Poly ferro-silicon-titanium coagulant used for treating low-sludge amount water and preparation technology thereof

A technology of water treatment and sludge volume, applied in the field of water treatment, to achieve the effect of mature technology, simple equipment and high efficiency of pollution removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

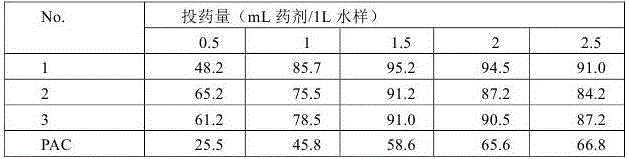

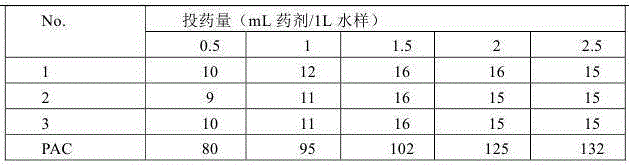

Embodiment 1

[0029] At a stirring speed of 100 rpm to 300 rpm, add 25L of water to 15L of water glass to obtain a water glass dilution, and then at a stirring speed of 300 rpm to 500 rpm, the Add the above diluted water glass solution to 3L of dilute sulfuric acid solution with a mass fraction of 45%, control the pH value to 3~3.5, stir for 5 minutes, and let it stand for 5 hours to obtain a polysilicic acid solution for later use. At a stirring speed of 50 rpm to 100 rpm, add 50L of water to 50kg of metatitanic acid waste to form a paste, and then stir at a temperature of 90 ° C ~ 100 ° C and 100 rpm At a stirring speed of ~200 rpm, 85L of concentrated sulfuric acid solution with a mass fraction of 80% was added to the above paste to carry out leaching reaction, and the reaction time was controlled to be 1 hour to obtain a leaching solution. Under the condition of 100 rpm to 300 rpm, add 100L of water to the above leaching solution to obtain a leaching dilution, filter to obtain a filtrat...

Embodiment 2

[0031] At a stirring speed of 100 rpm to 300 rpm, add 30L of water to 15L of water glass to obtain a water glass dilution, and then at a stirring speed of 300 rpm to 500 rpm, mix Add the above diluted water glass solution to 4L of dilute sulfuric acid solution with a mass fraction of 40%, control the pH value to 2~3, stir for 5 minutes, and let stand for 12 hours to obtain a polysilicic acid solution for later use. At a stirring speed of 50 to 100 rpm, add 28L of water to 28kg of metatitanic acid waste to form a paste, and then stir at a temperature of 90°C to 100°C and 100 rpm At a stirring speed of ~200 rpm, 45L of concentrated sulfuric acid solution with a mass fraction of 75% was added to the above-mentioned paste, and the leaching reaction was carried out. The reaction time was controlled to be 2 hours to obtain a leaching solution. Under the condition of 100 rpm to 300 rpm, add 50L of water to the above leaching solution to obtain a leaching dilution, filter to obtain a ...

Embodiment 3

[0033] At a stirring speed of 100 rpm to 300 rpm, add 30L of water to 15L of water glass to obtain a water glass dilution, and then at a stirring speed of 300 rpm to 500 rpm, mix Add the above diluted water glass solution to 4L of dilute sulfuric acid solution with a mass fraction of 40%, control the pH value to 2~3, stir for 5 minutes, and let stand for 12 hours to obtain a polysilicic acid solution for later use. At a stirring speed of 50 to 100 rpm, add 28L of water to 28kg of metatitanic acid waste to form a paste, and then stir at a temperature of 90°C to 100°C and 100 rpm At a stirring speed of ~200 rpm, 45L of concentrated sulfuric acid solution with a mass fraction of 75% was added to the above-mentioned paste, and the leaching reaction was carried out. The reaction time was controlled to be 2 hours to obtain a leaching solution. Under the condition of 100 rpm to 300 rpm, add 50L of water to the above leaching solution to obtain a leaching dilution, filter to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com