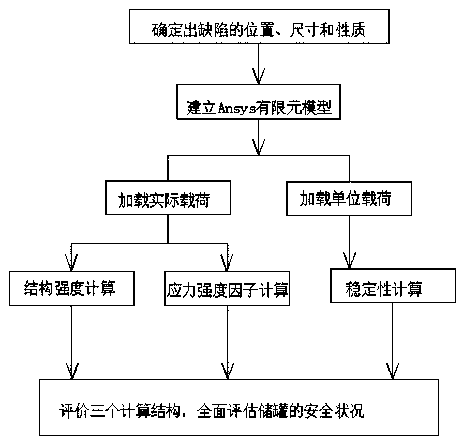

Overall evaluation method for normal-pressure storage tank containing defect

An atmospheric storage tank and evaluation method technology, applied in special data processing applications, instruments, electrical digital data processing, etc. The effect of crack propagation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

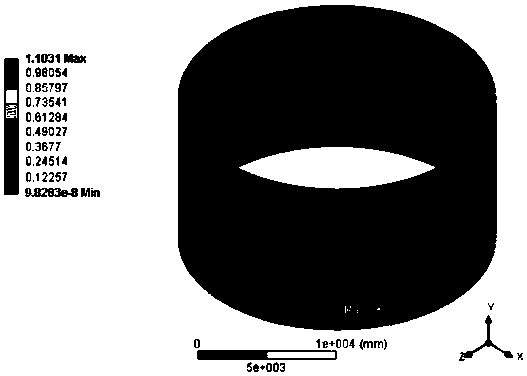

[0075] Stability analysis when 1 / 3 of the second layer weld at the bottom of the oil storage tank is not penetrated, the specific analysis is as follows: import the model into ANSYS Workbench, and when 1 / 3 of the weld at the bottom of the oil storage tank cracks, the oil storage tank The contact between the second layer of the tank model is set to 2 / 3 of the contact surface binding, and a fixed constraint is added at the bottom of the tank; gravity is applied to the tank model; wind load is applied to the tank model; the solution is obtained Stress results after linear buckling of the oil storage tank, such as figure 2 As shown, the linear buckling stress results obtained by solving, the graph area shows that the buckling load factor is only 0.49413. Therefore, when 1 / 3 of the second-layer weld at the bottom of the oil storage tank is not penetrated, the oil storage tank will be unstable under the action of wind load and gravity.

Embodiment 2

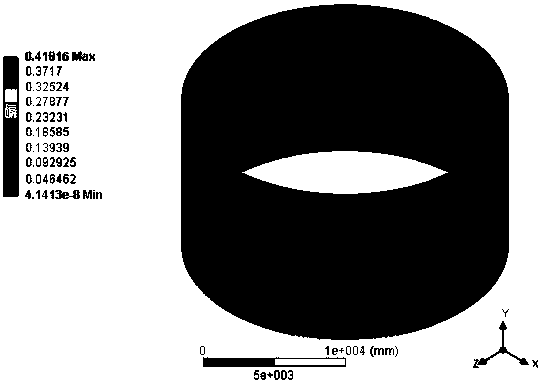

[0077] Stability analysis when 1 / 3 of the second-layer weld at the bottom of the oil storage tank is not penetrated (cracks are discontinuous), the specific analysis is as follows: When 1 / 3 of the weld is cracked and the crack is discontinuous (assuming that the weld has two cracks , and the weld cracks are all 1 / 6); when the model is imported into ANSYS Workbench, when 1 / 3 of the weld cracks are found on the second layer of the bottom of the oil storage tank and the weld cracks are discontinuous, the second layer of the bottom layer of the oil storage tank model The contact between them is set to 2 / 3 binding, and a fixed constraint is added to the oil storage tank model and a load is applied; the solution is obtained to obtain the stress result of the oil storage tank after linear buckling, such as image 3 As shown, the result obtained by solving the linear buckling stress, the graph area shows the buckling load factor is 1.5563. Therefore, when 1 / 3 of the second-layer weld ...

Embodiment 3

[0079] Stability analysis when 1 / 2 of the second layer weld at the bottom of the oil storage tank is not penetrated, the specific analysis is as follows: import the model into ANSYS Workbench, and when 1 / 2 of the weld at the bottom of the oil storage tank cracks, the oil storage tank The contact between the second layer of the tank model is set to 1 / 2 of the contact surface binding, and a fixed constraint is added at the bottom of the tank; gravity is applied to the tank model; wind load is applied to the tank model; the solution is obtained Stress results after linear buckling of the oil storage tank, such as Figure 4 shown; obtained by solving the linear buckling stress results, the graph area shows that the buckling load factor is 0.1391. Therefore, when 1 / 2 of the second-layer weld at the bottom of the oil storage tank is not penetrated, the oil storage tank will be unstable under the action of wind load and gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com