Patents

Literature

57results about How to "Low management requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

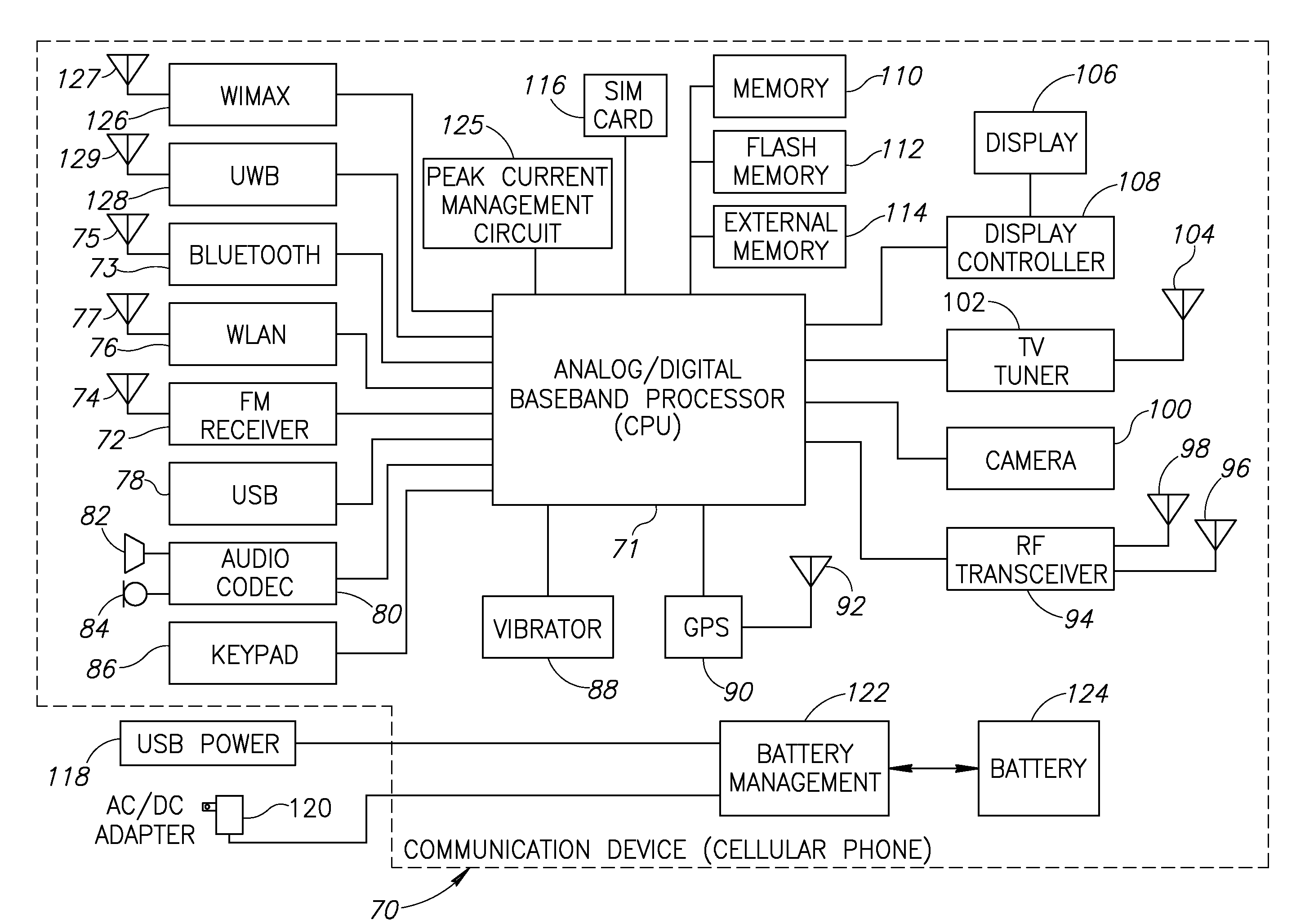

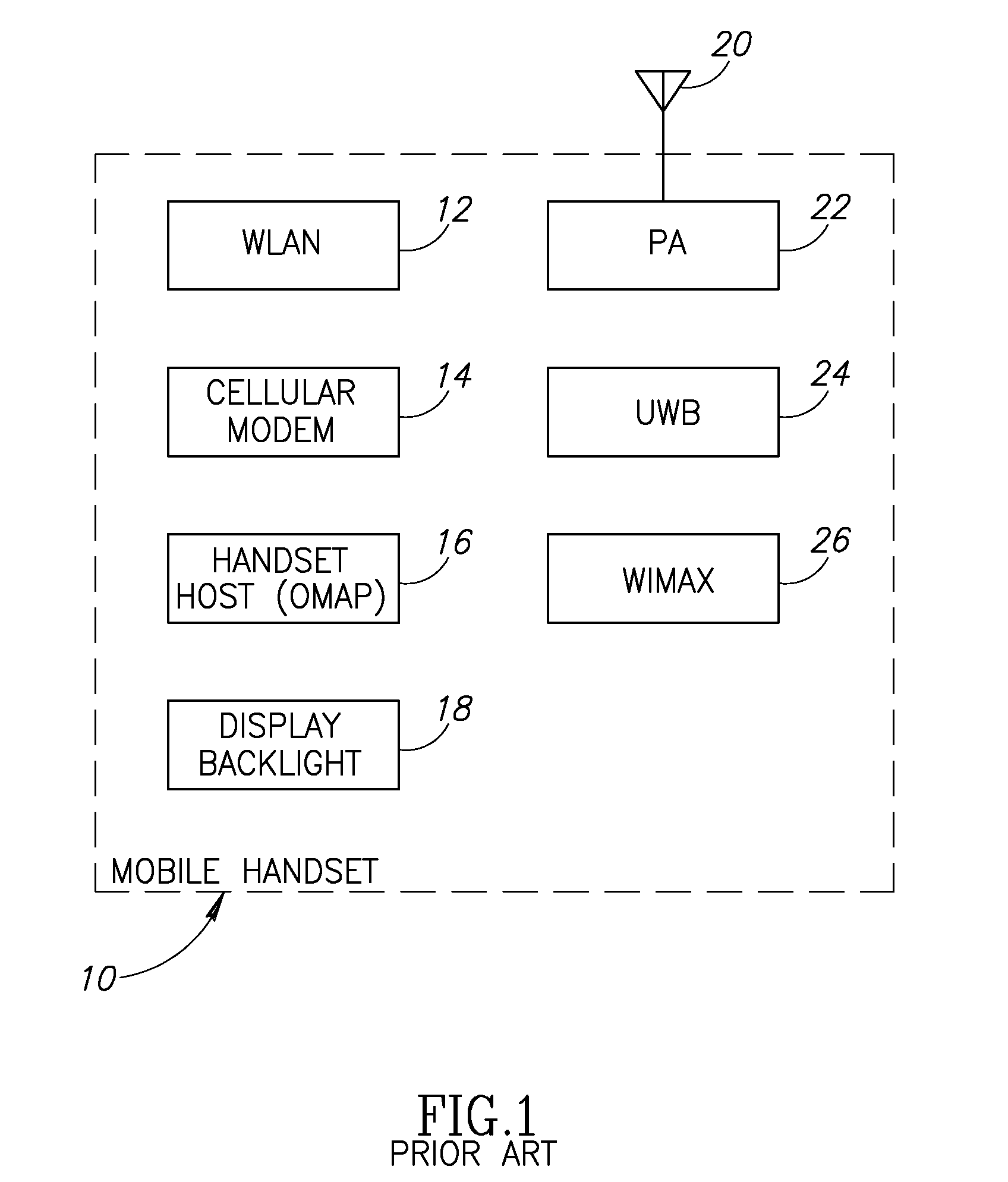

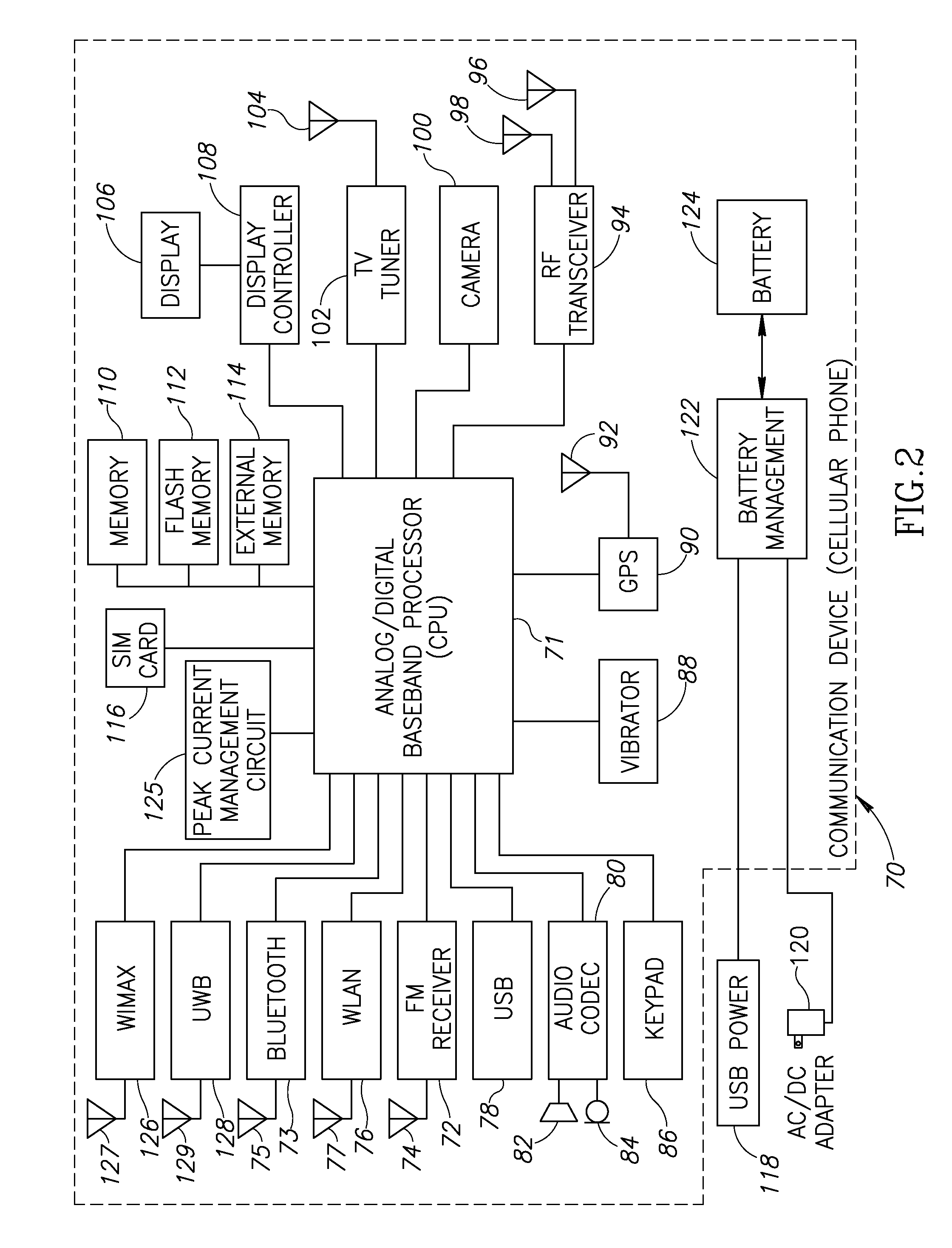

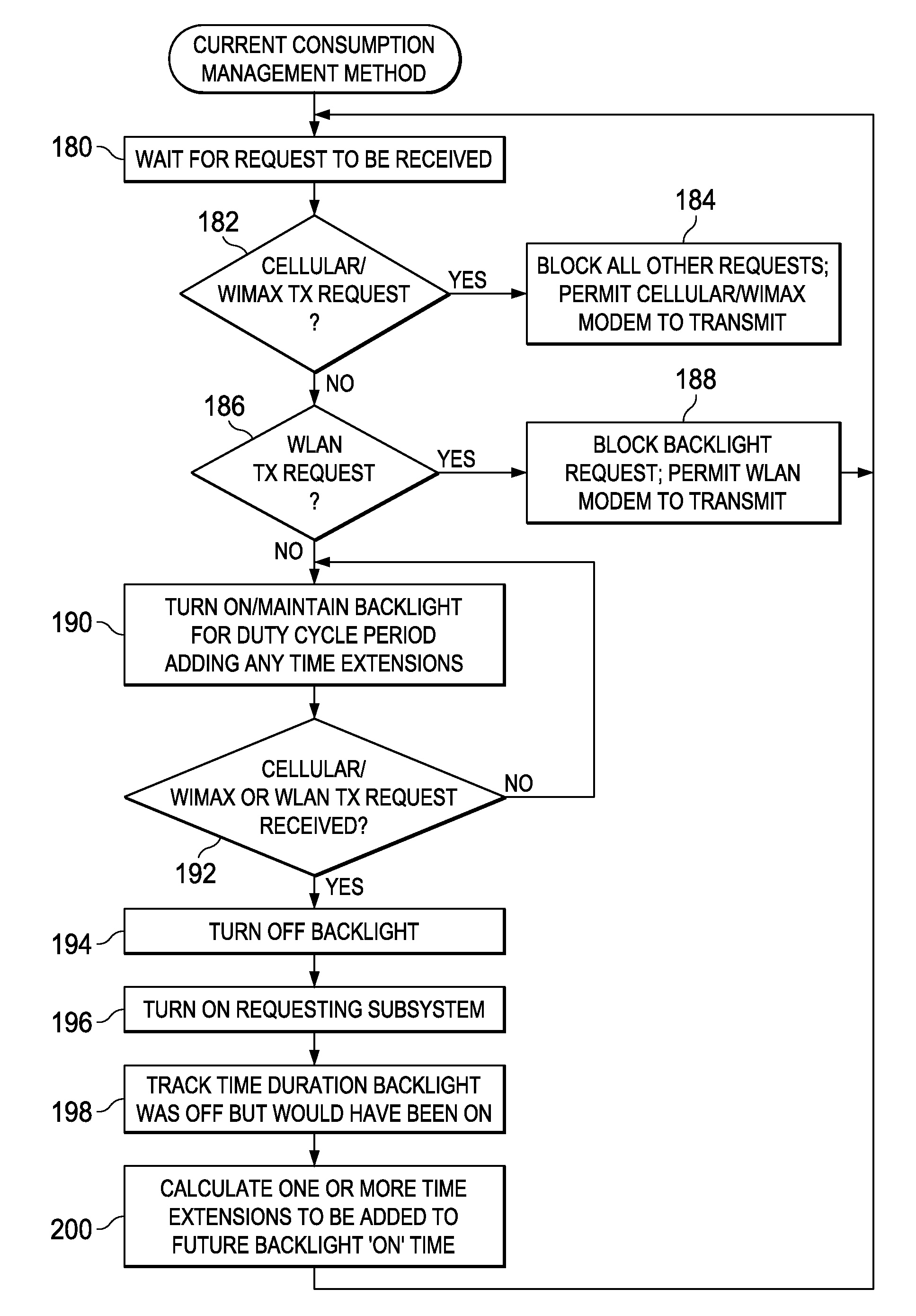

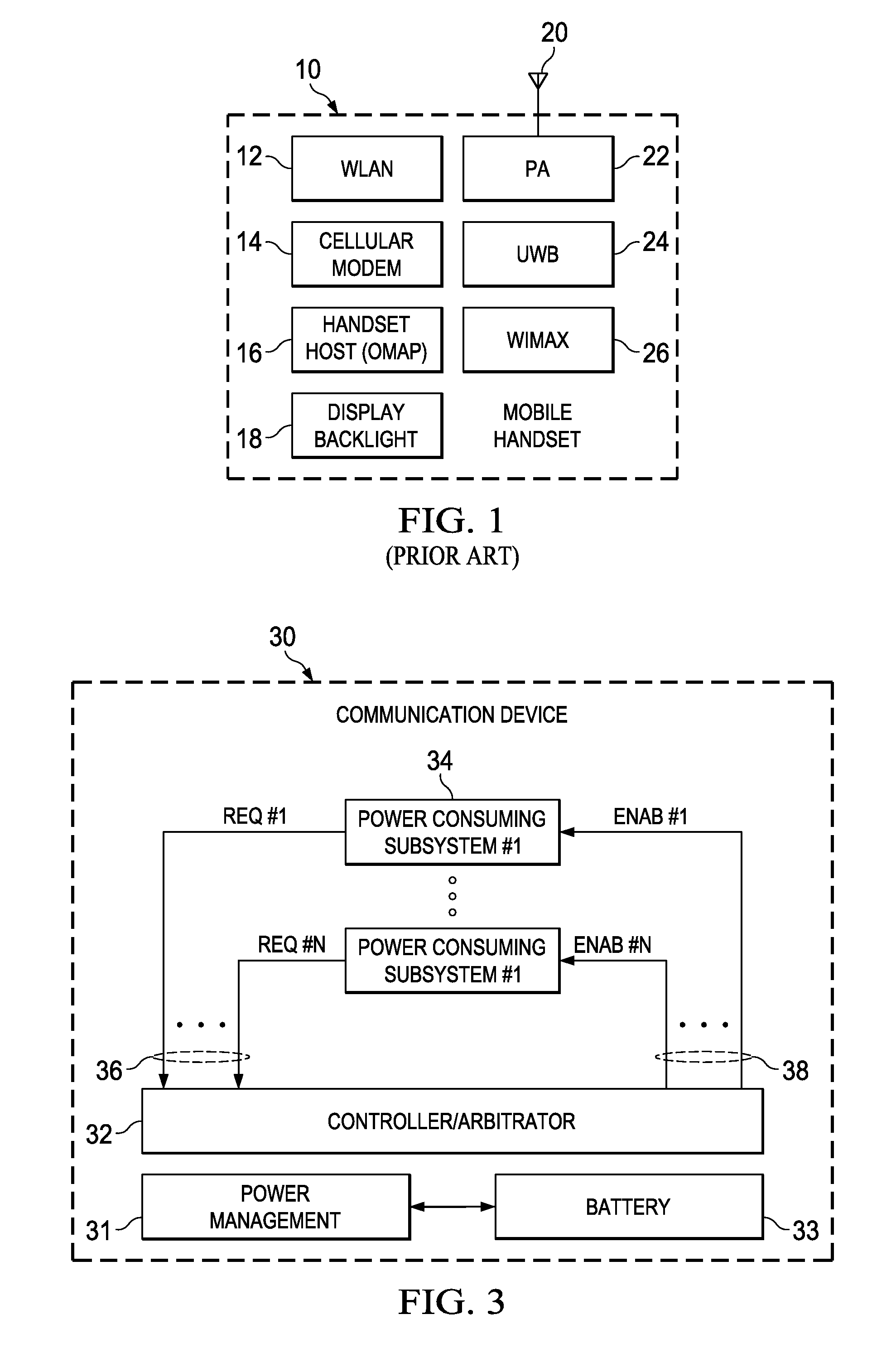

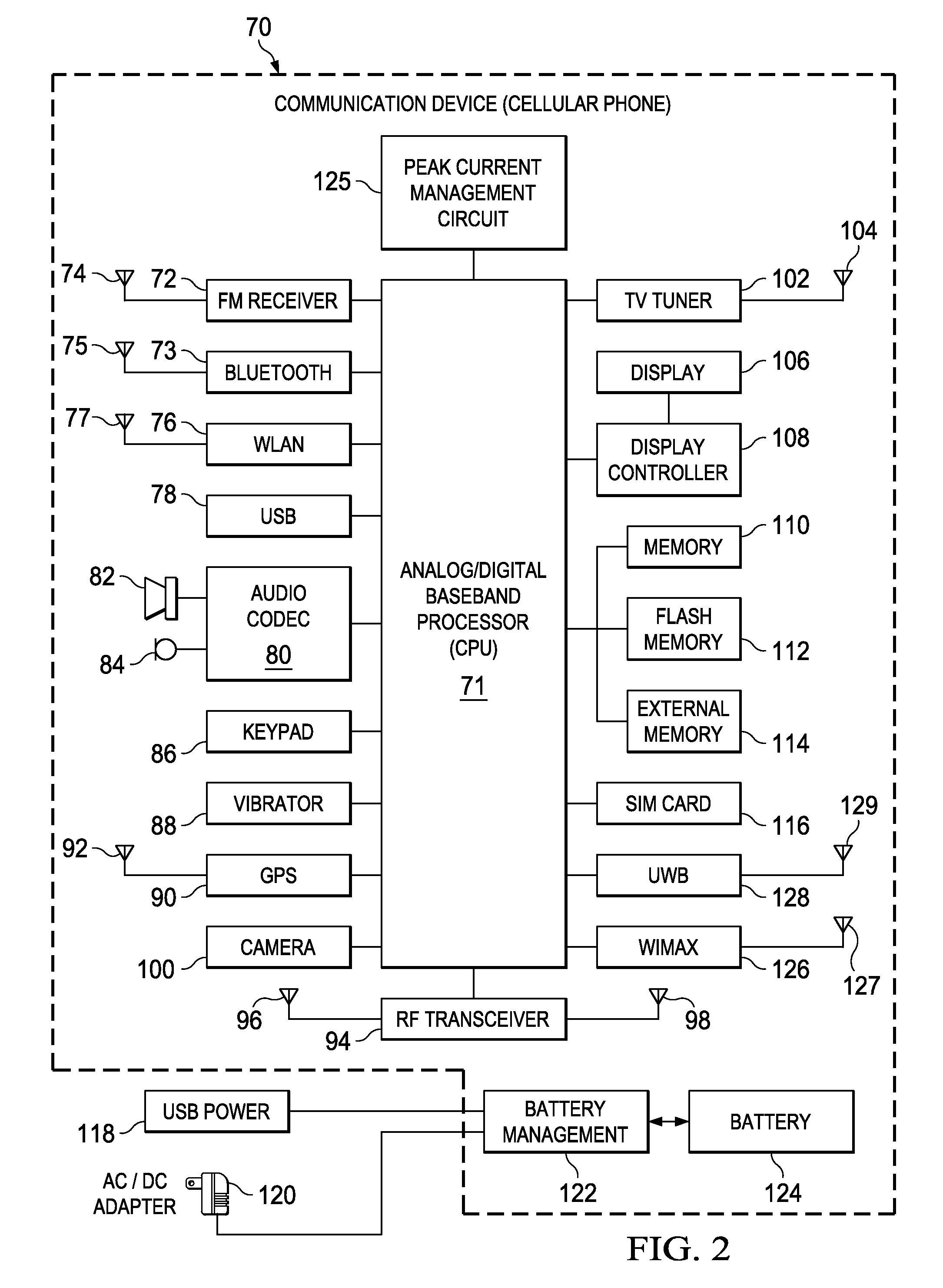

Apparatus for and method of managing peak current consumption of multiple subsystems in a mobile handset

ActiveUS20080161071A1Current consumptionTotal current dropPower managementCathode-ray tube indicatorsCurrent consumptionPeak current

A novel and useful mechanism for regulating and managing the peak current consumption of the subsystems in a mobile handset device. The mechanism of the present invention is operative to limit the current consumption at any point in time to a predetermined level that is within the current handling capability of the power management system of the handheld device. The mechanism operates by having the high peak current subsystems advertise in advance their intention to initiate a current peak. An arbitration mechanism considers the advertisements or requests sent from interested subsystems and determines whether a subsystem is either granted permission to initiate or is blocked from initiating a peak current session.

