Bauxite direct flotation composite collector and application method thereof

A bauxite and positive flotation technology, used in flotation, solid separation and other directions, can solve the problems of increasing the difficulty of wastewater treatment, poor flotation desilication effect, and increasing the cost of concentrate treatment, and achieve excellent performance. and wetting ability, excellent emulsifying and penetrating effect, beneficial to concentrate filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The chemical multi-element analysis results of a diaspore-type bauxite with a low aluminum-silicon ratio in Henan are listed in Table 1.

[0043] Table 1 Chemical multi-element analysis results of a diaspore-type bauxite with a low aluminum-silicon ratio in Henan

[0044] project

Al 2 o 3

SiO 2

MgO

CaO

TF

A / S

Content (%)

55.43

17.49

0.31

0.59

4.53

3.17

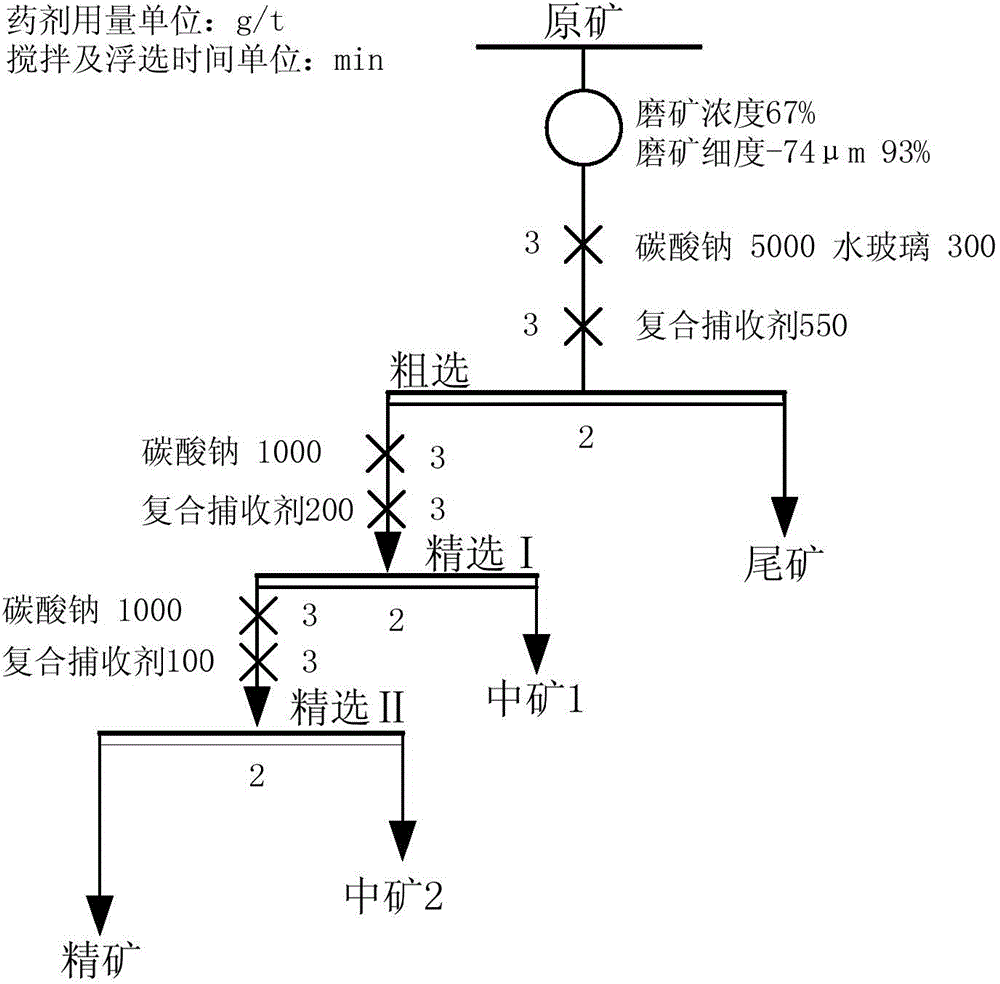

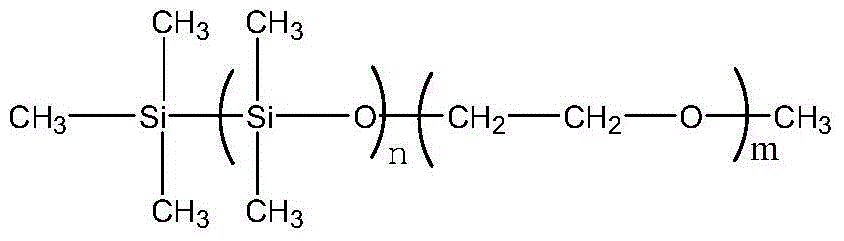

[0045] The ore samples were ground until the grinding fineness was -0.074㎜, accounting for 93%, and the collector type comparison test was carried out. The collectors used included oleic acid + OP-10, oleic acid + Tween-80, and the composite collector of the present invention Collector (oleic acid + synergist, synergist includes: compound of silicone surfactant, polyoxyethylene ether surfactant and mine foaming agent). The dosage of medicine is: oleic acid 800g / t, sodium carbonate 4000g / t, water glass 1000g / t, the mass ratio of synergist and ...

Embodiment 2

[0055] The degree of polymerization of ethylene oxide is 7-15 (ie n 1=7-15) the applicability of the polyoxyethylene surfactant in the collector of the present invention, choose the polyoxyethylene surfactant that degree of polymerization is 7,10,15 as polyoxyethylene ether described in the present invention Surfactants were subjected to roughing tests. The dosage of medicine is: oleic acid 800g / t, sodium carbonate 4000g / t, water glass 1000g / t, synergist (polyoxyethylene ether: silicone: pine alcohol oil mass ratio = 2:3:5) and fatty acid mass ratio The ratio is 1:4, and the results are shown in Table 3.

[0056] Table 3 Applicability test of polyoxyethylene ether surfactants

[0057]

[0058] From the test results, it can be seen that the selection of polyoxyethylene ether surfactants with different degrees of polymerization has little effect on the recovery rate of crude concentrate and the ratio of aluminum to silicon, which proves that polyoxyethylene ethers with a de...

Embodiment 3

[0060] For proving the applicability of mine foaming agents such as terpineol oil and isooctyl alcohol in the present invention, roughing test is carried out as mine foaming agents described in the present invention with pine alcohol oil and isooctyl alcohol. The dosage is: oleic acid 800g / t, sodium carbonate 4000g / t, water glass 1000g / t, synergist (polyoxyethylene ether: silicone: terpineol oil / isooctanol mass ratio = 2:3:5) The mass ratio with fatty acid is 1; 4, and the test results are shown in Table 2.

[0061] Table 4 Applicability test of mine foaming agent

[0062]

[0063] The test shows that when different types of mine foaming agents are used as the mine foaming agent described in the present invention, the recovery rate of bauxite coarse concentrate alumina and the ratio of aluminum to silicon have little difference, which proves that different types of mine foaming agents Agents are applicable to the mine foaming agent described in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com