Patents

Literature

36 results about "Parameterized computation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

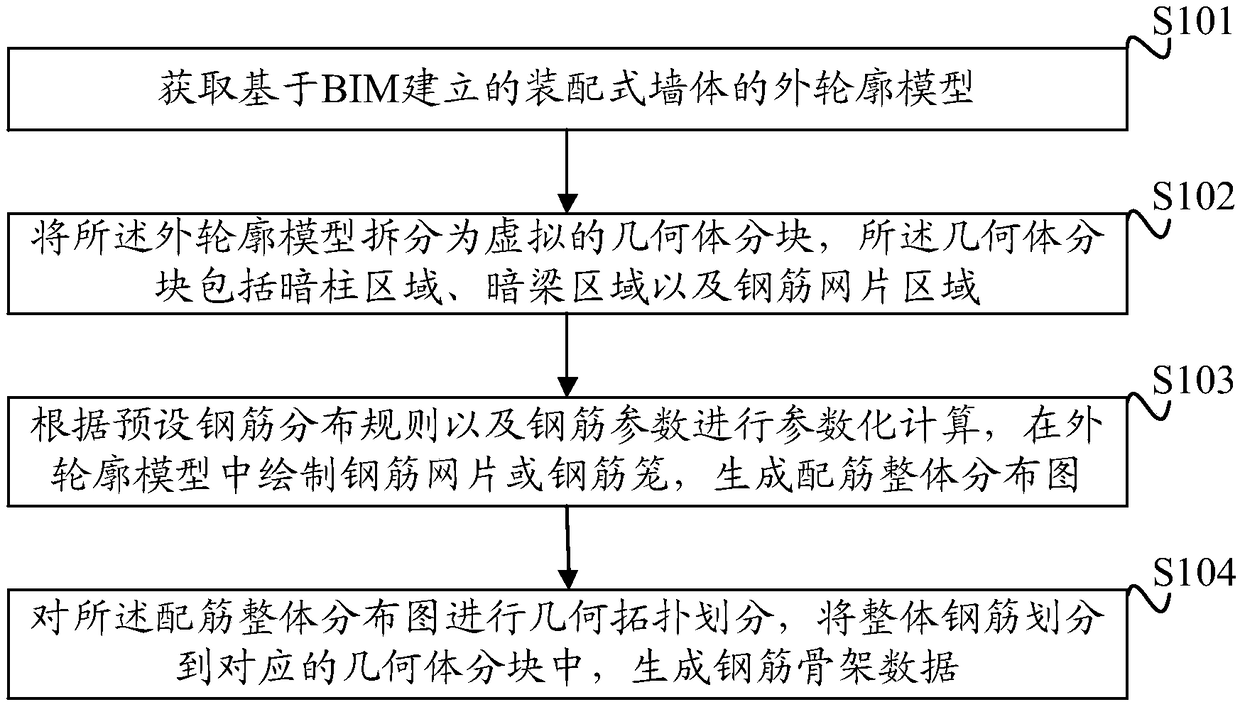

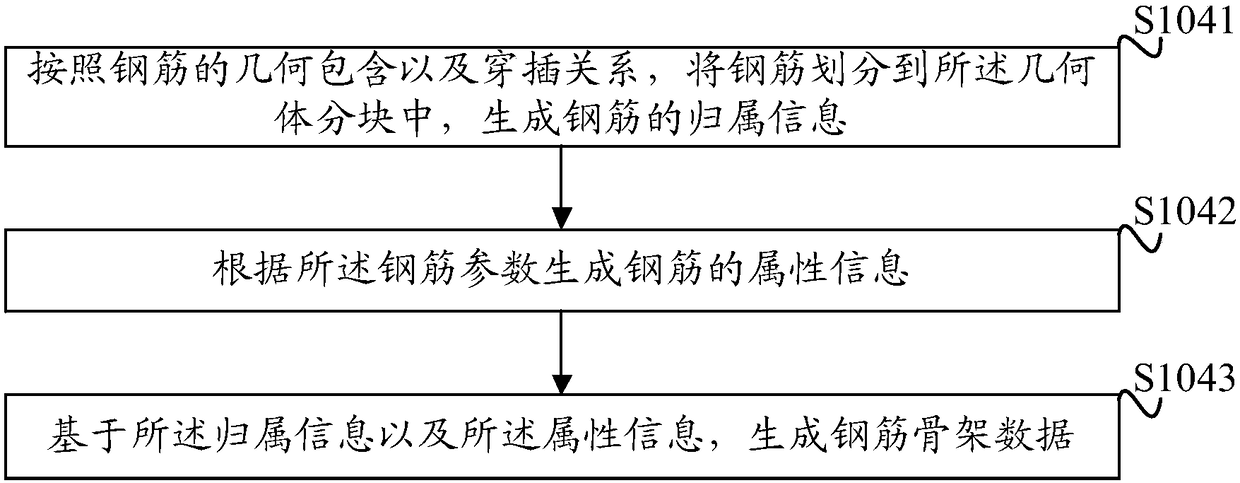

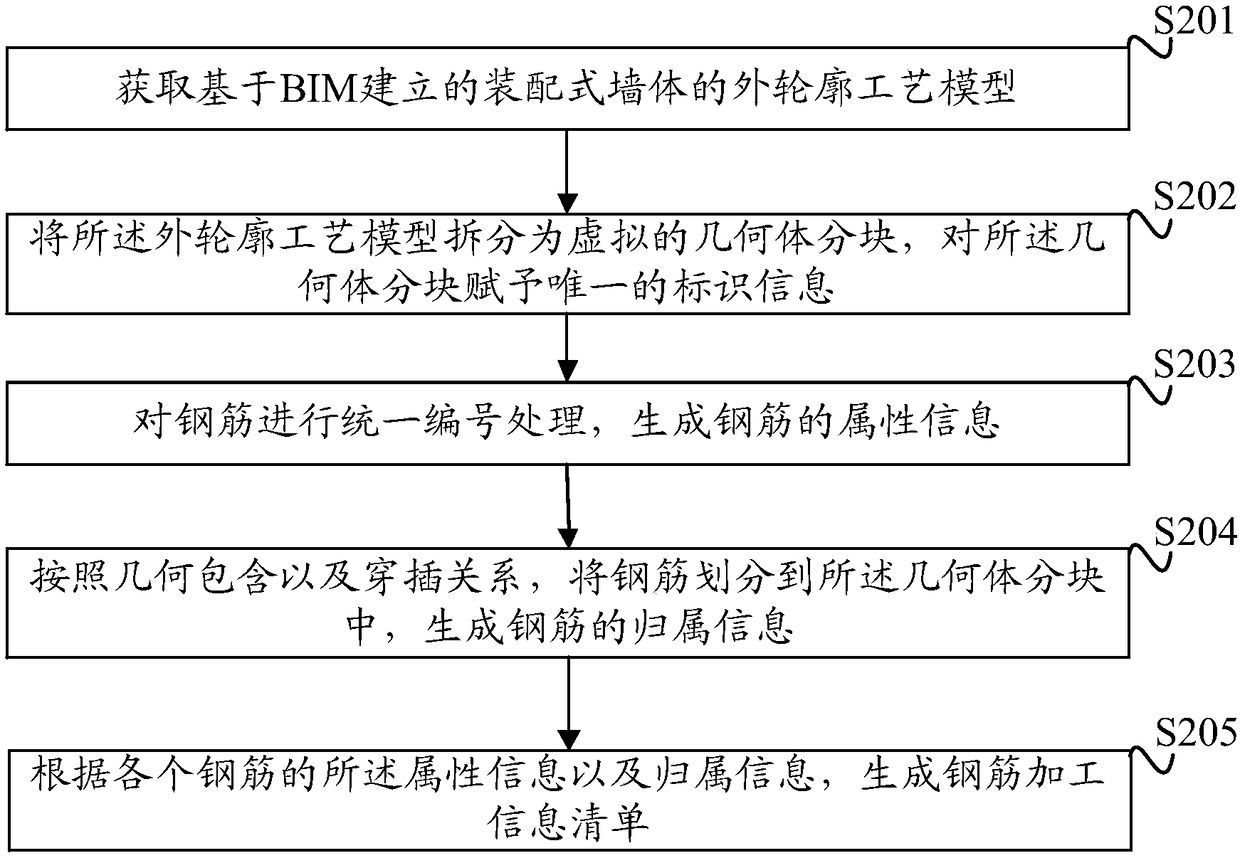

Prefabricated wall body steel reinforcement data processing method and apparatus

The invention discloses a prefabricated wall body steel reinforcement data processing method and apparatus. The method comprises the steps of obtaining an outer contour model of a prefabricated wall body, built based on a BIM; splitting the outer contour model into virtual geometry blocks, wherein each geometry block comprises a beam region, a column region, a hidden column region, a hidden beam region and a steel reinforcement mesh region; according to preset steel reinforcement distribution rules and steel reinforcement parameters, performing parametric calculation, and drawing steel reinforcement meshes or steel reinforcement cages in the outer contour model to generate an overall reinforcement distribution graph; and performing geometric topology division on the overall reinforcement distribution graph, and dividing overall steel reinforcement in the corresponding geometry blocks to generate steel reinforcement framework data. The steel reinforcement framework data can be quickly generated by adopting a virtual modeling method. Furthermore, the steel reinforcement is subjected to collection processing by a geometric topology relationship; initial process data required for steelreinforcement cage and mesh machining can be formed; and a feasible digital modeling method is provided for industrial large-scale mechanical building steel reinforcement processing.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

