Nanofiber membrane and membrane adsorbing assembly for extracting uranium from seawater and brine water and application of nanofiber membrane and membrane adsorbing assembly

A nanofiber membrane, brine technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor recycling performance, difficult to scale application, slow adsorption rate, etc. , to achieve the effect of stable cycle performance, improved mechanical strength and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of 0.1m by electrospinning 2 PET-PAN nanofiber film, wherein the content of PAN nanofiber is 0.625g, and the thickness of PAN nanofiber layer is 40 μm. A polyethylene (PE) hollow tube with a length of 50 mm and an outer diameter of 5 mm is used as the central tube, a polyvinyl chloride (PVC) tube with a length of 50 mm and an inner diameter of 20 mm is used as the membrane shell, and a PE grid with a thickness of 2 mm is used as the water distribution grid. Rolled membrane modules. Immerse the hand-rolled membrane module into the hydroxylamine hydrochloride solution with a mass fraction of 10%, and shake it in a 70°C water bath for 240 minutes. During the reaction, add sodium carbonate to maintain the pH value of the reaction system between 7-10, and take it out after the reaction is over. The membrane module was washed repeatedly with clean water until the pH was neutral, and then the amidoximated membrane was placed in a hydrochloric acid solution wit...

Embodiment 2

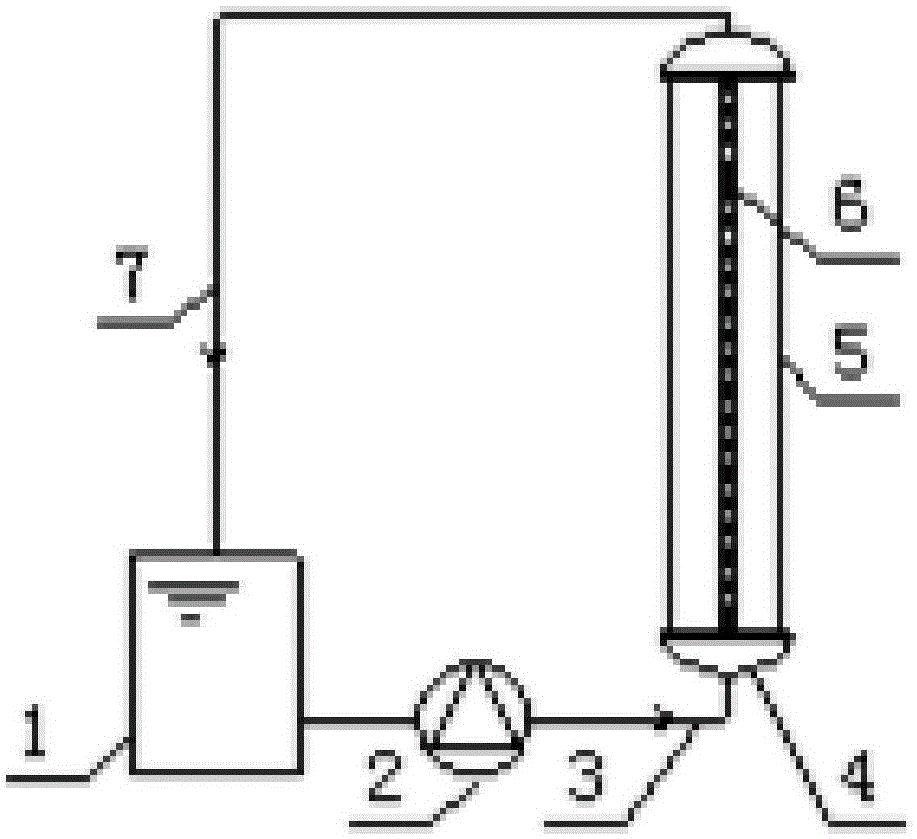

[0045] (1) Preparation of 4.0m by electrospinning 2 PET-PAN nanofiber film, wherein the content of PAN nanofibers is 50g, and the thickness of the PAN nanofiber layer is 40 μm. A polyethylene (PE) hollow pipe with a length of 1000mm and an outer diameter of 20mm is used as the central pipe, a polyvinyl chloride (PVC) pipe with a length of 1000mm and an inner diameter of 200mm is used as the membrane shell, and a PE grid with a thickness of 2mm is used as the water distribution grid. Machine-rolled to make a roll-type membrane module. see figure 1 , which is a schematic diagram of the device for the amidoximation reaction of the coiled membrane module. As shown in the figure, the configured hydroxylamine hydrochloride solution with a mass fraction of 10% is lifted from the drug dissolution tank 1 through the feed liquid pump 2, and then circulated through the feed pipeline 3 through the water distribution member 4 and injected into the rolled membrane module 5 , and then ret...

Embodiment 3

[0050] (1) Preparation of 4.0m by electrospinning 2 PET-PAN nanofiber film, wherein the content of PAN nanofibers is 50g, and the thickness of the PAN nanofiber layer is 40 μm. A polyethylene (PE) hollow pipe with a length of 1000mm and an outer diameter of 20mm is used as the central pipe, a polyvinyl chloride (PVC) pipe with a length of 1000mm and an inner diameter of 200mm is used as the membrane shell, and a PE grid with a thickness of 2mm is used as the water distribution grid. Machine-rolled to make a roll-type membrane module. like figure 1 As shown, the configured hydroxylamine hydrochloride solution with a mass fraction of 10% is lifted from the drug dissolving tank 1 by the feed liquid pump 2, and then circulated into the coiled membrane module 5 by the feed pipeline 3 through the water distribution member 4, and then Return to the medicine dissolving tank 1 via the discharge pipeline 7 to realize a cyclic reaction. Among them, the drug dissolving tank 1 is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com