Flotation process for recovering micro-fine particle mica from micro-fine particle iron separation tailings

A technology of fine particles and fine particles, applied in flotation, solid separation, etc., can solve the problems of increased specific surface area and surface energy of fine particles, easy entrainment of coarse particles by machinery with small quality, difficulty in improving concentrate grade, etc., to achieve The lower limit of particle size is low, the separation index is good, and the effect of improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

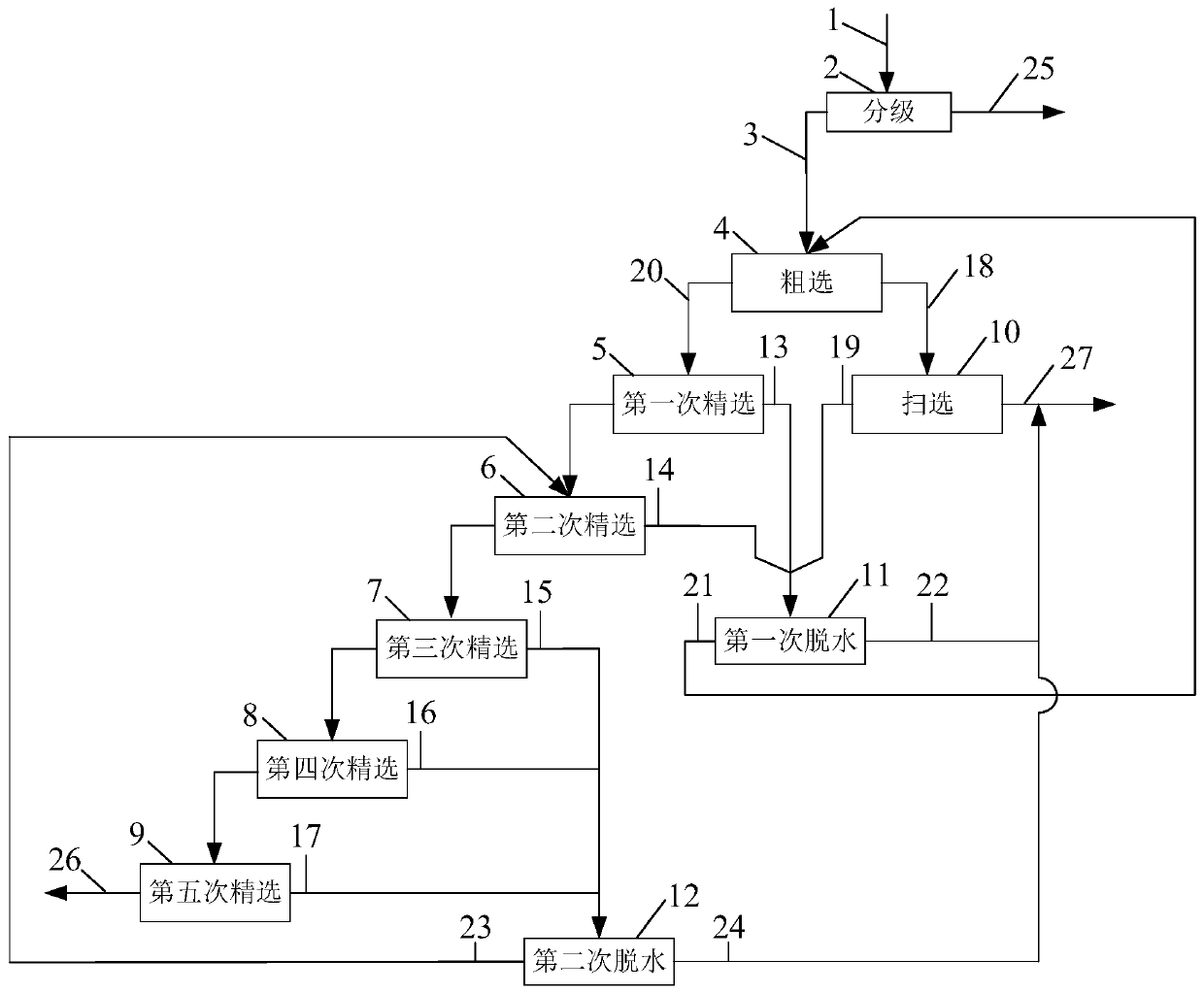

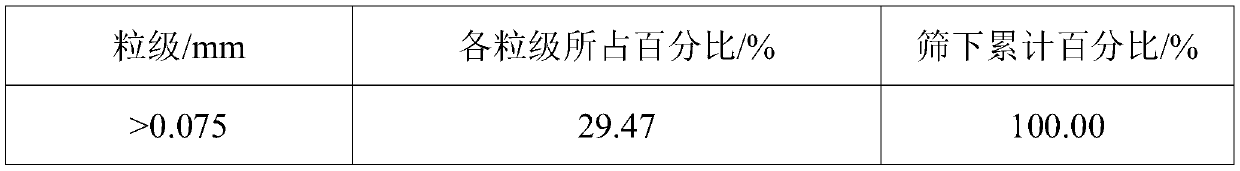

[0024] Example 1: Iron dressing tailings 1 enters the classification 2 operation, removes the fine particle product 25 of -0.025mm particle size that is difficult to separate, and obtains the coarse particle product 3 of +0.025mm; adds the combination to the coarse particle product 3 in turn The dosage of regulator sodium hydroxide is 100g / t, the dosage of sodium carbonate is 50g / t, adjust the pH value of the pulp to 10; then add the dosage of mixed inhibitor water glass 1200g / t, the dosage of sodium hexametaphosphate 500g / t, and mix the collector The dosage of sodium oleate is 150g / t, the dosage of dodecylamine is 100g / t, the dosage of octadecylamine is 50g / t, the dosage of foaming agent pine alcohol oil is 30g / t, and the flotation roughing 4 is carried out; the foam product mica obtained in roughing 4 Coarse concentrate 20 does not add chemicals, and conducts the first beneficiation 5; the foam product obtained in the first beneficiation 5 is sequentially added with 450g / t of...

Embodiment 2

[0027] Example 2: Iron dressing tailings 1 enters classification 2 operation, removes the fine particle product 25 of -0.025mm particle size that is difficult to separate, and obtains + 0.025mm coarse particle product 3; in the coarse particle product 3, add the combination in turn The dosage of regulator sodium hydroxide is 120g / t, the dosage of sodium carbonate is 80g / t (adjust the pH value of the pulp to 11), the dosage of mixed inhibitor water glass is 1500g / t, the dosage of sodium hexametaphosphate is 800g / t, and the dosage of mixed collector oleic acid The amount of sodium is 200g / t, the amount of dodecylamine is 150g / t, the amount of octadecylamine is 60g / t, the amount of foaming agent terpineol oil is 45g / t, and the flotation roughing 4 is carried out; Mine 20 does not add medicament, carries out the first selection 5; Adds water glass consumption 550g / t successively to the foam product obtained in the first selection 5, terpineol oil consumption 20g / t, carries out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com