Method preparing superfine metallic nickel powder with high frequency plasma

A technology of high-frequency plasma and metal nickel powder, which is applied in the field of preparation of fine spherical nickel powder, which can solve the problems of rough particle surface, unsuitability for preparing conductive paste, and small tap density, so as to avoid toxic and harmful products, disperse Good performance and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

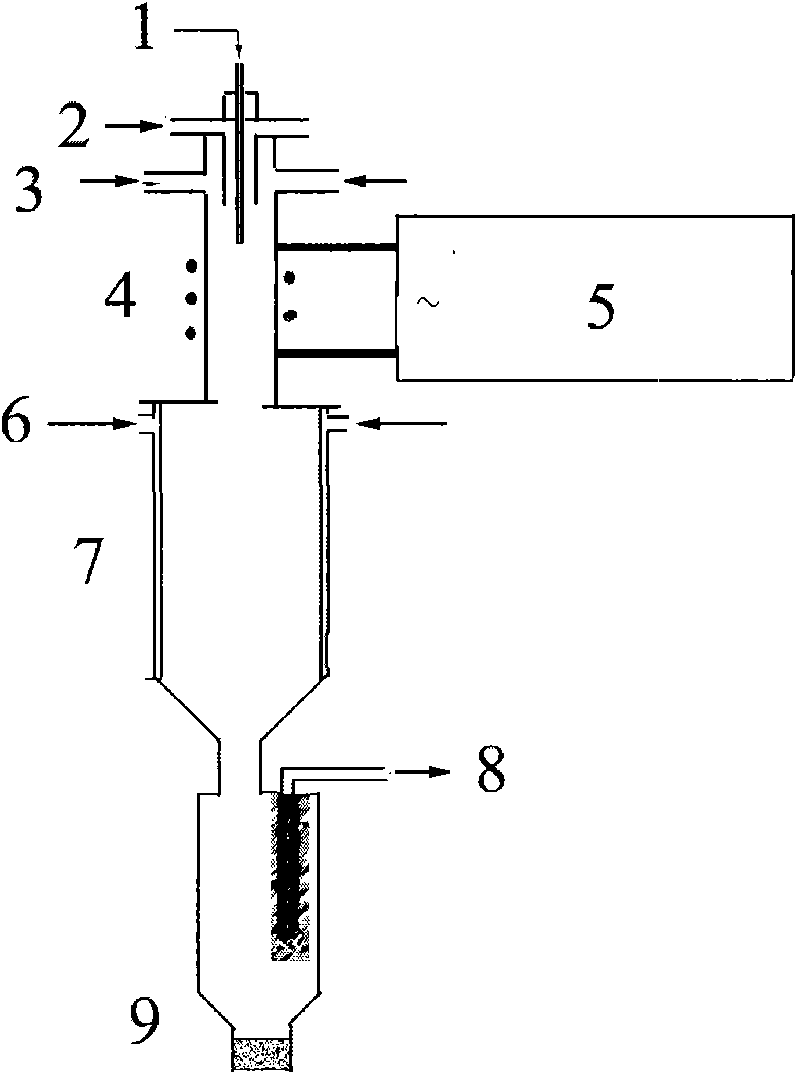

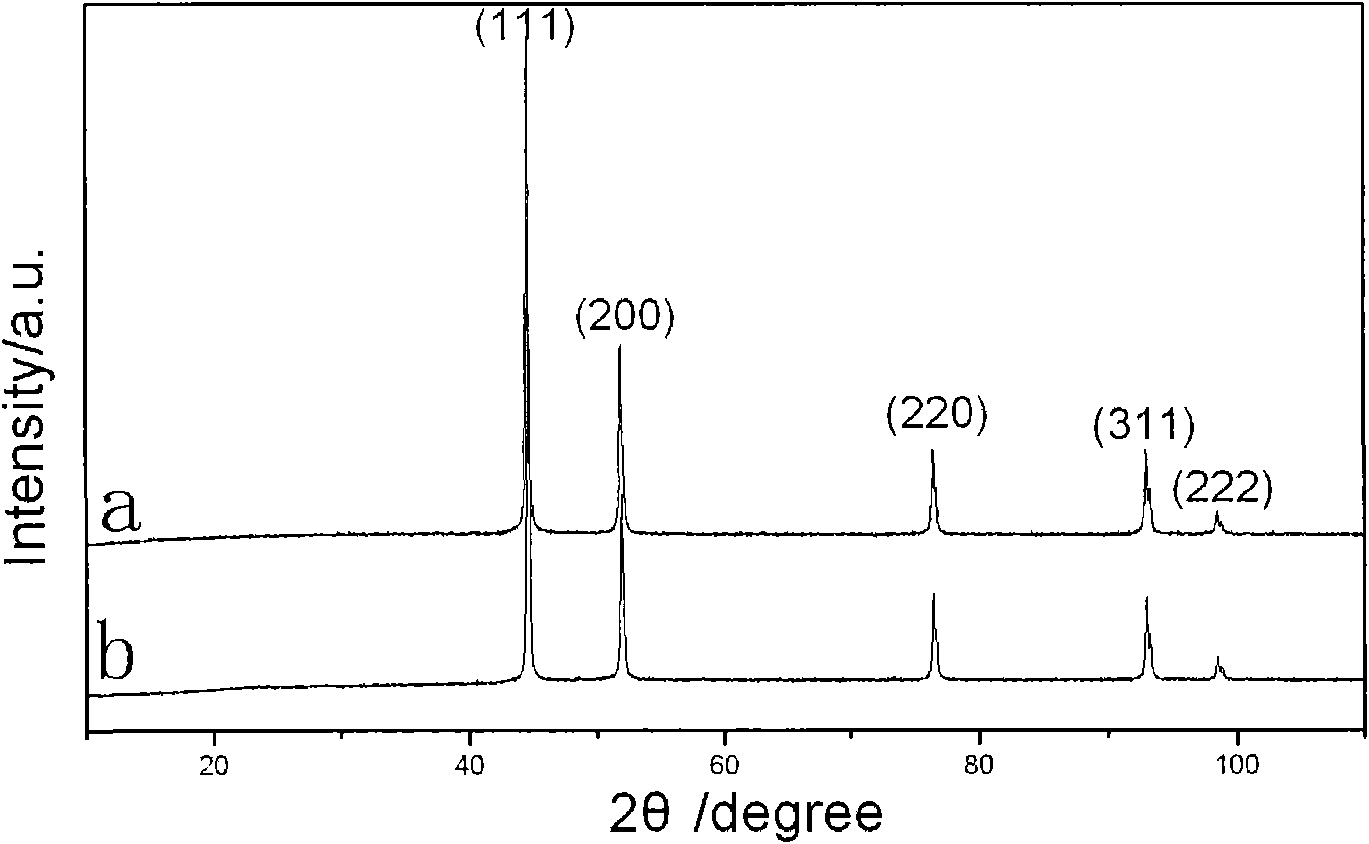

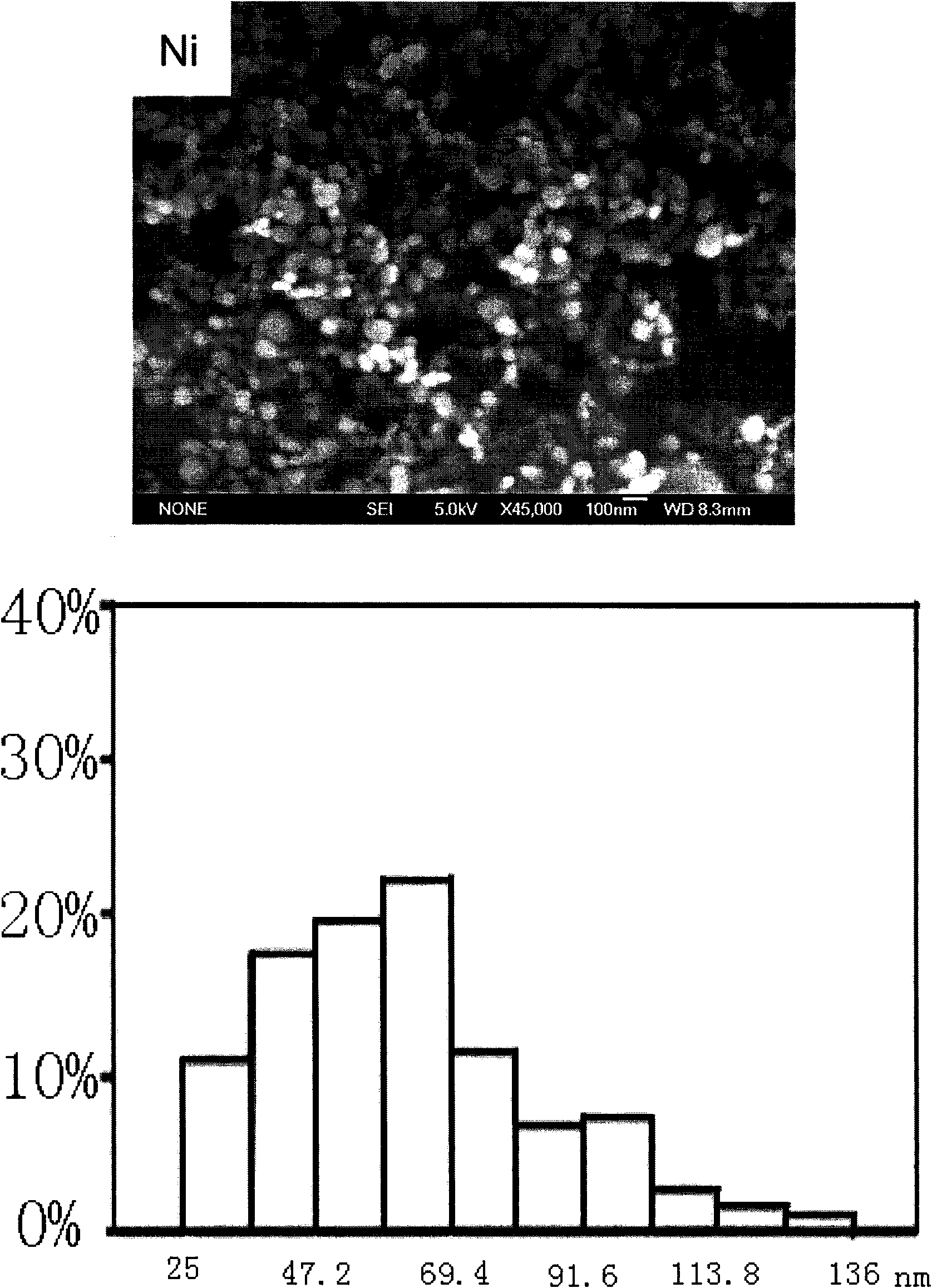