Owner:TEXAS INSTR INC

Method for utilizing bamboo reed charcoal to reduce soil nitrous oxide discharge

InactiveCN103053240AWide variety of sourcesIncrease productionBiofuelsSpecial form destructive distillationNitrous oxideSoil moisture content

The invention relates to a method for utilizing bamboo reed charcoal to reduce agricultural soil nitrous oxide (N2O) discharge and belongs to the technical field of greenhouse gas emission reduction. The method for utilizing the bamboo reed charcoal to reduce agricultural soil N2O discharge aims at reducing the soil N2O discharge caused by massive use of nitrogenous fertilizer in the agricultural production process. The technical scheme is that the method comprises the steps of first airing collected bamboo reed, cutting the bamboo reed into small sections of 1-5cm, preparing the bamboo reed into the charcoal in a thermal cracking method at 200-650 DEG C under protection of inert gases with the flow velocity of 200-500mL / min; smashing the well prepared charcoal into particles of 1-5mm, enabling the particles to be fully mixed with agricultural soil according to the proportion of 0.1-10%, keeping soil moisture content at 70-110%, and performing culture for 6-100 days at 20-30 DEG C so that the discharge of N2O in the agricultural soil can be effectively reduced. The method can be used for ordinary farmland soil and can also be used for facility agricultural soil.

Owner:OCEAN UNIV OF CHINA

Preparing and application method of Arundo donax biological charcoal serving as nitrogenous fertilizer synergist

InactiveCN102701886AReduce leachingReduce lossesClimate change adaptationAgriculture gas emission reductionRoom temperatureSoil moisture content

The invention provides a preparing and application method of an Arundo donax biological charcoal serving as a nitrogenous fertilizer synergist. The preparing and application method comprises the steps of: harvesting mature-stage Arundo donax, shearing into small segments of 2-5cm, and air-drying for later use; heating the Arundo donax segments to 350-650 DEG C at a heating rate of 1-20 DEG C / min under the protection of inert gas at a flow rate of 200-500mL / min for charring for 1-6h; after charring is finished, cooling to room temperature under the protection of inert gas; crushing prepared biological charcoal into particles of 1-5mm, sealing, and storing in a drying place for later use; and applying the crushed biological charcoal to agricultural soil at a ratio of 0.1-8%, and sufficiently mixing to be uniform, wherein the soil moisture content is kept at 60-80%. The preparing and application method is simple in operation, low in cost and significant in effect, and is suitable for the situation of China; and by using the method, the nitrogenous fertilizer absorption of the crop is promoted, the nitrogenous fertilizer loss is reduced and the nitrogenous fertilizer utilization efficiency of the crop is improved.

Owner:青岛贝尔卡环境生物工程有限公司

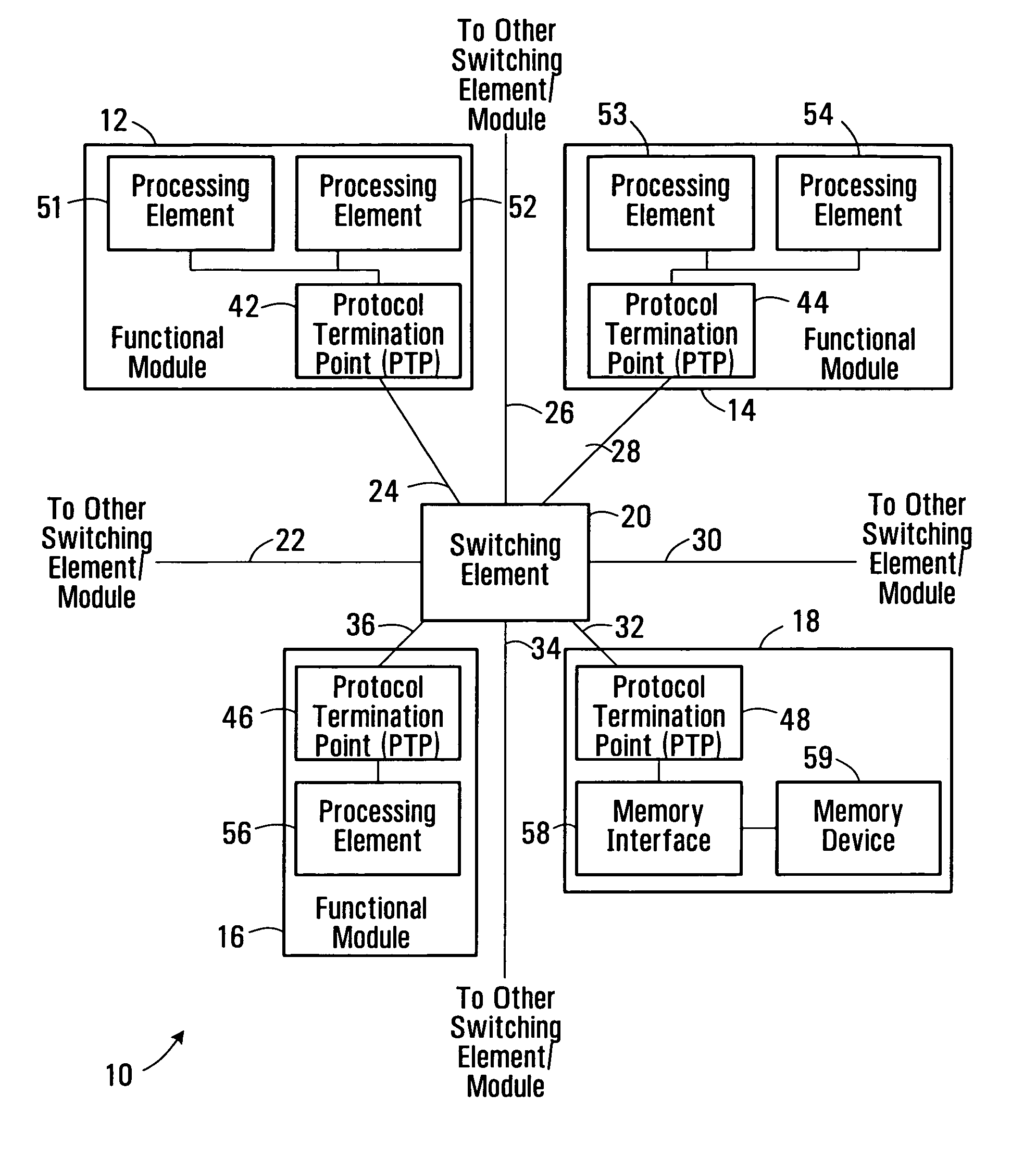

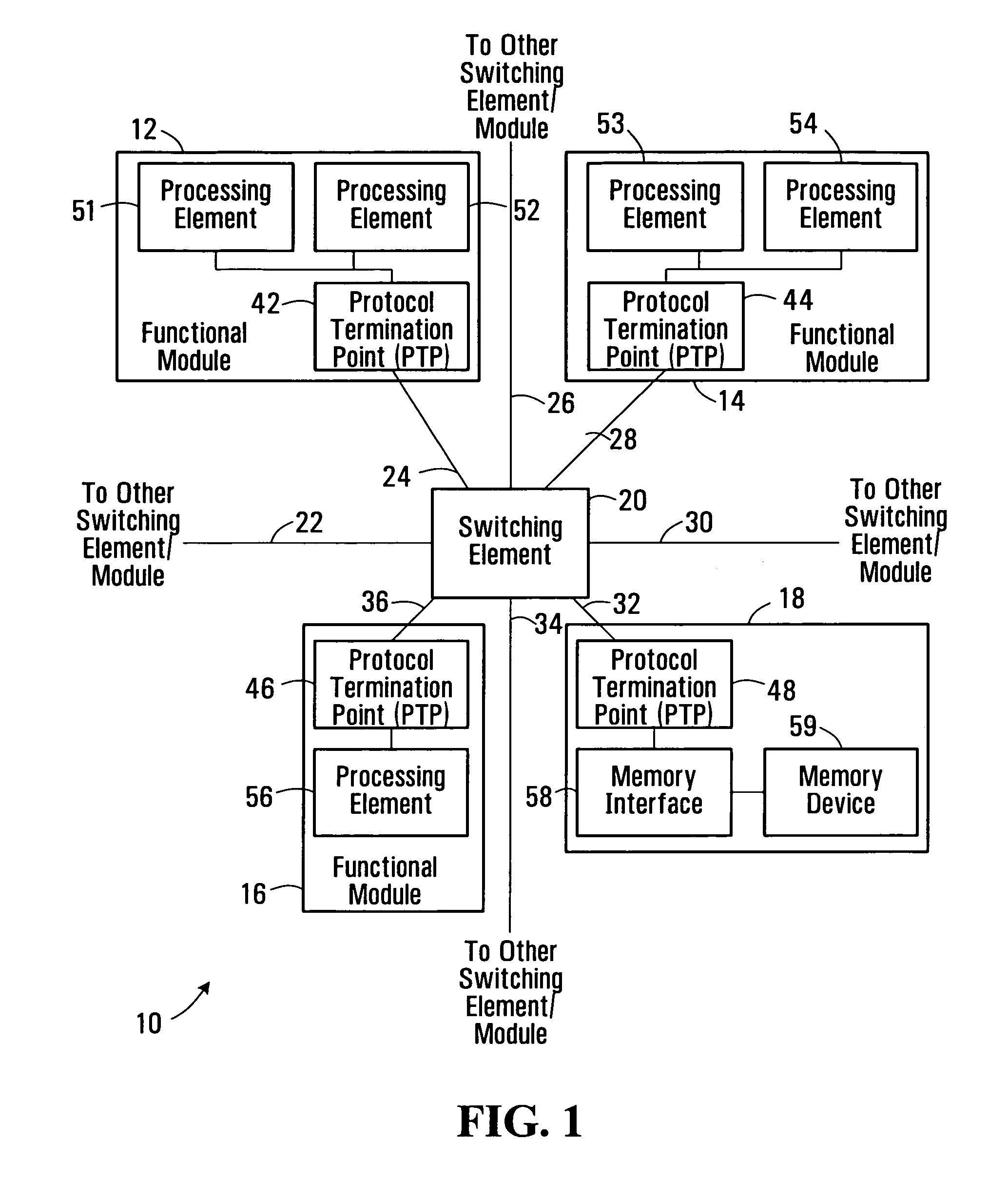

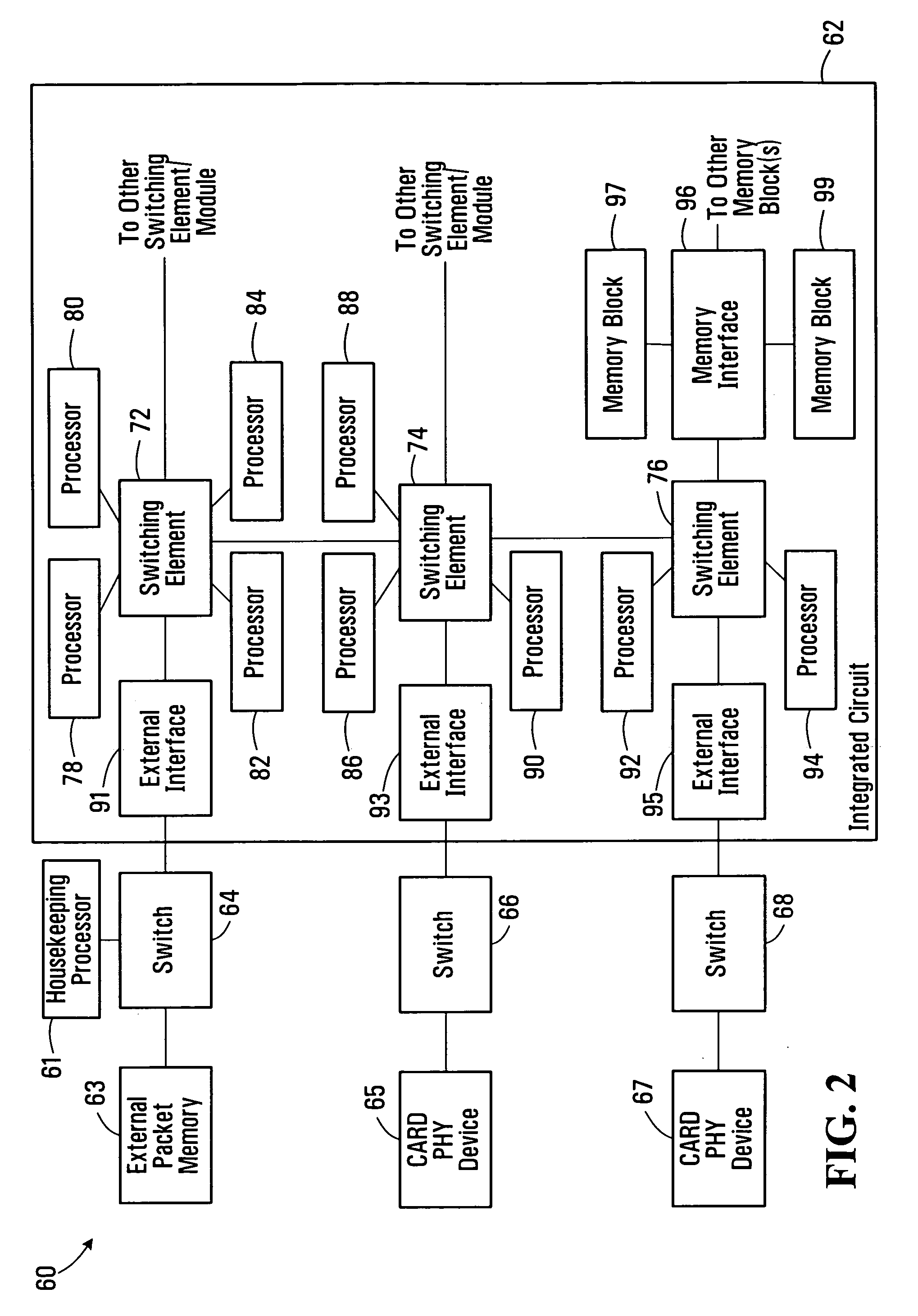

Switched integrated circuit connection architectures and techniques

InactiveUS20070109015A1Easy accessImprove performanceTransmissionLogic circuits using elementary logic circuit componentsComputer moduleEngineering

Switched integrated circuit connection architectures and techniques are disclosed. An integrated circuit includes connection segments and switching elements operatively coupled to the connection segments. Any of multiple switchable connections to a functional module of the integrated circuit can be established, as needed, by the switching elements through the connection segments. Protocol termination points associated with functional modules of the integrated circuit may be addressable in an address space that is used on an external connection outside the integrated circuit. An external protocol used on such an external connection may also be supported internally in the integrated circuit by the protocol termination points.

Owner:ALCATEL LUCENT SAS

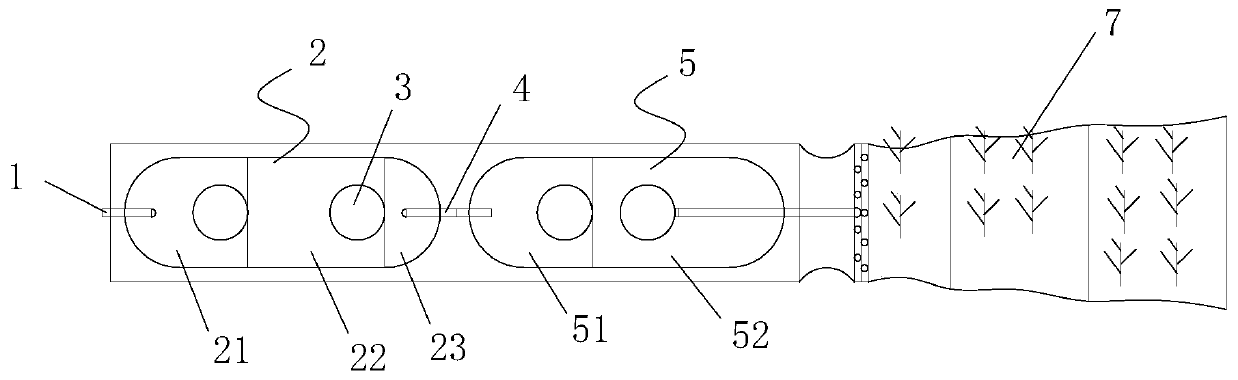

Slope farmland nitrogen phosphor loss control method

InactiveCN105684590AImprove adsorption capacityQuick filterSoil-working methodsAgricultural engineeringEngineering

The invention discloses a slope farmland nitrogen phosphor loss control method comprising the following steps: A, charcoal trench design and construction: 1, building a charcoal trench: building the charcoal trench on the bottom of the slope farmland, wherein the trench side slope and bottom are respectively soil texture; 2, filling a soil-charcoal layer: filling soil and modified small aperture charcoal in the trench in layers according to a certain proportion; 3, planting a plant fence: planting the plant fence on the first original surface layer soil; B, building a water stop ridge: building the water stop ridge between the most bottom slope of the slope farmland and the edge of the charcoal trench; C, burying a diversion pipe: burying the diversion pipe on the bottom of the charcoal layer; D, charcoal trench management and maintenance: 1, regularly cleaning sands; 2, regularly inspecting and maintaining the water stop ridge. The slope farmland nitrogen phosphor loss control method is simple in operation, cannot content soil with crops, the charcoal can be repeatedly used, and the plant fence has high economic benefits, thus providing important meanings for controlling slope farmland and orchard surface source pollution.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

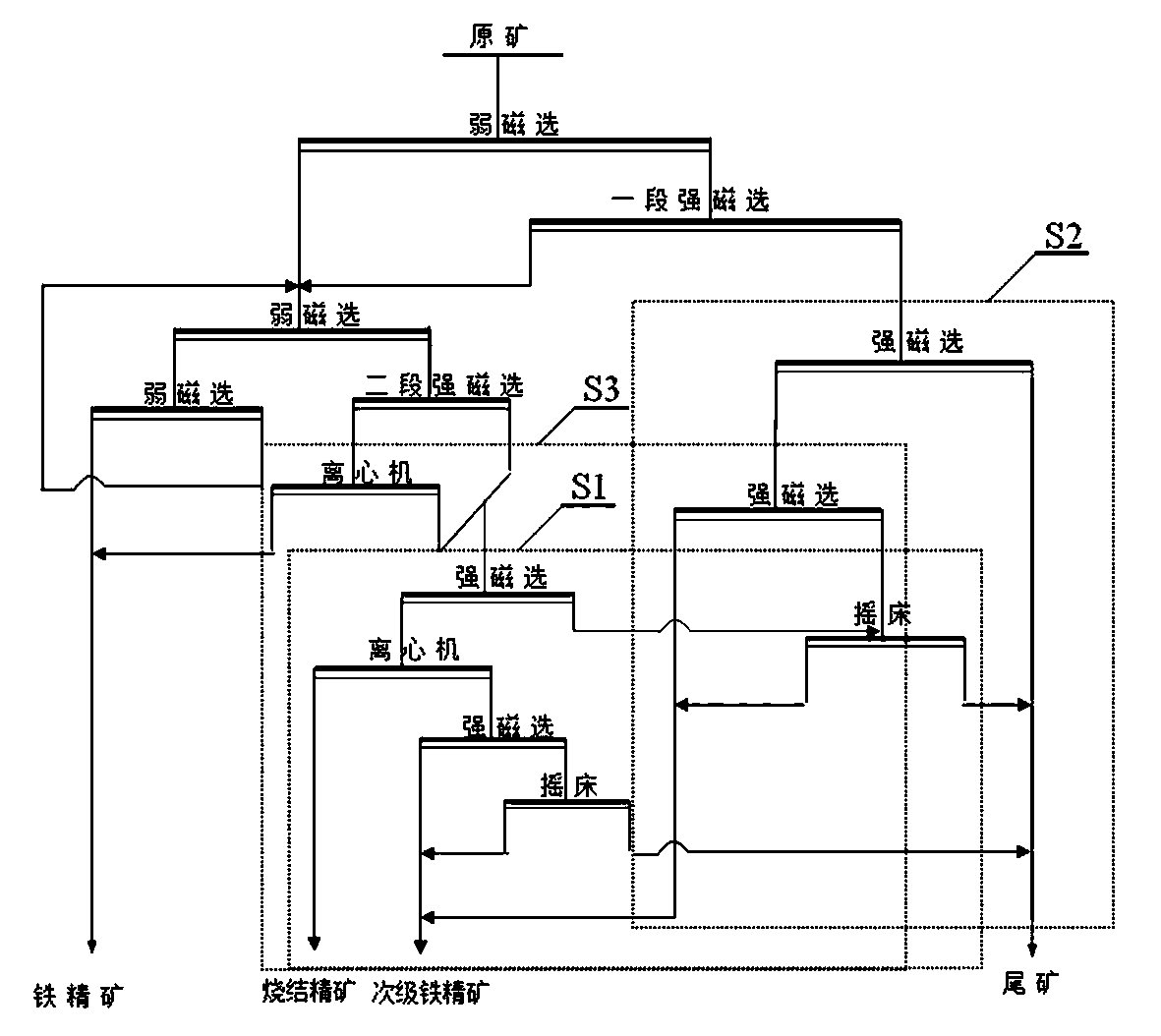

Separation process of ferrous high silicate type iron ore

ActiveCN103894283AOvercome the disadvantages of independent processingReduce secondary selectionWet separationResource utilizationFinings

The invention discloses a separation process of ferrous high silicate type iron ore. The process includes classifying, degrading tailings and upgrading. Tailing degrading includes S1 tailing degrading and S2 tailing degrading. The separation process has the advantages that the process is free of calcination and reverse floatation, short is process flow, low in process management requirement, low in operation cost, low in environmental pollution and suitable for industrial production; the iron grade of fine ferrous silicate type iron concentrate is increased, silicon content is lowered, the grade of fine high silicate type iron tailings is lowered, the grade of the iron concentrate is increased by about 10%, and the silicon content is lowered by about 10%; the iron ore in the tailings can be recycled effectively, the comprehensive grade of total tailings is lowered from 16.2% to about 10.53%; the separation process is environmental friendly, low in energy consumption, low in cost, high in fining and concentration degree, and capable of effectively increasing comprehensive resource utilization rate, increasing benefits, saving energy and reducing emission.

