Method for investigating fatigue crack expansion

A technology of fatigue crack propagation and fatigue test, which is applied in the direction of testing the ductility of materials, and can solve problems such as difficulty in implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

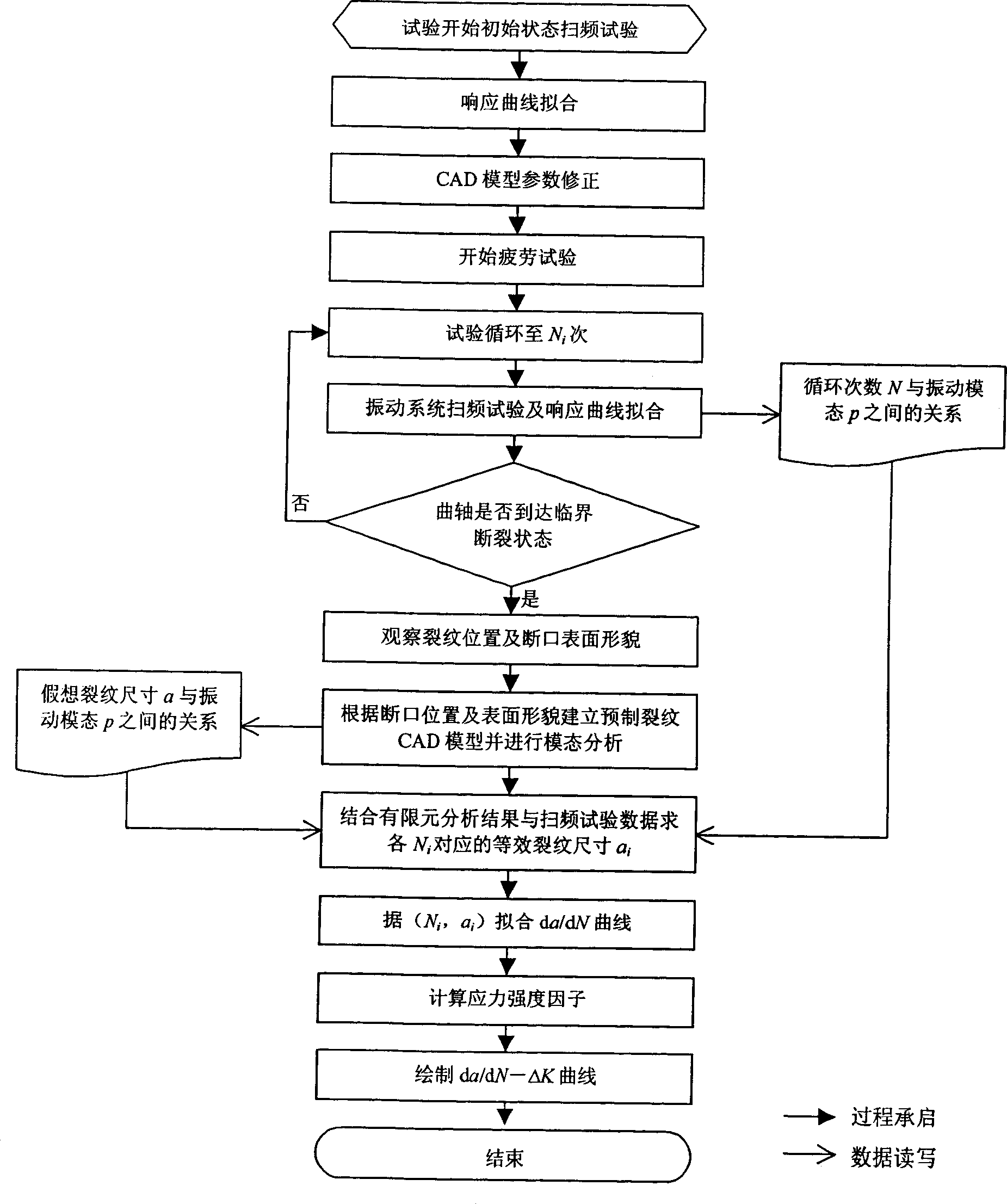

[0022] The method for fatigue crack propagation test of the present invention comprises the following steps:

