Phenyl alkoxy silane prepared by sodium condensation method

A technology of phenylalkoxysilane and sodium condensation, which is applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve problems such as low production efficiency and long reaction cycle, Achieve the effects of fast reaction speed, shortened reaction cycle, and reasonable process formula design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

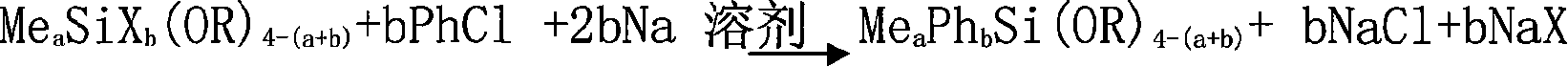

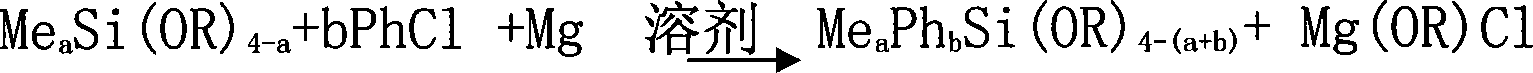

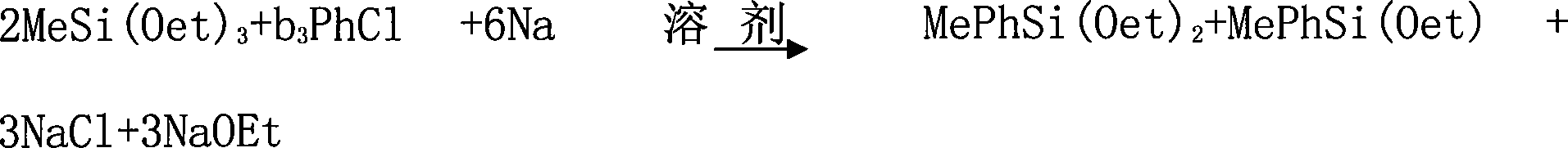

Method used

Image

Examples

Embodiment 1

[0031] Add 50g of n-octane and 11.5g of metallic sodium into a three-necked flask, heat to melt the sodium, start stirring and beat it into sodium sand, and then at 104°C, mix ClSi(OMe) 3 The mixed solution of 42g and 28.5gPhCl was gradually dropped into a three-necked flask within 2h, and then kept at reflux temperature for 3h. After vacuum distillation, 89g of crude product was evaporated, and the sample was analyzed by gas chromatography to measure phenyltrimethoxy 16.37 g of silane, 7.99 g of diphenyldimethoxysilane, and 1.2 g of triphenylmethoxysilane, and the conversion rate of benzene was 64%.

Embodiment 2

[0033] Add 164g of methyl orthosilicate and 23g of metal sodium into a three-necked flask, heat and stir to beat the metal sodium into sodium sand, and then mix 57g of PhCl and 83g of ClSi(OMe) at 120°C 3 The mixed solution was added dropwise within 2 hours, after the drop was completed, it was kept at reflux temperature for another 1 hour, and then the crude product was evaporated under reduced pressure, and analyzed by gas chromatography, the content of phenyltrimethoxysilane was 58.8g, diphenyldimethoxysilane The base silane was 10.6g, and the conversion rate of benzene was calculated to be 89%.

Embodiment 3

[0035] Add 164g of tetraethyl orthosilicate and 23.5 g of sodium metal into the three-necked flask, beat the metal sodium into sodium sand under heating and stirring, and mix 56 g of PhCl and 24 g of SiCl at 110 ° C 4The mixed solution was dripped into a three-necked flask within 2 hours, and after dropping, it was kept at reflux temperature for 2 hours, and then the crude product was evaporated by distillation under reduced pressure, and analyzed by gas chromatography, the amount of phenyltriethoxysilane was 58.2g, two The phenyldiethoxysilane was 19.4g, the triphenylsilane was 2.1g, and the conversion rate of benzene was calculated to be 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com