Method and device for collecting steam of flushing cinder and afterheat of hot water in iron-making blast furnace

A technology for hot water waste heat and iron-smelting blast furnace, which is applied in the steam generation method, steam superheating, steam generation and other directions, can solve the problems of heat loss, waste heat, loss of water resources, etc. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

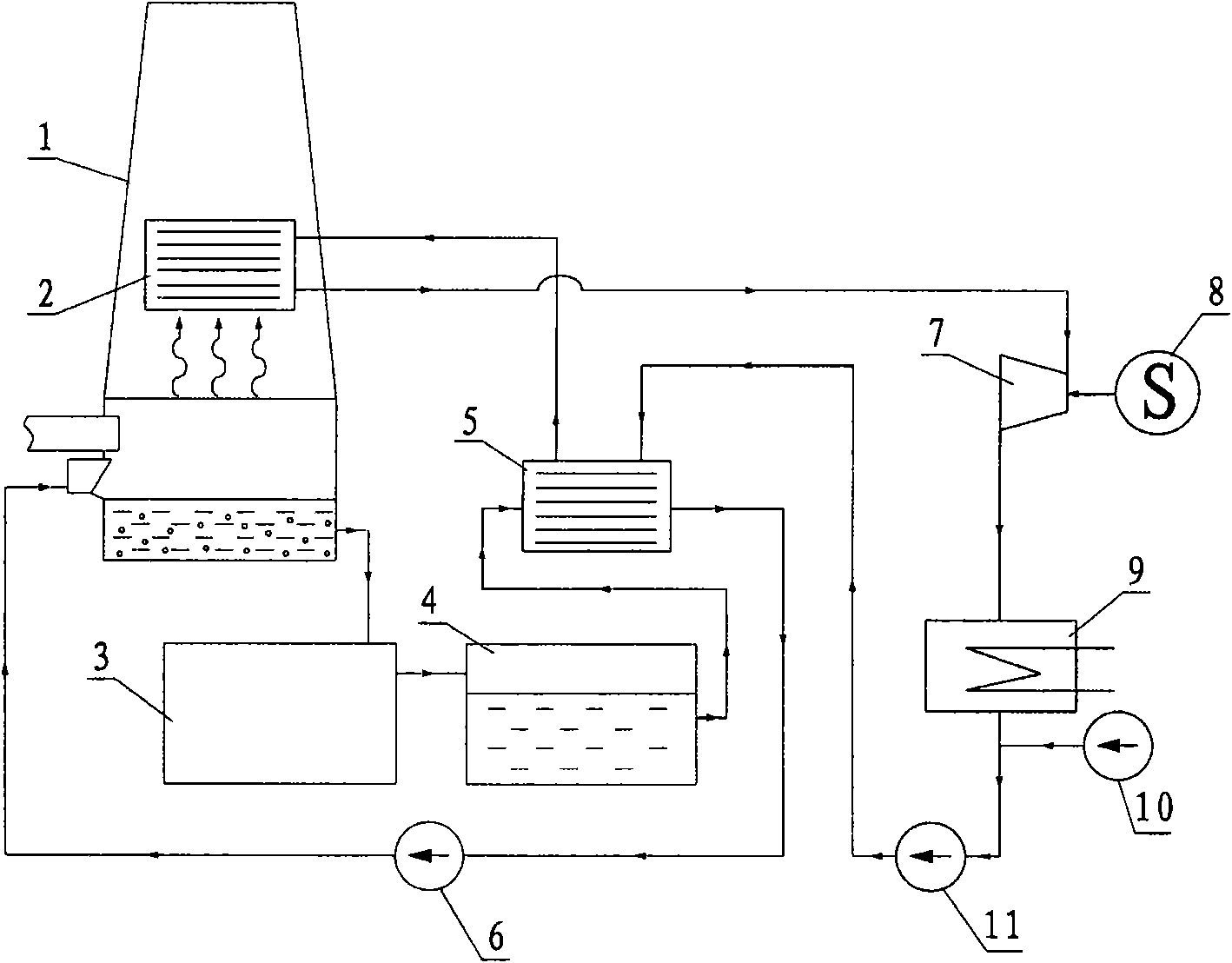

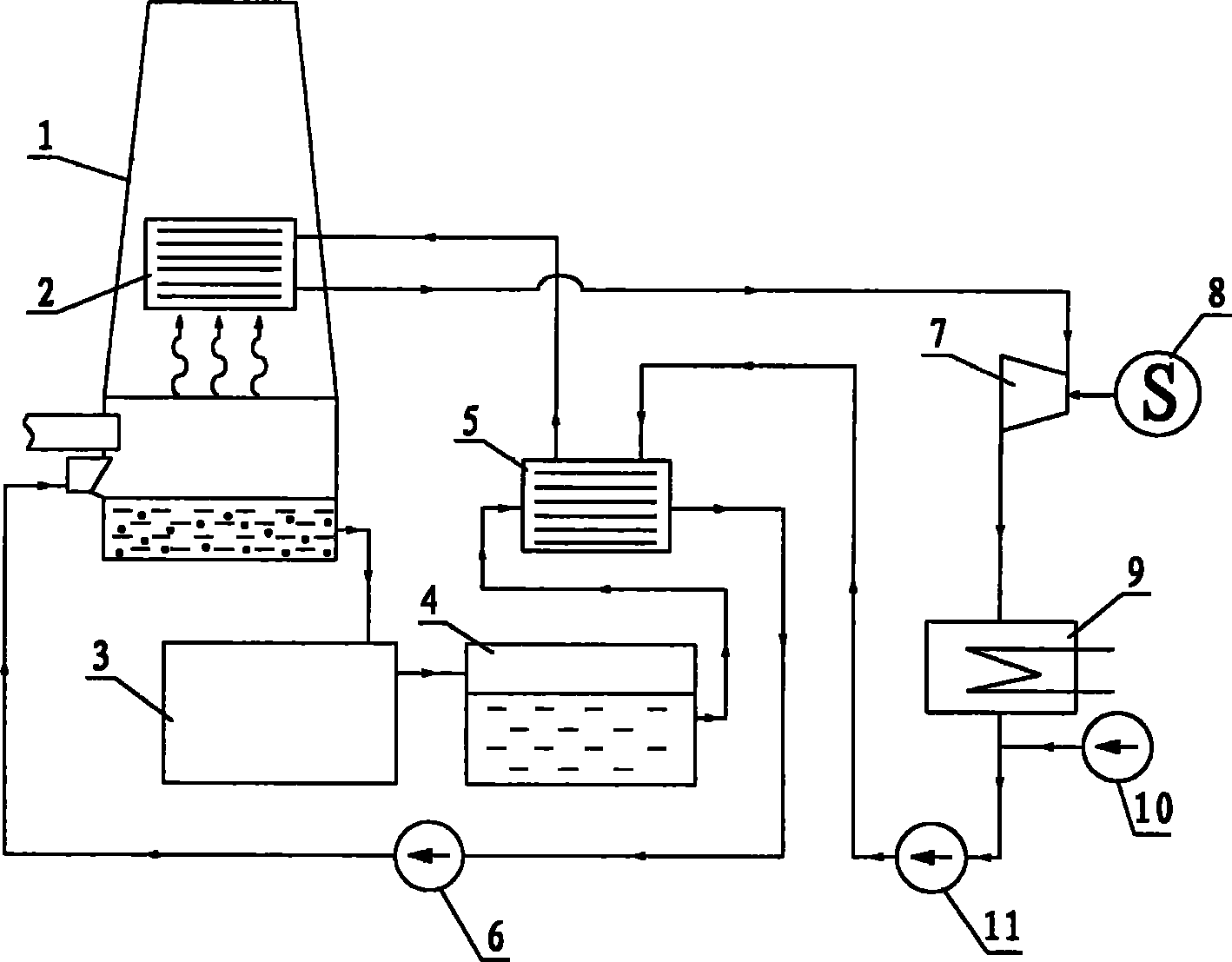

[0009] See figure 1 , The special equipment of the present invention includes a slag flushing steam heat exchange loop, a slag flushing water heat exchange loop and a working medium loop. Water slag granulation tower (or chimney) 1, evaporation heat exchanger 2 are sequentially connected to form a slag flushing steam heat exchange circuit; slag flushing and filtration system equipment 3, hot water pool 4, preheating heat exchanger 5, circulating hot water pump 6 sequence The connection constitutes a slag flushing water heat exchange circulation loop; the working medium circulation pipes of the preheating heat exchanger 5 and the evaporation heat exchanger 2 are sequentially connected with the steam turbine 7, the condenser 9, and the organic working medium pump 11 to form a working medium circulation loop.

[0010] Attached below figure 1 Describe the waste heat collection process of slag flushing steam and slag flushing water in the present invention: a large amount of steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com