Dismounting design method of automobile equal-strength superposition steel plate spring

A leaf spring and design method technology, applied in spring/shock absorber, calculation, leaf spring, etc., can solve the problem that the split design does not give an accurate and reliable analytical design method, and achieve the goal of reducing design and test costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Embodiment: the load F borne by one end of a certain vehicle single-wheel leaf spring W =10000N, half the length l of equal-strength leaf spring 1 =600mm, width b=40mm, safe allowable stress [σ]=700MPa, elastic modulus E of leaf spring material=200GPa.

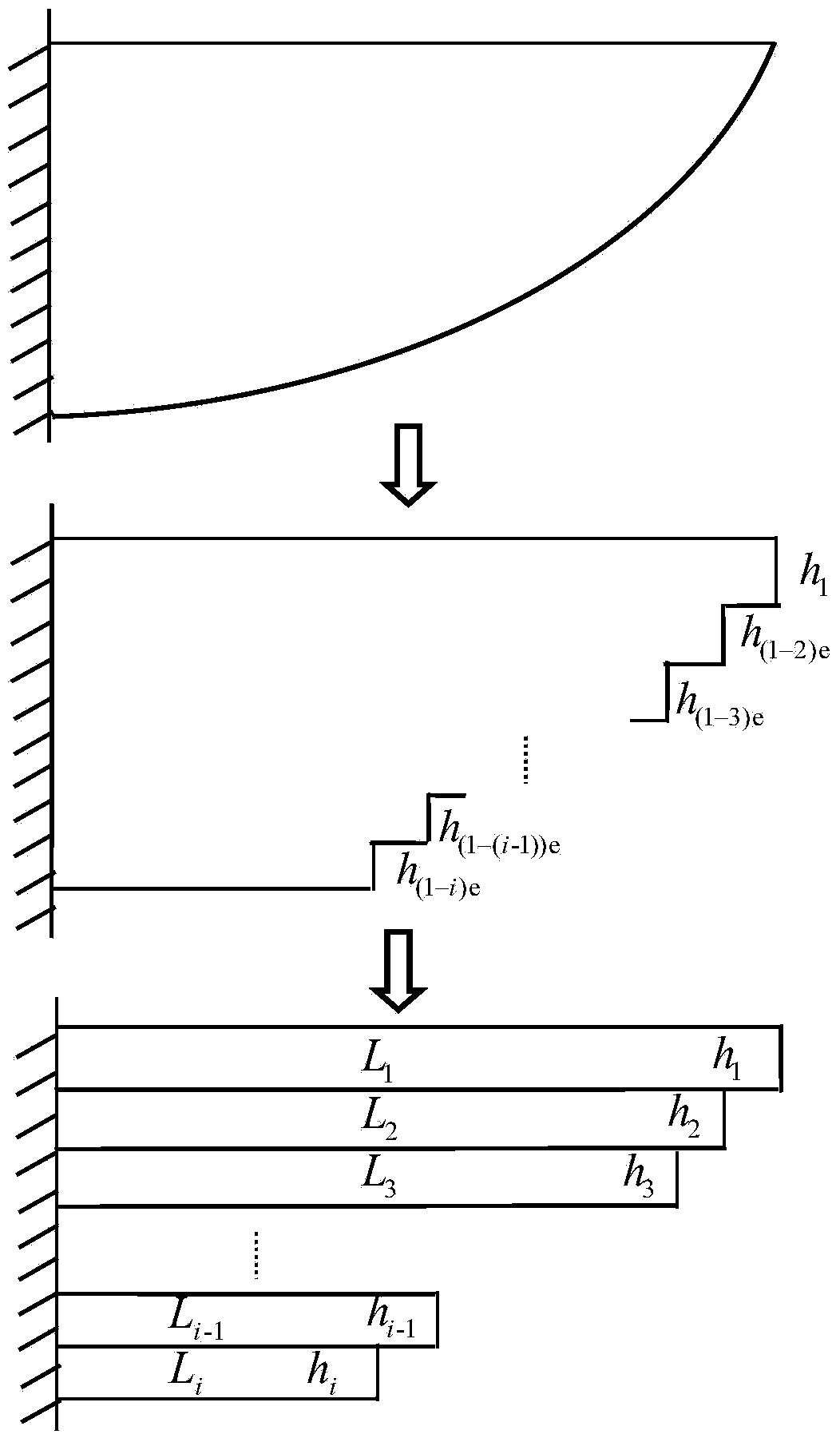

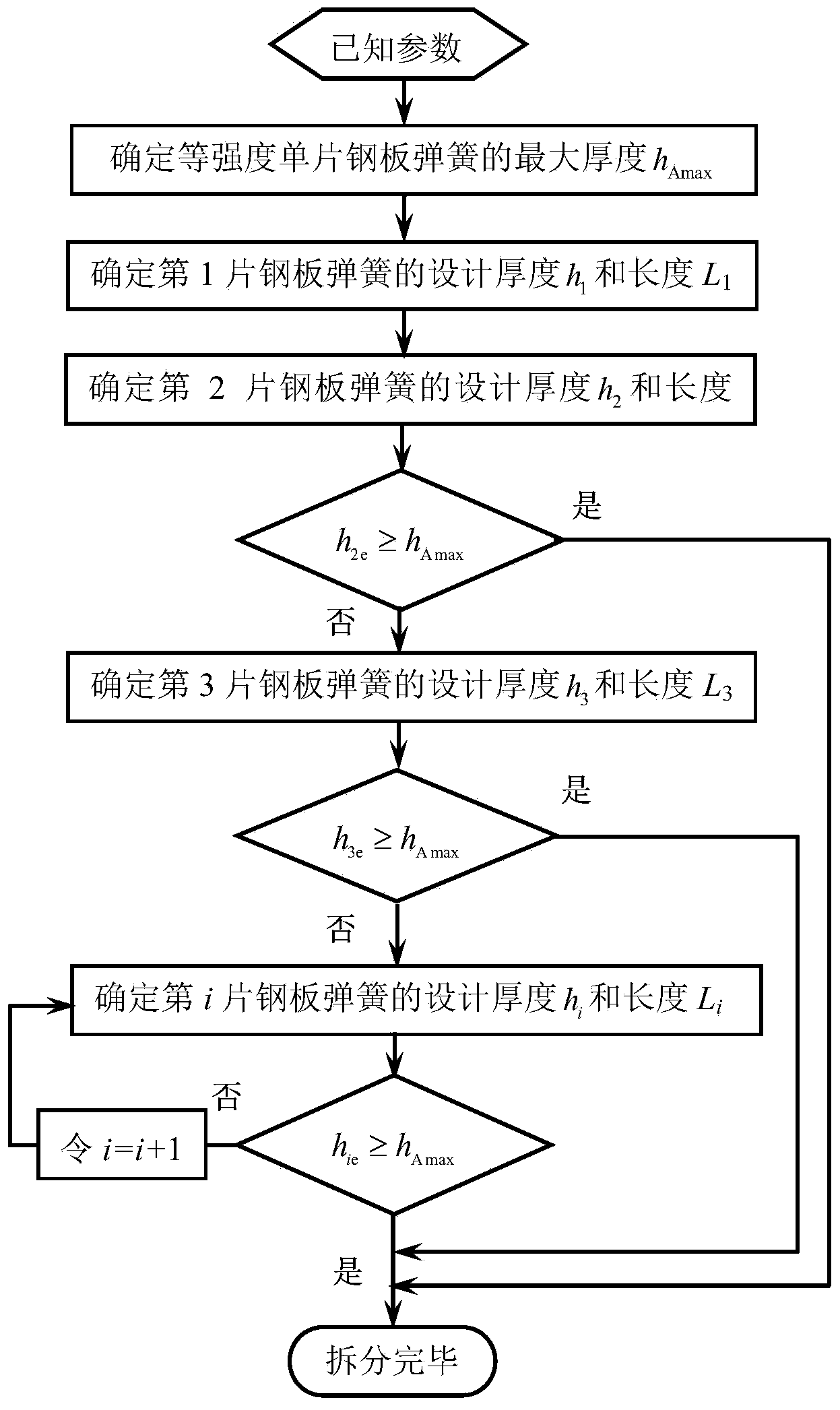

