Suspension for chassis of four-wheel moving robot

A mobile robot and suspension technology, applied in the direction of suspension, elastic suspension, interconnection system, etc., can solve the problems such as the adhesion between the wheel and the ground and the deterioration of driving comfort, so as to improve the adhesion and driving comfort, Improved load distribution and good installability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are further explanations and descriptions of the present invention, and do not constitute any limitation to the present invention.

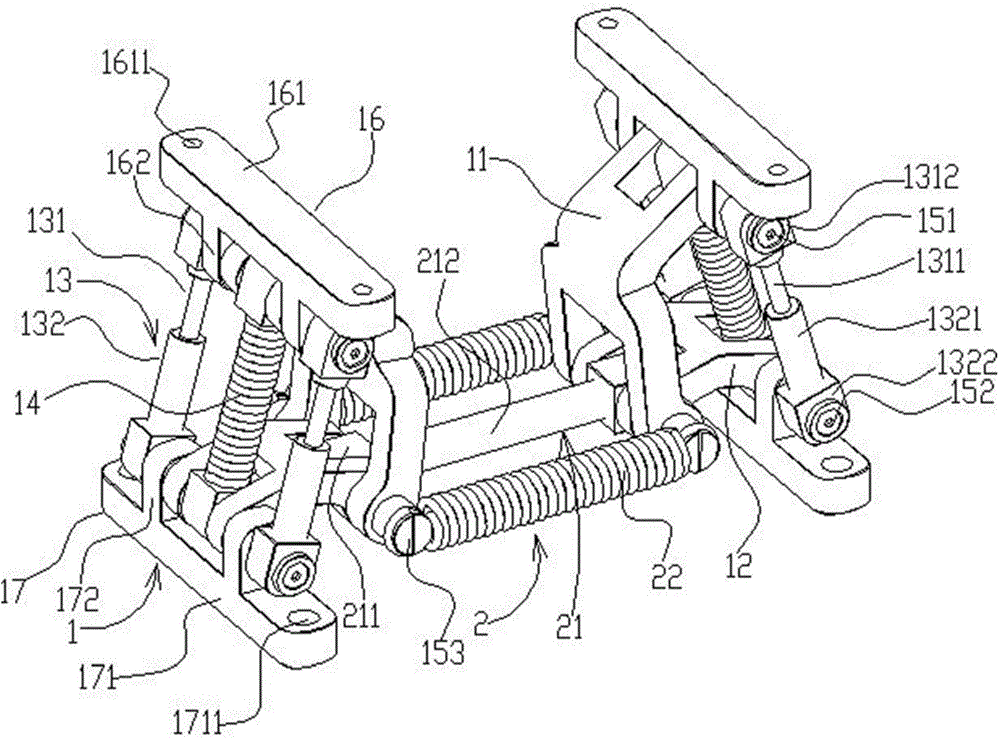

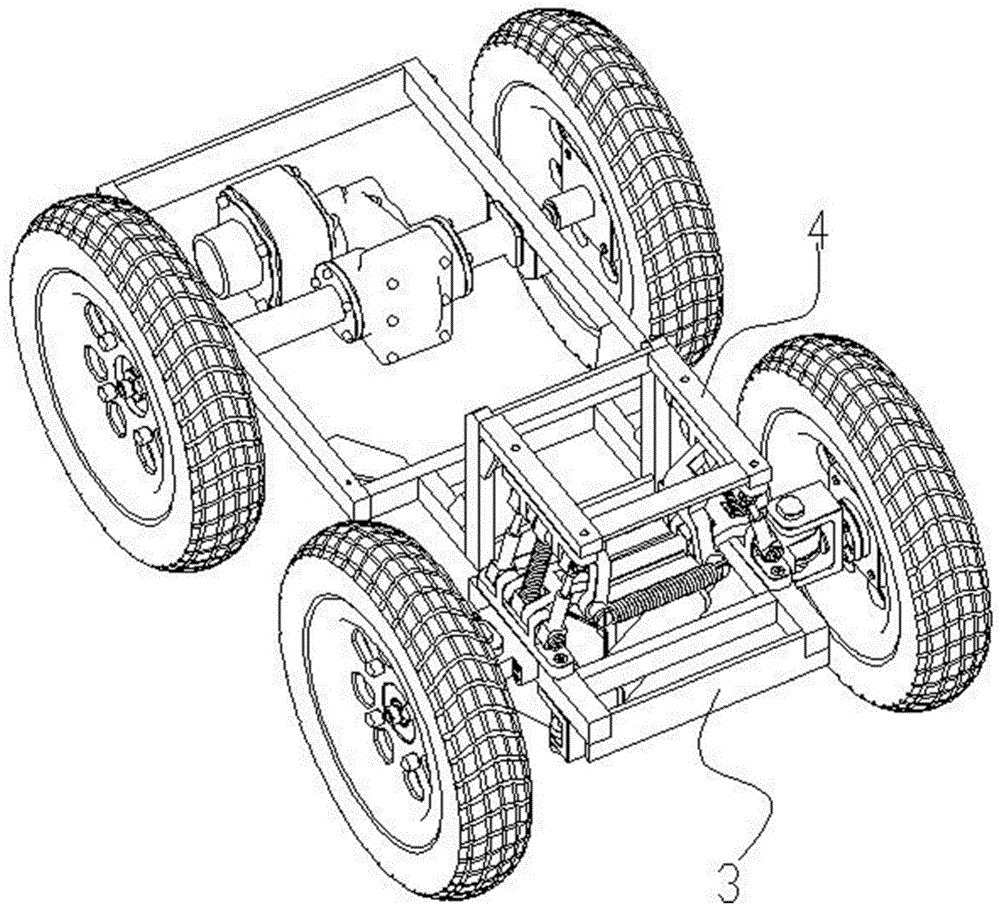

[0023] Such as figure 1 As shown, the suspension used for the chassis of the four-wheel mobile robot of the present invention