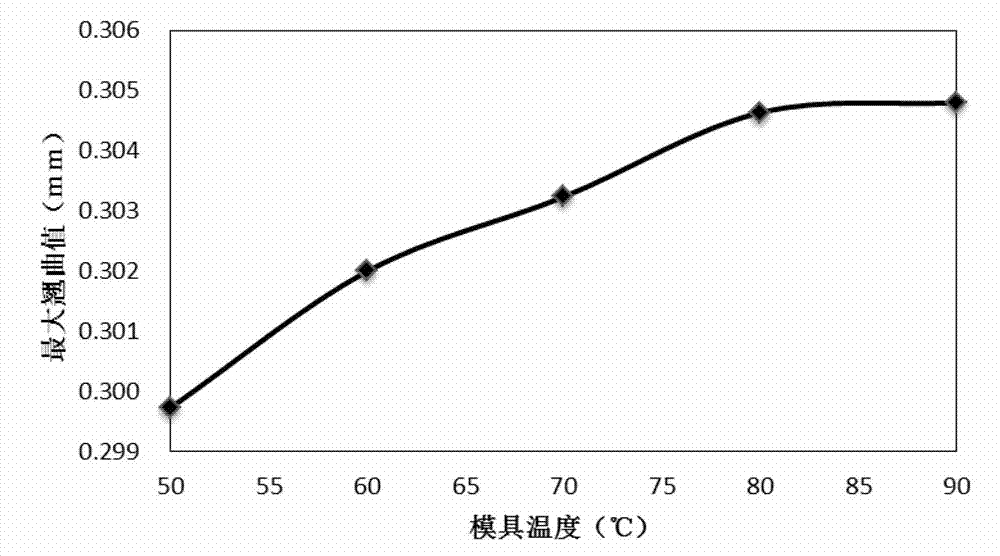

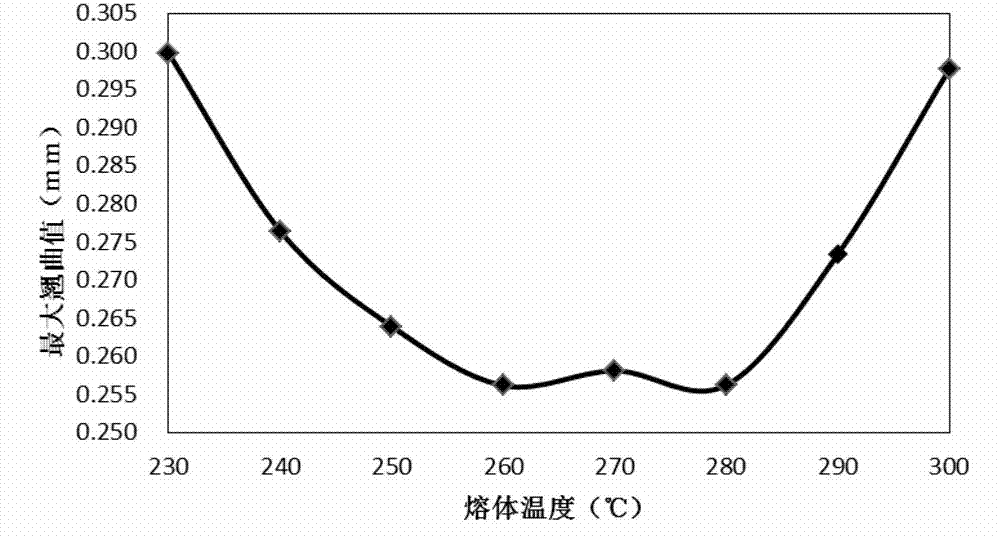

Parametric analysis method of effect of injection molding process to plastic part buckling deformation

InactiveCN103093062AQuick analysisEfficient analysisSpecial data processing applicationsSimulationInjection molding process

