Tire for heavy vehicle

A technology for tires and crowns, applied to wheels, vehicle parts, tire parts, etc., can solve problems such as tire crown impact and tire damage, and achieve the effects of improving durability, improving load distribution, and optimizing ply connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

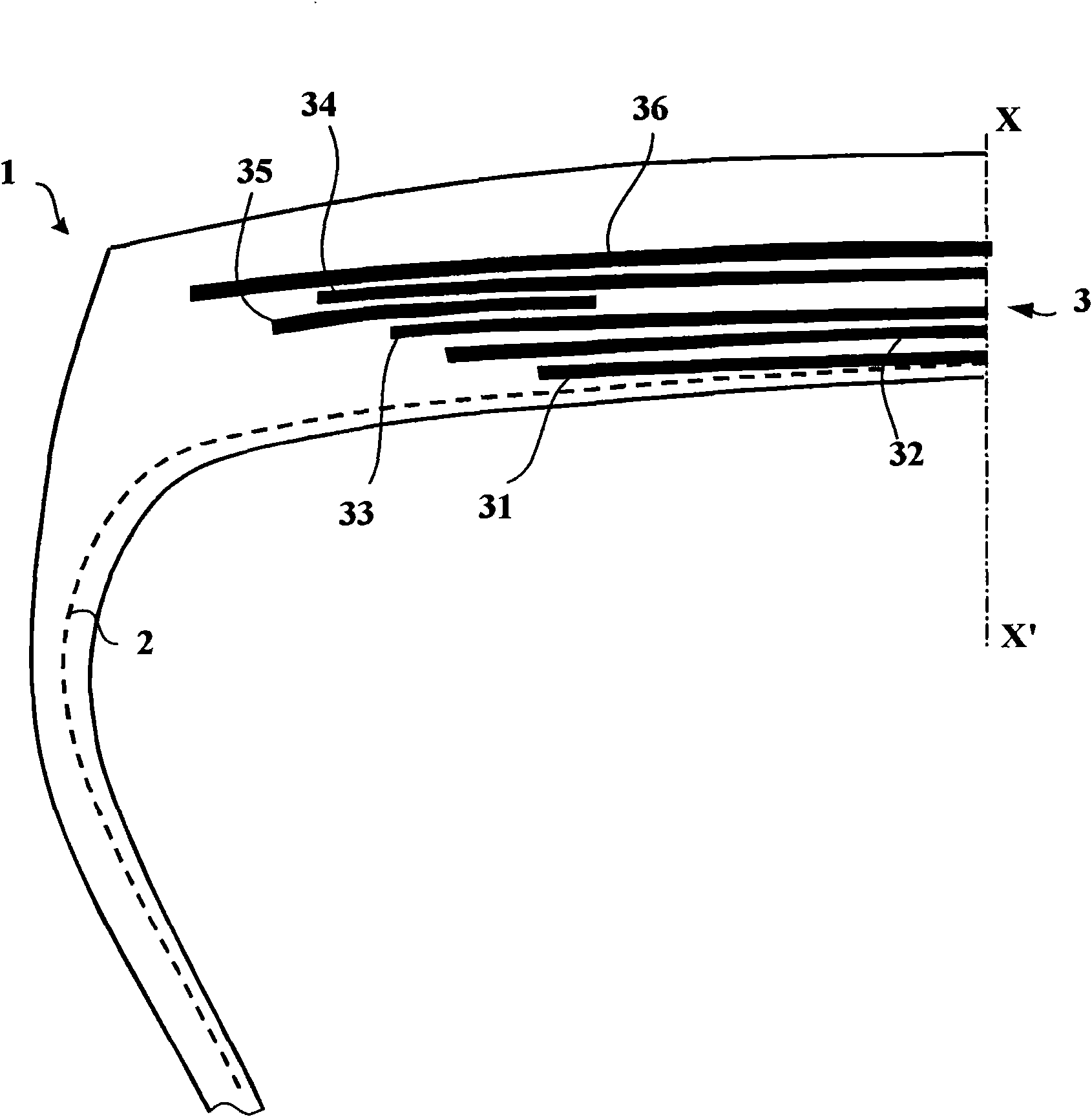

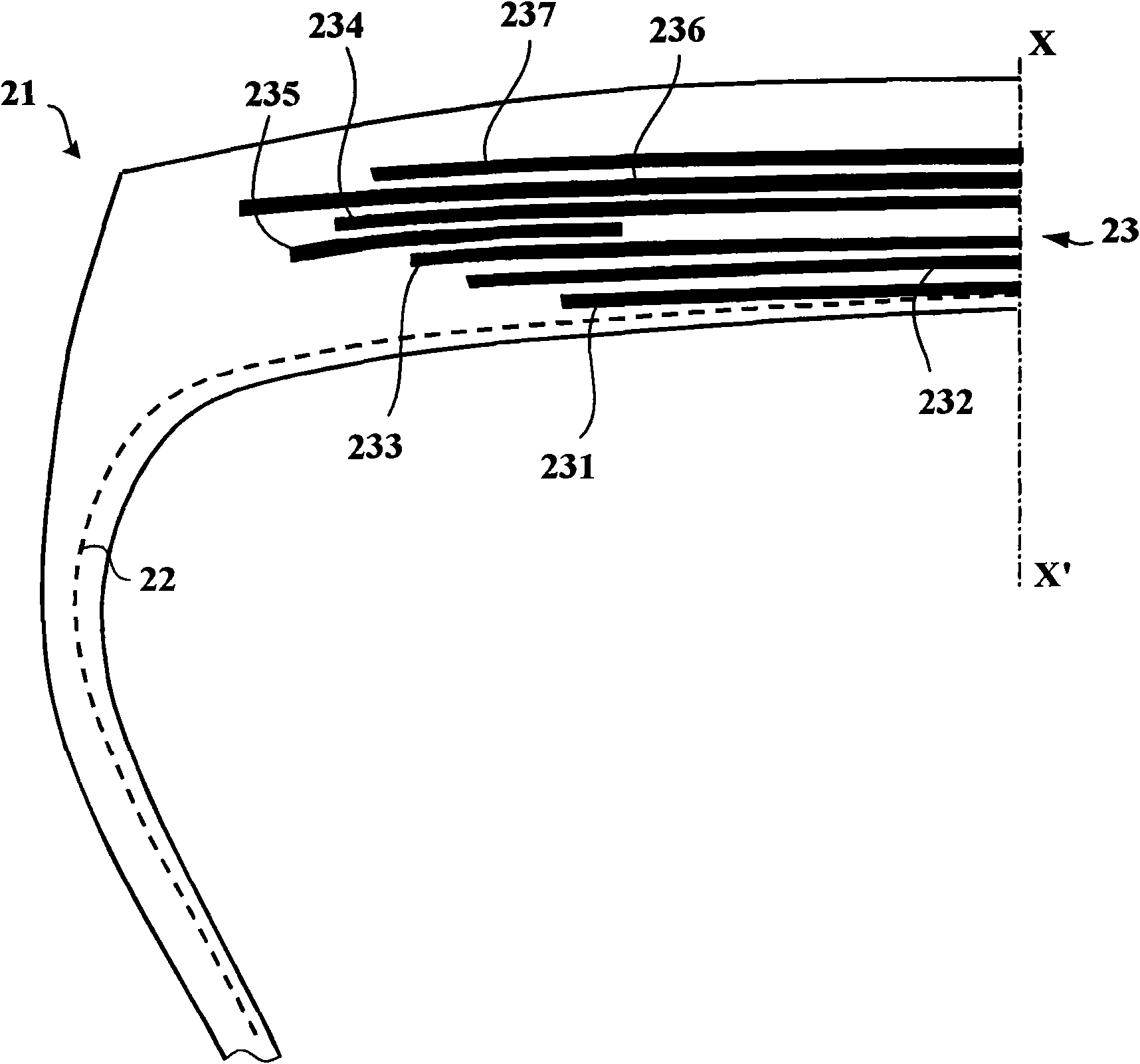

[0028] For ease of understanding, the figures are not shown to scale. The drawings show only a half view of the tire, which is continuous and symmetrical with respect to the XX' axis, which represents the circumferential mid-plane of the tyre.

[0029] The dimensions quoted are theoretical values, that is, reference values used in tire manufacture; actual values may differ slightly, especially as a result of uncertainties related to the manufacturing method of such tires.

[0030] Furthermore, with regard to the angle of the reinforcement of the ply, the value quoted is the minimum value, that is to say the value corresponds to the area of the ply closest to the central axis of the tire. The angle of said reinforcement varies in the direction of the axis of the tyre, in particular as a result of the bending of the tyre.

[0031] figure 1 A radial section through a tire 1 manufactured according to the invention is depicted. A tire 1 of size 59 / 80R63 comprises a carcass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com