Owner:KUNMING UNIV OF SCI & TECH +1

Artificial propagation and roe incubation method for schizopygopsis malacanthus

ActiveCN103875572AEasy to operateImprove controllabilityClimate change adaptationPisciculture and aquariaSchizopygopsis malacanthusFresh water organism

The invention relates to an artificial propagation and roe incubation method for freshwater fishes, in particular to an artificial propagation and roe incubation method for schizopygopsis malacanthus, and belongs to the technical field of artificial propagation and roe incubation of fishes. The artificial propagation and roe incubation method for schizopygopsis malacanthus mainly comprises the steps of parent fish selection, spawning induction, artificial impregnation, roe incubation and fry raising. The artificial propagation and roe incubation method for schizopygopsis malacanthus has the advantages that the fertilization rate can reach 89.6%, the incubation rate can reach 95%, and the problem of resource scarcity caused by environmental problems is resolved; the fry incubation process is convenient to conduct, the controllability is improved, and requirements for manpower and management in the incubation process are lowered.

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

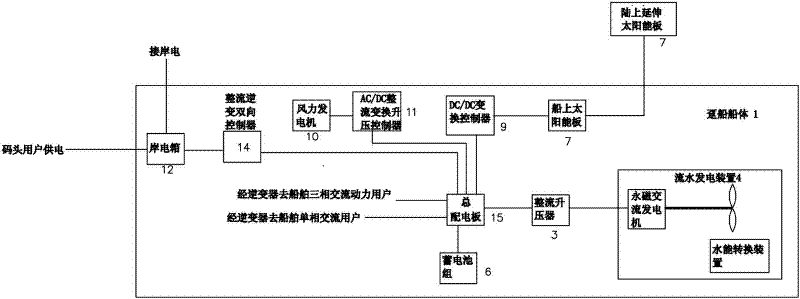

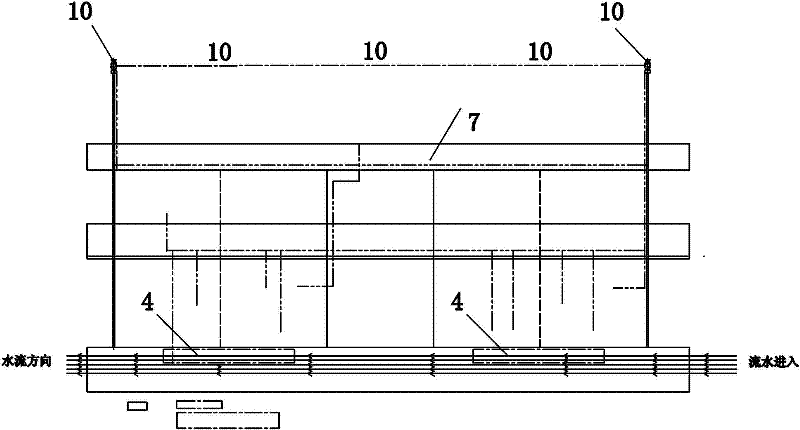

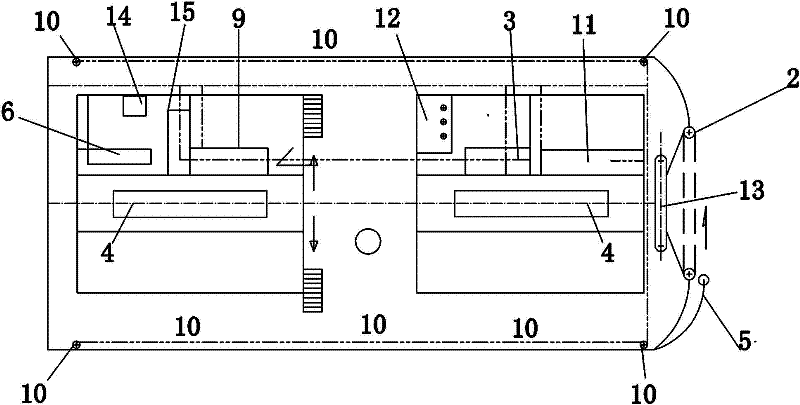

Pontoon and water flow power generation combined power station

InactiveCN102518545AEasy to installEasy maintenance and managementBatteries circuit arrangementsPV power plantsAutomatic controlEngineering

A pontoon and water flow power generation combined power station comprises a pontoon. A belt hydraulic engine type water flow power generation device, a solar power generation device and / or wind driven power generation device are arranged on the pontoon, and the belt hydraulic engine type water flow power generation device is provided with an automatic working water level regulating unit, a super-flood preventing unit and a float cleaning unit. A belt hydraulic power generator, a magnetic suspension wind driven power generator and a solar power generator are assorted mutually and are integrated with the shore supply to realize interaction and compensation, and specifically, power generated from flood and / or wind and solar energy in peak periods is fed back to the shore supply, and the shore supply resupplies power for the pontoon when in off-peak periods of flood and / wind and solar energy, so that uninterrupted power supply is formed, and the multipurpose pontoon with new clean energy self-generating devices is assembled. Besides, automatic control and dispatching of various power supplies can be realized, and accordingly the pontoon and water flow power generation combined power station has the advantages of operational simplicity, safety and reliability, high efficiency, adaptability to non-professional management, and can be used as a composite marine facility with double functions of the pontoon and the power station or can be used as a special shore power station utilizing integral energy.

Owner:庞志森 +4

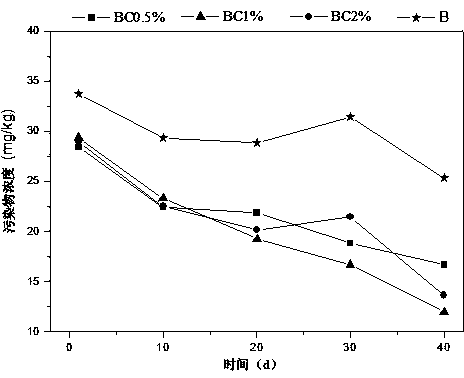

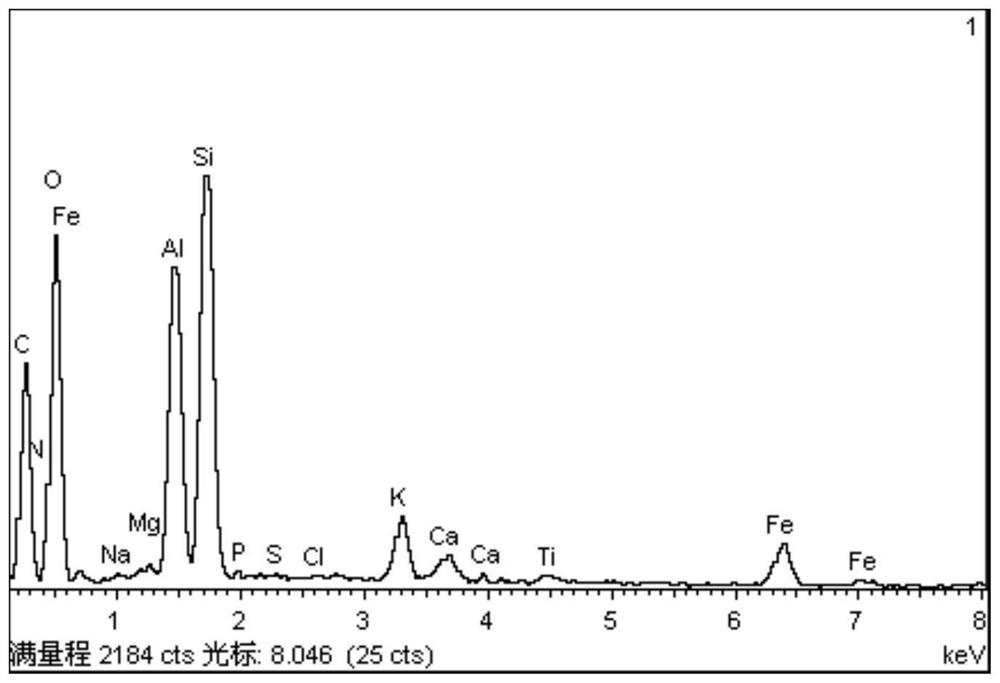

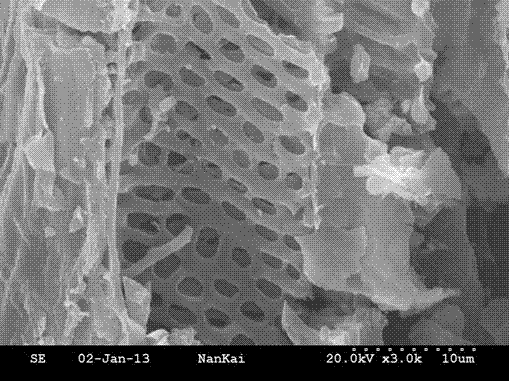

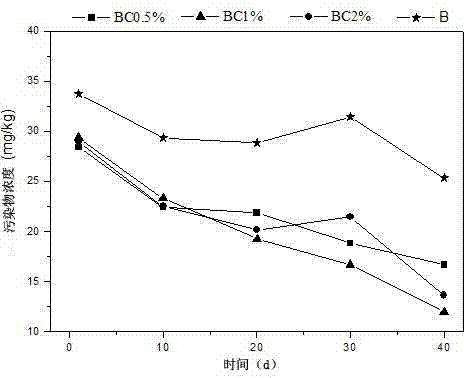

Restoration method of soil polluted by cypermethrin

ActiveCN103861869AWide variety of sourcesImprove resource utilizationContaminated soil reclamationCypermethrinEdaphic

The invention provides a restoration method of soil polluted by cypermethrin and belongs to the field of application of ecological restoration. The restoration method utilizes corn straws as main materials, uses a muffle furnace to pyrolyze and prepare a soil restoration agent, i.e., biological carbon, then applies the soil restoration agent into the soil polluted by the cypermethrin according to certain proportion to restore the soil. The restoration method mainly comprises the steps of: (1) collecting the materials and preparing the soil restoration agent; (2) applying the soil restoration agent into the soil polluted by the cypermethrin according to certain proportion; (3) detecting and controlling the degradation condition of the substance polluted by the cypermethrin. The restoration method provided by the invention has the advantages that the process is simple, the cost is low, and the application range and conditions are wide; the materials of the biological carbon are agricultural and forestry wastes and bioconversion wastes and are wide in resource, and due to the application of the biological carbon, the soil polluted by the cypermethrin can be effectively restored.

Owner:NANKAI UNIV

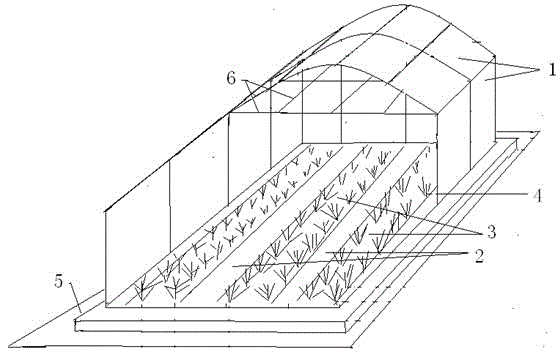

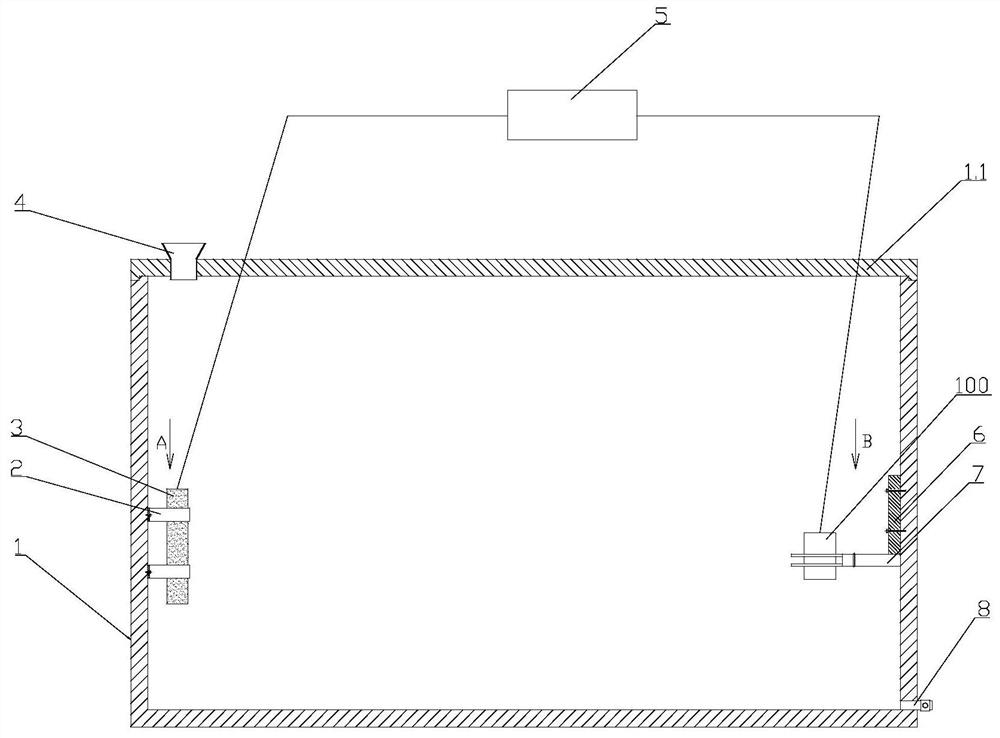

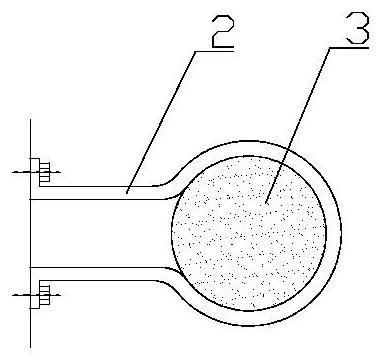

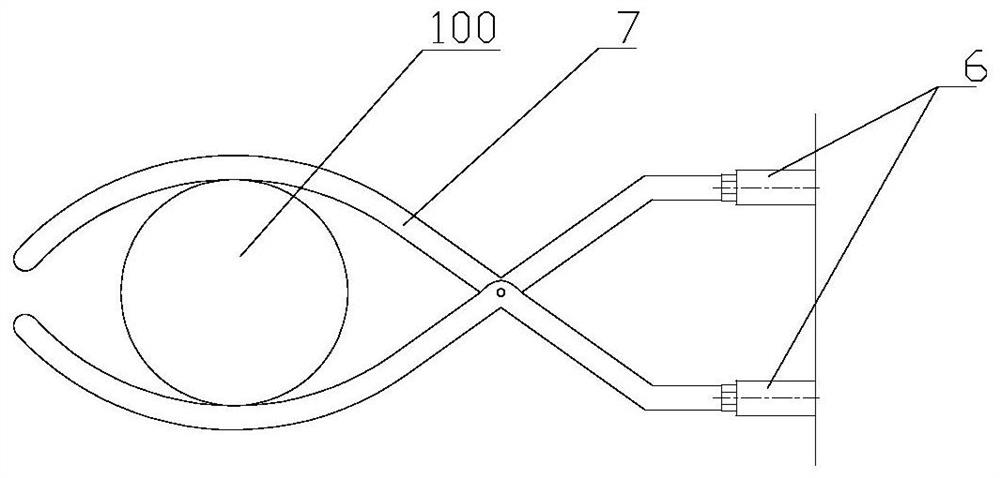

Breeding method and device for young tussah

InactiveCN102715135AReduce lossesSolve the problem that the silkworm reduction rate remains high in the young silkworm stageAnimal husbandryHabitSeedbed

The invention discloses a breeding method and a breeding device for young tussah. A greenhouse is built, hatching tree seedlings are planted in the greenhouse, and a hatching seedling bed is formed; after the fixed planting of the hatching tree seedlings, the hatching tree seedlings are bred into low-trunk tree forms, and 5 to 6 branches are left for each strain; graine is loaded into a kraft paper bag for hastening the hatching of silkworms, after the breakthrough of young silkworms, an opening of the kraft paper bag is opened, after the silkworm head tree climbing completion, the paper bag is removed, and the hatching is completed; the temperature in the greenhouse is maintained at 16 DEG C to 28 DEG C; the young silkworms are fed to 2 to 3 days at the molting of primary sleeping silkworms, and the silkworm heads are moved to a field silkworm plant for breeding outside cages before 9 o'clock in the morning or after 17 o'clock in the afternoon in sunny days. The young tussah is bred through adopting a mode of building three-dimensional breeding environment in rooms, the harm to the young tussah caused by natural environment and natural enemy can be effectively prevented, the labor work for picking and storing oak leaves is also avoided, the ventilation three-dimensional breeding environment is provided, the natural attributives of upward climbing habit, scattering habit and the like of the tussah are met, the disease rate of the silkworm body is reduced, the management requirement is reduced, the disease prevention difficulty and the cost are reduced.

