Technology forming method of small and medium-sized unmanned aerial vehicle composite material outer wing

A technology of composite materials and molding methods, which is applied in the direction of mechanical equipment, combustion engines, internal combustion piston engines, etc., can solve the requirements of high performance and light weight that are not suitable for small and medium-sized UAVs, uneven glue content and thickness, and unfavorable environments Protection and other issues to achieve the effect of solving rapid mass production, uniform load distribution, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0052] The first step, the manufacture of product forming molds:

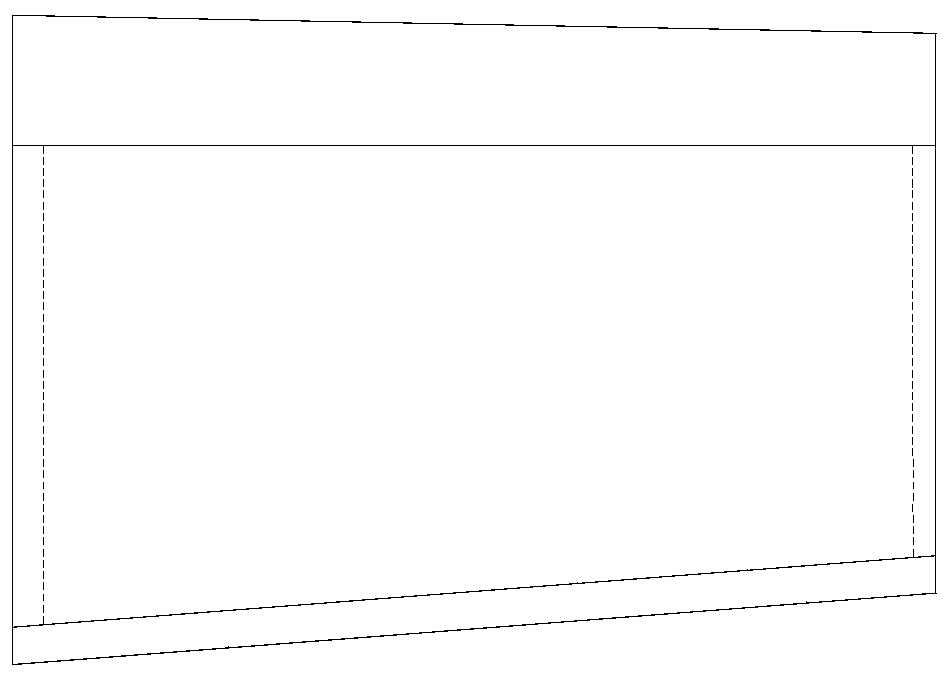

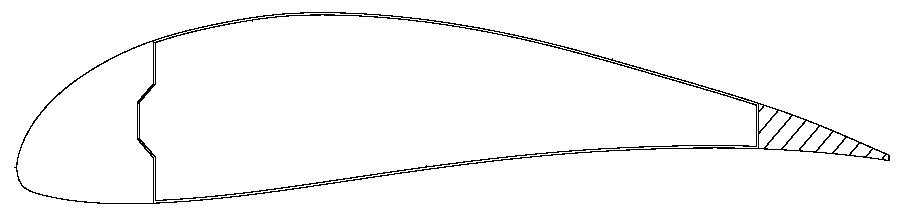

[0053] refer to figure 1 , figure 2 , the outer wing of composite material is mainly composed of the leading edge of the outer wing and the main structure; the left end of the main structure is provided with rib grooves for installing rib connectors, and the right end is provided with a shape depression for installing wingtip fairings.

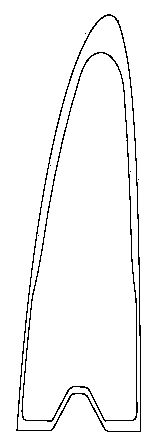

[0054] refer to image 3 The leading edge of the outer wing is a closed composite tubular laminated rigid body with both ends open, which not only effectively ensures the good force and impact resistance of the leading edge, but also facilitates the separation of the leading edge from the main structure. Easy disassembly and replacement when damaged. refer to Figure 4 The bottom surface of the front edge is connected to the main structure by the left positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com