Beneficiation method for improving ore dressing recovery percentage of copper sulfide mineral hard to dispose

A technology for copper sulfide ore and beneficiation method, which is applied in flotation, solid separation and other directions, can solve the problems that copper sulfide minerals cannot be separated by efficient flotation of talc and pyrite, and the beneficiation index of refractory copper sulfide ore cannot be improved. Achieve the effect of good sorting index, easy degradation and strong collection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

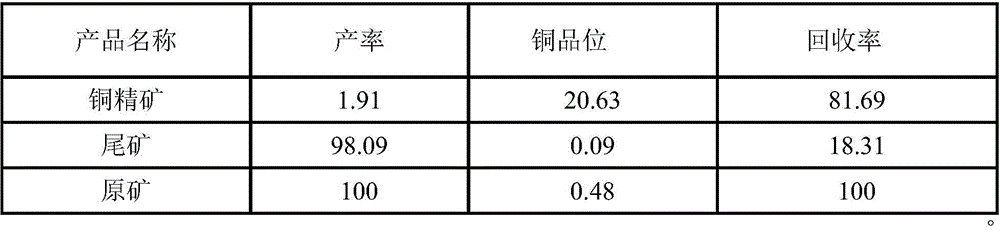

[0016] A certain copper ore in Jiangxi Province, the original ore contains 0.48% copper, the copper minerals in the ore are mainly chalcopyrite, the iron minerals are mainly pyrite and pyrrhotite, and the gangue minerals are talc, quartz, serpentine and Mica. Grind the copper ore to -0.074mm and the content is 78%, transfer the ground pulp to the flotation tank, add 900g / t sodium carbonate, 1500g / t combination inhibitor TYZ01, 180g / t combination collector TBS02, 20g / t No. 2 oil slurry, and then roughing, to obtain roughing tailings and roughing concentrate, add 60g / t and 30g / t combined collector TBS02 to the roughing tailings for two sweeping Concentration operation, to obtain the final tailings, return to the roughing for the first sweep, and return to the first sweep for the second sweep; add 600g / t combined inhibitor TYZ01 to the coarse concentrate obtained by roughing for the first For the second beneficiation, the obtained concentrate is added with 250g / t combined inhibi...

Embodiment 2

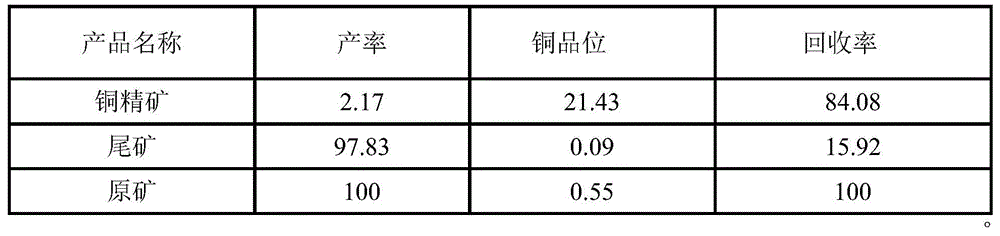

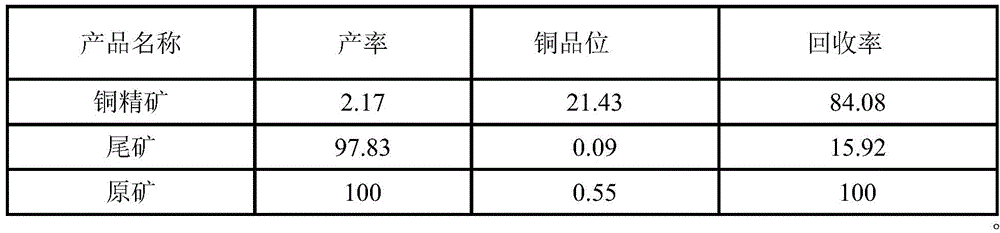

[0023] A certain copper ore contains 0.55% copper in the raw ore. The copper minerals in the ore are mainly chalcopyrite, the iron minerals are mainly pyrite, and the gangue minerals in the ore are mainly talc, quartz, mica, and feldspar. Grind the copper ore to -0.074mm and the content is 65%, transfer the ground pulp to the flotation tank, add 500g / t sodium carbonate, 600g / t combined inhibitor TYZ01, 120g / t combined collector TBS02 , 20g / t No. 2 oil for roughing to get roughing tailings and roughing concentrate, add 60g / t and 30g / t combination collector TBS02 to the roughing tailings respectively for two sweeping operations to get the final For the tailings, return to the rougher for the first sweep, and return to the first sweep for the second sweep; add 300g / t combined inhibitor TYZ01 to the coarse concentrate obtained by the rougher for the first concentration, and get Add 100g / t combined inhibitor TYZ01 to the concentrated ore for the second beneficiation to obtain the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com