Owner:GUIZHOU SERICULTURE RES INST GUIZHOU PEPPER RES INST

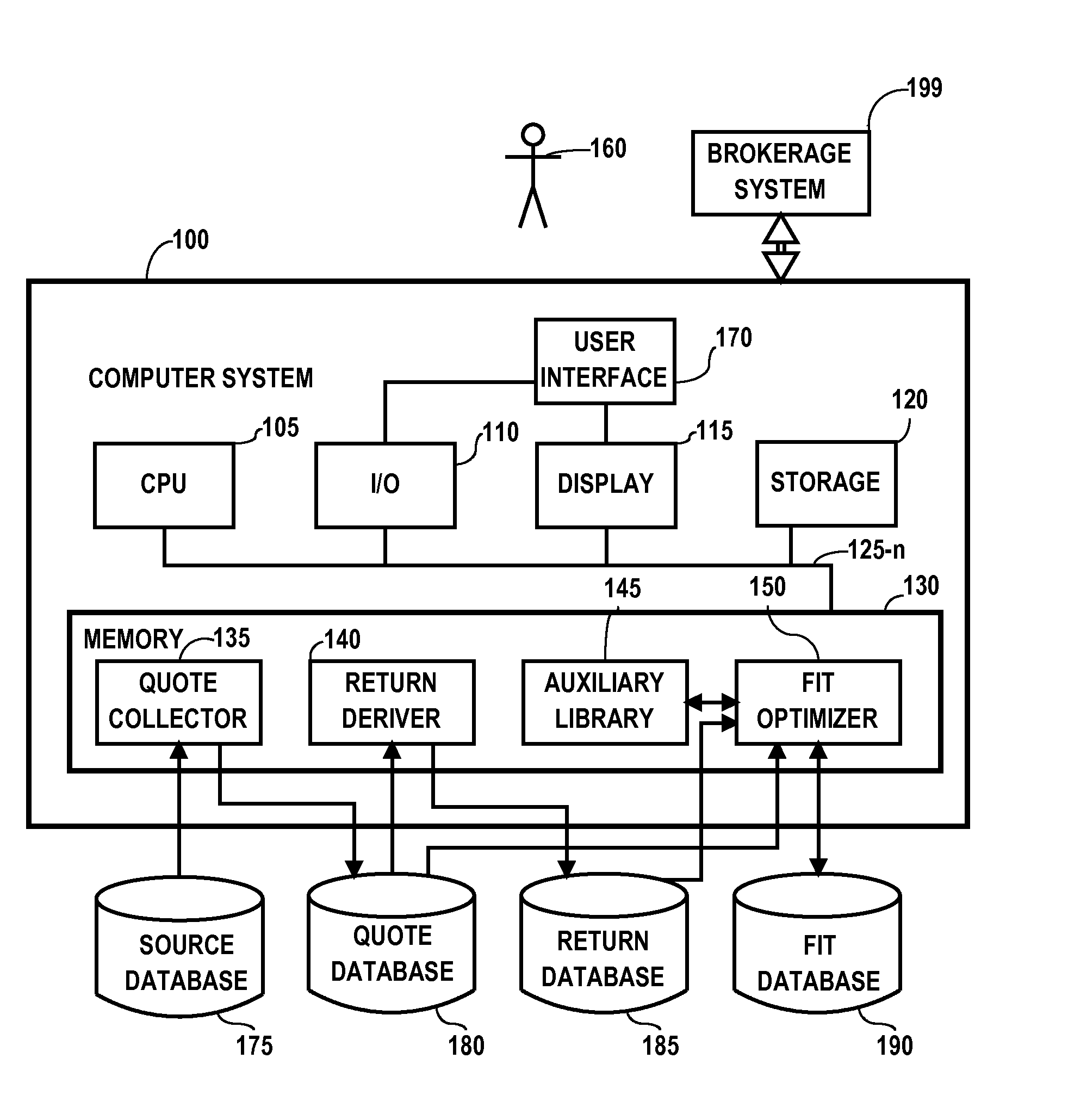

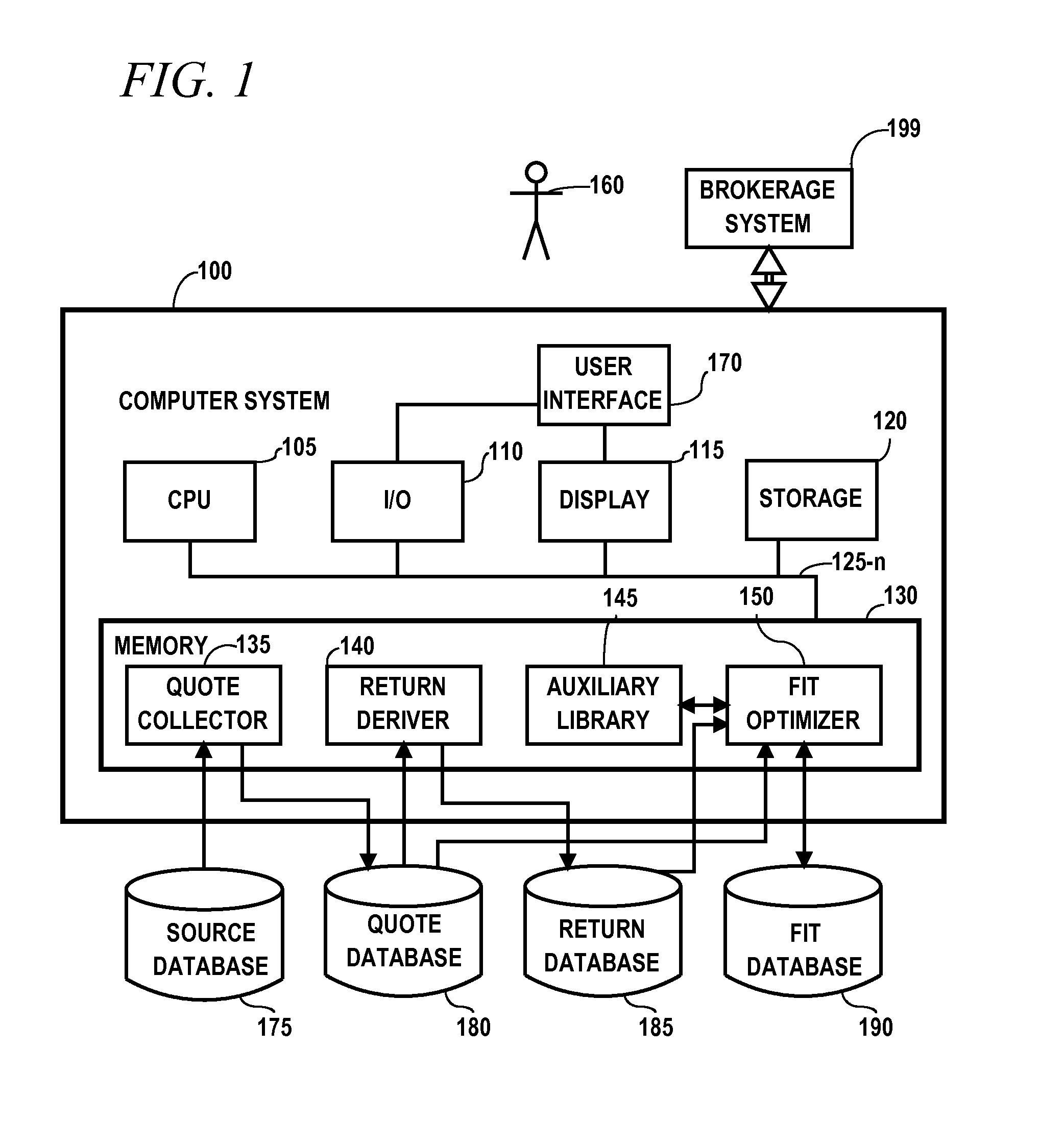

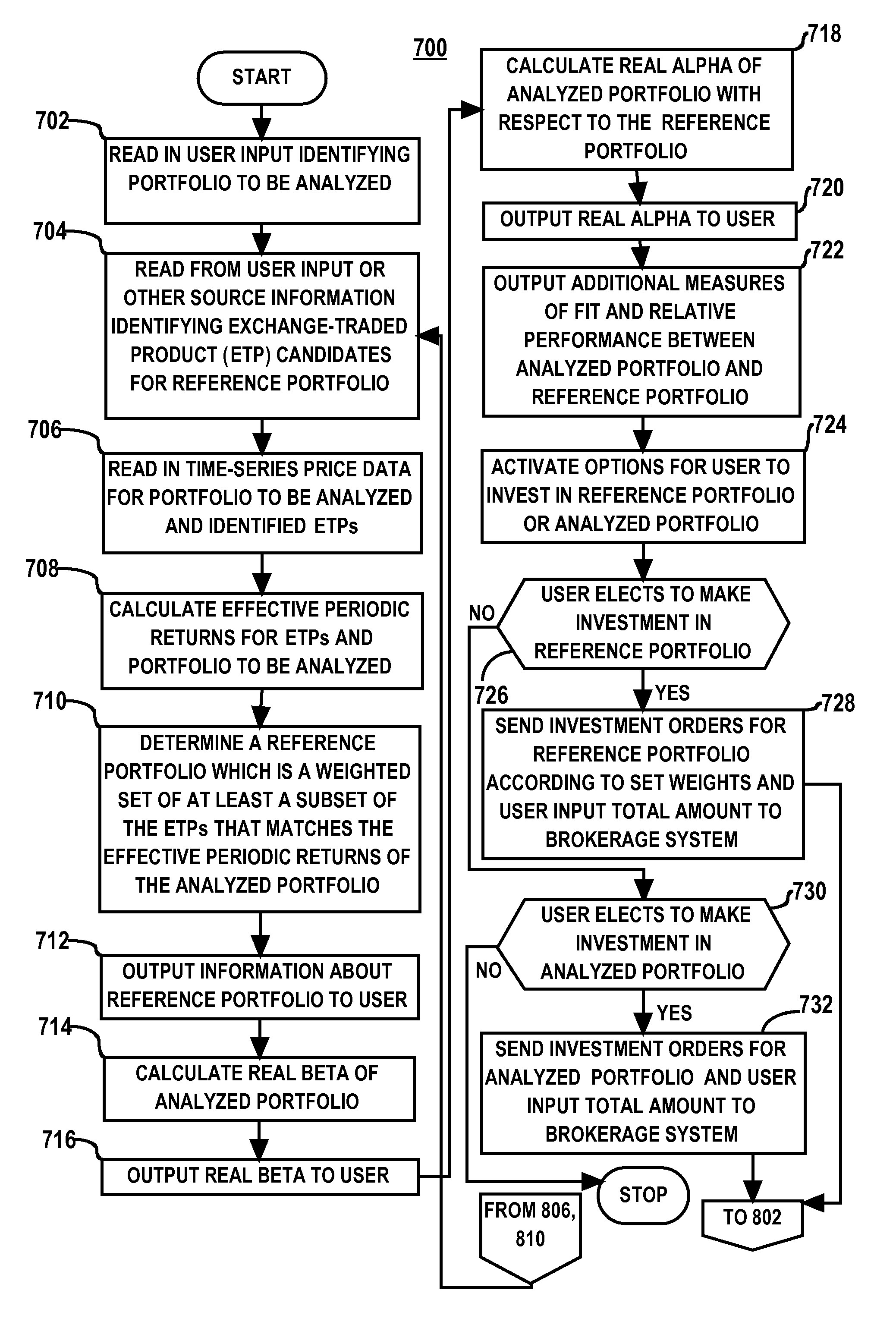

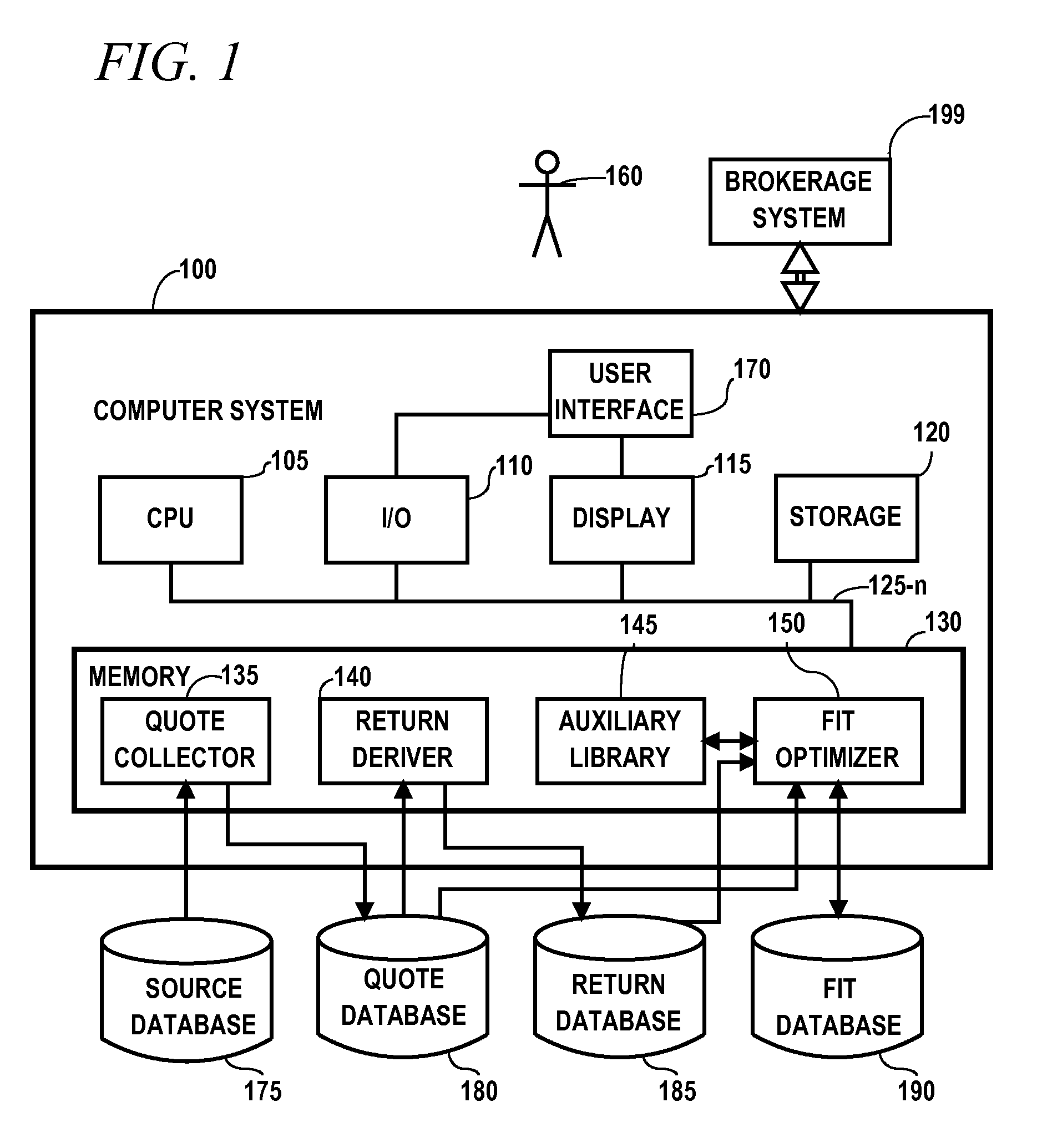

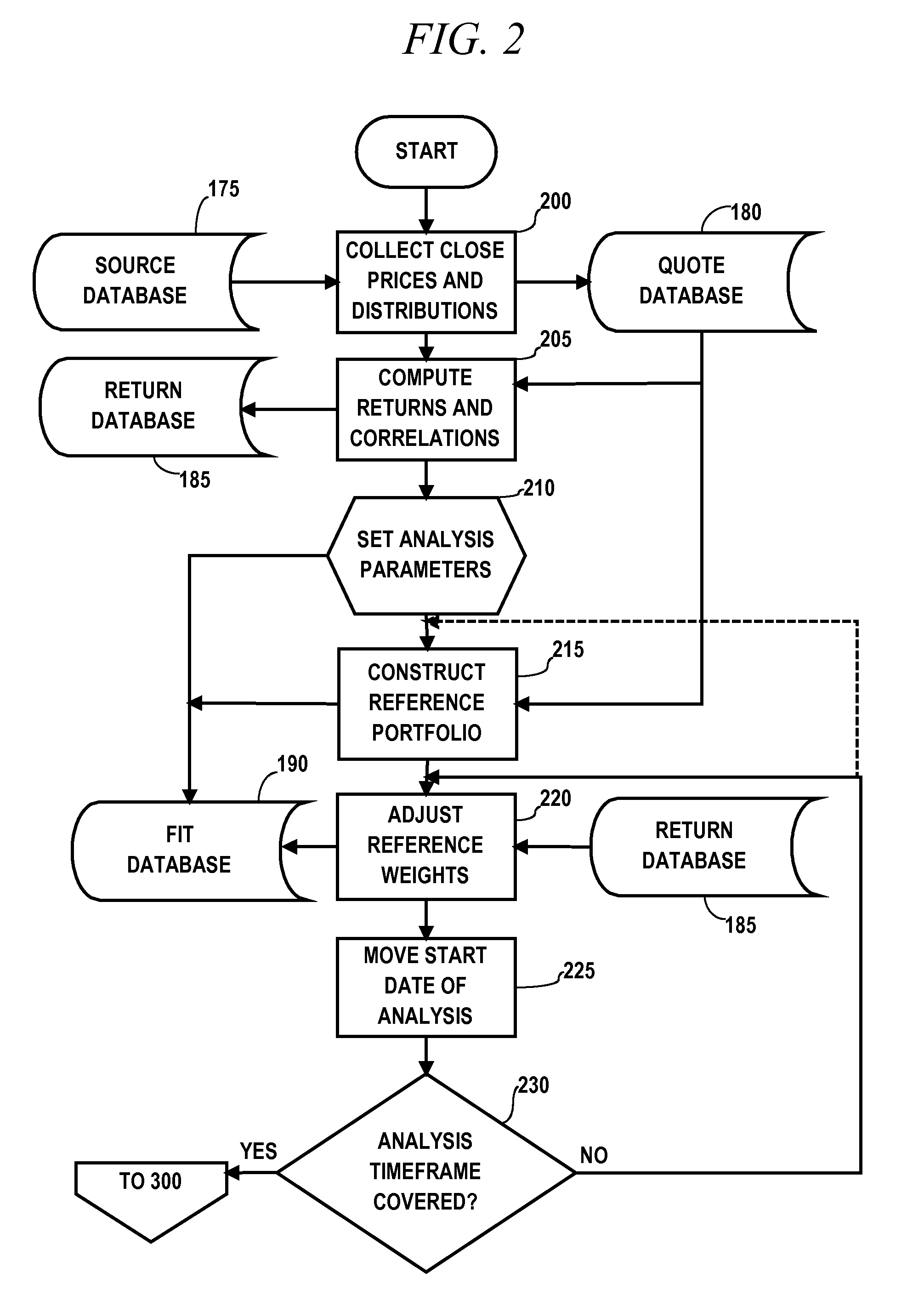

Computerized investor advisement and investment management system

A system and method for evaluating, substituting and optimizing investment asset portfolios based on performance history to facilitate the investment process. An analyzed investment portfolio is compared to a dynamically composed reference portfolio of exchange-traded products whose periodic returns best approximate periodic returns of the analyzed portfolio. Excess periodic returns of the analyzed portfolio over those of the reference portfolio are discounted in time by a risk-adjusted rate, and the resulting normalized measure is used to rate and rank the analyzed portfolios. The analyzed portfolio is substituted with the reference portfolio through a periodic execution of adjustment trades in the latter, so that returns are closely tracked over time. The analyzed portfolio is optimized by using a lag fit of the reference portfolio, which smoothes out suboptimal market timing and macro-based investment decisions of the analyzed portfolio manager.

Owner:KOTELBA MAREK R

Packing medium for permeable reactive barrier and application of packing medium to aspect of in-situ treatment on underground water nitrate pollution and method thereof

ActiveCN105347515ARaw materials are easy to getReduced operating requirementsWater treatment compoundsWater contaminantsGroundwater nitrateNitrate salts

The invention provides a packing medium for a permeable reactive barrier and application of the packing medium to an aspect of in-situ treatment on underground water nitrate pollution, and a method thereof. The packing medium is formed by evenly mixing polyhydroxyalkanoate and ceramsite with the grain sizes of 4-6.5mm and 5-8mm respectively according to a ratio; raw material components of the packing medium are simple, and simple and easy to obtain. The invention also provides the application of the packing medium to an aspect of treatment on underground water nitrate pollution, in particular to the application to an aspect of in-situ treatment on underground water nitrate pollution. In addition, the invention also provides a method for in situ removal of underground water nitrate pollutants; the method takes a mixture of the polyhydroxyalkanoate and the ceramsite as the packing medium for the permeable reactive barrier. The method has the advantages of being simple and practicable, low in cost, long in service life, and small in secondary pollution, not easily causing aquifer blocking, and the like.

Owner:四川发展环境科学技术研究院有限公司

Computerized investor advisement and investment management system

A system and method for evaluating, substituting and optimizing investment asset portfolios based on performance history to facilitate the investment process. An analyzed investment portfolio is compared to a dynamically composed reference portfolio of exchange-traded products whose periodic returns best approximate periodic returns of the analyzed portfolio. Excess periodic returns of the analyzed portfolio over those of the reference portfolio are discounted in time by a risk-adjusted rate, and the resulting normalized measure is used to rate and rank the analyzed portfolios. The analyzed portfolio is substituted with the reference portfolio through a periodic execution of adjustment trades in the latter, so that returns are closely tracked over time. The analyzed portfolio is optimized by using a lag fit of the reference portfolio, which smoothes out suboptimal market timing and macro-based investment decisions of the analyzed portfolio manager.

Owner:KOTELBA MAREK R

Apparatus for and method of managing peak current consumption of multiple subsystems in a mobile handset

ActiveUS7962183B2Total current dropRelaxes peak current requirementPower managementCathode-ray tube indicatorsCurrent consumptionEngineering

A novel and useful mechanism for regulating and managing the peak current consumption of the subsystems in a mobile handset device. The mechanism of the present invention is operative to limit the current consumption at any point in time to a predetermined level that is within the current handling capability of the power management system of the handheld device. The mechanism operates by having the high peak current subsystems advertise in advance their intention to initiate a current peak. An arbitration mechanism considers the advertisements or requests sent from interested subsystems and determines whether a subsystem is either granted permission to initiate or is blocked from initiating a peak current session.