is a three-degree-of-freedom elastic parallel mechanism. The top end of the three-degree-of-freedom elastic parallel mechanism is fixed to the frame, and the bottom end is fixed to the axle. A closed loop structure is formed between the frame, the three-degree-of-freedom elastic parallel mechanism, and the axle.

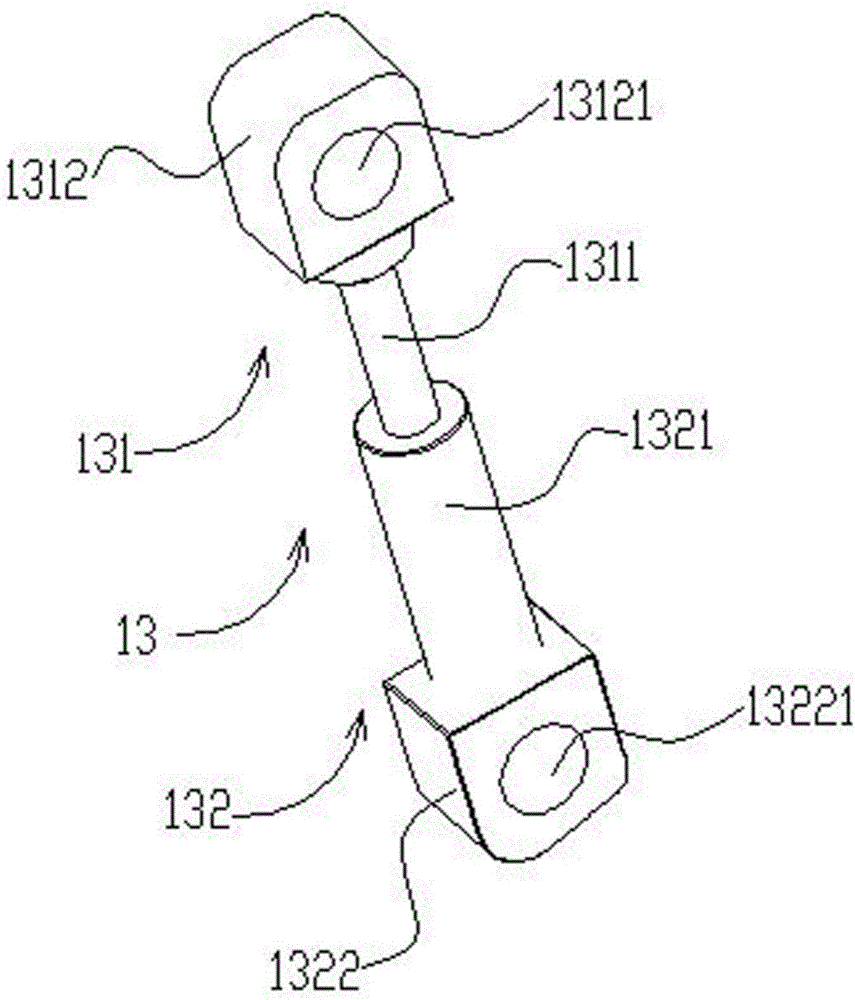

[0024] Such as figure 1 As shown, the suspension for the chassis of a four-wheel mobile robot includes: a pair of elastic support devices 1 and a connecting assembly 2 connecting the elastic support devices 1. The elastic support device 1 includes an upper link 11, a lower link 12, and a first Stroke limiting structure 13 and compression spring 14. The upper connecting rod 11 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com