Using method for rotary device for removing indoor harmful gas

A harmful gas, runner technology, applied in separation methods, chemical instruments and methods, applications, etc., can solve problems such as large equipment, inconvenient inspection and maintenance, and civil construction, occupation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

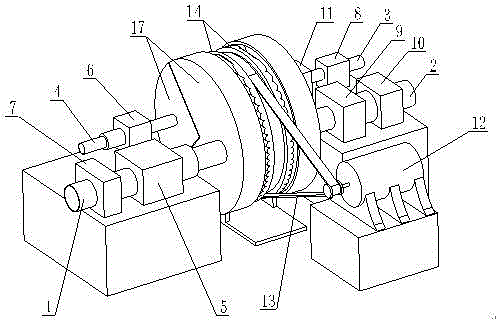

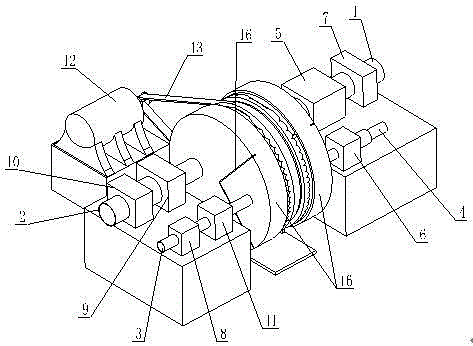

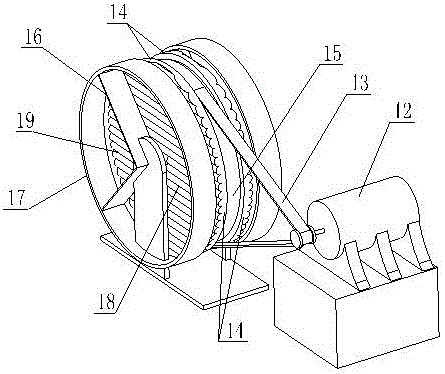

[0019] Specific embodiment one, please refer to figure 1 , figure 2 and image 3 , the wheel-type indoor harmful gas removal device, including a motor 12, a transmission belt 13, an adsorption runner 14, a partition 16 and an adsorption cover 17, the middle part of the adsorption runner 14 is provided with a transmission belt placement groove 15, and the transmission belt 13 is placed In the transmission belt placement groove 15, the motor 12 can drive the adsorption runner 14 to rotate through the transmission belt 13, and the partition plate 16 and the adsorption cover 17 divide the front and rear sides of the adsorption runner 14 into a purification zone 18 and a regeneration zone 19 The purification zone 18 on one side of the adsorption runner 14 is provided with a purification inlet pipe 1, and the purification zone 18 on the other side of the adsorption runner 14 is provided with a purification outlet pipe 2. The regeneration zone 19 of the regeneration zone 19 is pro...

specific Embodiment 2

[0026] Specific embodiment two, please refer to figure 1 , figure 2 and image 3 , the use method of the rotary wheel type indoor harmful gas removal device, comprising a motor 12, a transmission belt 13, an adsorption runner 14, a dividing plate 16 and an adsorption cover 17, the steps of which are:

[0027] (1), the air to be purified enters the device from the purified air intake pipe 1 under the drive of the purification fan 5, and the air to be purified first passes through the primary filter one 7, and the primary filter one 7 can remove dust and dust in the air to be purified Particles, forming preliminary air purification;

[0028] (2), then the preliminary purified air enters the adsorption runner 14 after passing through the purification fan 5, and the preliminary purified air will pass through the purification zone 18 of the adsorption runner 14 under the constraints of the partition plate 16 and the adsorption cover 17, and the adsorption runner 14 can absorb t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com