A fully automatic assembly and testing machine for electronic transformers

An electronic transformer, assembly and testing technology, applied in the manufacture of inductors/transformers/magnets, measuring electrical variables, instruments, etc., can solve problems such as low degree of automation, inability to intelligently cooperate with equipment test data, analysis data, and cumbersome structural devices. Achieve the effects of high automation, rapid analysis and integration, and structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

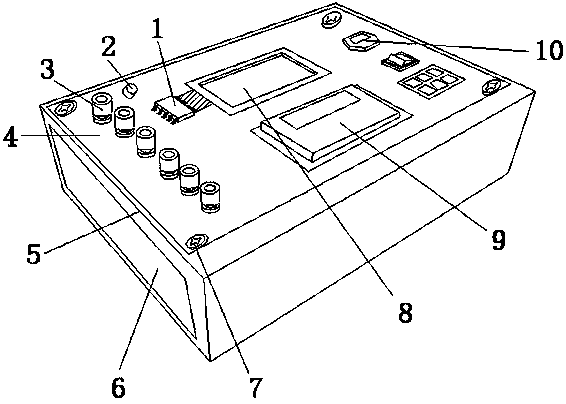

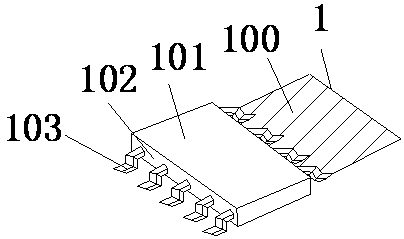

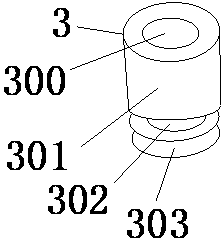

[0021] see figure 1 , figure 2 and image 3 , the present invention provides a fully automatic assembly and testing machine for electronic transformers: its structure includes: intelligent single-chip microcomputer 1, adjustment knob 2, terminal tube 3, integrated circuit board 4, aluminum alloy frame 5, anti-collision side plate 6, fixing bolt 7 , a data display board 8, a program memory board 9, and a power socket 10, the terminal tubes 3 are provided with more than two wires arranged in a straight line and vertically fixed on the integrated circuit board 4, the terminal tubes 3 and The integrated circuit board 4 is electrically connected, the adjustment knob 2 is arranged on the integrated circuit board 4, and the adjustment knob 2 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com