[0035] The analytical split design method of the automobile equi-intensity superimposed leaf spring provided by the example of the present invention, the concrete steps are as follows:

[0036] (1) Calculation of the maximum thickness of the equal-strength single-piece variable-thickness curved surface leaf spring:

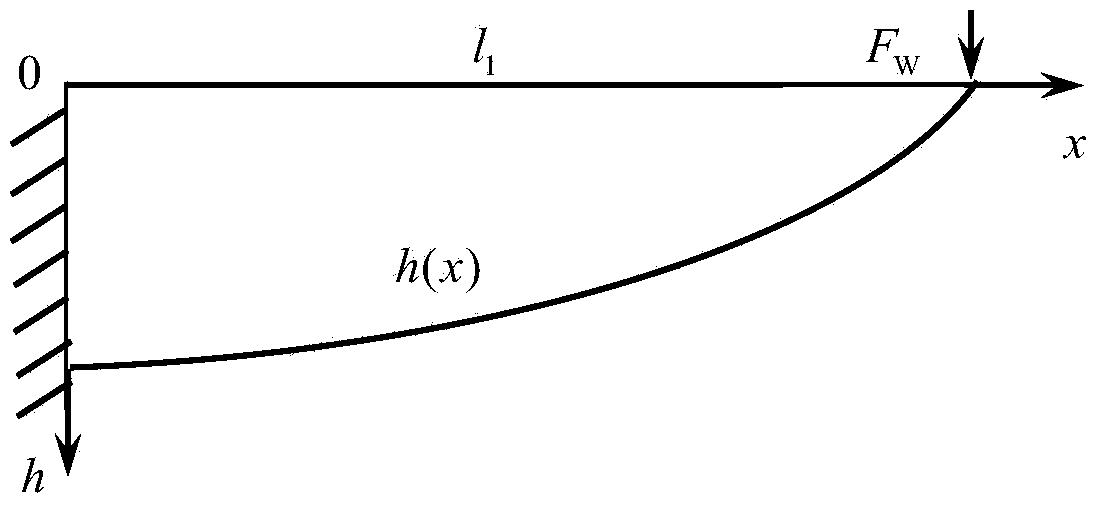

[0037] According to the load F on one end of the single-wheel leaf spring of the vehicle W =10000N, half the length l of equal-strength leaf spring 1 =600mm, width b=40mm, the required safe allowable stress [σ]=700MPa, and the mechanical model of equal-strength single-piece variable-thickness curved surface leaf spring, determine the maximum thickness h of equal-strength single-piece variable-thickness c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com