The invention discloses a parametric analysis method of effect of an injection molding process to plastic part buckling deformation and aims to solve the technical problem that the prior parametric analysis method of plastic part buckling deformation is low in efficiency. The technical scheme is that the parametric analysis method of effect of the injection molding process to plastic part buckling deformation comprises of first, conducting secondary development to a commercialize mold flow analysis software MoldFlow to achieve parametric calculation and background execution of injection molding numerical modeling; then embedding MoldFlow secondary development procedures into an open-type multidisciplinary parametric analysis and optimization design platform BOSS Quattro, and automatically modifying process parameters according to a BOSS Quattro parametric analysis module and invoking the MoldFlow secondary development procedures to calculate plastic part buckling deformation; and last, acquiring plastic part buckling deformation under conditions of different process parameter values after automatically modifying and calculating the plastic part buckling deformation for several times. Analysis results of the parametric analysis method of effect of the injection molding process to plastic part buckling deformation provides variation tendencies of buckling deformation within each parameter value range, and provides the basis for arrangement of process parameters in the practical production. The whole analysis process is automatically finished, human input is reduced and analysis efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

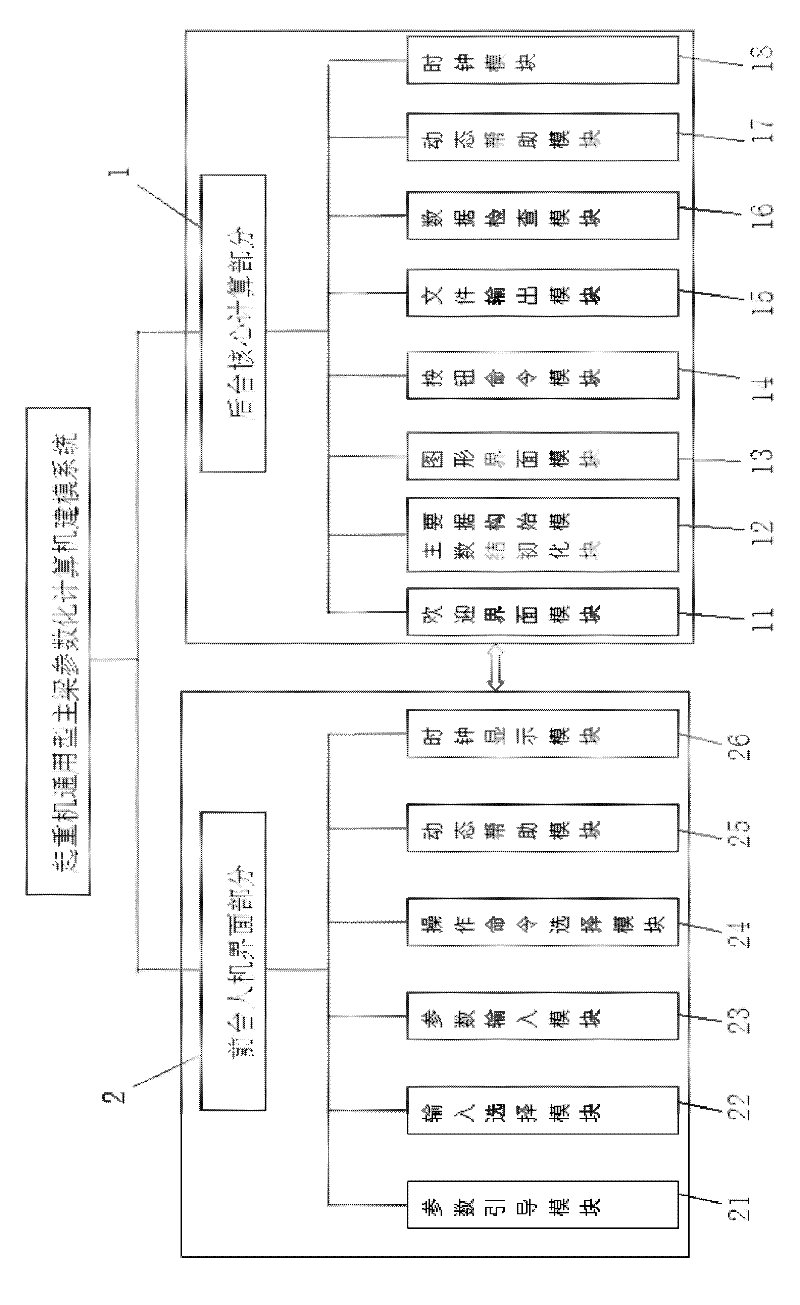

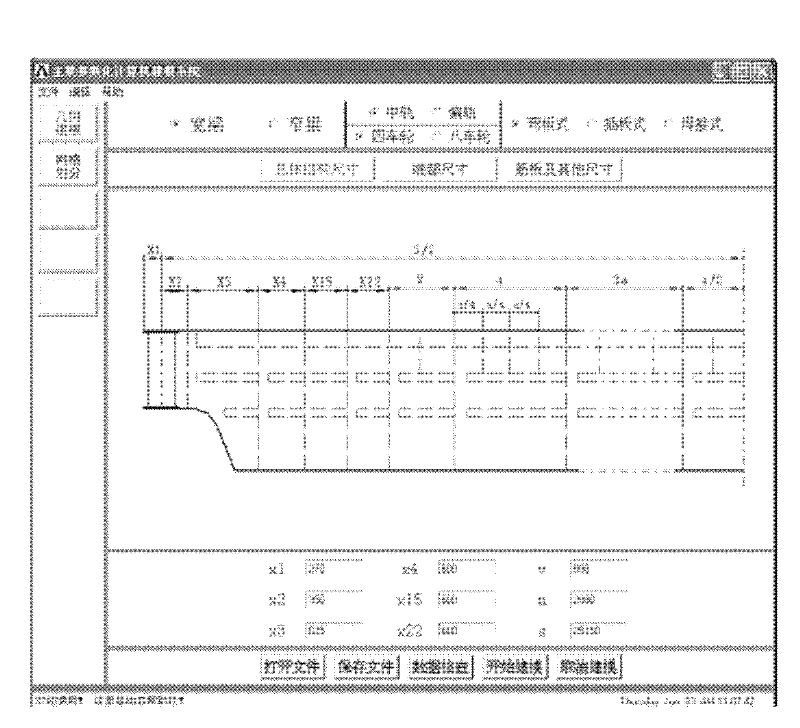

A Parameterized Computer Modeling System for Universal Main Girder of Crane

InactiveCN102289530APowerful parametric modeling capabilitiesPrevent Modeling Analysis FailuresSpecial data processing applicationsGraphicsGeneral purpose

The invention discloses a parametric computer modeling system for a universal main girder of a crane, which includes a front man-machine interface part and a background core calculation part, wherein the background core calculation part includes a welcome interface module, a main data structure initialization module, a graphics Interface module, button command module, parameter output module, data inspection module, dynamic help module, clock module, the front man-machine interface part includes parameter guidance module, input selection module, parameter input module, operation command selection module, dynamic help module , clock display module, the characteristics of the present invention have powerful main girder parameter modeling capabilities, perfect data error checking capabilities, good human-computer interaction, good compatibility and portability, and provide guidance for the design and manufacture of large crane girders Opinions, improve the design efficiency and processing quality of the main beam, and reduce the cost of the main beam product.

