Weak acid cation exchange microballoon resin of magnetic acrylic acid series and synthesis method thereof

A technology of weak acid cation and synthesis method, which is applied in the field of acrylic weak acid cation exchange microsphere resin and its synthesis, can solve the problem of low exchange capacity, and achieve high and weak acid exchange capacity, excellent adsorption, and easy desorption kinetics.

Inactive Publication Date: 2011-01-19

NANJING UNIV

View PDF4 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with traditional acrylic weak acid cation exchange resins, the exchange capacity is too low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

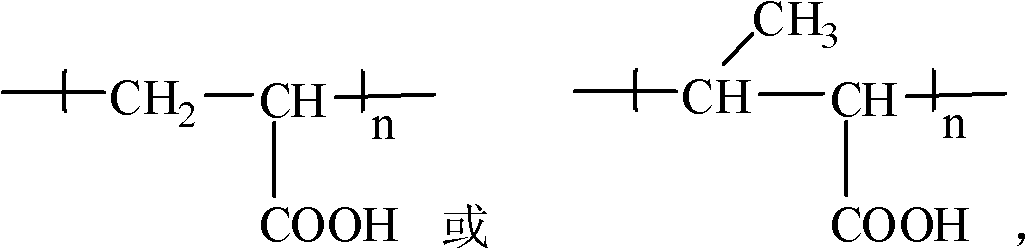

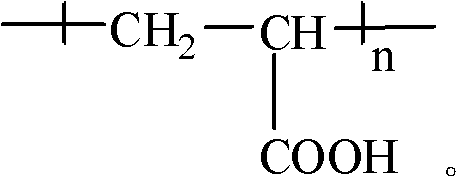

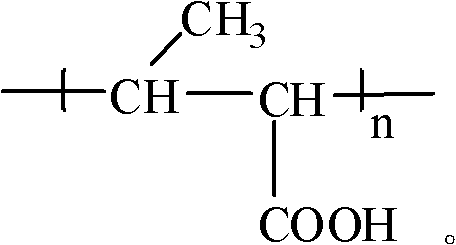

The invention discloses a weak acid cation exchange microballoon resin of magnetic acrylic acid series and a synthesis method thereof, belonging to the field of magnetic resin. The method comprises the following steps of: evenly mixing magnetic particles with the size of 0.01-10mu m with an oil phase, carrying out suspension polymerization under a certain temperature and conditions, and hydrolyzing to finally form the weak acid cation exchange resin. The microballoon resin consists of weak acid cation exchange microballoon resin frames and the magnetic particles packaged therein, wherein the weight ratio of the resin frames to the magnetic particles is 1:(0.05-1), a basic structure formula of the resin frames is shown following the specification of the invention: wherein n can be 1,2,3......; the weak acid volume exchange capacity of the resin is 1.0-5.0mol / L, the average particle diameter thereof is 20-500mum, the specific saturation magnetization intensity thereof is 5.1-33.4emu / g, and the weak acid exchange capacity is 1.0-5.0mol / L. The microballoon resin of the invention can be used in treatment of various water bodies and used for removing ammonia nitrogen and a plurality of metal ions, such as calcium, magnesium, copper, nickel, cadmium, and the like.

Description

technical field The invention discloses an acrylic weak acid cation exchange microsphere resin and a synthesis method thereof, more specifically an acrylic weak acid cation exchange microsphere resin containing magnetic particles and a synthesis method thereof. Background technique The particle size of the traditional weak acid cation exchange resin is 0.3mm ~ 1.2mm, and the fixed bed process is generally used in the application. If the powder microsphere resin with smaller particle size is synthesized, its desorption and adsorption performance can be further improved in application due to the increase of its external specific surface area. However, in the operation of the fixed bed process, the resin with too small particle size will increase the water resistance and reduce the amount of treated water. The magnetic particles are implanted into the resin with small particle size to make it magnetic, so as to solve the separation problem of the resin, and the traditional fix...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F220/14C08F220/18C08F220/06C08F2/44C08F2/18C08F8/12C08K3/22C08K3/08B01J39/20

CPCB01J39/046C02F2001/425C08F220/06C08F2/44C02F1/42C02F1/488C08F220/14C08F220/18B01J39/20B01J39/185B01J39/07B01J39/19C08F220/1802

Inventor 李爱民双陈冬周庆周扬张满成杨峰王津南范俊龙超刘福强王琼杰张海云

Owner NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com