Grabbing device of metal waste block conveying mechanism

A technology of conveying mechanism and grasping device, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as accidents, lifting troubles, shaking, etc., and achieve convenient removal of metal waste blocks, ensure normal operation, and place them easily. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

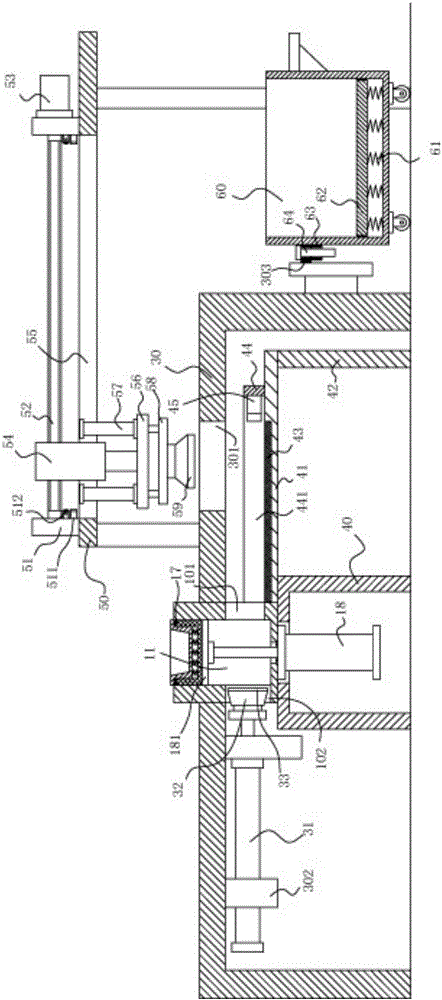

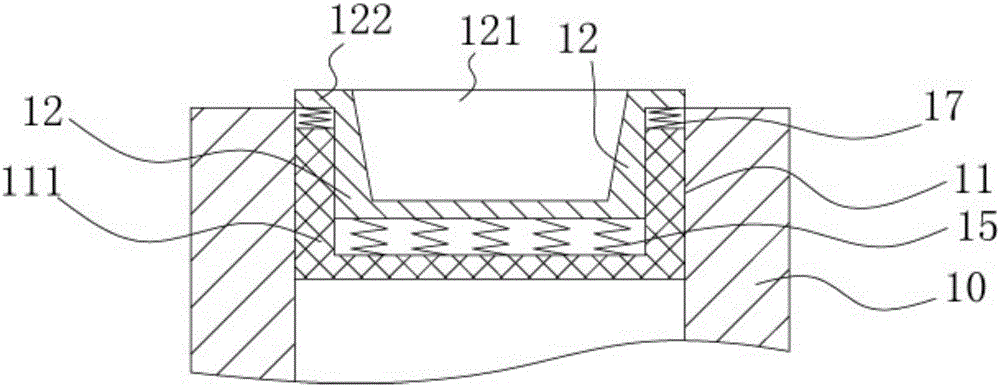

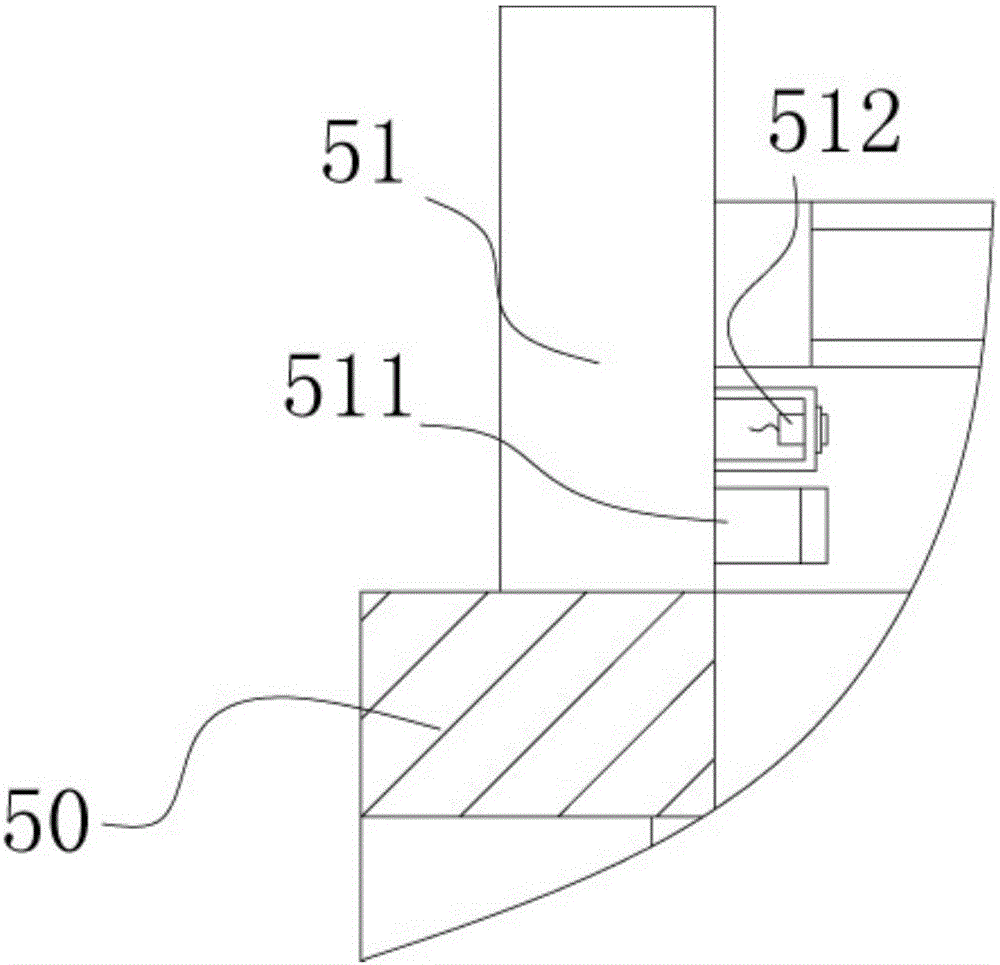

[0020] Example: see Figure 1 to Figure 4 As shown, a grabbing device for a metal scrap block conveying mechanism includes a main support frame 30 and a bottom pressing block 10, and the bottom pressing block 10 is inserted into the installation through hole in the middle of the top plate of the main support frame 30 and fixed on the On the inner side wall of the installation through hole, the bottom surface of the bottom pressing block 10 is fixed on the bottom support seat 40, the bottom support seat 40 is below the top plate of the main support frame 30, and the ground on the right side of the main support frame 30 is provided with a grab Mobile frame 50, grabbing the left end of the top plate of mobile frame 50 is above the right side of main support frame 30, grabs the both sides of the top plate of mobile frame 50 and is fixed with grab support plate 51, grabs the two ends of screw rod 52 and is hinged on On the two grasping support plates 51, one of the grasping support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com