Prefabricated erect column pile anti-settlement chuck and solar photovoltaic flexible support system

A solar photovoltaic and support system technology, applied in the field of prefabricated column pile anti-settling chucks, can solve the problems of long working hours, poor inclination angle accuracy of solar photovoltaic modules, and low efficiency, so as to increase the load area and strength, and solve the foundation strength Not enough, good anti-settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

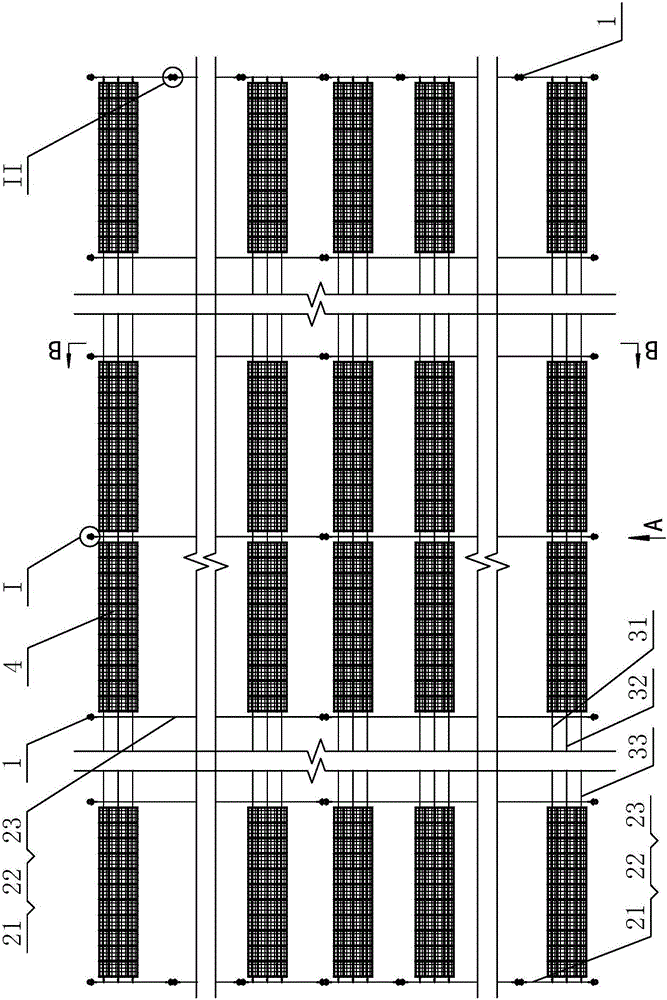

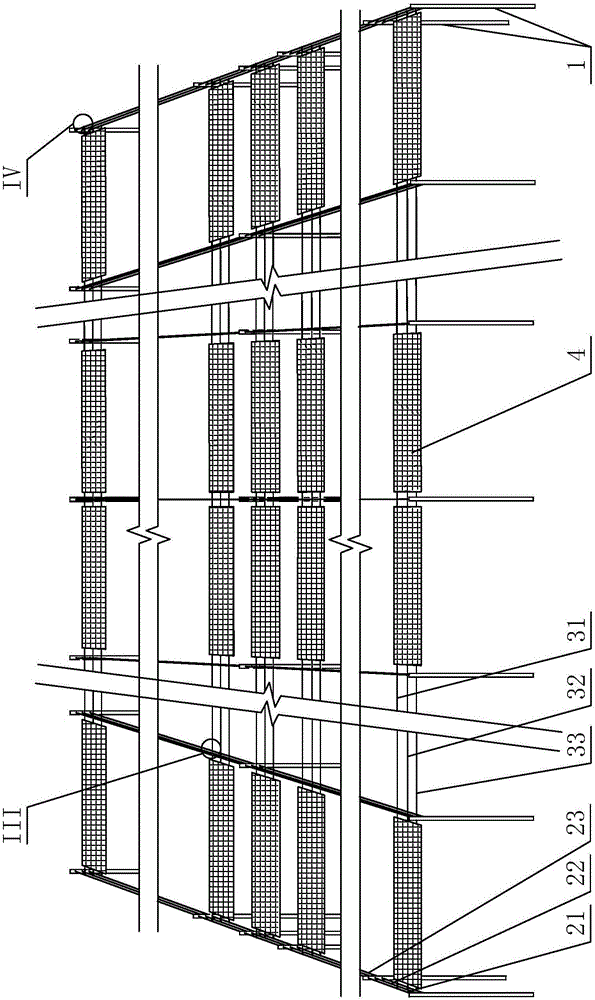

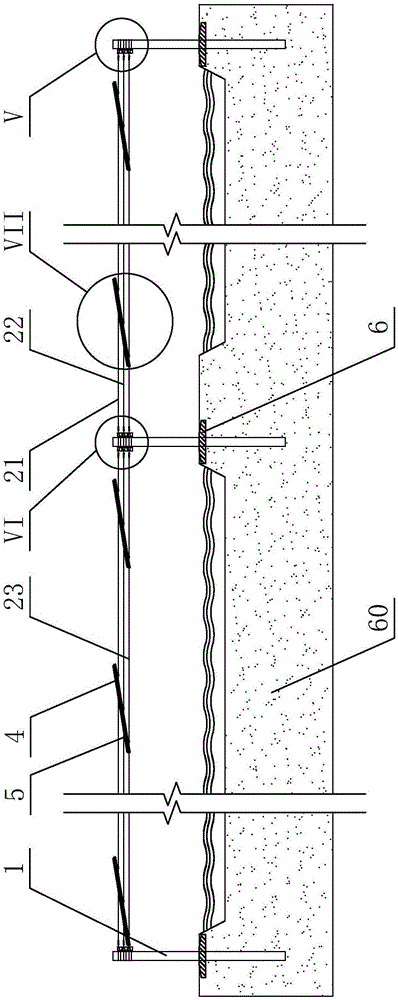

[0042] Such as Figure 1 to Figure 16 As shown, the solar photovoltaic flexible support system of the embodiment of the present invention includes several prefabricated column piles 1 arranged in a matrix, several groups of meridional cables 2, several groups of weft cables 3, several groups of photovoltaic modules 4, and photovoltaic module mounting frames 5 , and prefabricated column pile anti-settlement chuck 6, each group of said warp cables 2 is fixedly connected with said prefabricated column pile 1 on a warp line, and each group of said latitudinal cables 3 is connected to said warp line on a latitude line The cables 2 are fixedly connected to form a mesh cable structure, and the warp cables 2 of each group include an upper warp cable 21, a middle warp cable 22, and a lower warp cable 23 from top to bottom, and the warp cables 23 in the same group. The upper warp cable 21, the middle warp cable 22, and the lower warp cable 23 are parallel to each other and are located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com