[0017] Nickel hydroxide is used as raw material to carry out high-frequency plasma hydrogenation reduction to prepare metal nickel powder. The flow rate of carrier gas hydrogen is 1.0m 3 / h, the feeding amount is 15g / min, the system negative pressure is 100mm water column, and the central argon gas flow rate is 2.0m 3 / h, side gas nitrogen flow rate 4.0m 3 / h, the flow rate of cooling gas nitrogen is 10.0m 3 / h. figure 2 is the XRD spectrum of the product. image 3 It is the scanning electron micrograph and particle size distribution of the product nickel powder.

example 2

[0019] Nickel hydroxide is used as raw material to carry out high-frequency plasma hydrogenation reduction to prepare metal nickel powder. The flow rate of carrier gas hydrogen is 1.0m 3 / h, the feeding amount is 15g / min, the system negative pressure is 100mm water column, and the central argon gas flow rate is 2.0m 3 / h, side gas nitrogen flow rate 4.0m 3 / h, without cooling air.

example 3

[0021] Metal nickel powder was prepared by plasma hydrogenation reduction using basic nickel carbonate as raw material. The flow rate of carrier gas hydrogen is 1.0m 3 / h, the feeding amount is 20g / min, the system negative pressure is 100mm water column, and the central argon gas flow rate is 2.0m 3 / h, side gas nitrogen flow rate 4.0m 3 / h, without cooling air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com