Spur gear profile modification method based on thermal elastic deformation of gear teeth and deflection deformation of gear

A thermoelastic, spur gear technology, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., to improve the uniform load distribution on the tooth surface, improve the modification accuracy, and extend the uniform stress distribution of the gears Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make it easy to understand the technical means, innovative features, work flow, and implementation methods of the present invention to achieve the purpose and effect, the present invention will be further described below in conjunction with specific examples.

[0057] A method for modifying the tooth profile of cylindrical spur gears based on thermoelastic deformation of gear teeth and skew deformation of gears. The detailed steps are as follows:

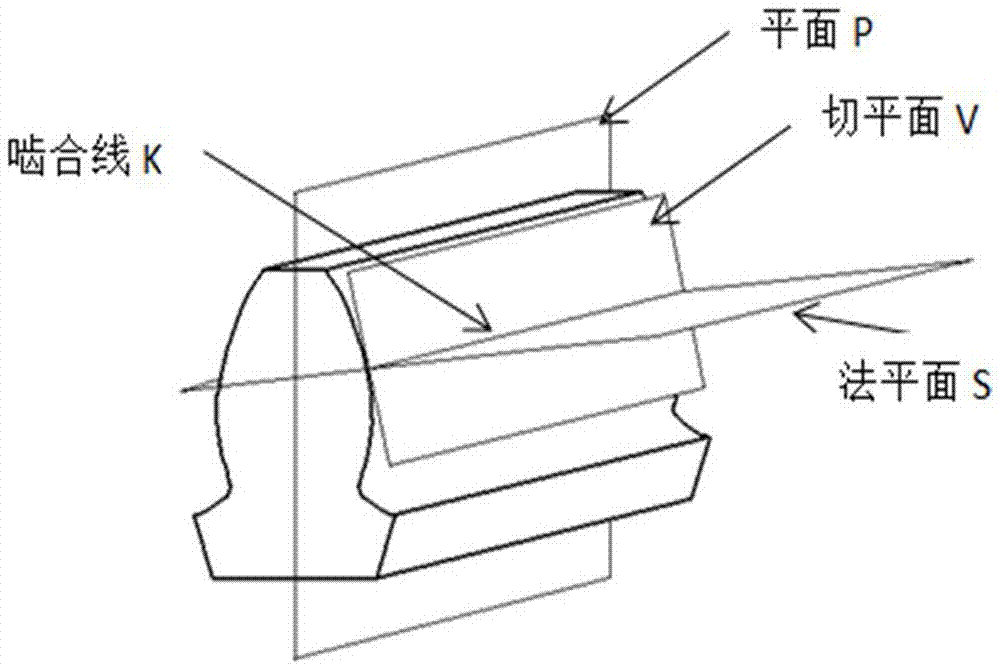

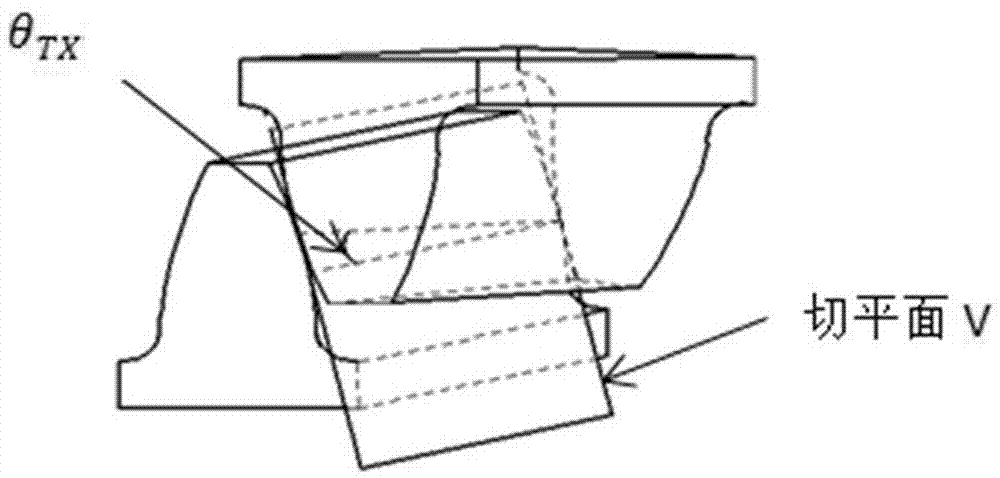

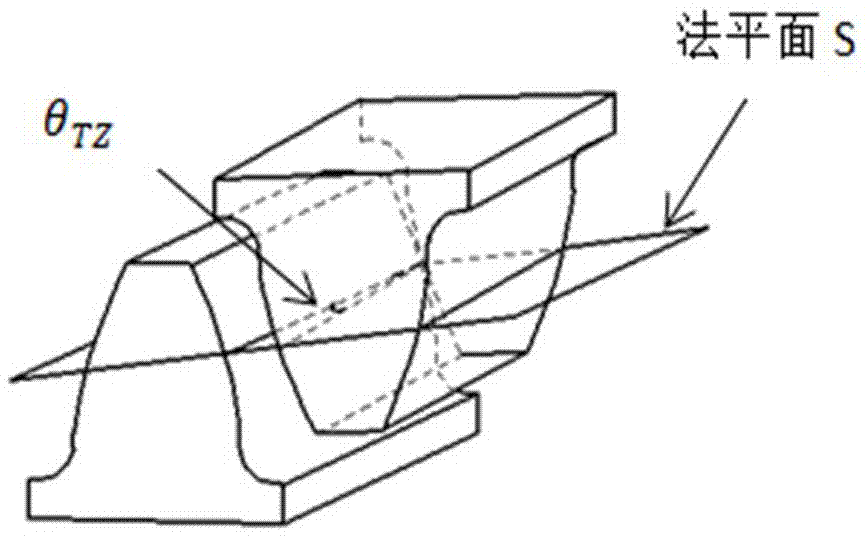

[0058] Step 1: Establish a 3D model of the gear based on UG, the gear parameters are shown in Table 1, and the 3D model is shown as Image 6 Shown:

[0059] Table 1 gear parameters

[0060]

[0061] Step 2: Import the 3D model of the gear into the finite element software Workbench to analyze the thermoelastic deformation of the gear under the loading condition. The basic working condition parameters are 3000N / m and 4500r / min. The results are as follows Figure 7 shown.

[0062] Step 3: Establish the overall 3D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com