages are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com