Parametric analysis method of effect of injection molding process to plastic part buckling deformation

A technology of injection molding process and process parameters, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low efficiency, achieve the effect of improving analysis efficiency and reducing manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific steps of the parametric analysis method of the influence of the injection molding process on the warping deformation of the plastic part of the present invention are as follows:

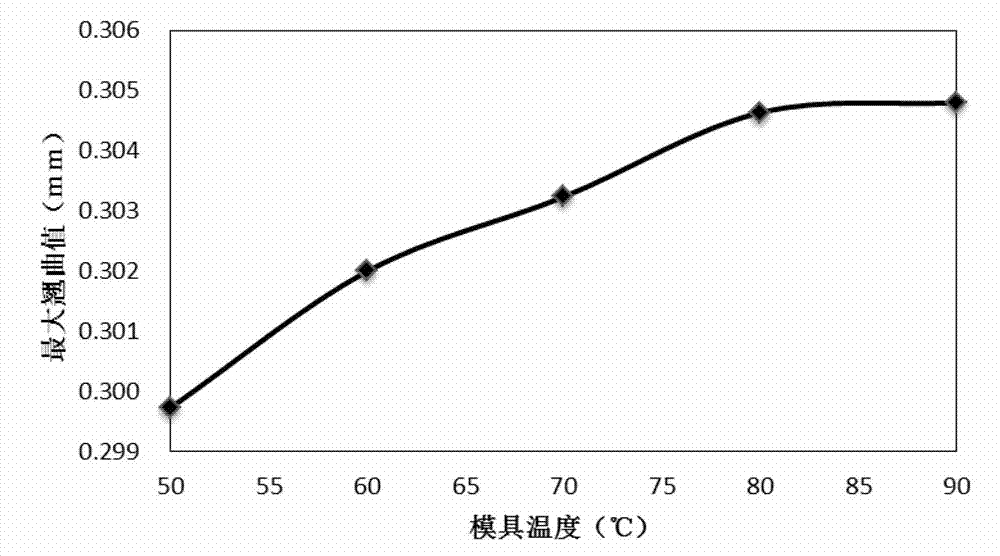

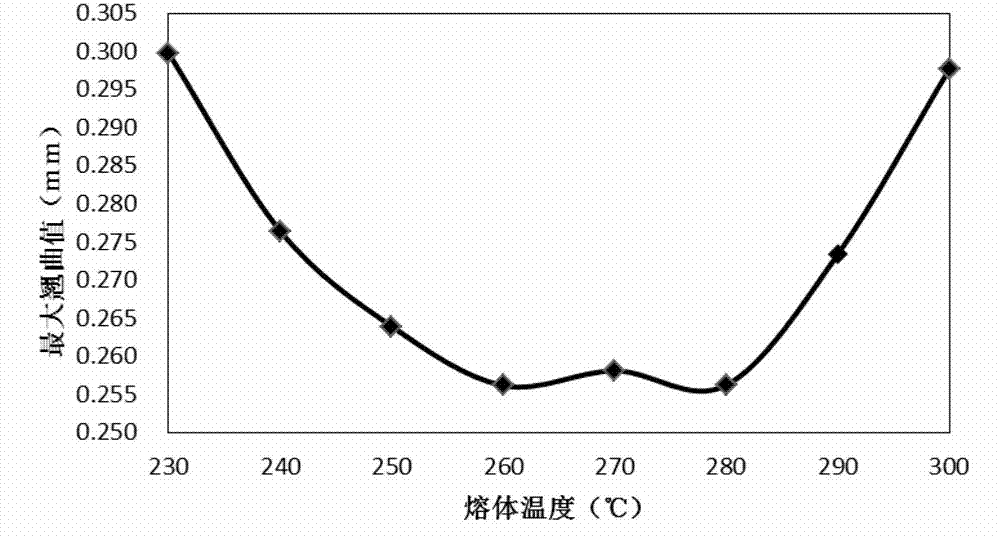

[0021] refer to Figure 1~5 . The research object selected in this embodiment is a certain type of mobile phone casing, the thickness of the geometric model of the casing is 1 mm, and the length, width, and height are 130 mm, 55 mm, and 11 mm, respectively. The injection molding material is PC / ABC, the grade is MultilonTN-3812B, and the single-gate pouring system is adopted. Select mold temperature, melt temperature, holding pressure, and holding time as the analysis objects of this embodiment.

[0022] Step 1: According to the secondary development interface provided by the MoldFlow software, use the programming language Visual Basic to write the MoldFlow secondary development program to realize the parametric automatic execution of the injection molding simulation, including t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com