Owner:TEXAS INSTR INC

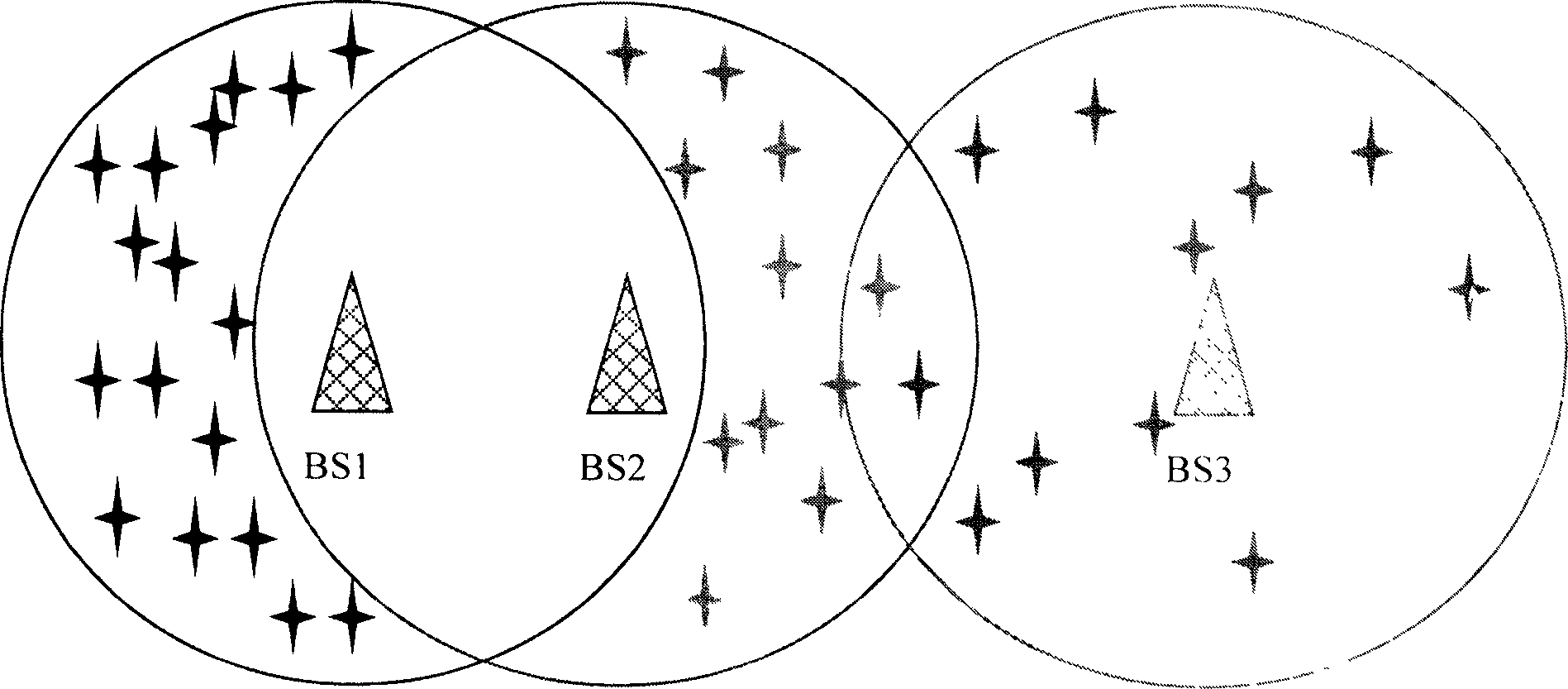

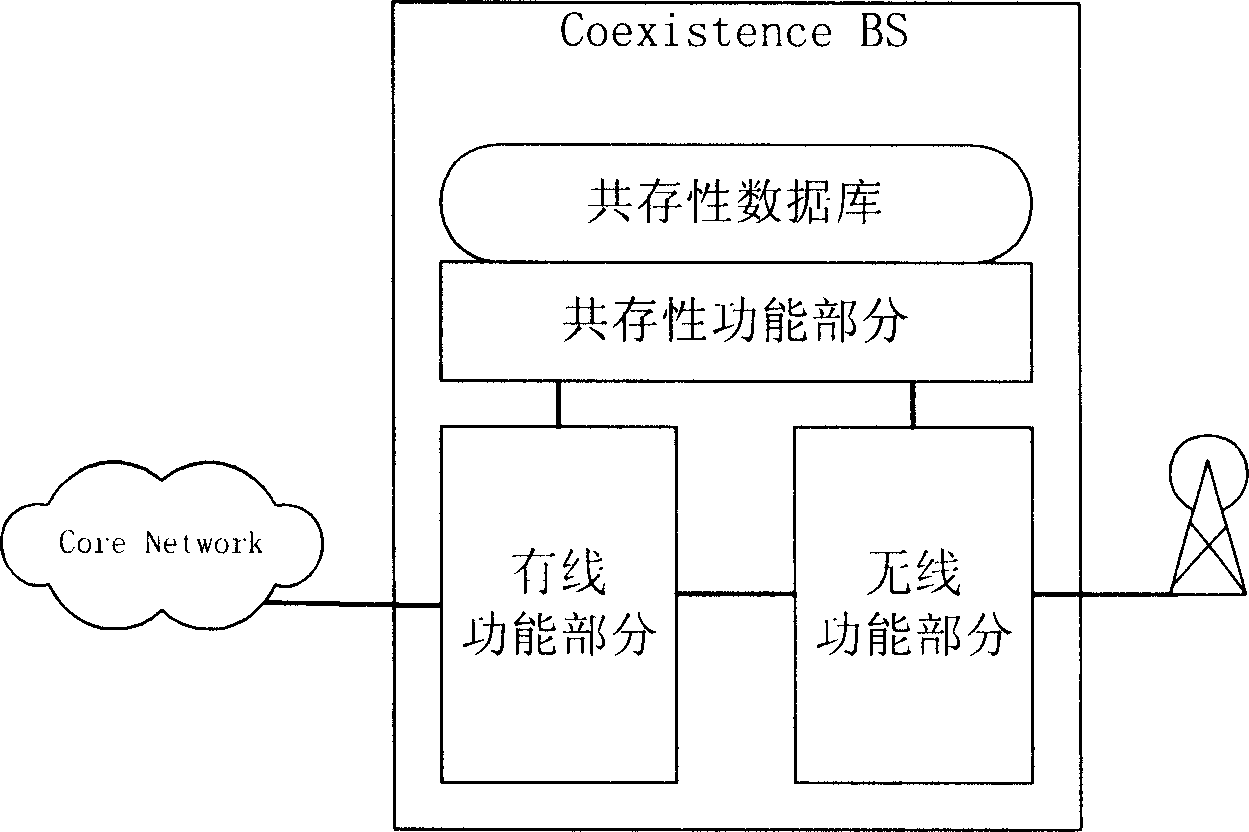

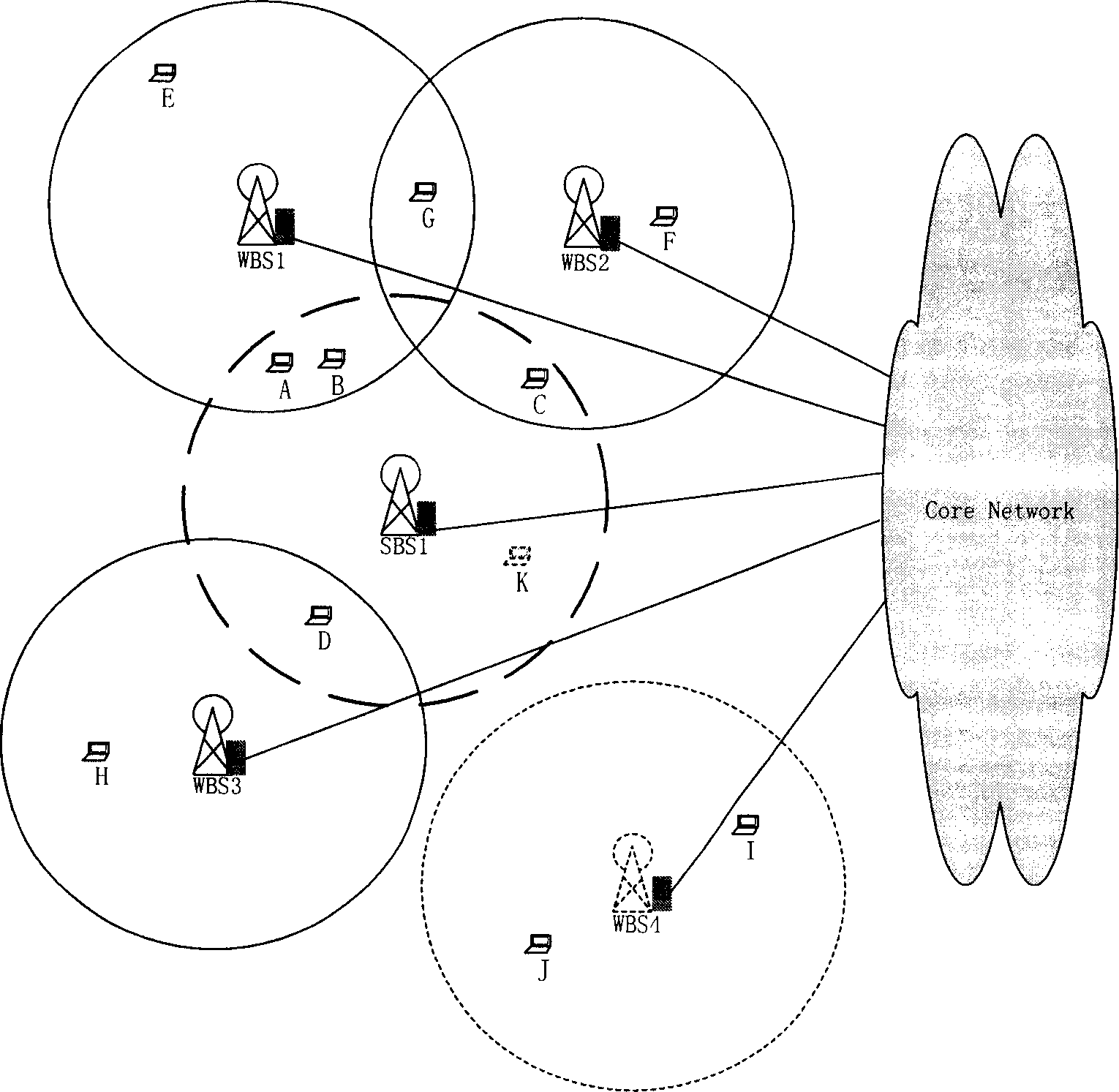

Method of coexisting base station finding neighborhood station and establishing liaison on initiation

ActiveCN1863345AQuick discoveryAvoid hidingRadio transmission for post communicationWireless communicationBase station

This invention provides a method for finding an adjacent station and setting up connection with it by a coexistent base station at the initialization including: setting a section of DCTS in a down frame structure of a coexistent base station, in which, a newly started base station utilizes said DCTS to send a connection request report to a terminal in the region overlapped with the adjacent station to find the station and connect liaison with it based on the fed back report.

Owner:HUAWEI TECH CO LTD

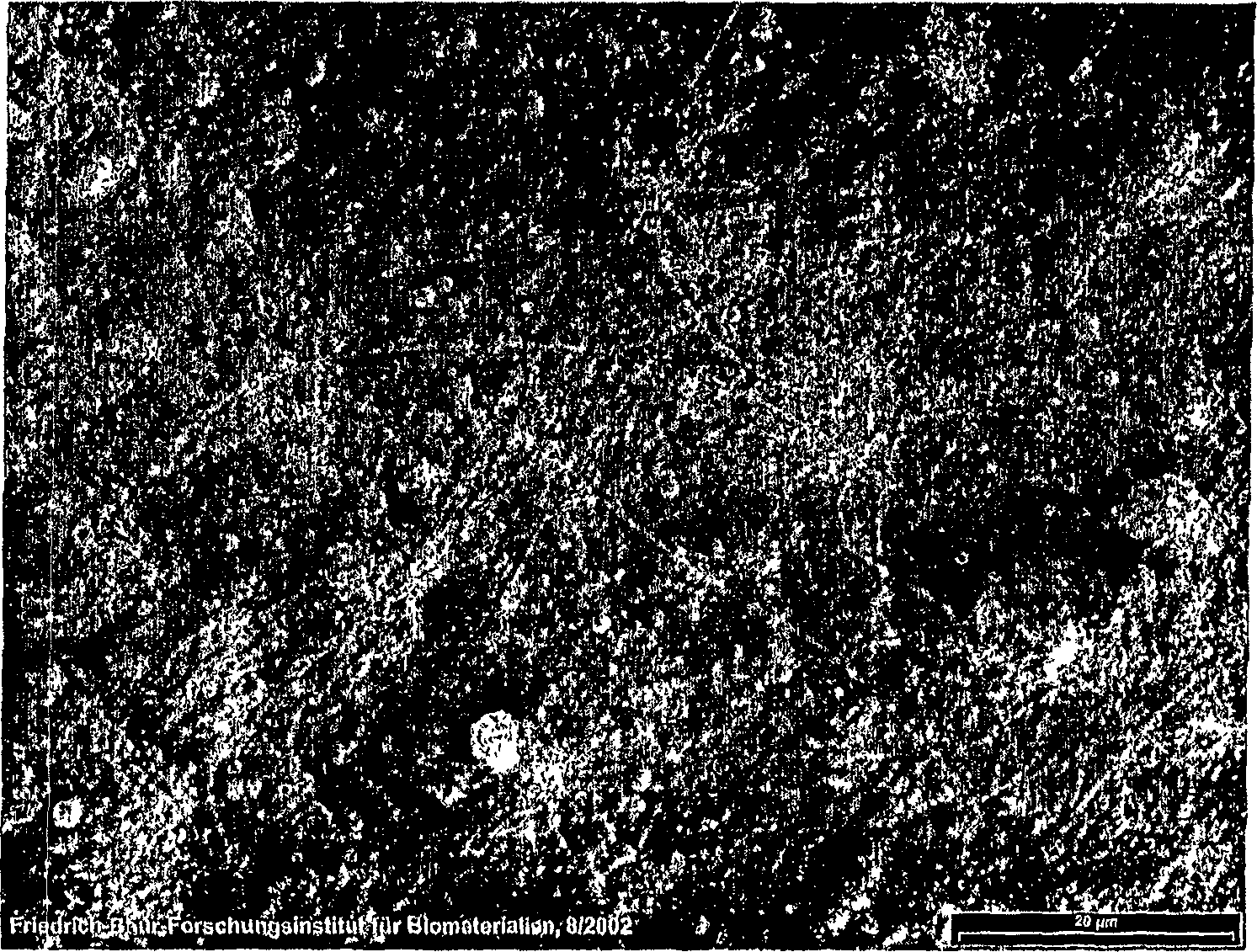

Methods for repairing and regenerating human dura mater

ActiveCN1832773ALow risk of spreading diseaseReduced risk of spreading diseaseProsthesisDiseaseFiber

A method of using a substantially non-porous equine collagen foil to repair and regenerate dura mater tissue of mammals when the dura mater tissue is damaged as a result of injury, tumors, surgery, and the like. The non-porous equine collagen foil comprises collagen fibrils which provides a replacement dura mater composition that is elastic, liquid-tight, and which has a high tensile strength. The non-porous equine collagen foil is furthermore resorbable and provides a biomatrix, wherein a neodura is rapidly formed which becomes indistinguishable from the autologous dura mater in a matter of weeks. The process for making the equine collagen foil reduces the likelihood of disease transmission.

Owner:BAXTER INT INC +1

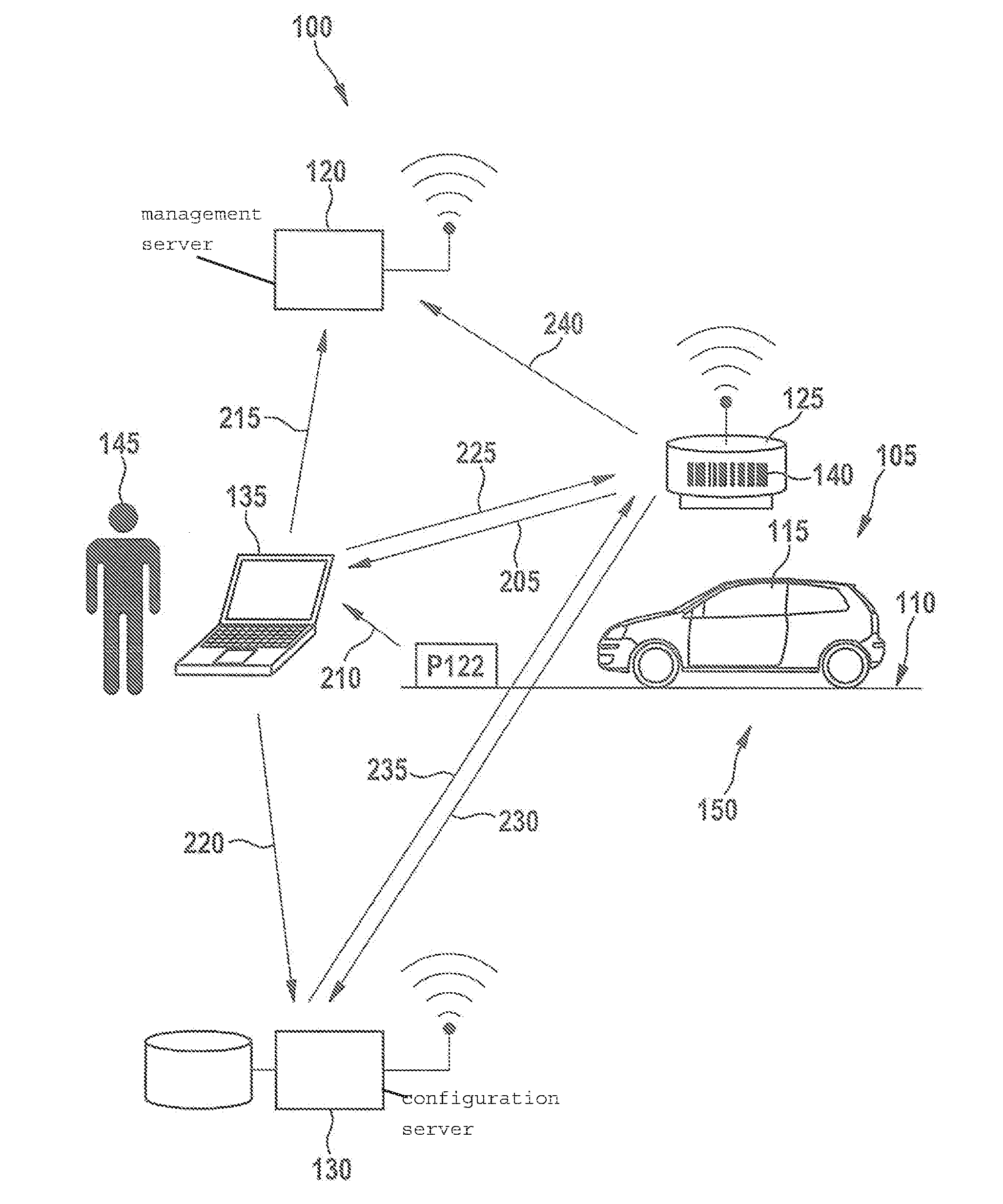

Parking lot management system

InactiveUS20160359671A1Little expenditureSimple mannerTicket-issuing apparatusIndication of parksing free spacesParking spaceManagement system

A parking lot management system includes a management server, a vehicle sensor for detecting a motor vehicle in a parking space and for transmitting a detection result to the management server, and furthermore a configuration server as well as a mobile device. The mobile device is designed to transmit an identification of the vehicle sensor to the configuration server. The configuration server is designed to transmit to a vehicle sensor, whose identification it previously received from the mobile device, a configuration that includes communication data for communicating with the management server.

