Load type honeycomb ceramic catalytic material and preparation method thereof

A technology of honeycomb ceramics and catalytic materials, applied in the field of supported honeycomb ceramic catalytic materials and their preparation, can solve the problems of expensive raw materials, unsuitable for industrial production and large-scale promotion, etc., and achieves simple preparation method, simple structure and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

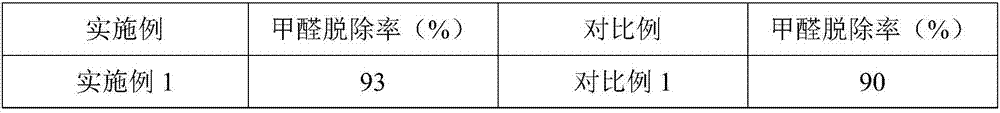

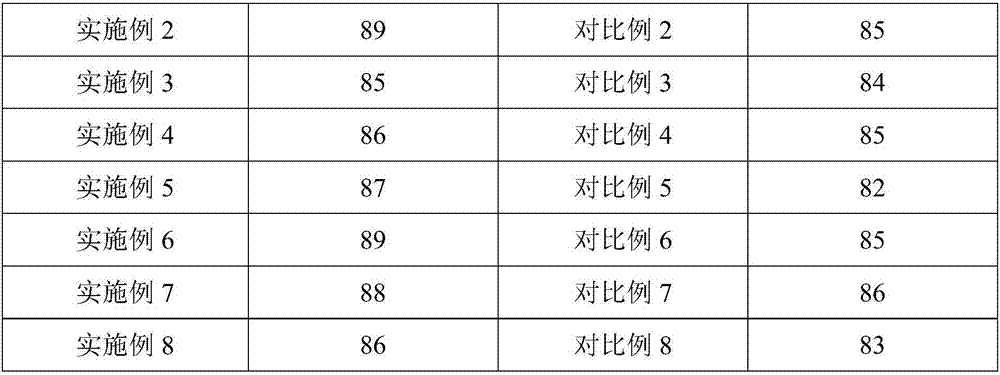

Examples

Embodiment 1

[0035] 1) 750g mass fraction is 50% Mn(NO 3 ) 2 aqueous solution and 188g of Cu(NO 3 ) 2 Add to 1Kg of water, stir until dissolved to obtain a metal salt solution;

[0036] 2) Add 800g titanium dioxide and 200g nano-anion powder (commercially available materials from Shijiazhuang Huabang Mineral Products Co., Ltd.) to the metal salt solution to obtain a suspension, stir the suspension until it is uniformly dispersed, and use a mass fraction of 25 % ammonia water to adjust its pH to 8, stir for 3h, wash and filter to obtain the catalyst component;

[0037] 3) Mix 800g of the above-mentioned catalyst component, 140g of aluminum sol with a mass fraction of 30%, 200g of sodium carboxymethylcellulose with a mass fraction of 1%, 10g of Tween-20, and 1800g of water, and stir for 1 hour to obtain a slurry;

[0038] 4) Dip 100mm*100mm*40mm cordierite honeycomb into the slurry for 10 minutes and drain;

[0039] 5) Dry the coated cordierite honeycomb catalyst at 100°C for 10 hours, ...

Embodiment 2

[0042] 1) 750g mass fraction is 50% Mn(NO 3 ) 2 aqueous solution and 242g of Fe(NO 3 ) 3 Add to 1Kg of water, stir until dissolved to obtain a metal salt solution;

[0043] 2) Add 800g of activated carbon and 200g of nano-anion powder into the metal salt solution to obtain a suspension, stir the suspension until it is uniformly dispersed, adjust its pH to 11 with ammonia water with a mass fraction of 25%, stir for 3 hours, and wash , filtered to obtain the catalyst component;

[0044] 3) Mix 800g of the above-mentioned catalyst component, 140g of aluminum sol with a mass fraction of 30%, 200g of sodium carboxymethylcellulose with a mass fraction of 1%, 10g of Tween-20, and 1800g of water, and stir for 1 hour to obtain a slurry;

[0045] 4) Dip 100mm*100mm*40mm cordierite honeycomb into the slurry for 10 minutes and drain;

[0046] 5) The coated cordierite honeycomb catalyst was dried at 120° C. for 4 hours, then heated to 500° C. at a rate of 3° C. / min, and calcined for 5 h...

Embodiment 3

[0049] 1) 750g mass fraction is 50% Mn(CO 3 ) 2 aqueous solution and 287g of Zn(NO 3 ) 2 Add to 1Kg of water, stir until dissolved to obtain a metal salt solution;

[0050] 2) Add 800g of diatomaceous earth and 200g of nano-anion powder into the metal salt solution to obtain a suspension, stir the suspension until it is uniformly dispersed, adjust its pH to 11 with ammonia water with a mass fraction of 25%, and stir for 3 hours , washed and filtered to obtain the catalyst component;

[0051] 3) Mix 800g of the above-mentioned catalyst component, 140g of aluminum sol with a mass fraction of 30%, 200g of sodium hydroxyethylcellulose with a mass fraction of 1%, 10g of Triton X-100 and 1800g of water, and stir for 1 hour to obtain a slurry;

[0052] 4) Dip 100mm*100mm*40mm cordierite honeycomb into the slurry for 10 minutes and drain;

[0053] 5) Dry the coated cordierite honeycomb catalyst at 130°C for 3h, under a nitrogen atmosphere, then raise the temperature to 600°C at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com