High-efficiency condensing type heat exchanger

A heat exchanger and condensing technology, applied in the field of high-efficiency condensing heat exchangers, can solve the problems of difficult cleaning, maintenance, low heat exchange efficiency, complex manufacturing process, etc., to achieve easy cleaning and maintenance, and improve heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

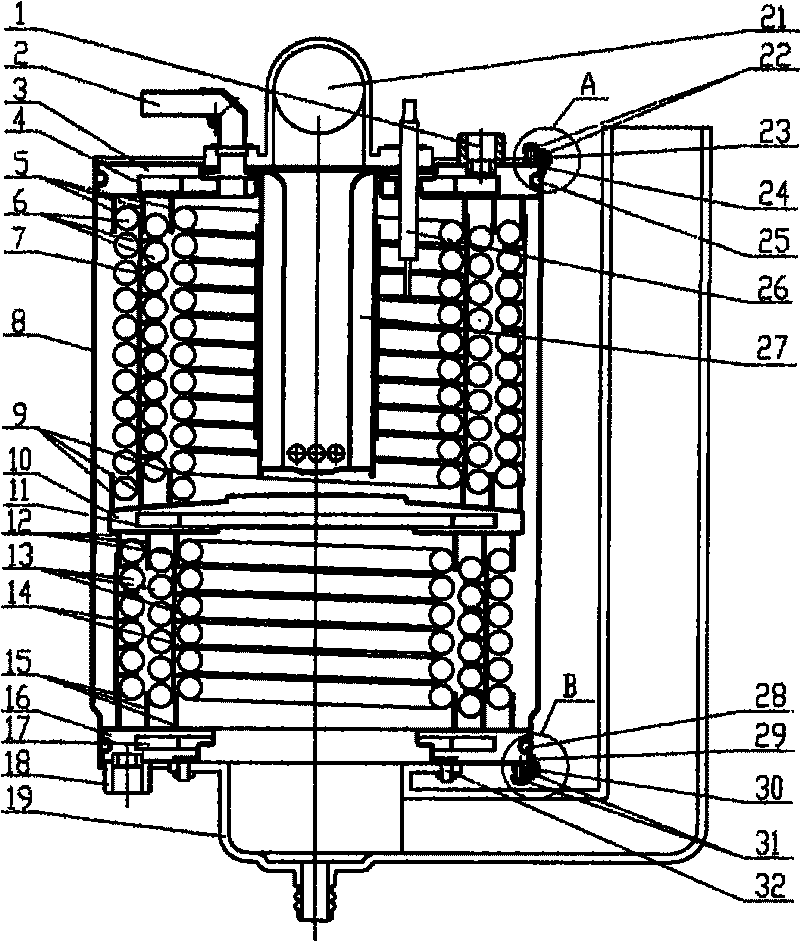

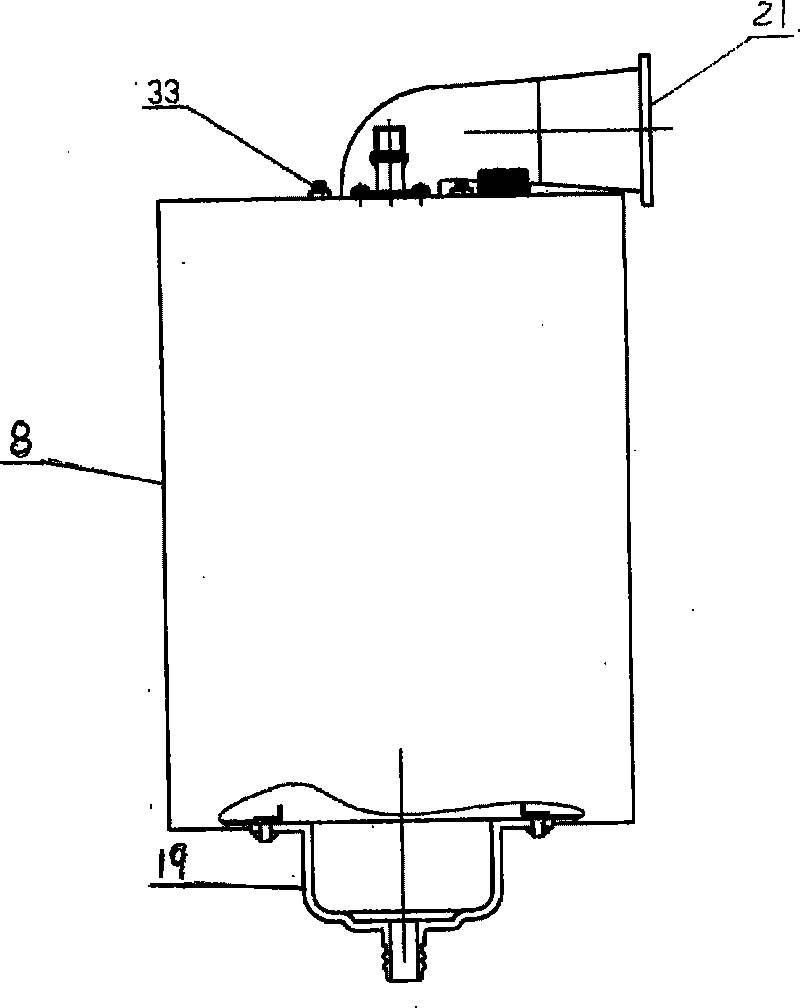

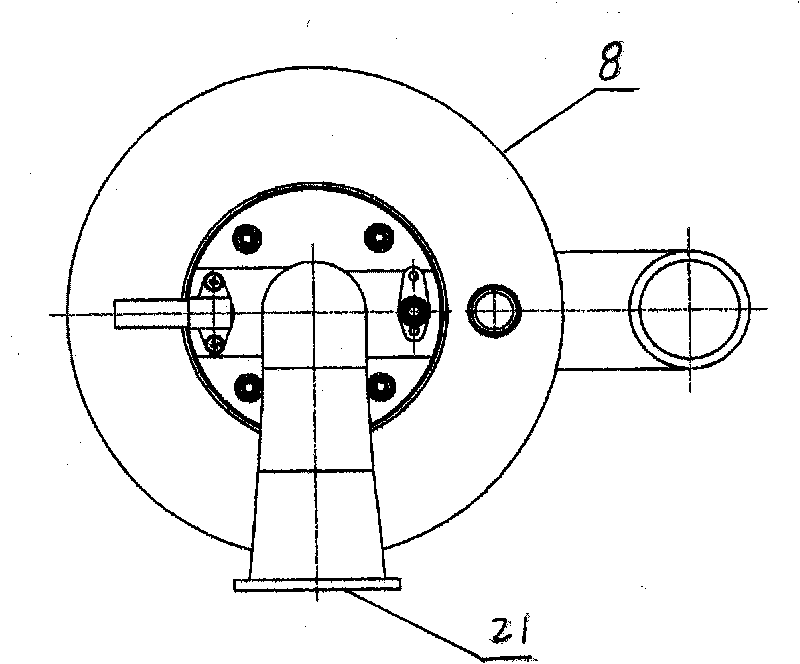

[0025] Such as Figure 1-10 As shown, the device is divided into a water heat exchange circuit and a combustion heating circuit.

[0026] The water heat exchange circuit during implementation: under the action of pressure, cold water enters the lower water tank 16 from the water inlet 18, and is disturbed by the spoiler 17. The water with uniform temperature enters the lower water tank 16 from multiple connection ports of the lower water tank 16 respectively. Layer spiral casing 13, water flows in the spiral direction in each layer of spiral pipe, and enters the middle water tank 10 through the connection port and is disturbed by the spoiler 11, and the water with uniform temperature enters the upper spiral through the multiple connection ports of the middle water tank 10. Casing 6. Water flows in the spiral direction in each spiral tube, enters the upper water tank 3 respectively through the connection port, and is disturbed by the spoiler 4, and the water with uniform tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com