Owner:SHANGHAI ELECTRICGROUP CORP

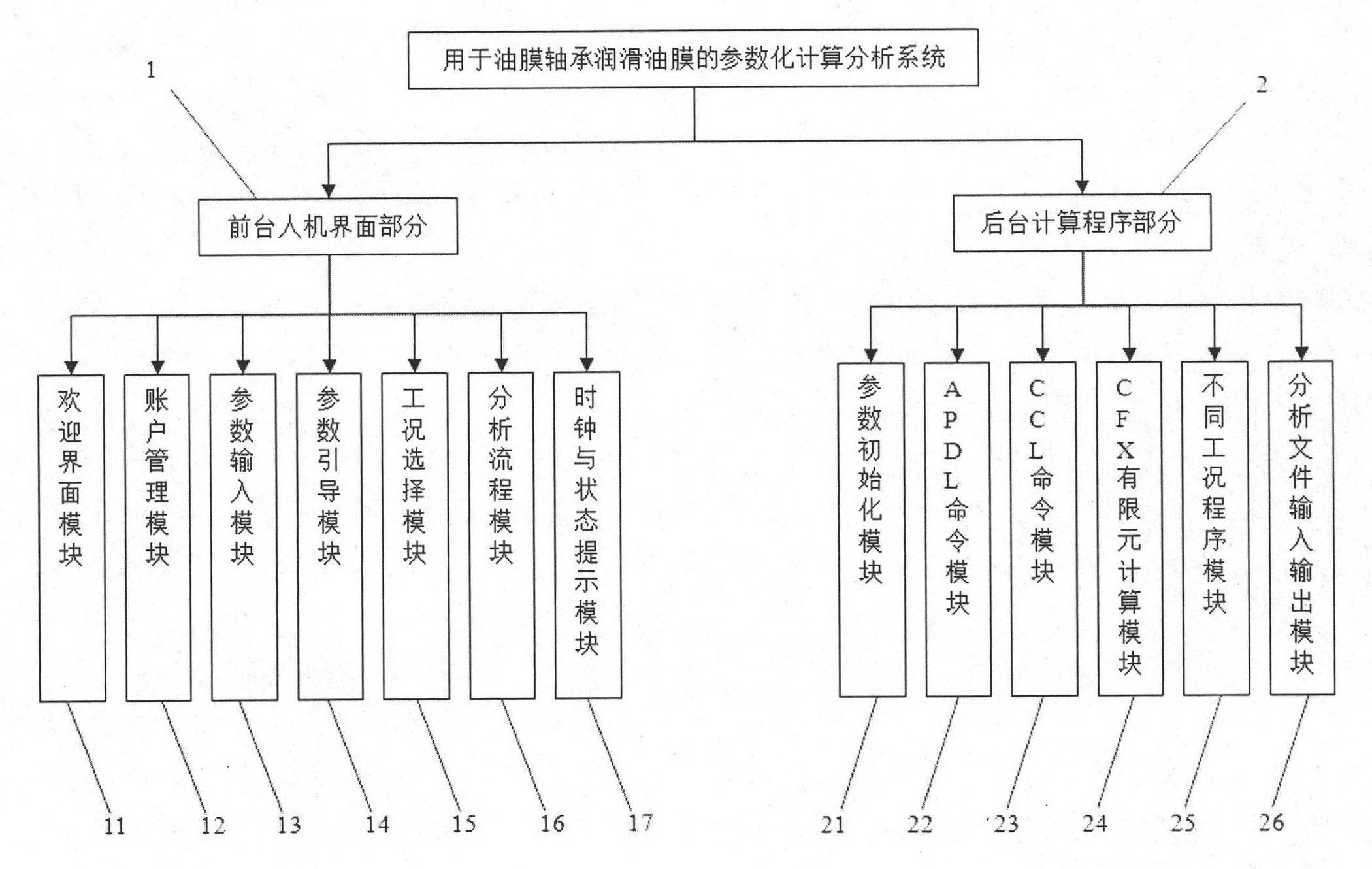

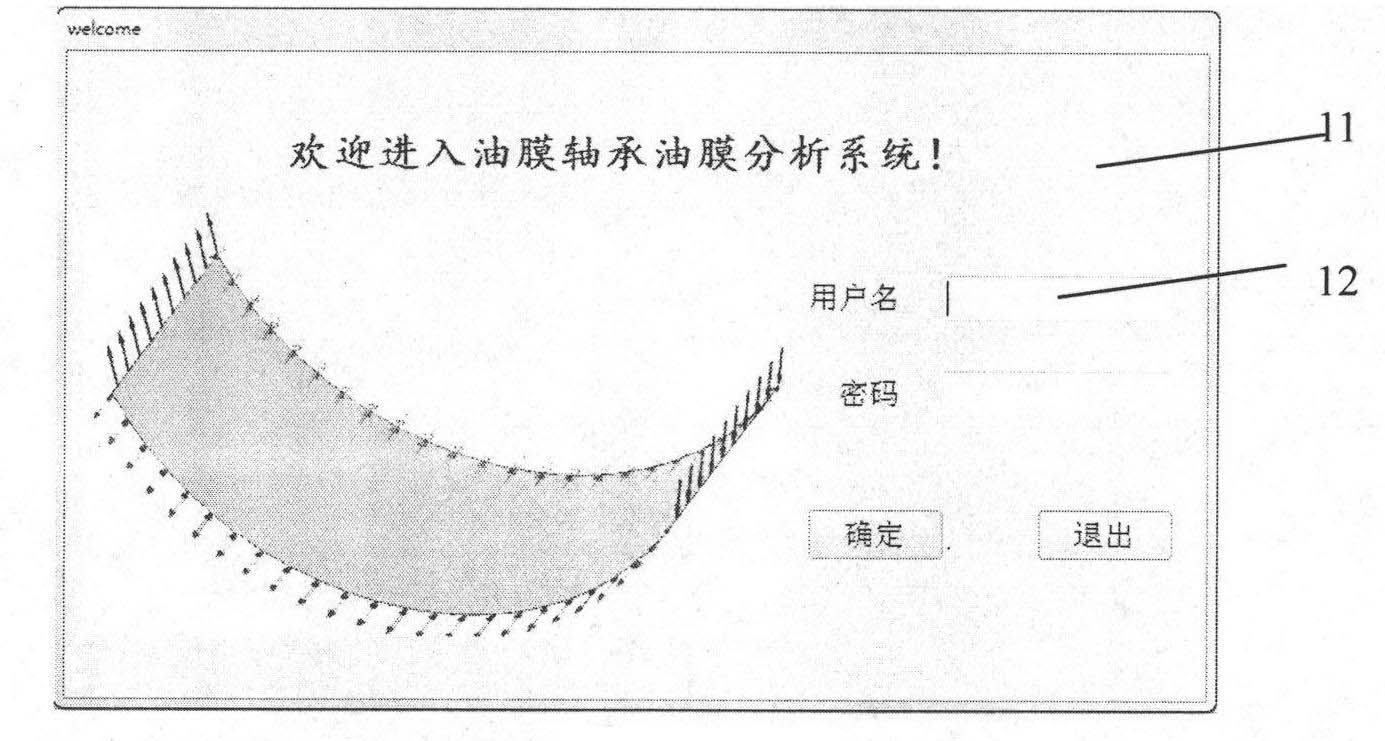

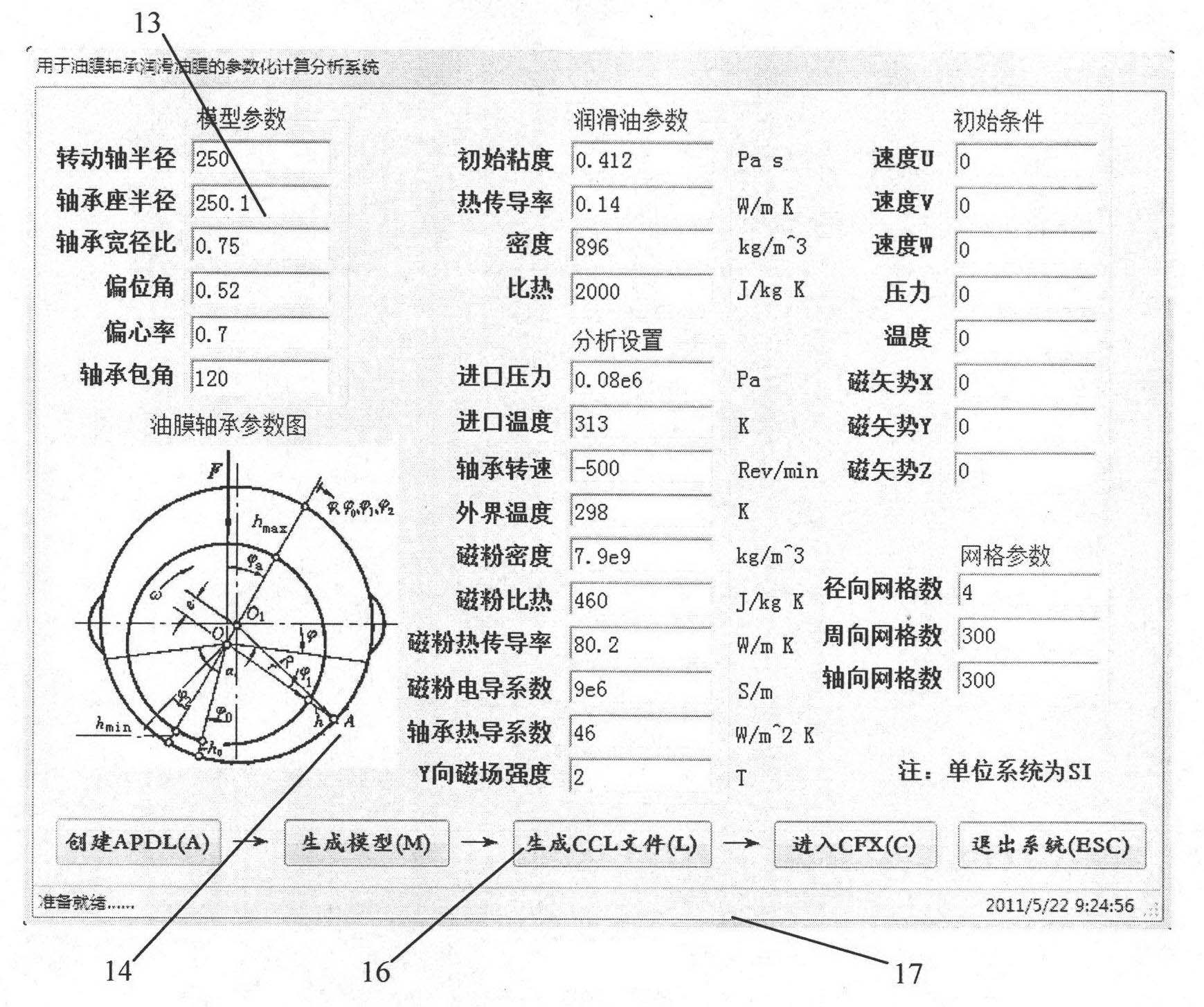

Parameterized computational analysis system for lubricating oil film of oil film bearing and operating method of parameterized computational analysis system

InactiveCN102214260AIntuitive finite element calculation and analysisThe finite element calculation and analysis are convenientSpecial data processing applicationsCommand languageComputer science

