High-corrosion-resistance permanent magnet rich in high-abundance rare earth and preparation method of high-corrosion-resistance permanent magnet rich in high-abundance rare earth

A rare earth permanent magnet, high abundance technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of high melting point, poor grain boundary bonding, etc., to achieve a simple process, increase the proportion, The effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The main phase alloy is divided into nominal composition (La 0.2 Ce 0.3 PR 0.1 Nd 0.4 ) 31 Fe 67 Z 1.0 B 1.0 The wt.% ratio is weighed, and the alloy powder is prepared by induction melting, quick-setting casting, hydrogen explosion and jet milling. The average particle size of the powder is about 3.5 μm, where Z is Al=0.2, Co=0.3, Cu= 0.4, Ga=0.1;

[0038] The auxiliary alloy is divided into nominal composition (Ce 0.8 PR 0.1 Nd 0.1 ) 56 Fe 44 wt.% proportioning and weighing, induction melting, alloy 800°C vacuum homogenization heat treatment for 10 hours, mechanical crushing, jet milling powder, the average particle size of the powder is about 1.0 μm;

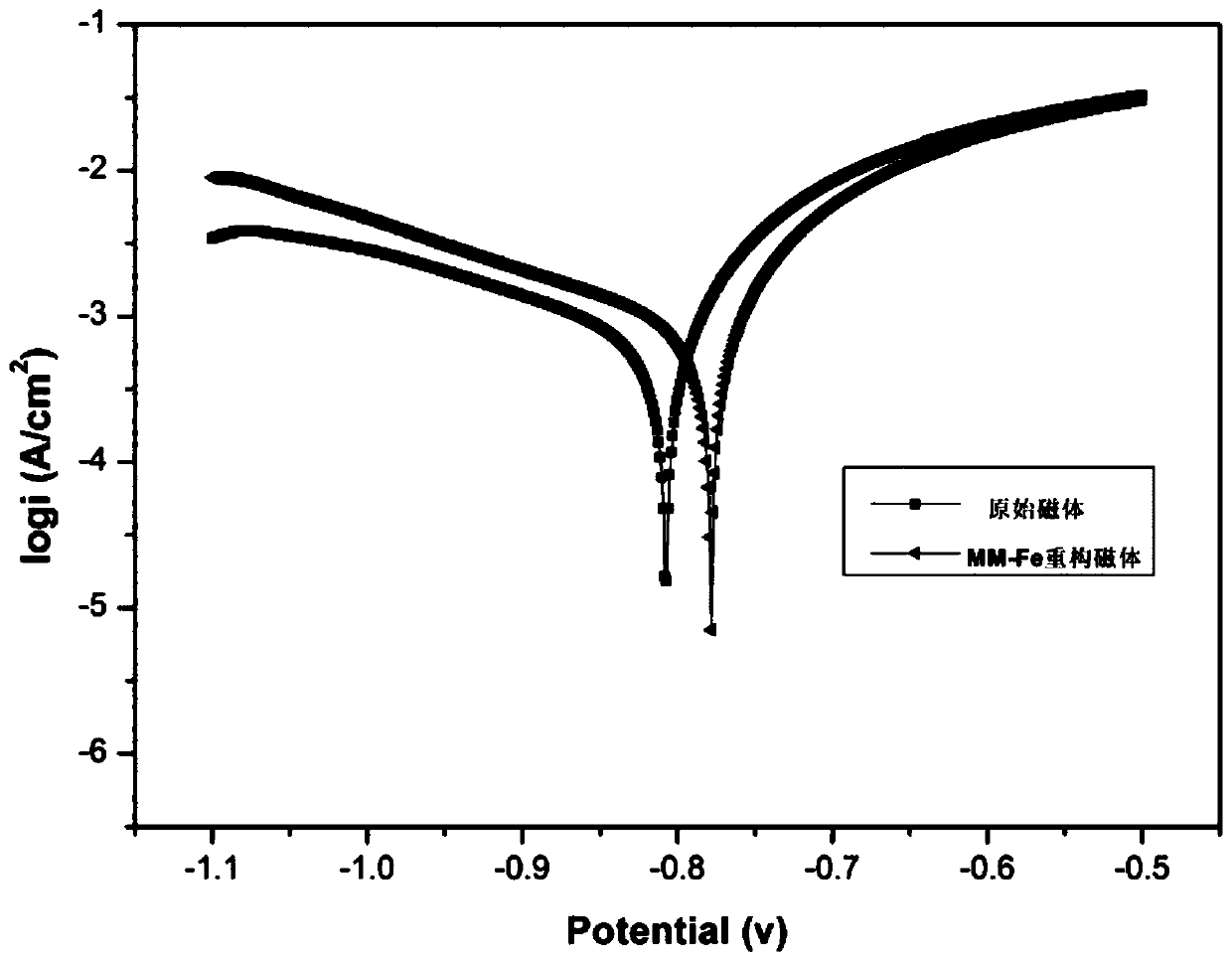

[0039] The obtained main phase alloy powder and auxiliary alloy powder are placed in a mixer in a protective atmosphere (nitrogen or argon) according to a certain ratio, and 0.05% of antioxidant is added at the same time, and uniformly mixed for 0.5-1.0h. Wherein, the mass percent of MM-Fe auxiliary alloy ...

