Polytetrafluoroethylene porous grid and its manufacturing method

A technology of polytetrafluoroethylene and its manufacturing method, which is applied in the direction of slender elements, building elements, etc., can solve problems affecting normal production, environmental pollution, and insufficient strength, and achieve the effects of simple structure, low manufacturing cost, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

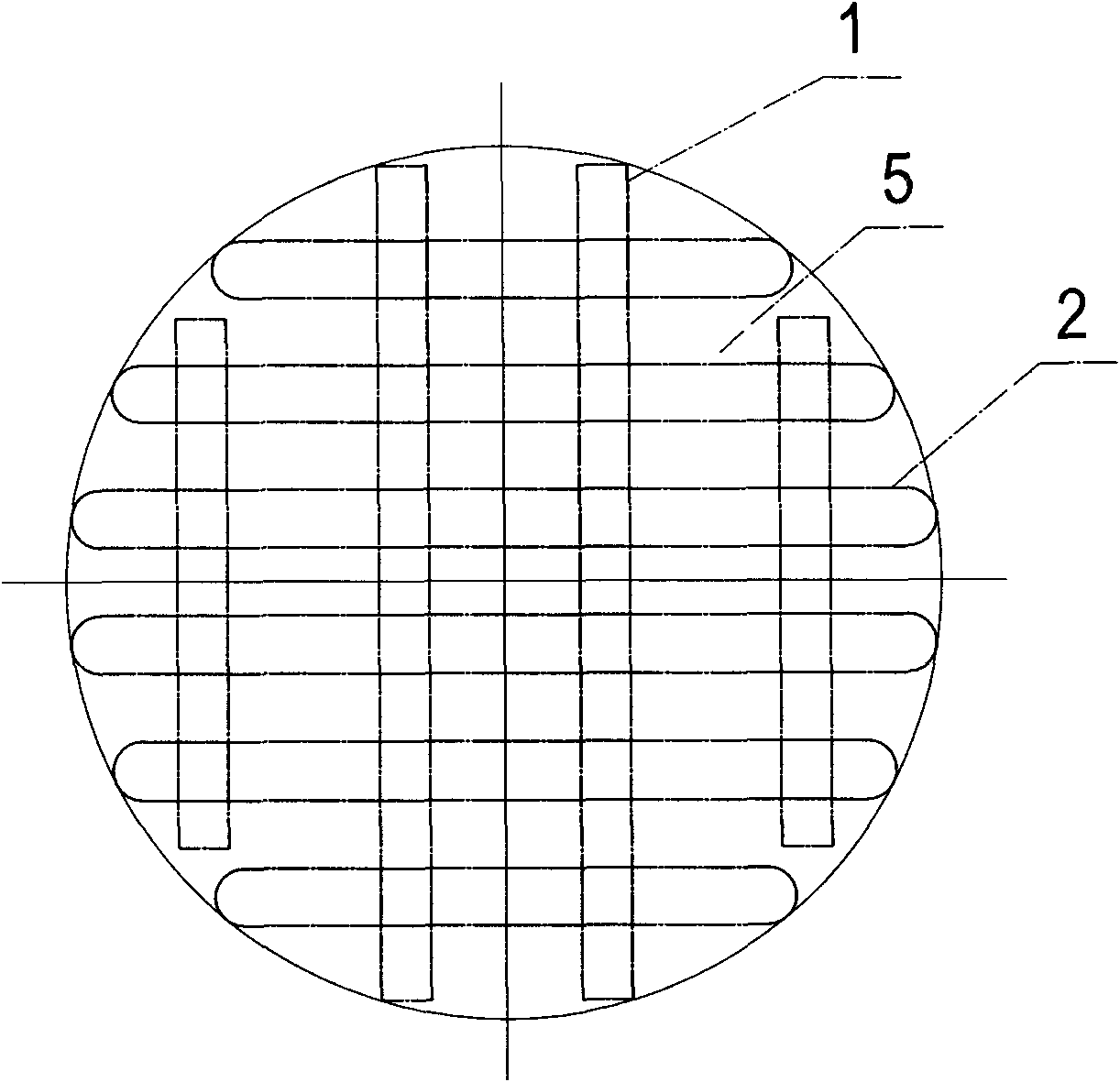

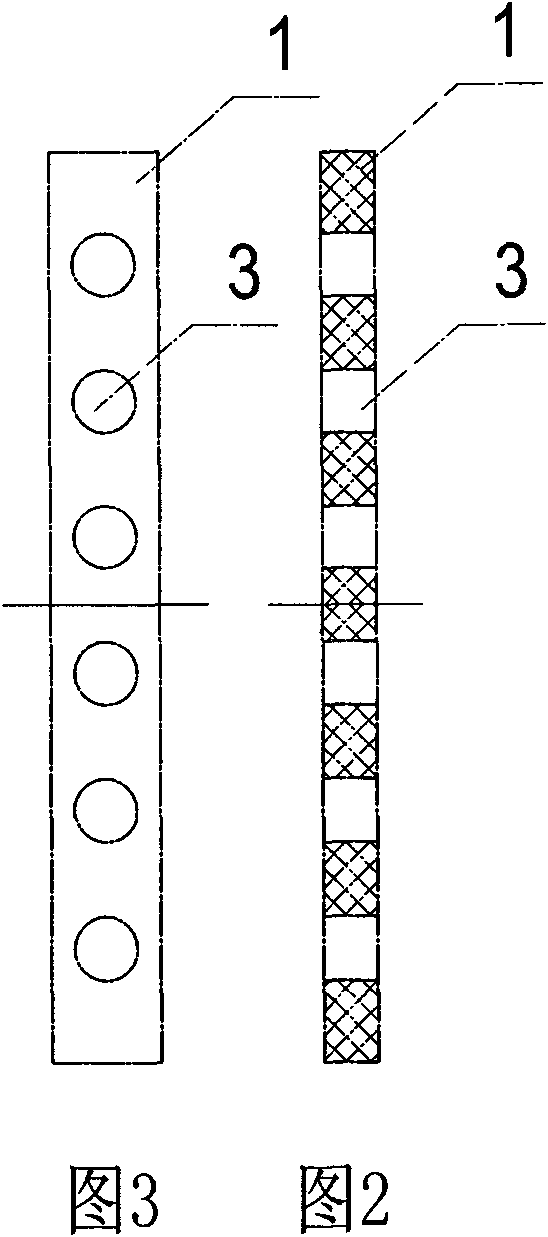

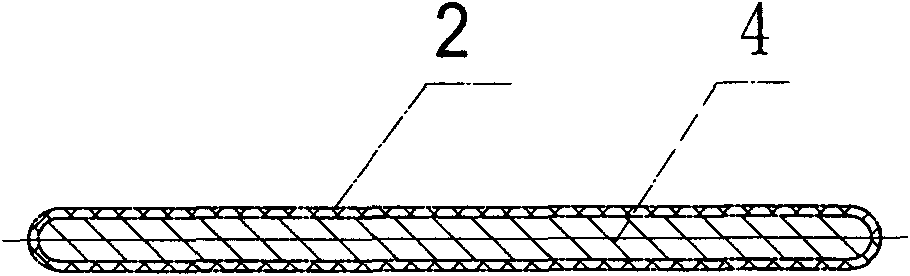

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the polytetrafluoroethylene porous grid plate in this embodiment is a circular porous plate 5, consisting of several polytetrafluoroethylene square strips 1 of different lengths and several polytetrafluoroethylene round rods of different lengths containing reinforcing ribs 4 2 are interspersed and combined. The side of the polytetrafluoroethylene square bar 1 is provided with several round holes 3, and the outer diameters of the round holes 3 and the round polytetrafluoroethylene rod 2 are matched with each other. In order to improve the supporting strength and uniformity of force, the reinforcing rib 4 is a circular steel bar, and the distances between the circular holes 3 are equal. The quantity and thickness of the polytetrafluoroethylene square strips and the polytetrafluoroethylene round rods are determined according to specific usage occasions. For the board deletion of other shapes, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com