Three-dimensional (3D) printing method based on three-dimensional braiding

A 3D printing and three-dimensional weaving technology, applied in the field of 3D printing based on three-dimensional weaving, can solve problems such as insufficient force strength, and achieve the effect of solving insufficient force strength and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

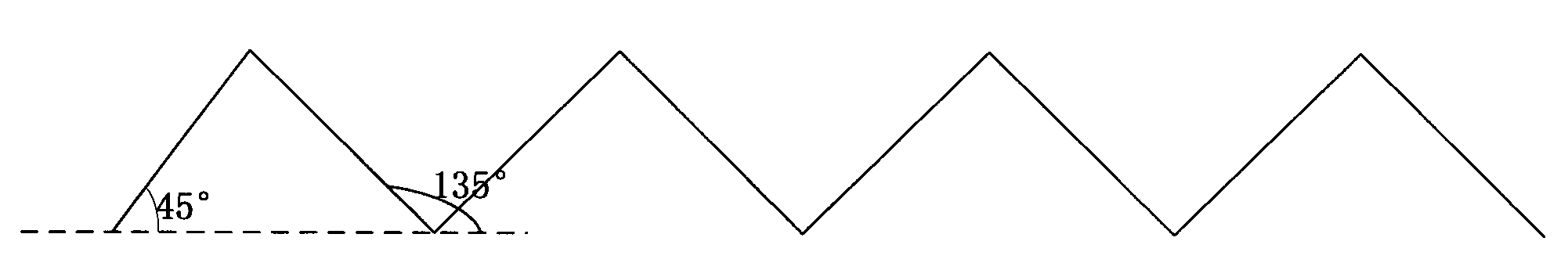

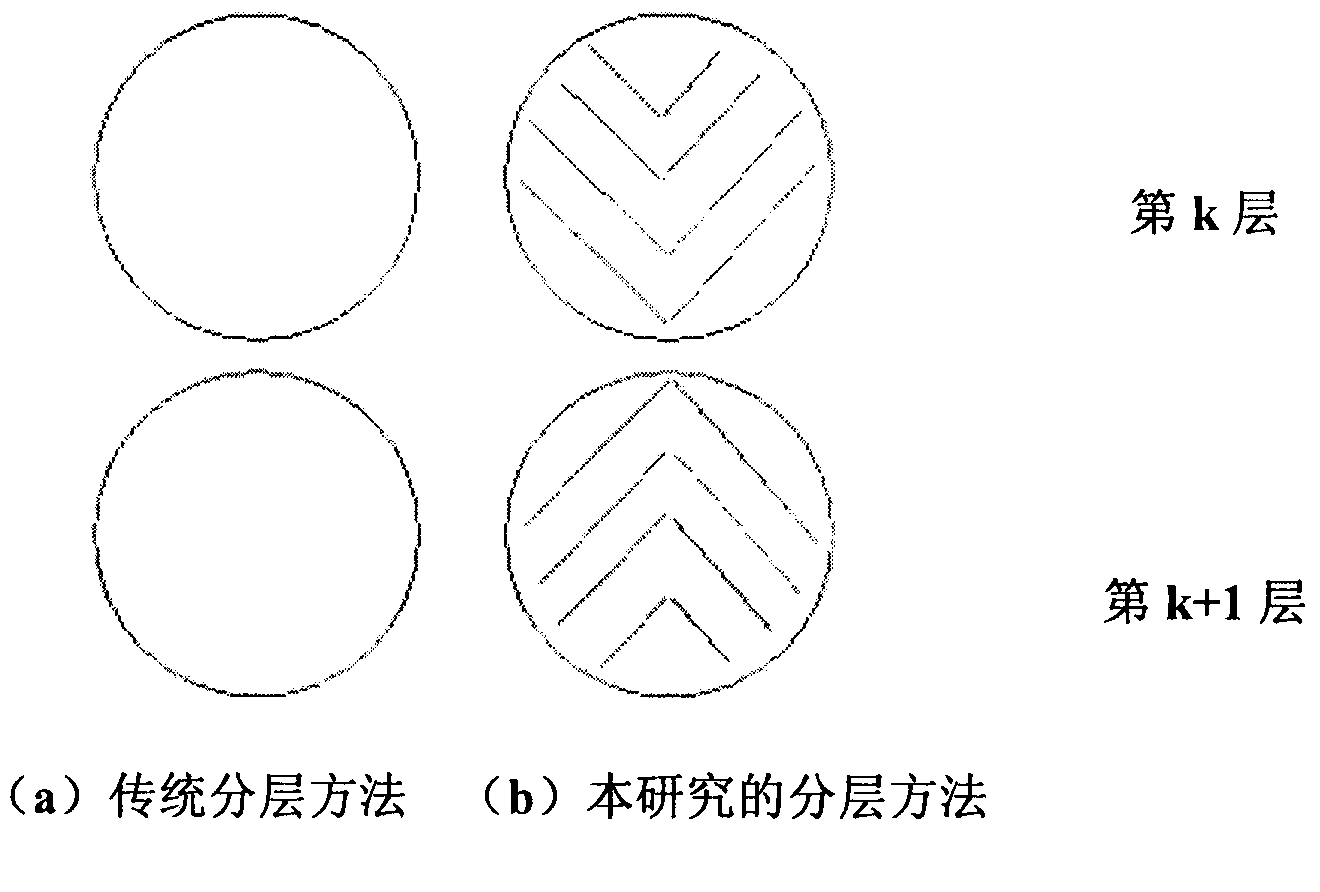

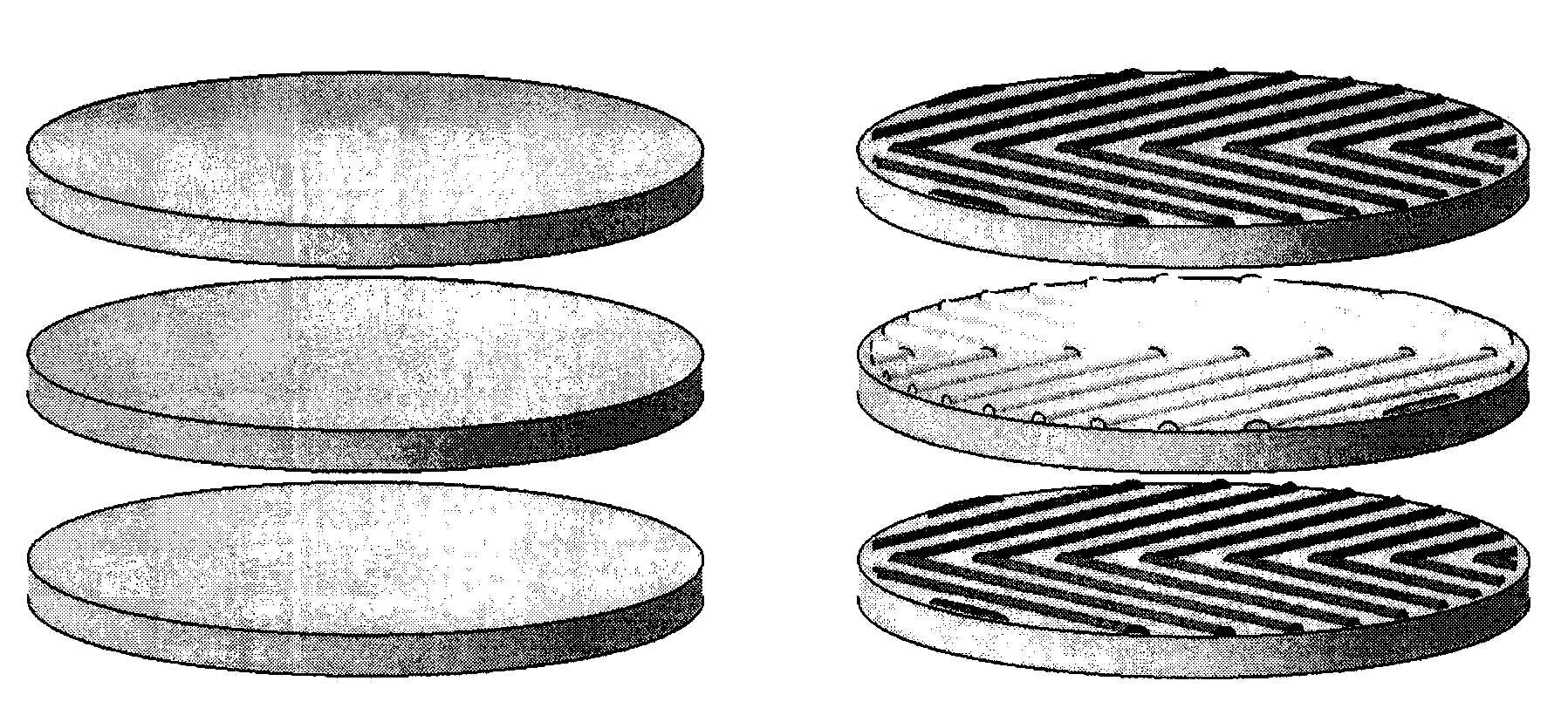

[0023] The products printed by the existing 3D printing methods are prone to breakage at the layered places after being stressed, and it is difficult to be used for making main load-bearing structural parts and high-function parts. In order to solve the above problems, the present invention designs a TDBP (Three Dimension BraidPrinter) three-dimensional braid printing method, which effectively integrates the three-dimensional braiding method and the three-dimensional printing method in the textile industry, and is used to improve the force strength of the 3D printed product. In order to realize the TDBP method, the present invention proposes a two-way circular weaving route method, that is, two directions of 45° and 135° are used within a layer and between adjacent layers to weave circularly. The two-way loop knitting route method can be subdivided into a horizontal loop knitting method and a vertical loop knitting method.

[0024] The horizontal circular weaving method is a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com