Owner:ROBERT BOSCH GMBH

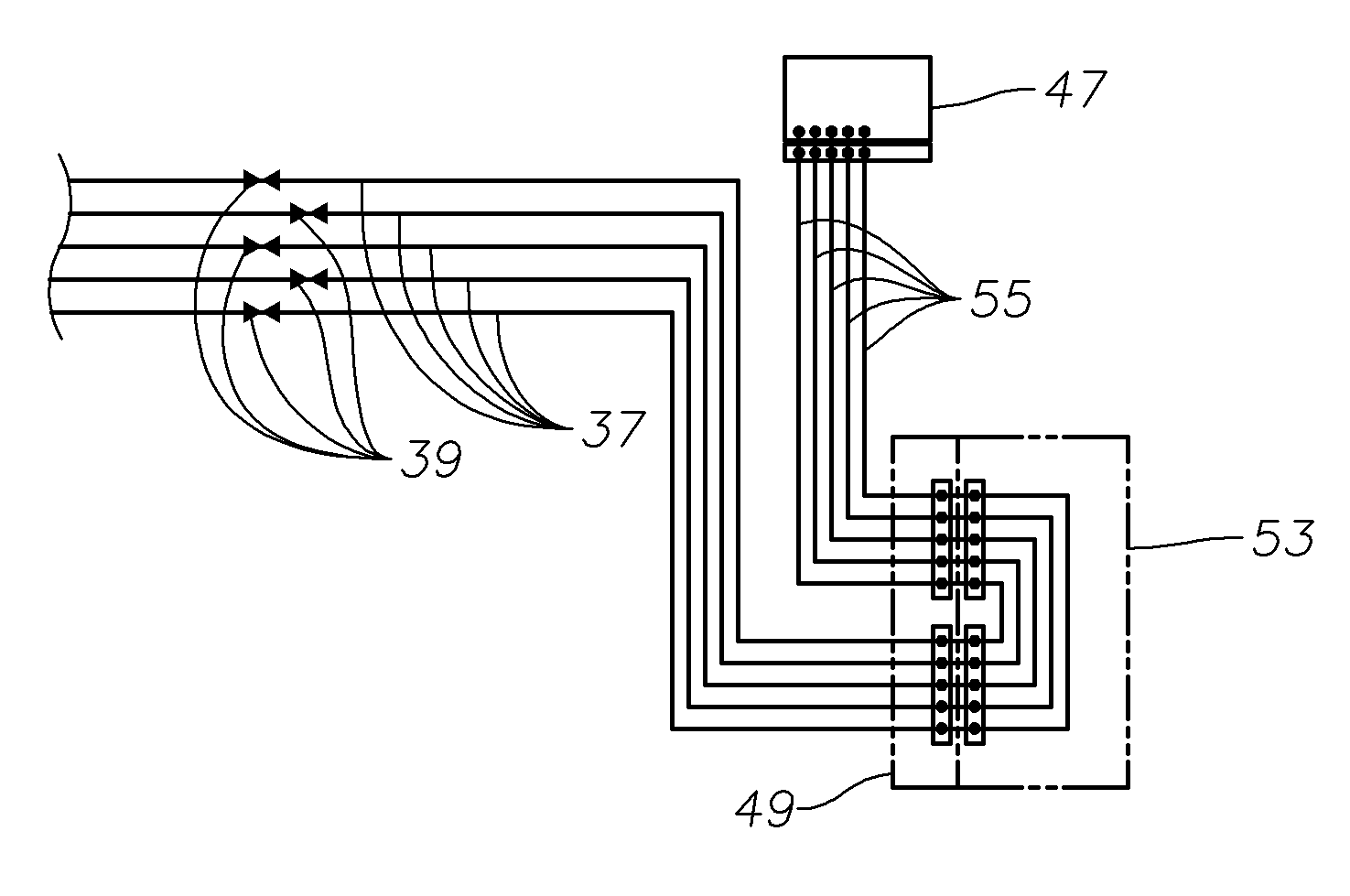

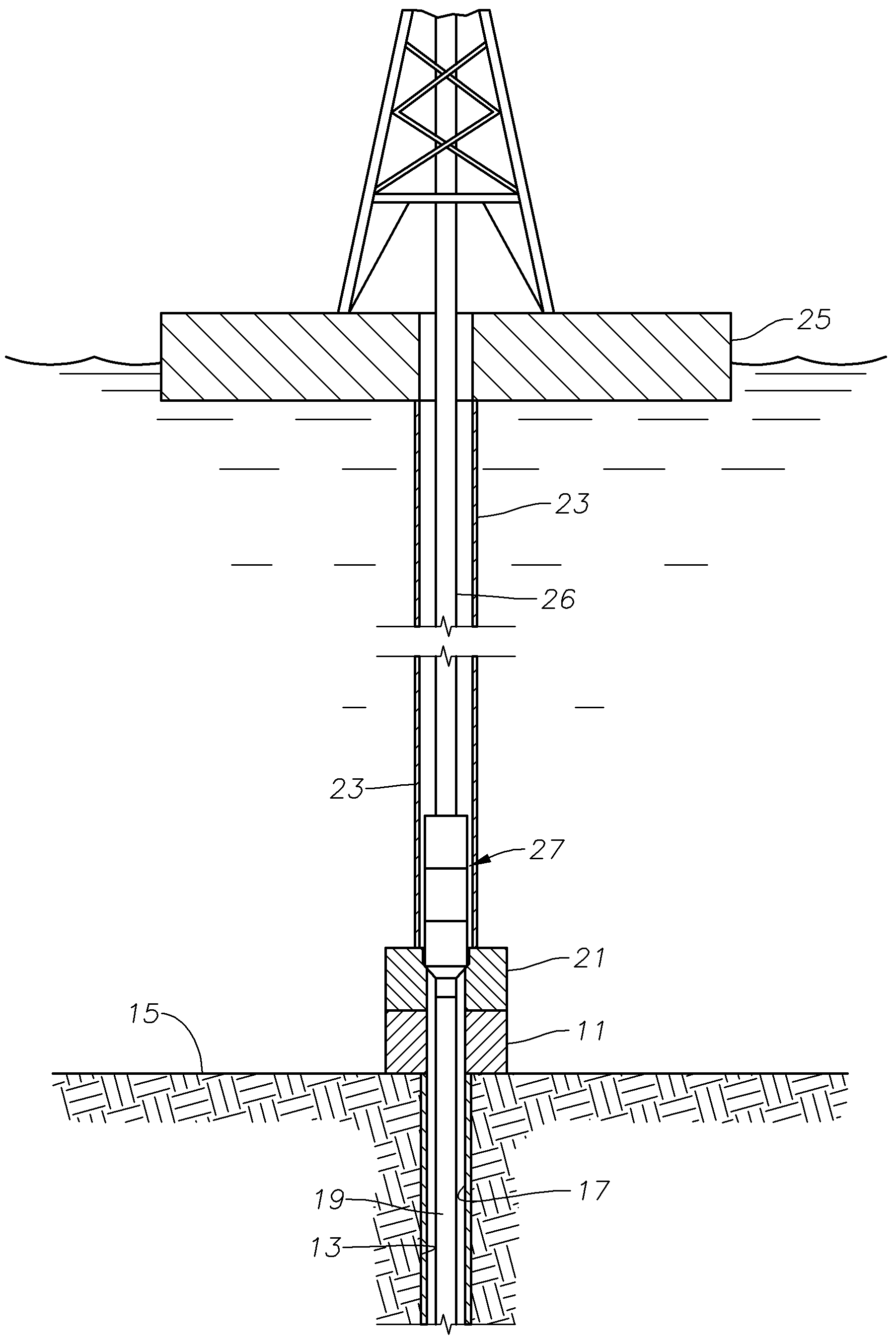

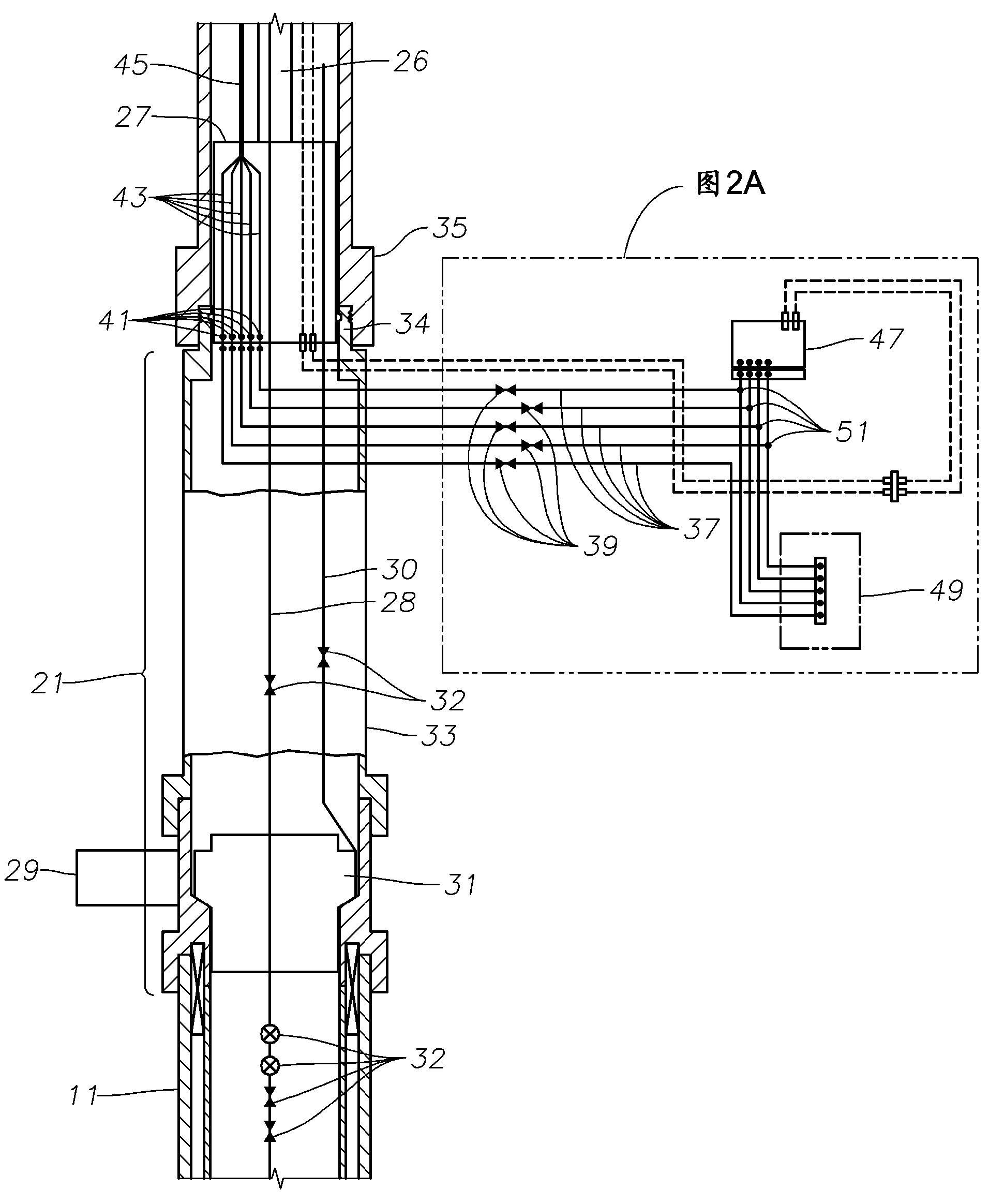

Vertical subsea tree assembly control

InactiveCN103184845ASave installation timeReduced use of capital expendituresWell/borehole valve arrangementsSealing/packingElectric powerAerospace engineering

The invention relates to a vertical subsea tree assembly control. A vertical subsea tree (21) is operated by a subsea control module (47) supplied with hydraulic and electric power from the surface via umbilical 45. Landing sub (27) connects to and is run into the vertical subsea tree (21) through riser (23). The landing sub (27) engages mating penetrations (41) on an upper portion of the master valve block (33) of the vertical subsea tree (21) to supply flow passages (37) extending from the penetrations (41) and through the master valve block (33)to the subsea control module (47) on the exterior of the tree. The subsea control module (47) is then operated through the landing sub umbilical (45) to control operation of the vertical subsea tree (21).

Owner:VETCO GRAY

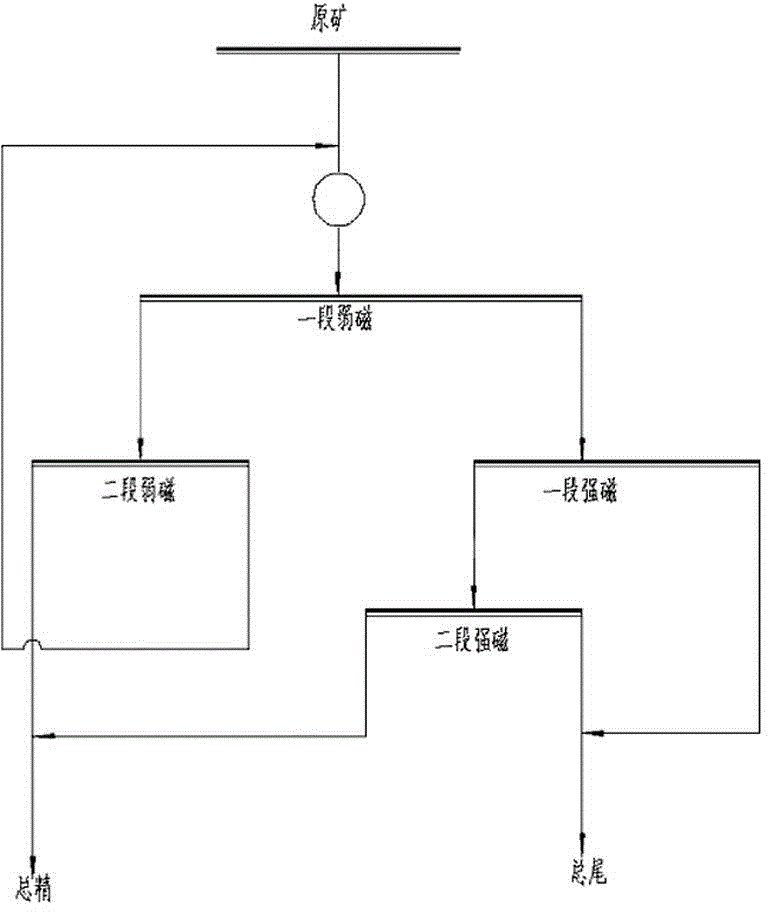

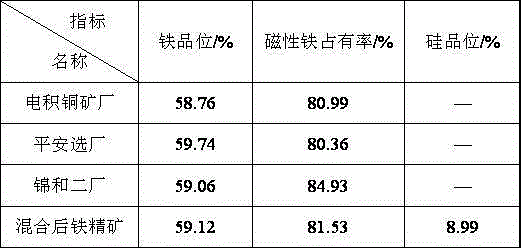

Mineral processing process for improving quality and reducing silicon of iron ore concentrate

ActiveCN104689905AFully dissociatedGood sorting indexMagnetic separationMagnetic separatorMineral processing

The invention discloses a mineral processing process for improving the quality and reducing silicon of iron ore concentrate. The process comprises the following steps: finely grinding raw ores to obtain ore powder or ore pulp of which the ore powder or ore pulp with the granularity of 325 meshes accounts for 80%, performing magnetic separation by using a 800-1000T magnetic separator to obtain a section of inferior fine magnetite concentrate and a section of inferior magnetic tailing, performing magnetic separation on the section of inferior magnetic tailing by using a 10000-14000T magnetic separator to obtain a section of high fine magnetic concentrate and a section of high magnetic tailing, performing magnetic separation on the section of inferior fine magnetite concentrate by using a 800-1200T magnetic separator to obtain two sections of inferior fine magnetite concentrate and two sections of inferior magnetic tailing, feeding back the two sections of inferior magnetic tailing to an ore grinding procedure for fine grinding, and performing magnetic separation on the section of high fine magnetic concentrate by using a 6000-10000T magnetic separator to obtain two sections of high fine magnetite concentrate and two sections of high magnetic tailing; and combing the two sections of inferior fine magnetite concentrate and the two sections of high fine magnetite concentrate to obtain total fine concentrate, and combining the section of high magnetic tailing and the two sections of high magnetic tailing to obtain total tailing. By adoption of the process, the grade of the iron ore concentrate can be increased by about 8.5%, the grade of a silicon product can be reduced by about 6.5%, the fineness of the iron ore concentrate can be improved, the abrasion of a conveying pipeline can be reduced, and the process is short in process procedure, low in operation cost and applicable to industrial popularization and application.

Owner:YUXI DAHONGSHAN MINING

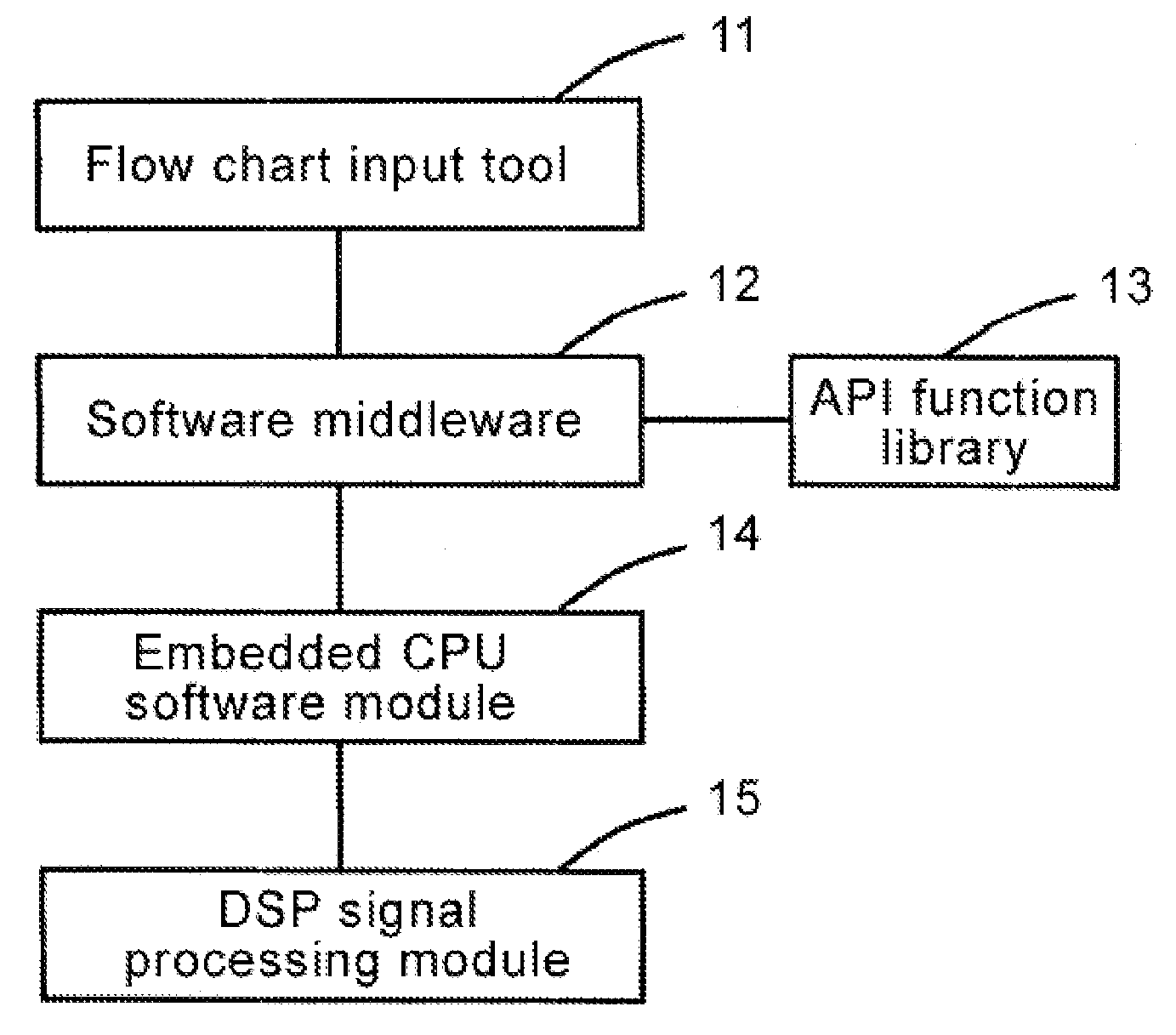

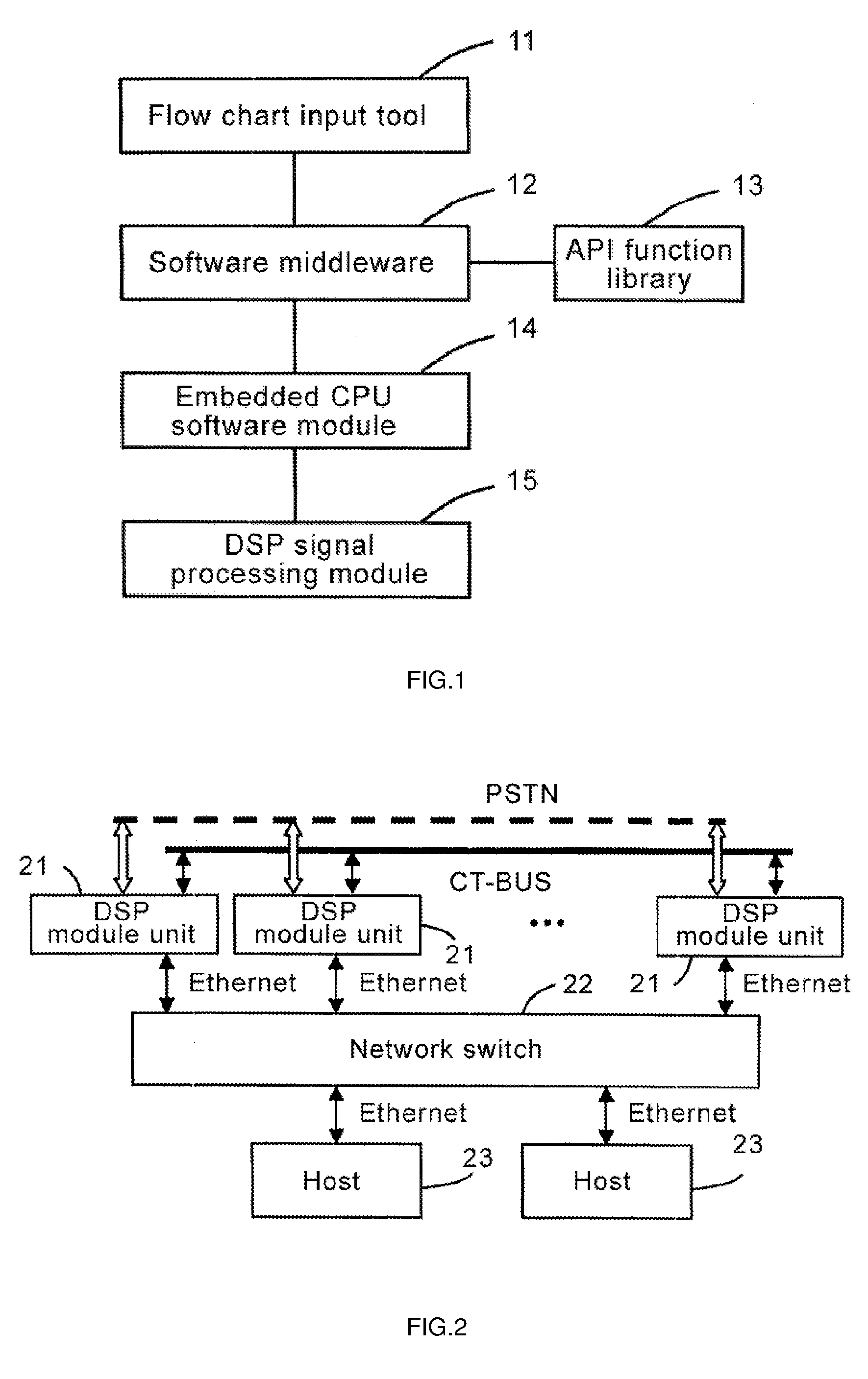

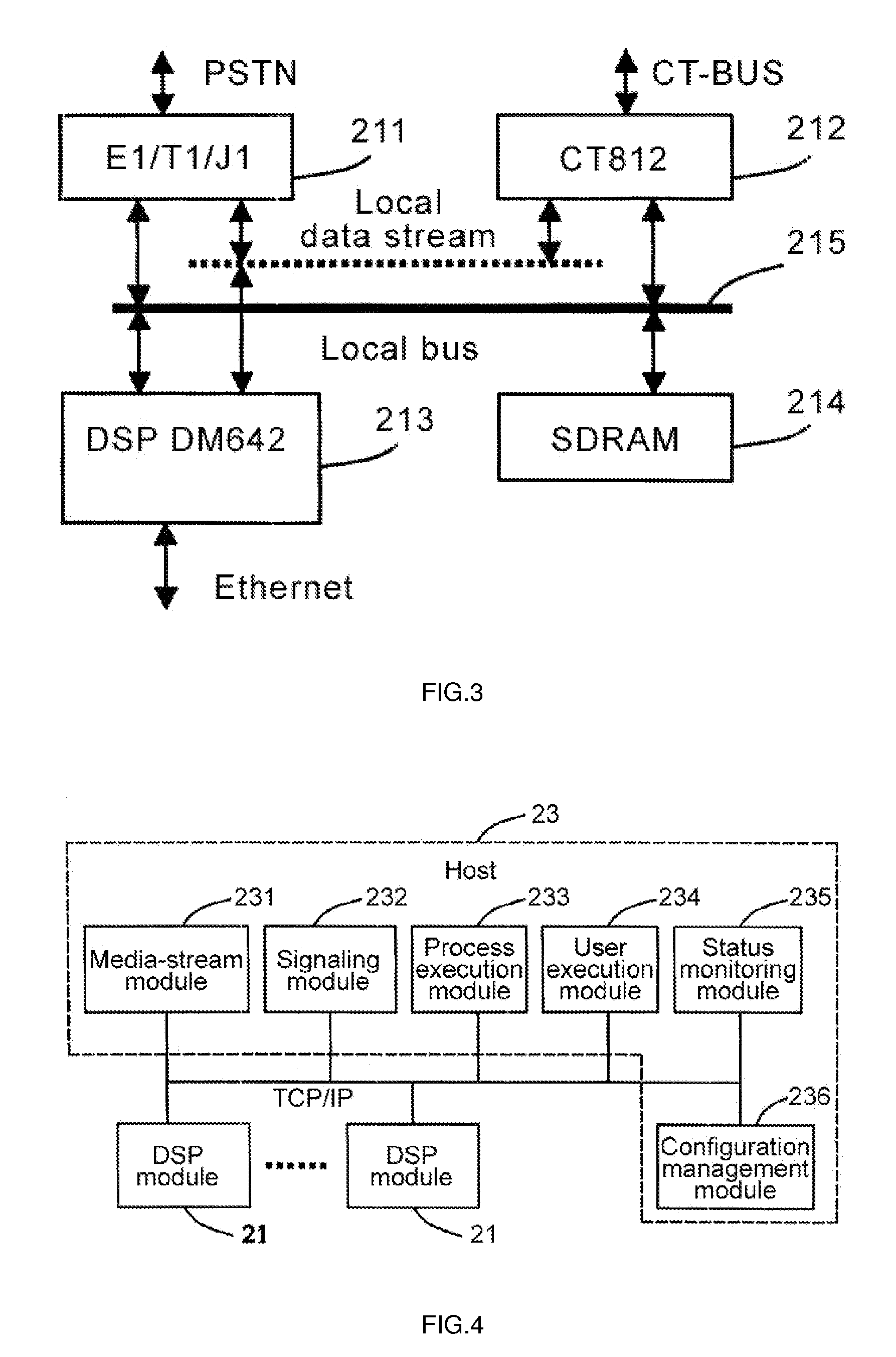

Approach and System for Process Execution of an Integrated Telecom Platform

InactiveUS20080134157A1Low management requirementsLow efficiencyInterconnection arrangementsSoftware engineeringProcess dynamicsData structure

An approach for process execution for an integrated telecom platform including the following steps: (a) The process execution module loads the process dynamic link library according to the set process parameters; (b) process execution module dispatches process creating function to create the corresponding process data structure duplicate according to the set resource channel number; (c) use the event information to activate the process data structure duplicate to a process, then the activated process will call the process running function or system functional function to process the event packets of resource channels bound to it. This invention also offers a process execution system for an integrated telecom platform. This invention makes the system operates at a higher efficiency by directly dispatching the execution process through the process execution modules.

