Bidirectional fatigue crack expansion rate testing method and testing system

A technology of crack growth rate and test method, applied in the field of bidirectional fatigue crack growth rate test method and test system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0081]Considering that testing the fatigue crack growth rate in multiple directions according to the standard method consumes a lot of manpower and material resources and has high requirements on the specimen, the present invention provides a method and system for testing the fatigue crack growth rate in two directions.

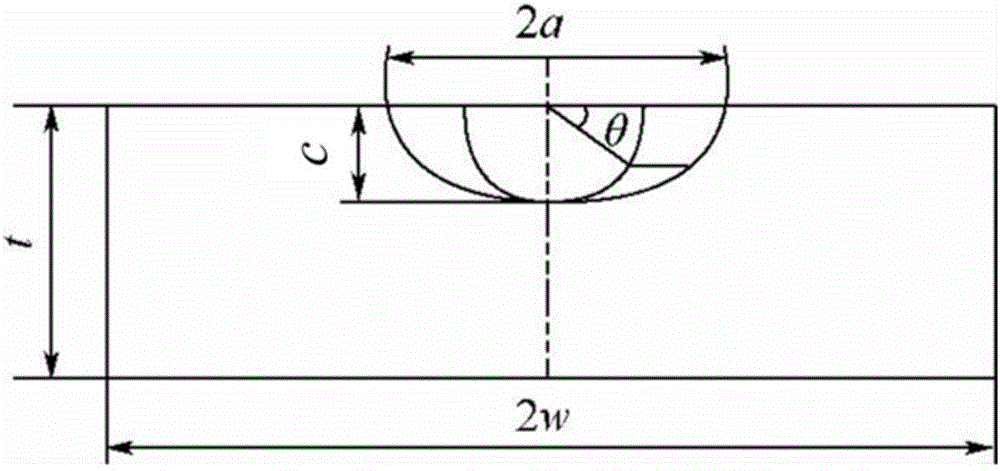

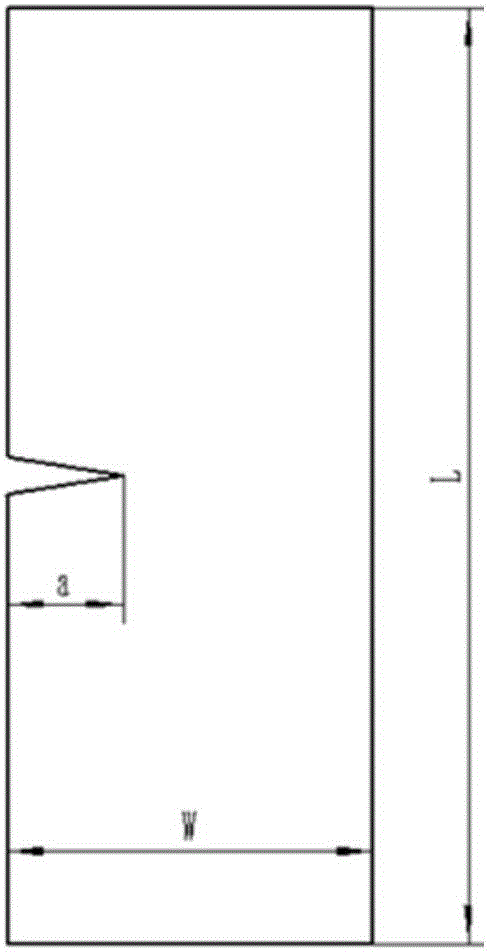

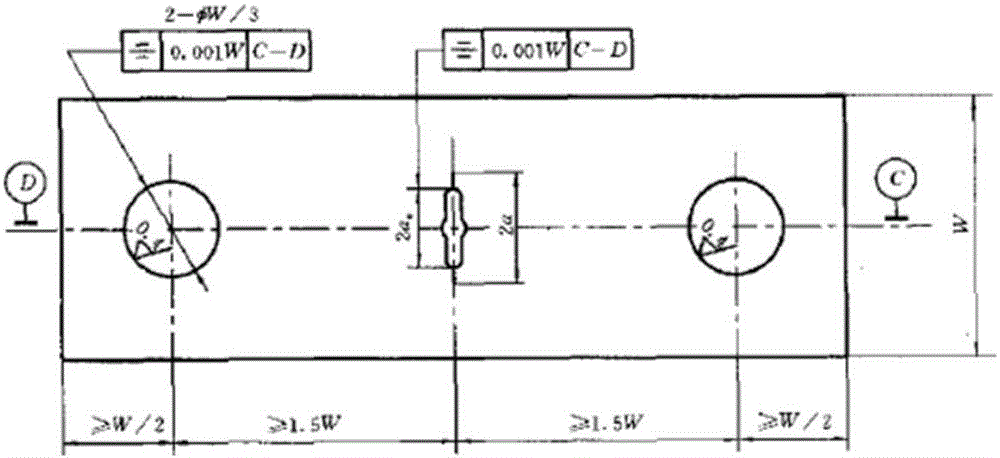

[0082] The test method includes: selecting a rectangular parallelepiped specimen; prefabricating a semicircular notch at the center of the surface of the specimen; The distance to the upper and lower chucks is the same; apply alternating loads to prefabricate fatigue cracks on the test piece; adopt the constant equal amplitude cyclic loading method, that is, use the equal amplitude spectrum with constant stress ratio and amplitude, to carry out the fatigue crack growth test, test Apply the marking load to lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com