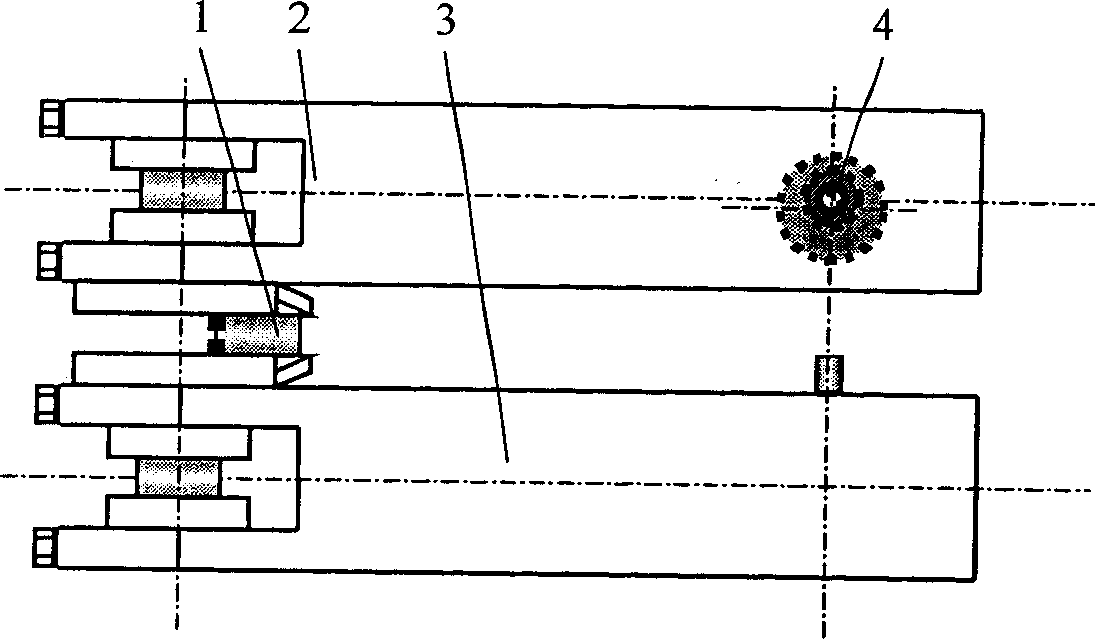

[0023] 1) will be the test piece, e.g. figure 1 The shown crankshaft 1 is mounted on a resonant loading mechanism consisting of an active arm 2 , a passive arm 3 and an eccentric vibration exciter 4 .

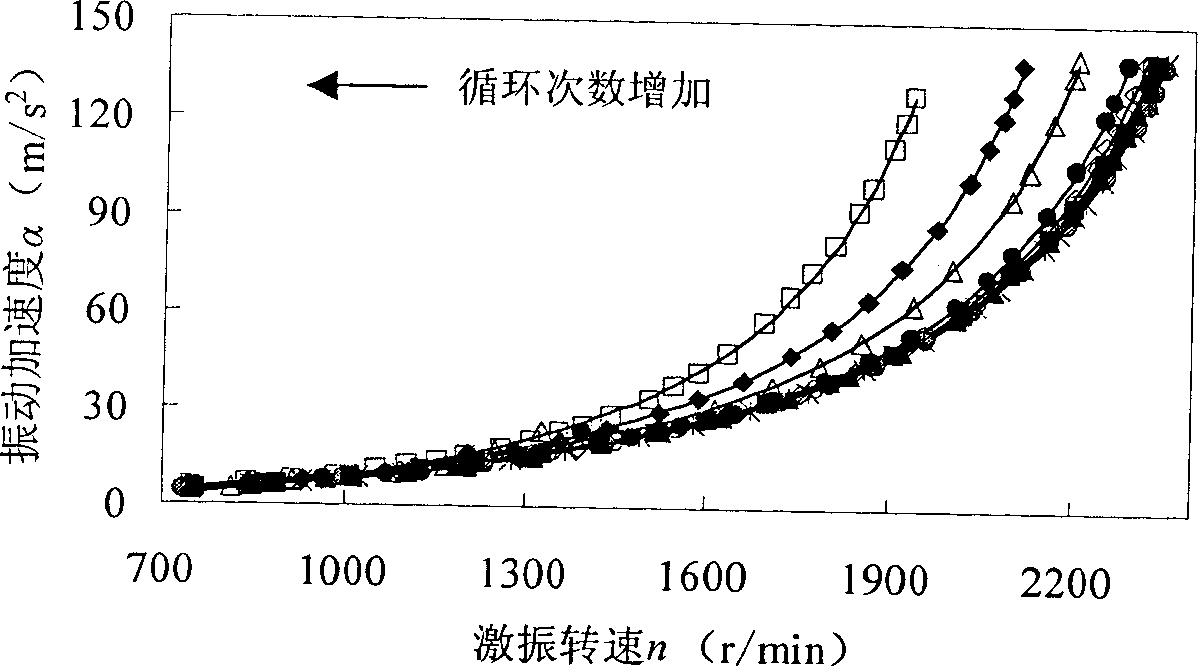

[0024] 2) Load the fatigue test, and perform a frequency sweep test every certain time interval, such as 50,000 times or 100,000 times. The frequency sweep test is to obtain the resonance frequency of the vibration system under the condition of forced vibration. The method is to apply excitation of different frequencies and record the response acceleration value of the system under the excitation of each frequency. That is to get the data sequence {ω i , a i | i=1,2,3...}, the measured sequence is drawn on the graph, and the sweep frequency graph can be obtained, image 3 An example of some time sweep plots is given. As the number of test cycles increases, the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com