Owner:SHENZHEN DONJIN COMM TECH

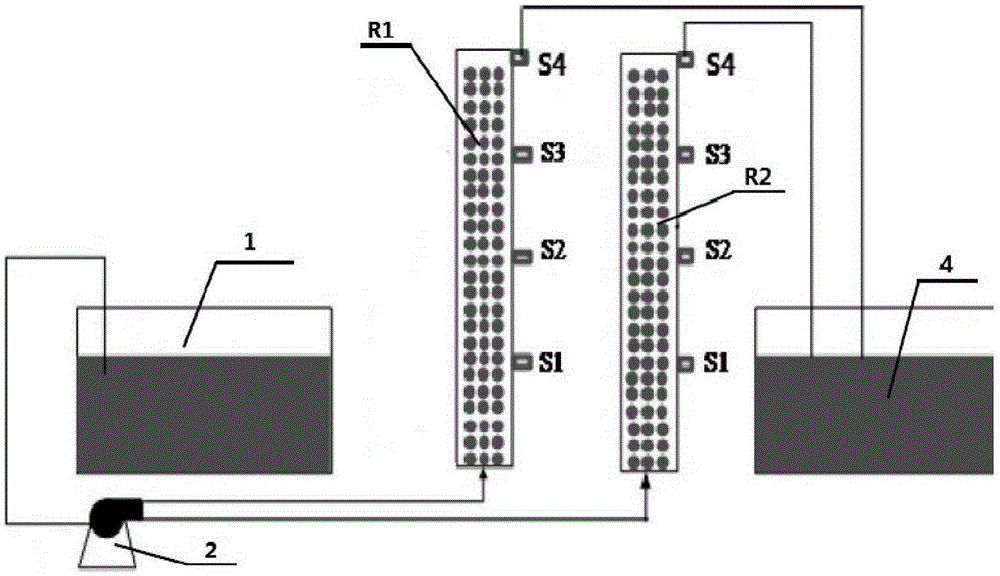

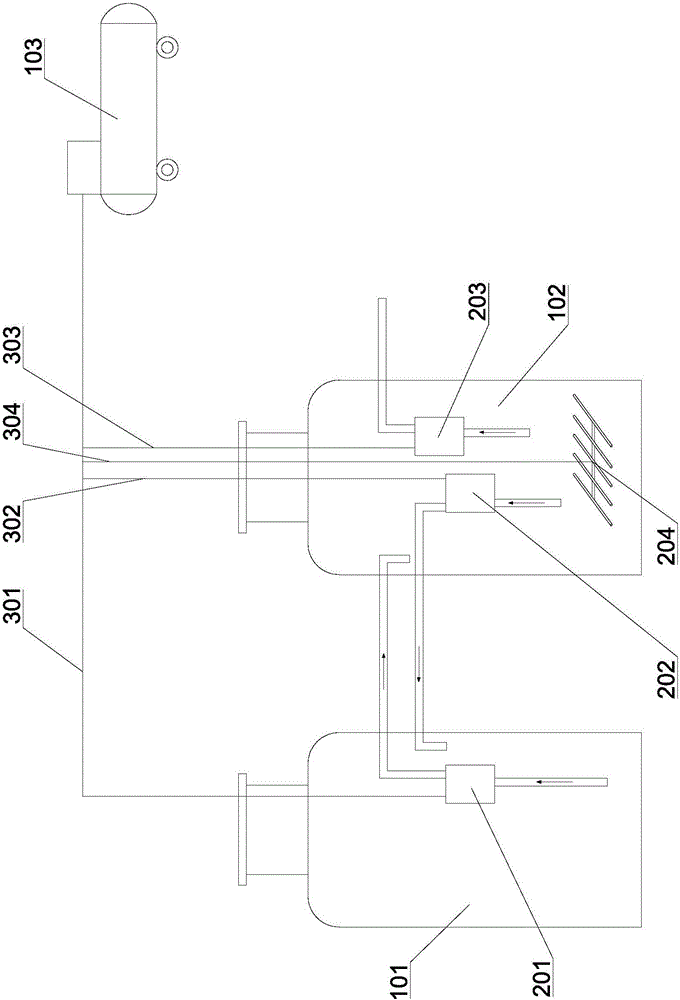

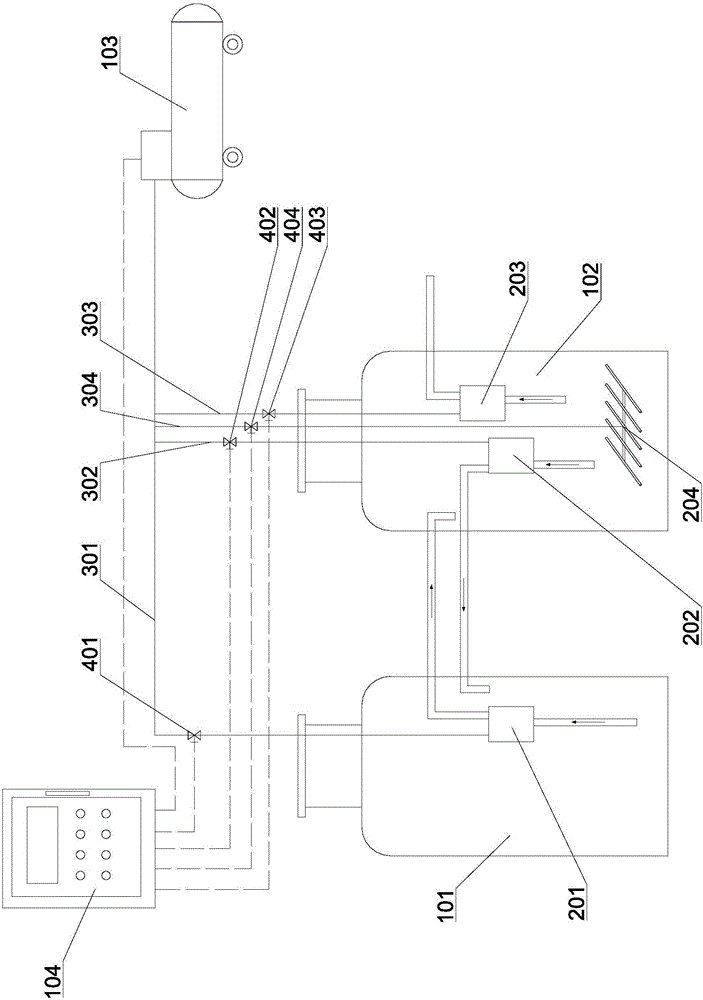

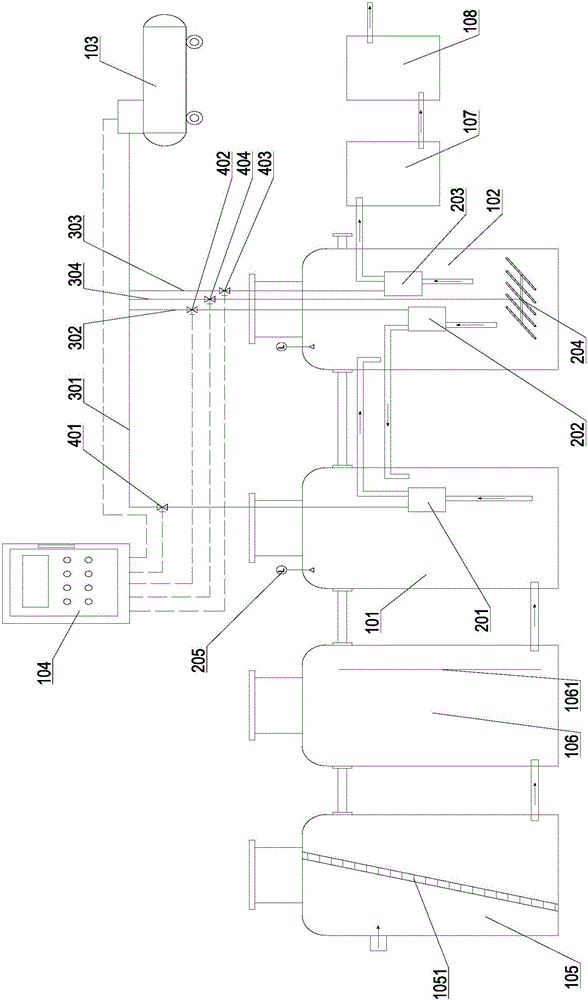

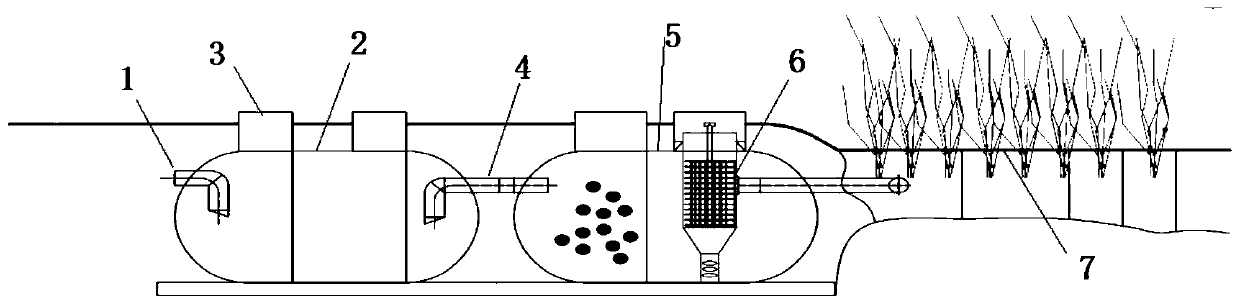

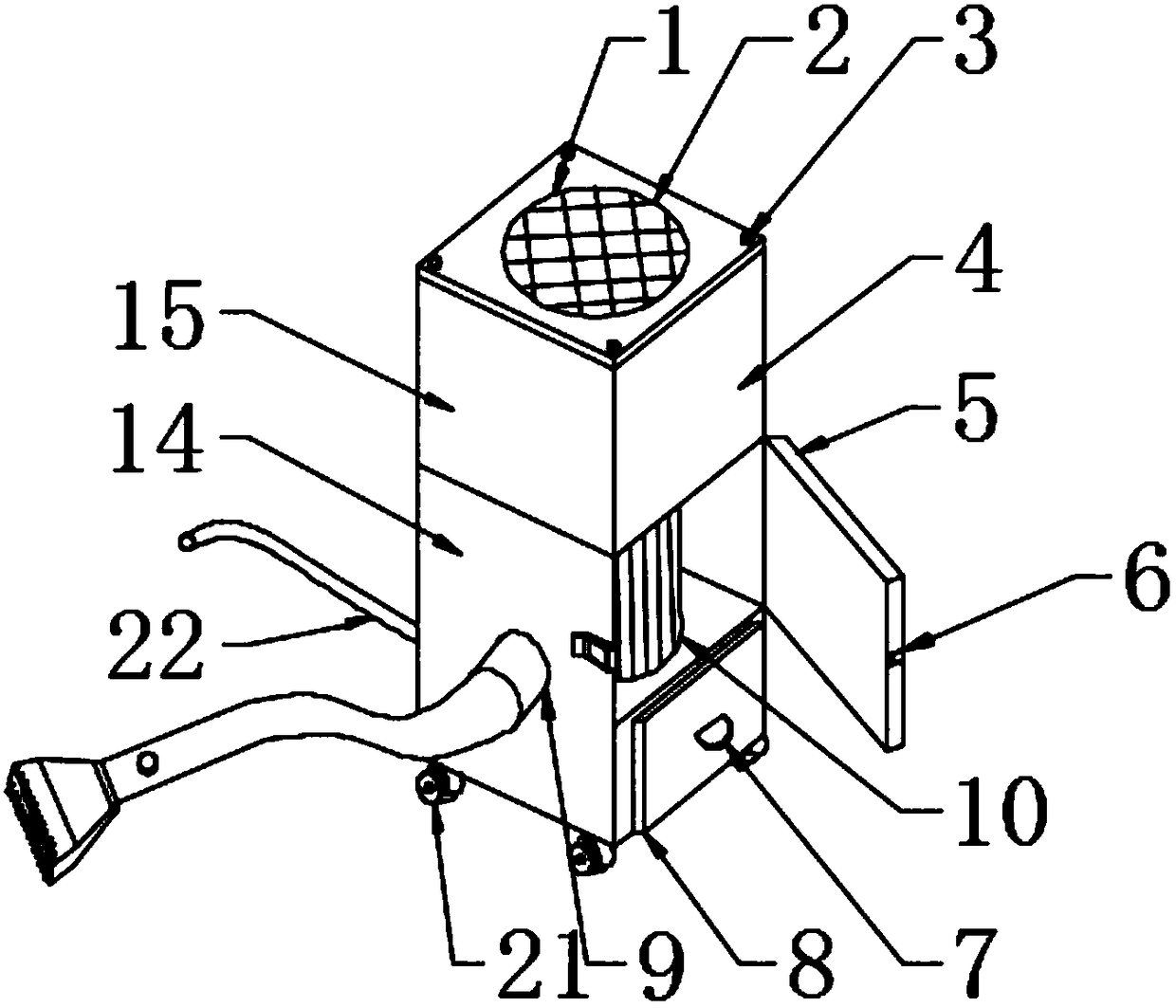

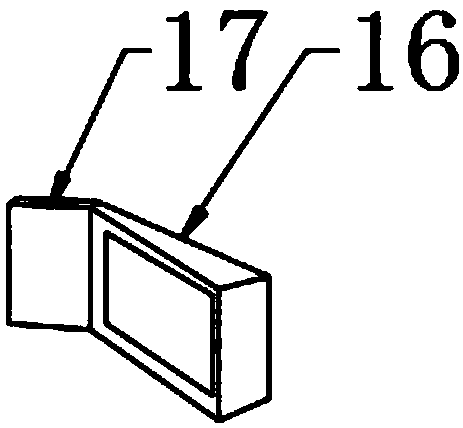

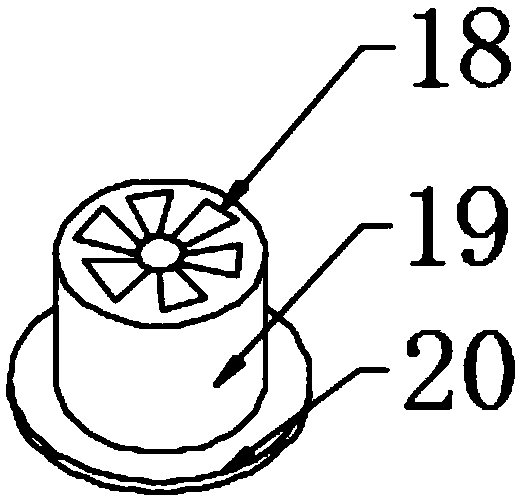

Buried sewage treatment system and sewage treatment method

InactiveCN105776514AFast and stable purificationEasy to operateFatty/oily/floating substances removal devicesTreatment using aerobic processesGas compressorSewage

The invention relates to the field of sewage treatment, in particular to a buried sewage treatment system. The buried sewage treatment system comprises a regulating tank, a biochemical tank and an air compressor, wherein a first air lift pump is arranged in the regulating tank; a feeding opening of the first air lift pump is near the bottom of the regulating tank; a discharging opening of the first air lift pump is communicated with the biochemical tank; the first air lift pump is connected with the air compressor through a first pipeline; a second air lift pump, a water outlet air lift pump and an aerator are arranged in the biochemical tank; a discharging opening of the second air lift pump is communicated with the regulating tank; the second air lift pump is connected with the air compressor through a second pipeline; a water outlet of the water outlet air lift pump is communicated with the outside of the biochemical tank; the aerator is connected with the air compressor through a fourth pipeline. The invention also provides a sewage treatment method. The buried sewage treatment system and the sewage treatment method have the advantages that sewage can be fast and stably purified; meanwhile, power equipment is little; the system can be conveniently installed and maintained; the long-time and stable operation can be realized.

Owner:成都太古科技有限公司

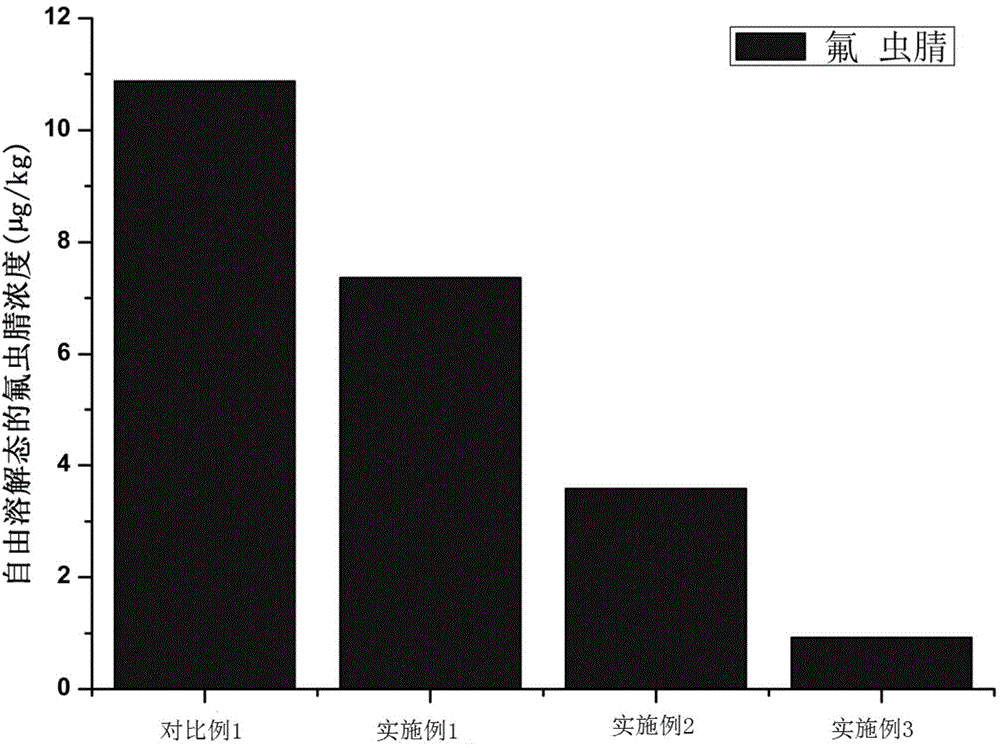

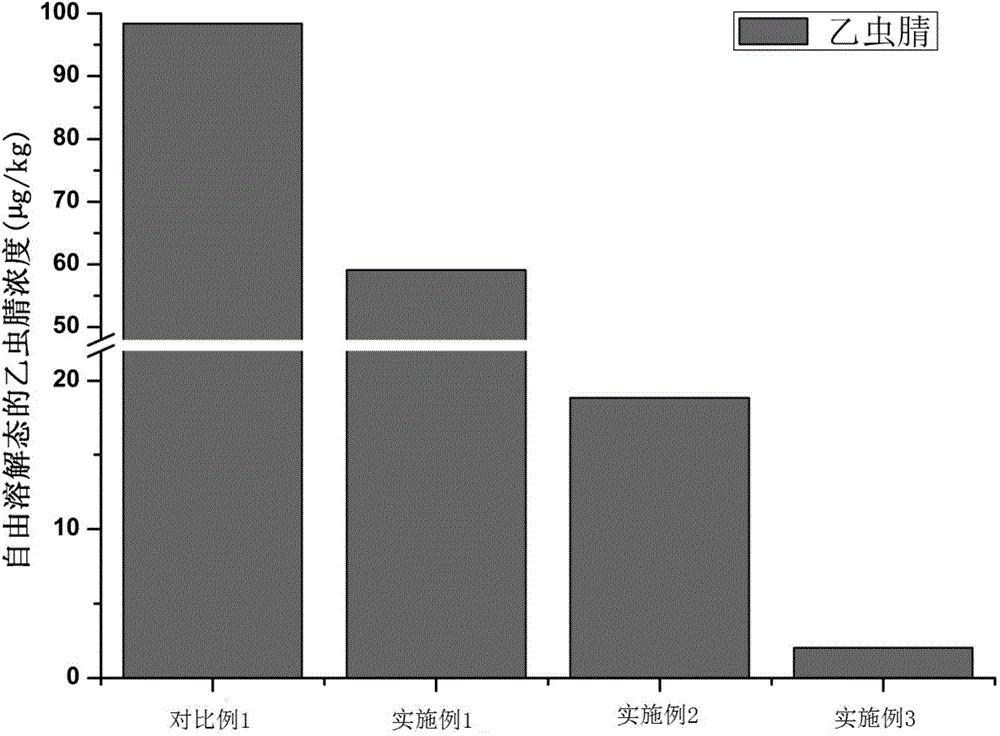

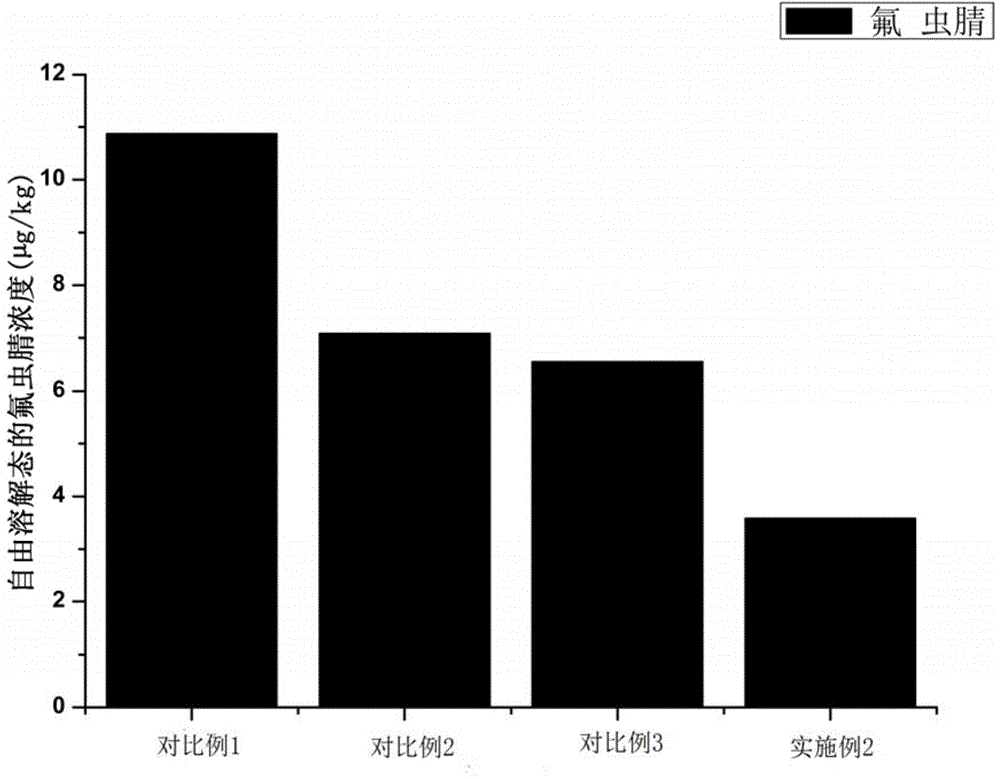

Remediation of fipronil and/or ethiprole contaminated sediments by using biochar and detection method thereof

InactiveCN104785511ALow priceMaterials are readily availableComponent separationContaminated soil reclamationSites treatmentFipronil

