Metallographic detection device and metallographic detection method for corrosion-resistant iron matrix welded joint

A technology for welding joints and metallographic detection, applied in the direction of measuring devices, chemical instruments and methods, and cleaning methods using liquids, etc., can solve the problems of slow electrolysis process of ordinary DC power supply, inability to form clearly visible metallographic morphology, and corrosion of corrosive solutions Insufficient effect and other problems, to achieve the effect of improving electrolysis efficiency, preventing splashing, and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

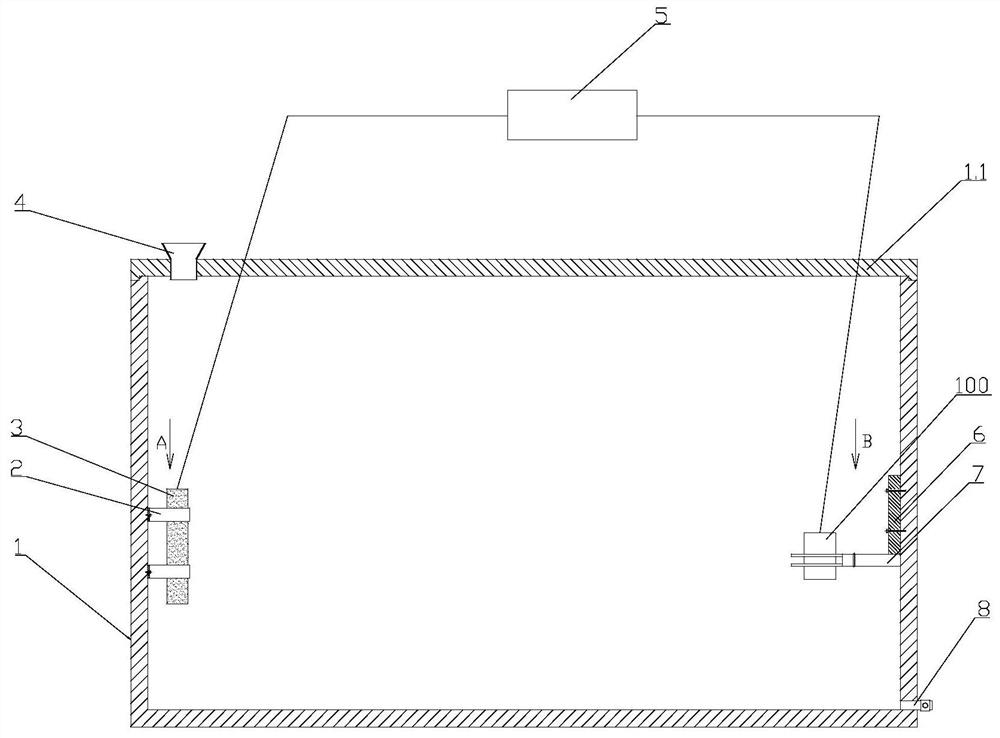

[0035] A metallographic detection device for corrosion-resistant iron matrix welded joints, see Figure 1-3 , its invention point is: include electrolysis box 1 and pulse power supply 5. The pulse power supply is arranged outside the electrolytic box, and the electrolytic box is used to contain electrolyte;

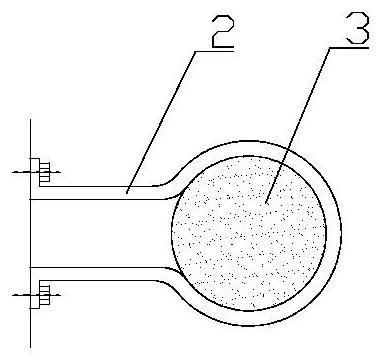

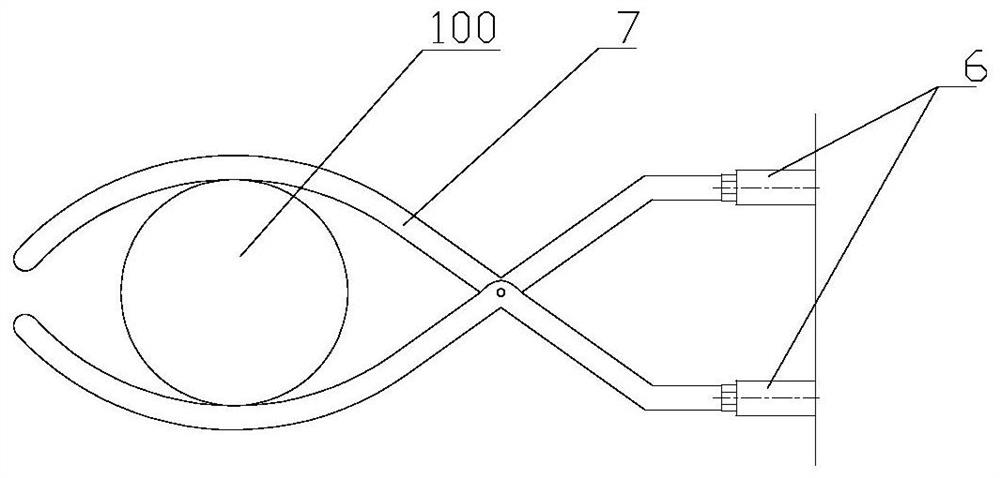

[0036] The electrolytic box is an airtight container made of plexiglass. The top of the electrolytic box is provided with an openable lid 1.1. A graphite rod 3 is installed on one side of the electrolytic box, and on the other side of the electrolytic box. A test piece holder is installed, and the graphite rod and the test piece holder are respectively connected to the pulse power supply through their respective connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com