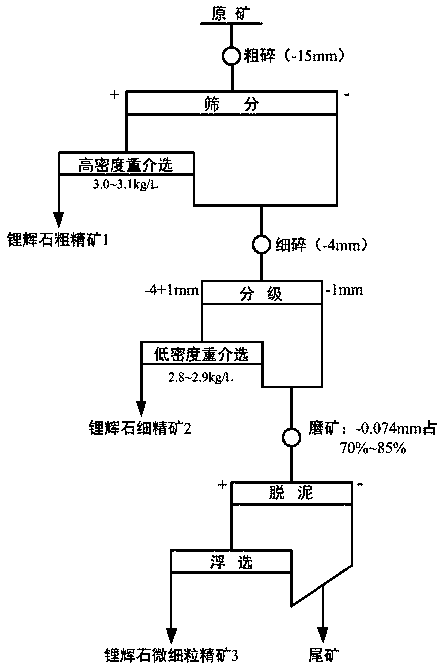

Spodumene particle-size double-dense-medium-flotation benefication method

A beneficiation method and spodumene concentrate technology are applied in the field of spodumene classifying double meso-flotation beneficiation, which can solve the problems of low concentrate grade, high sorting cost, and coarse-grained minerals that cannot be pre-segregated. selection and other issues to achieve the effect of avoiding pollution and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, a certain spodumene ore in Sichuan is taken as the research object, and the specific test includes the following steps:

[0033] (1) Coarsely crush the raw ore to 15mm, and remove the -8mm particle size by sieving.

[0034] (2) The spodumene ore after ore washing enters the high-density heavy medium (ferrosilicon) cyclone with a density of 3.0kg / L for sorting, and obtains coarse-grained light products and heavy products, and the heavy products are de-medium Coarse-grained spodumene concentrate I was obtained after sieving and de-intermediation.

[0035] (3) The light product in step (2) is de-mediumed through a de-medium sieve, then dried naturally, and combined with the product under the sieve in step (1) to be finely crushed to 4mm, and the -1mm particle size is removed after classification by a cyclone.

[0036] (4) In step (3), the cyclone in step (3) enters the low-density heavy medium (ferrosilicon) cyclone with a density of 2.8kg / L for sortin...

Embodiment 2

[0042] The ore used in the present embodiment is identical with embodiment 1, and concrete test comprises the following steps:

[0043] (1) Coarsely crush the raw ore to 15mm, and remove the -6mm particle size by sieving.

[0044](2) The spodumene ore after ore washing enters the high-density heavy medium (ferrosilicon) cyclone with a density of 3.1kg / L for sorting, and obtains coarse-grained light products and heavy products, and the heavy products are de-medium Coarse-grained spodumene concentrate I was obtained after sieving and de-intermediation.

[0045] (3) The light product in step (2) is de-mediumed through a de-medium sieve, then dried naturally, and combined with the product under the sieve in step (1) to be finely crushed to 4mm, and the -1mm particle size is removed after classification by a cyclone.

[0046] (4) The cyclone in step (3) is gritted into a low-density heavy medium (ferrosilicon) cyclone with a density of 2.9kg / L for sorting, and fine-grained light p...

Embodiment 3

[0052] The present embodiment takes a certain spodumene in Jiangxi as the research object, and the specific test includes the following steps:

[0053] (1) Coarsely crush the raw ore to 15mm, and remove the -8mm particle size by sieving.

[0054] (2) The spodumene ore after ore washing enters the high-density heavy medium (ferrosilicon) cyclone with a density of 3.1kg / L for sorting, and obtains coarse-grained light products and heavy products, and the heavy products are de-medium Coarse-grained spodumene concentrate I was obtained after sieving and de-intermediation.

[0055] (3) The light product in step (2) is de-mediumed through a de-medium sieve, then dried naturally, and combined with the product under the sieve in step 1) to be finely crushed to 4mm, and then classified by a cyclone to remove the -1mm particle size.

[0056] (4) The cyclone in step (3) is gritted into a low-density heavy medium (ferrosilicon) cyclone with a density of 2.9kg / L for sorting, and fine-grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com