The invention relates to remediation of fipronil and / or ethiprole contaminated sediments by using biochar and a detection method thereof. The method for remediation of the fipronil and / or ethiprole contaminated sediments by the biochar comprises the steps of preparation of the biochar from michelia alba wood and remediation of the fipronil and / or ethiprole contaminated sediments. The method for determining the concentration of free-dissolved fipronil and / or ethiprole in the sediments after remediation comprises the steps of determination of the concentration of free-dissolved fipronil and / or ethiprole in the sediments after remediation by polyformaldehyde resin. Raw materials of the method are wide in sources and are easily available; the biochar prepared from the michelia alba wood has large specific surface area and strong adsorption ability; the operation flow is simple, the condition requirements are low, and the remediation method can be used for remote treatment and on-site treatment of contaminated sediments; environment risk is low, no secondary pollution exists, and the practical application value is high; and with use of the detection method, the determination result is accurate, and the operations are simple and efficient.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

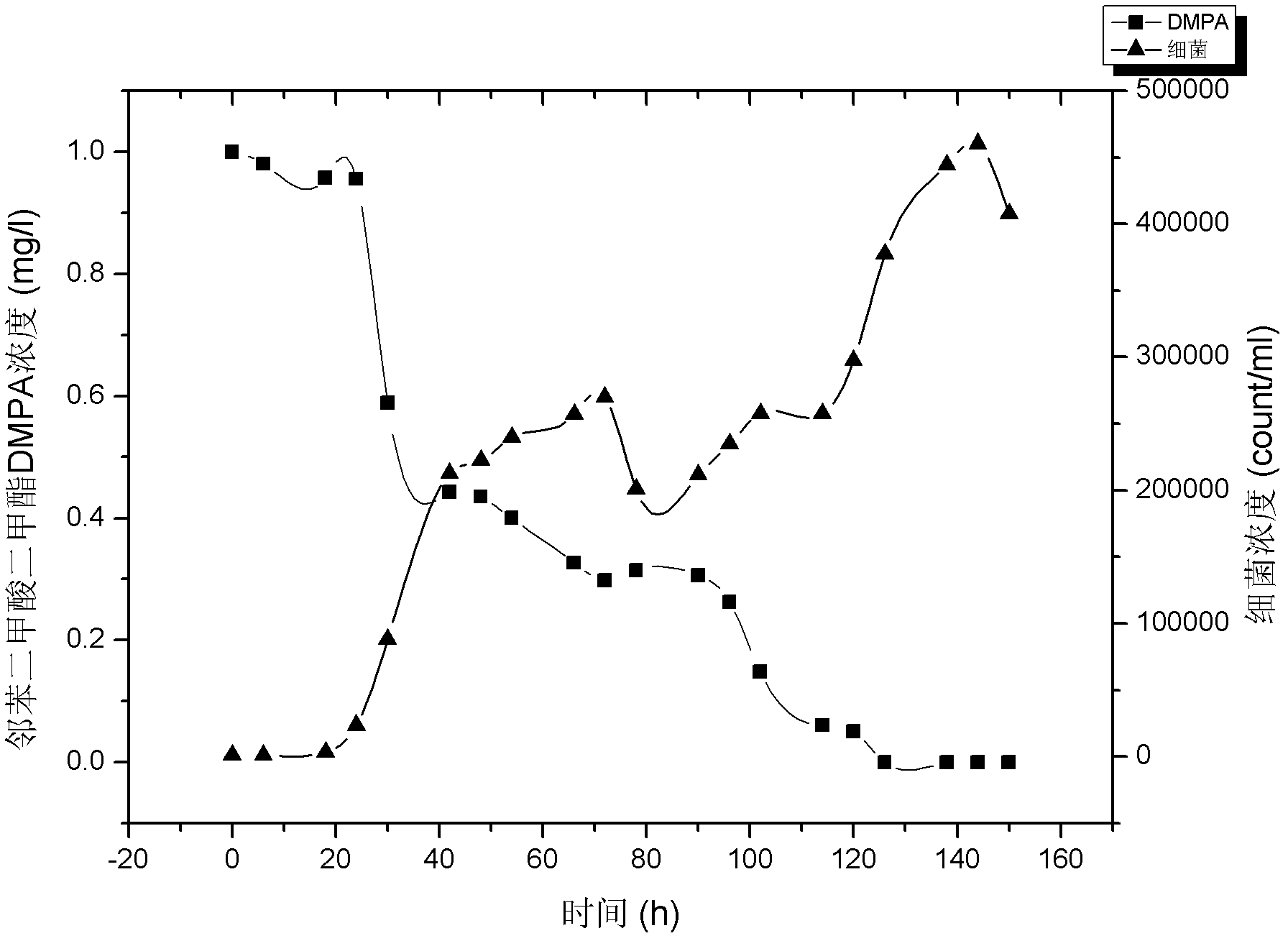

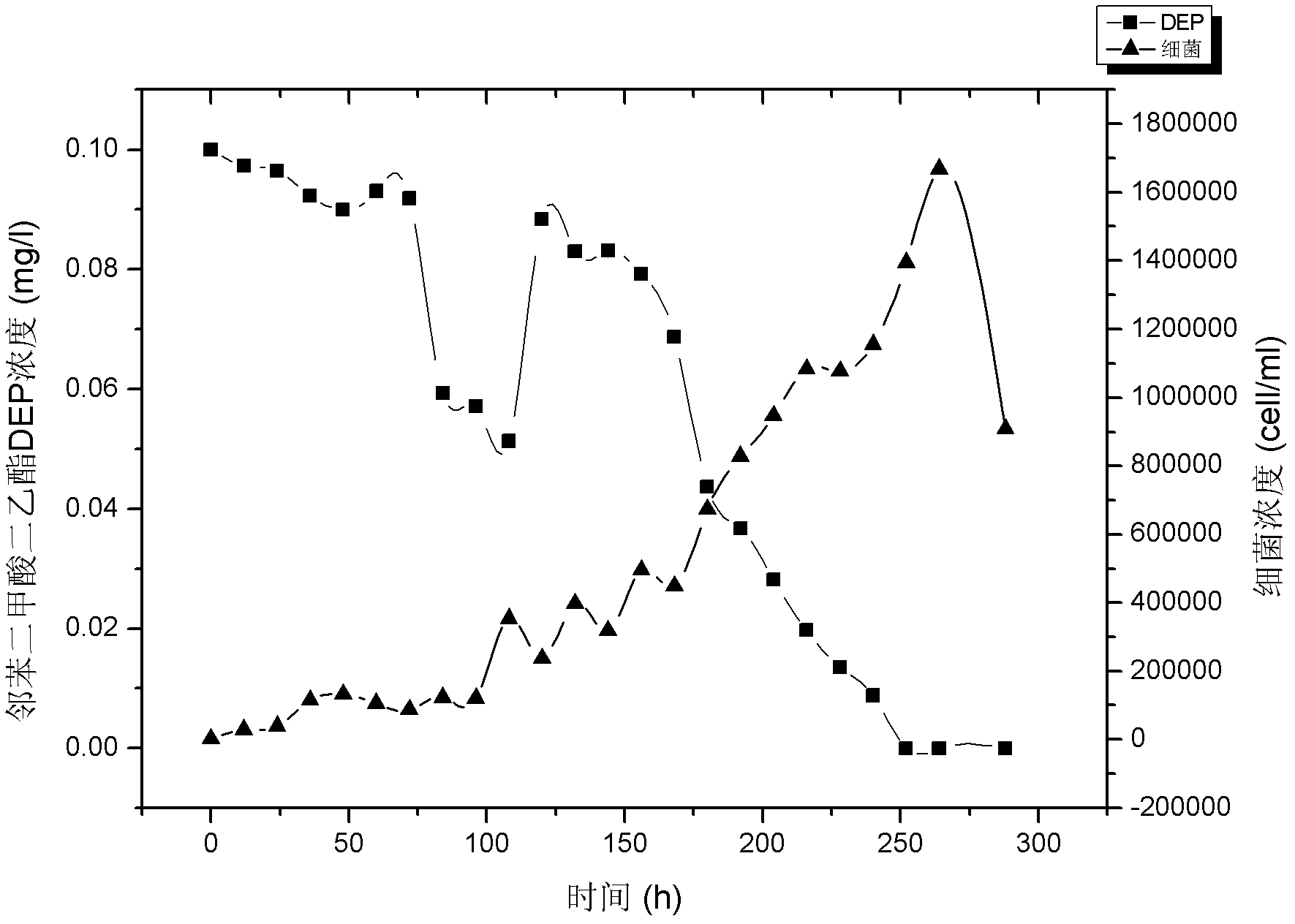

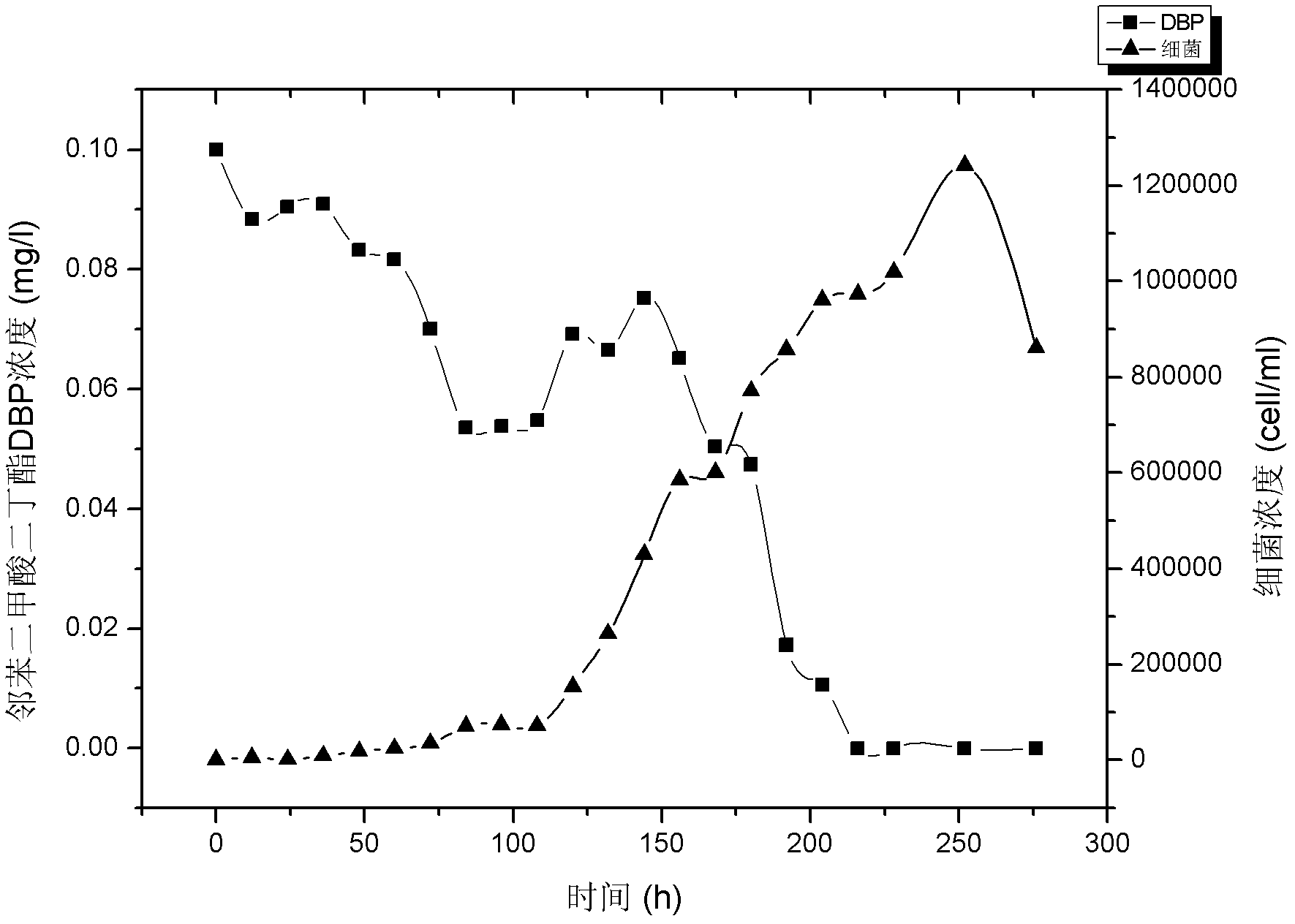

Method for degrading phthalic acid esters in water by using ultramicro bacteria under oligotrophic conditions

The invention discloses a method for degrading phthalic acid esters (PAEs) plasticizer pollutant in water by using ultramicro-bacteria proteus Rhodoferax ferrireducens PAE-UM (CGMCC No.5917) capable of growing under oligotrophic conditions, belonging to the application field of micro-biological degradation and restoration of pollutants in water, solving the problem of degrading the PAEs pollutants in water under oligotrophic conditions that can not be solved in the existing micro-biological degradation methods. The method comprises the following steps: (1) culturing and preparing strains; (2)inoculating and degrading the PAEs pollutants in water; and (3) carrying out detection control on the degradation status of the PAEs pollutants. The method has the advantages of simple process flow, low cost, and wide application range and conditions, and the cultured strains has strong ability to degrade the PAEs pollutants under oligotrophic conditions.

Owner:NANKAI UNIV

A method for artificial reproduction and hatching of fish eggs

ActiveCN103875572BImprove fertilization rateEasy to operateClimate change adaptationPisciculture and aquariaSchizopygopsis malacanthusFresh water organism

The invention relates to an artificial propagation and roe incubation method for freshwater fishes, in particular to an artificial propagation and roe incubation method for schizopygopsis malacanthus, and belongs to the technical field of artificial propagation and roe incubation of fishes. The artificial propagation and roe incubation method for schizopygopsis malacanthus mainly comprises the steps of parent fish selection, spawning induction, artificial impregnation, roe incubation and fry raising. The artificial propagation and roe incubation method for schizopygopsis malacanthus has the advantages that the fertilization rate can reach 89.6%, the incubation rate can reach 95%, and the problem of resource scarcity caused by environmental problems is resolved; the fry incubation process is convenient to conduct, the controllability is improved, and requirements for manpower and management in the incubation process are lowered.

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

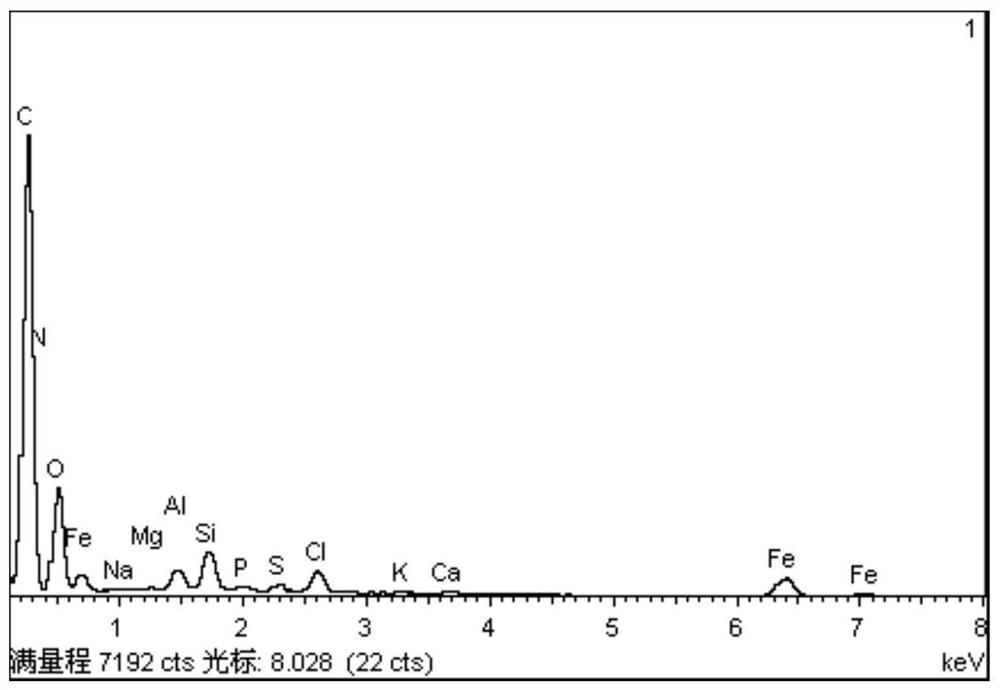

Method for preventing pesticide from being sprayed to strawberry fruits

InactiveCN102919046AControl Pesticide ResiduesAvoid direct contactPlant protective coveringsFragariaPesticide

The invention belongs to the technical field of strawberry cultivation, and particularly relates to a method for preventing a pesticide from being sprayed to strawberry fruits. According to the method, through the steps of setting up a fruit covering shed, separating fruits and leaves, picking the fruits and the like, an operating method for preventing the pesticide from being sprayed to the strawberry fruits is established; and the method is simple, low in cost, stable, efficient, and convenient to use.

Owner:JINLING INST OF TECH

Method for preparing biochar from bottom mud and garden waste and application of biochar

ActiveCN113171750APrevent eutrophicationReduce the amount of fertilizerOther chemical processesWater contaminantsEnvironmental engineeringBiochar

The invention provides a method for preparing biochar from bottom mud and garden waste and application of the biochar. The preparation method comprises the following steps: cleaning and drying bottom mud and garden waste, crushing for later use, taking the bottom mud and the garden waste according to a mass ratio of 1:(0.25-4), adding water, uniformly mixing, drying to obtain a mixture A, pyrolyzing the mixture A at 300-700 DEG C for 1-5 hours to obtain a mixture B, adding water into NaOH or FeCl3 serving as a modifier, uniformly mixing with the mixture B, and drying to obtain the biochar. The biochar can adsorb nitrogen and phosphorus in a water body to be used by landscape plants, and nutrients are provided for the plants to reduce the fertilizing amount of the plants, so that waste recycling is achieved, the problems that bottom mud and garden waste are difficult to dispose, and the concentration of phosphorus in the water body is high are effectively solved, a virtuous circle of multiple substances in the water body environment is formed, and the maintenance cost of the water body environment is greatly reduced.

Owner:GUANGDONG UNIV OF TECH

A kind of remediation method of cypermethrin polluted soil

ActiveCN103861869BWide variety of sourcesImprove resource utilizationContaminated soil reclamationCypermethrinEdaphic

The invention provides a restoration method of soil polluted by cypermethrin and belongs to the field of application of ecological restoration. The restoration method utilizes corn straws as main materials, uses a muffle furnace to pyrolyze and prepare a soil restoration agent, i.e., biological carbon, then applies the soil restoration agent into the soil polluted by the cypermethrin according to certain proportion to restore the soil. The restoration method mainly comprises the steps of: (1) collecting the materials and preparing the soil restoration agent; (2) applying the soil restoration agent into the soil polluted by the cypermethrin according to certain proportion; (3) detecting and controlling the degradation condition of the substance polluted by the cypermethrin. The restoration method provided by the invention has the advantages that the process is simple, the cost is low, and the application range and conditions are wide; the materials of the biological carbon are agricultural and forestry wastes and bioconversion wastes and are wide in resource, and due to the application of the biological carbon, the soil polluted by the cypermethrin can be effectively restored.

Owner:NANKAI UNIV

Ecological excrement treatment system used in rural area

InactiveCN110526506ALess investmentLow management requirementsTreatment involving filtrationTreatment with anaerobic digestion processesWater qualityEngineering

The invention discloses an ecological excrement treatment system used in a rural area. The ecological excrement treatment system comprises a septic tank, a purification tank and a water-manual aquaticplant ecological ditch, wherein a water inlet is formed in one end of the septic tank and is used for feeding sewage discharged from a water flashing toilet in a rural area into the septic tank; theother end of the septic tank communicates with the purification tank through a communicating tube; and the tail part of the purification tank communicates with the aquatic plant ecological ditch through a communicating tube. The ecological septic tank+wetland system used in the rural area, which is disclosed by the invention, has the advantages of being low in investment, low in management requirement and good in effluent quality, and is adaptive to the characteristics that the management level in the rural area is low and the water quantity is not greatly changed. The system has high social benefits, has large application ranges and wide application prospects in improving living environments in rural areas, and is easy to popularize.

Owner:HOHAI UNIV

Steel-wire brush roller type dust collector

InactiveCN108261855AEasy to moveEasy to operateDispersed particle filtrationCleaning processes and apparatusElectricityEngineering

The invention discloses a steel-wire brush roller type dust collector which comprises a dust collector. An air outlet is arranged at the top of the dust collector and is embedded in the dust collectorspecifically; an air outlet cover arranged at the top of the air outlet and is particularly embedded in the air outlet; a power box is arranged at the top of the dust collector and closely welded with the dust collector; fixing screws are arranged at the top of the power box and embedded in the power box particularly; a fan is arranged in the power box and runs through the inside of the power box. The dust collector provided with the dust-collecting roller and the steel-wire brush can suck air and can brush with the steel-wire brush arranged at a sucking head so as to solve the problem of poor cleaning effect; the dust collector is provided with wheels and accordingly can move conveniently while operation of the dust collector is facilitated; the dust collector is provided with the fan having high power but needing low electricity, and thus work efficiency is improved.

Owner:天津泰广网络科技有限公司

Metallographic detection device and metallographic detection method for corrosion-resistant iron matrix welded joint

PendingCN111855556AAvoid spillingAvoid overall overturningWeather/light/corrosion resistanceCleaning using liquidsElectrolytic agentGraphite

The invention relates to a metallographic detection device and a metallographic detection method for a corrosion-resistant iron matrix welded joint. The device comprises an electrolysis box and a pulse power supply. The pulse power supply is arranged outside the electrolysis box, and the electrolysis box is used for containing electrolyte; the electrolysis box is a closed container made of organicglass, a box cover capable of being opened or closed is arranged at the top of the electrolysis box, a graphite rod is installed on the inner side wall of one side of the electrolysis box, a test piece clamp is installed on the inner side wall of the other side of the electrolysis box, and the graphite rod and a test piece clamp are connected with a pulse power supply through wires connected withthe graphite rod and the test piece clamp respectively to form an electrolysis loop; a liquid injection port is formed above the side, provided with the graphite rod, of the top of the electrolysis box, a liquid outlet connector is formed below the side, provided with a test piece clamp, of the bottom of the electrolysis box, and a switch valve or a detachable blocking piece is installed at the position of the liquid outlet connector. According to the invention, the test operation is facilitated, and the test safety is improved.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com