Cooling system for amorphous metal member formed in laser 3D printed manner and cooling method of cooling system

A metal component and 3D printing technology, applied in the field of laser 3D printing, can solve the problems of reducing the performance of metal components, the heat of the molten pool cannot be quickly diffused, and crystallization, etc., to achieve the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

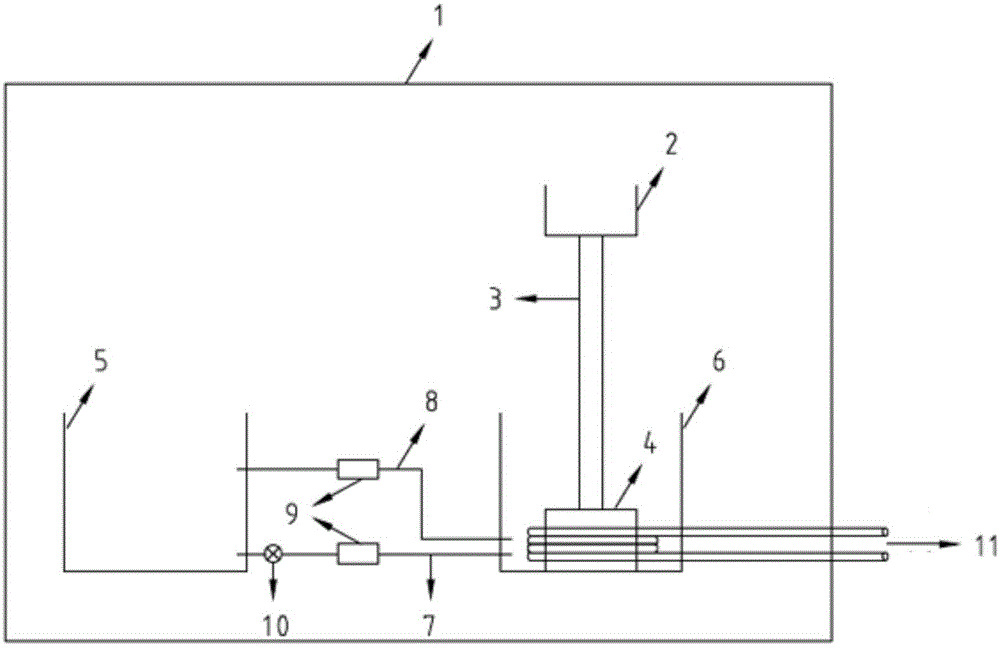

[0018] like figure 1 As shown, a laser 3D printing forming amorphous metal component cooling system includes a cooling liquid storage pool 5 and a cooling liquid working pool 6 arranged in a vacuum glove box 1 .

[0019] The cooling liquid storage pool 5 communicates with the cooling liquid working pool 6 through the cooling liquid delivery pipe 7 through the cooling liquid pump I9, and the cooling liquid delivery pipe 7 is provided with a control valve 10 for adjusting the flow rate of the cooling liquid. Driven by the coolant pump I9 to flow from the coolant storage pool 5 to the coolant working pool 6, the flow rate is regulated by the flow control valve 10;

[0020] The coolant working pool 6 communicates with the coolant storage pool 5 through the coolant return pipe 8 through the coolant pump II 9, and the coolant is driven by the coolant pump II 9 from the coolant working pool 6 to the coolant storage pool 5 flow;

[0021] The worktable 4 is installed in the cooling l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com