Embodiment 2

[0048] The main phase alloy is weighed according to the nominal composition (La0.1Ce0.4Pr0.1Nd0.4)28.5Fe69.5N1.0B1.0wt.%, prepared by induction melting, quick-setting casting, hydrogen explosion and jet milling Alloy powder, the average particle size of the powder is about 3.5μm, where N is Al=0.2, Cu=0.5, Zr=0.1, Nb=0.1, Ga=0.1;

[0049] The auxiliary alloy is weighed according to the nominal composition of Ce56Fe44wt.%, and the alloy is subjected to induction melting, vacuum homogenization heat treatment at 800 °C for 10 hours, mechanical crushing, high-energy ball milling, and the average particle size of the powder is about 0.8 μm;

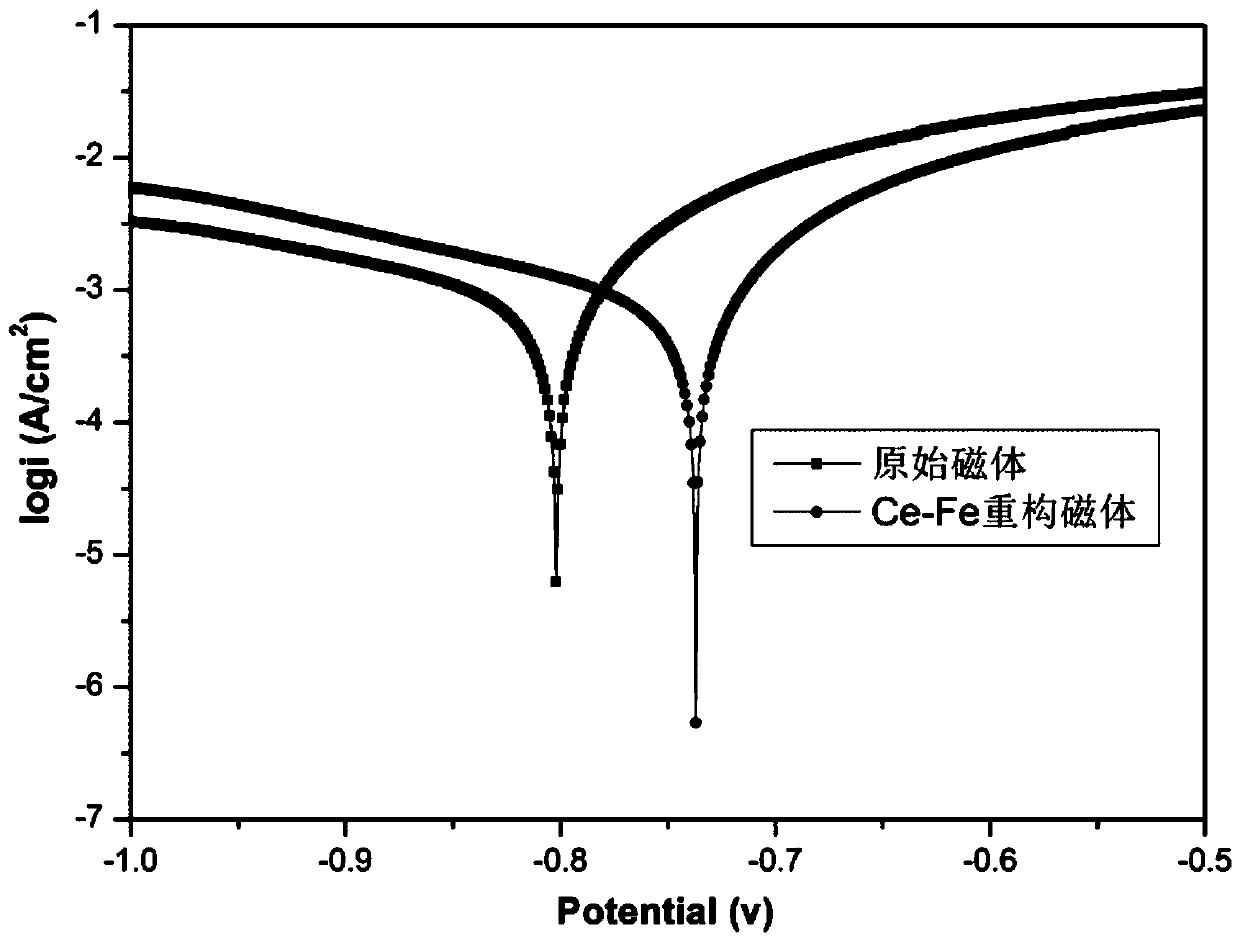

[0050] The obtained main phase alloy powder and auxiliary alloy powder are placed in a mixer in a protective atmosphere (nitrogen or argon) according to a certain ratio, and 0.05% of antioxidant is added at the same time, and uniformly mixed for 0.5-1.0h. Wherein, the mass percent of Ce-Fe auxiliary alloy powder is 5%;

[0051] The uniformly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com