Cylindrical spur gear tooth trace modification method based on tooth surface stress edge action and gear skew deformation

A technology of force deformation and tooth surface, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of gear elastic deformation and cannot guarantee the quality of gear transmission, so as to improve fatigue strength and tooth surface Uniform load distribution and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make it easy to understand the technical means, innovative features, work flow, and implementation methods of the present invention to achieve the purpose and effect, the present invention will be further described below in conjunction with specific examples.

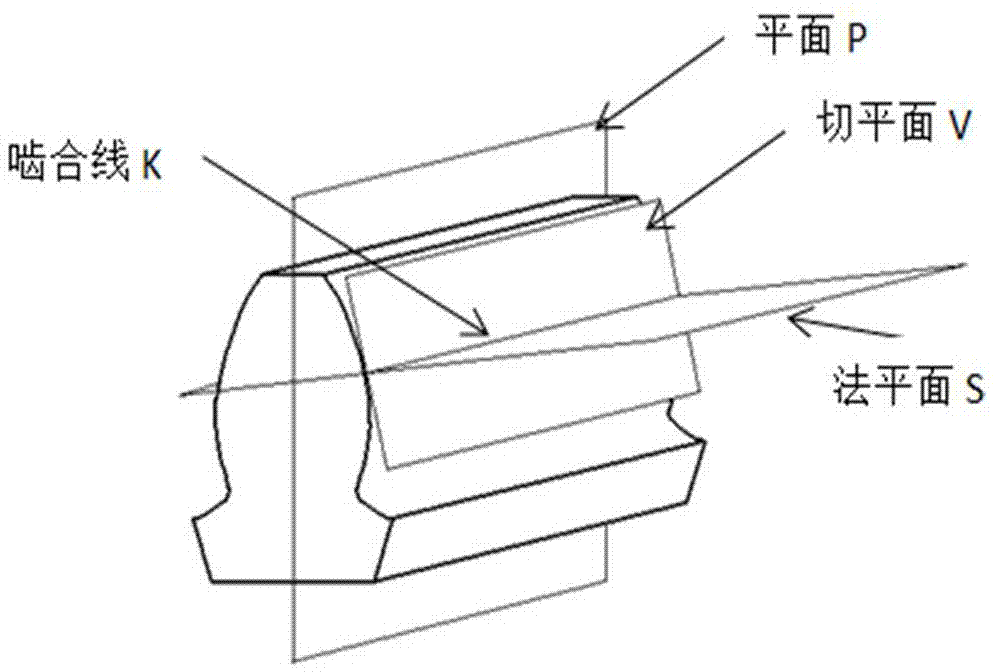

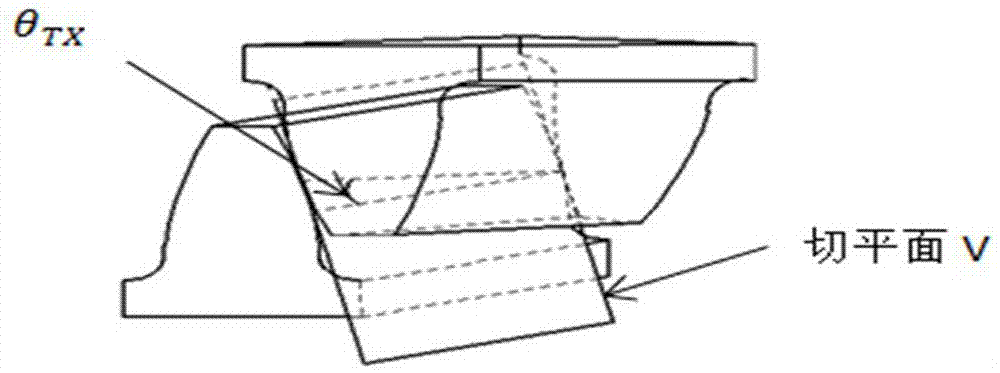

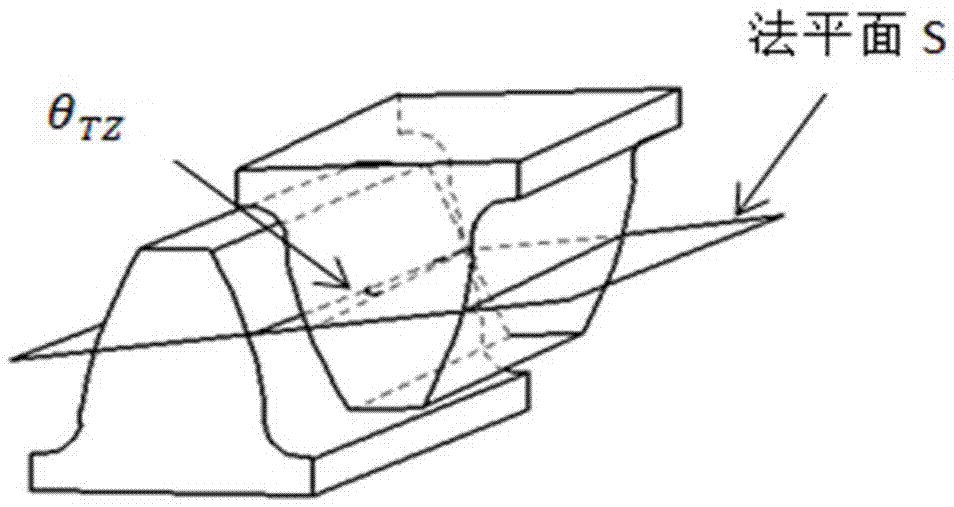

[0048] A tooth profile modification method for cylindrical spur gears based on tooth surface stress and edge action and gear skew deformation, including: (1) establishing a three-dimensional model of the gear based on UG; (2) importing the three-dimensional model of the gear into the finite element software Workbench for analysis in a certain Elastic deformation of gear teeth under working conditions, and "edge action" of tooth surface stress; (3) Establish the overall 3D model of the gearbox based on UG; (4) Import the 3D model of the gearbox into the finite element software Workbench to analyze the gear box under certain working conditions The gear box is deformed by force; (5) Analysis of the deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com