Column type short-stage tungseten crude grading process and equipment

A short-flow, roughing technology, applied in flotation, solid separation, etc., can solve the problems of large chemical consumption, large power consumption, and long flotation process, and achieve the effect of improving recovery rate and concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

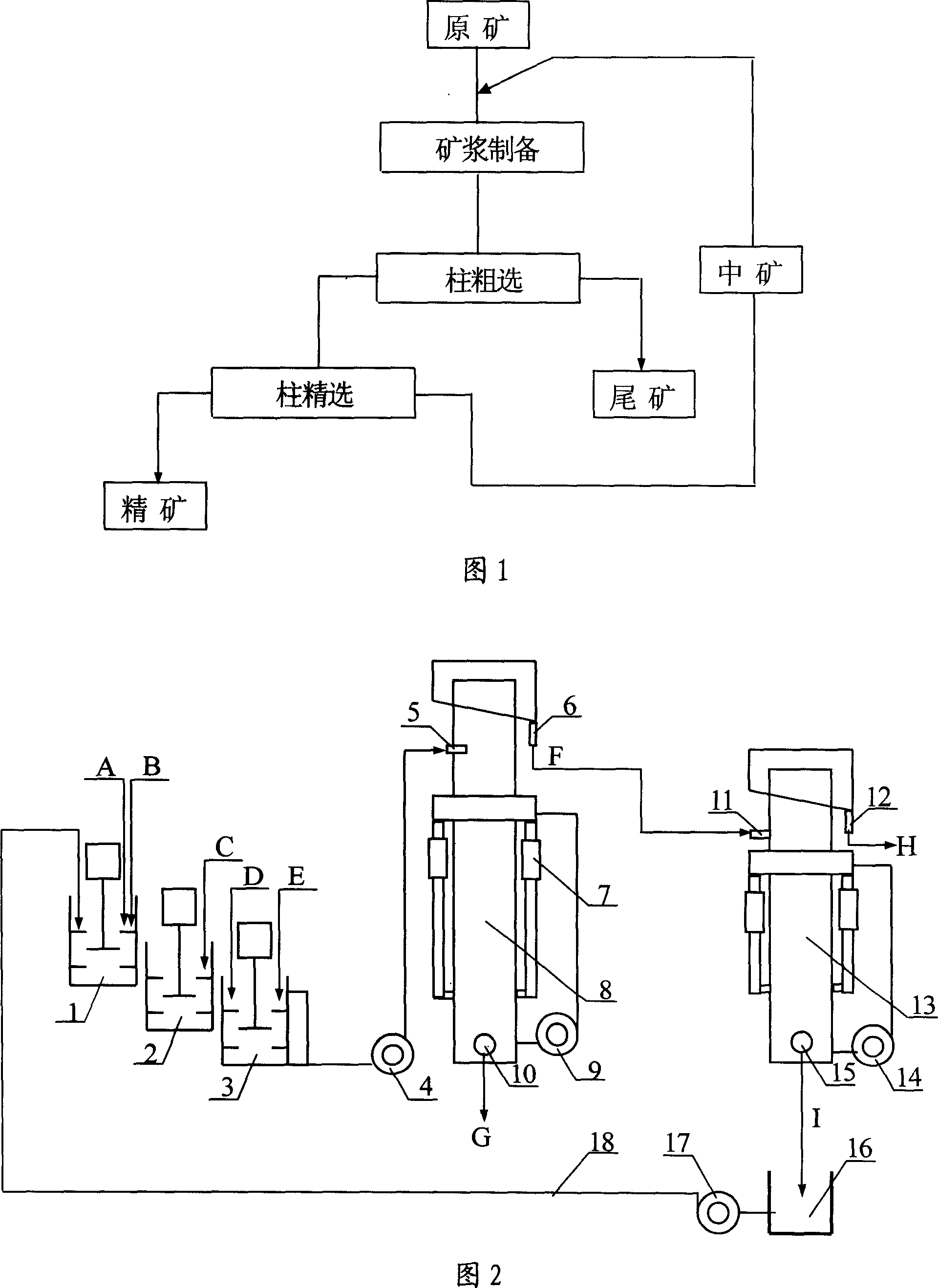

[0026] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] As shown in Figures 1 and 2, the column-type short-flow tungsten roughing process of the present invention feeds the tungsten roughing raw ore A into the slurry tank 1, and simultaneously adds lead nitrate activator B (lead nitrate consumption is about 450g / t), After pulping, the pulp enters the pulping tank 2, and water glass inhibitor C (the amount of water glass is about 3000g / t) is added to continue stirring, and then the pulp enters the pulping tank 3, and the chelates code-named GYB and GYR are added therein. Combined collector (the dosage of GYB is about 300g / t, and the dosage of GYR is about 40g / t) to continue stirring and mixing. After the raw ore is continuously stirred by the mixing tank for 10-15 minutes, the flotation feed material with a mass concentration of 30-50% is obtained, and the flotation feed material is transported by the roug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com