The invention discloses a parameterized computational analysis system for a lubricating oil film of an oil film bearing and an operating method of the parameterized computational analysis system. The invention belongs to the technical field of designing of the oil film bearing. A foreground human-computer interface comprises a welcoming interface module, an account management module, a parameter input module, a parameter guide module, a working condition selection module, an analysis flow module and a clock and state prompt module. A background computation program comprises a parameter initialization module, an Ansys parametric design language (APDL) command module, a common command language (CCL) command module, a compound file explorer (CFX) finite element computation module, a different-working-condition program module and an analysis file input / output module. The operating method comprises the following steps of: (1) installing an Ansys in a D disk; (2) starting the parameterized computational analysis system and logging in the system; (3) inputting corresponding parameters; (4) generating an APDL file; (5) starting the Ansys in the background, and generating a model; (6) generating a CCL file; (7) activating a CFX, and carrying out CFX pre-processing; (8) importing an analysis file, and directly solving; (9) carrying out CFX post-processing, checking an analysis result, and outputting an analysis report; and (10) logging out of the system.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

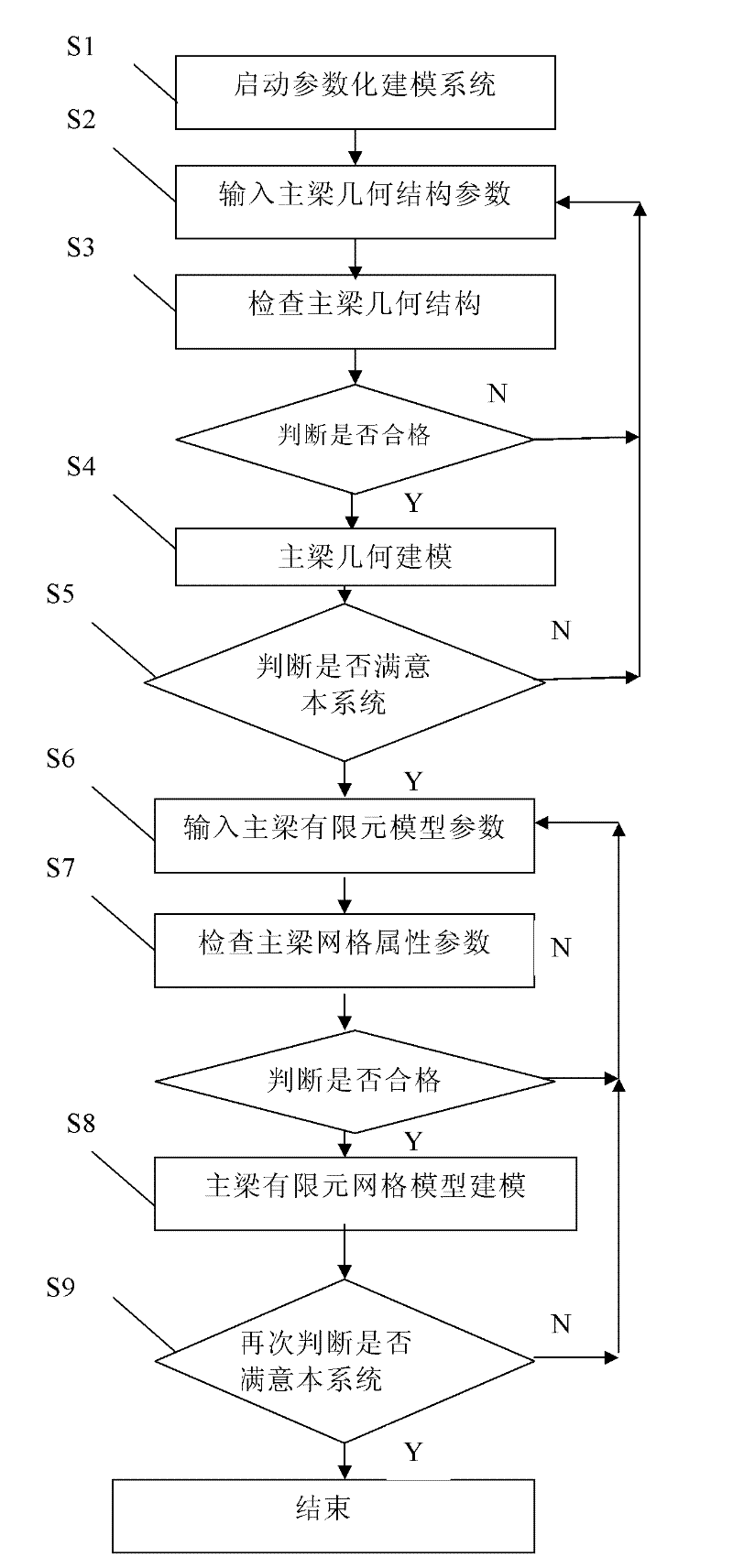

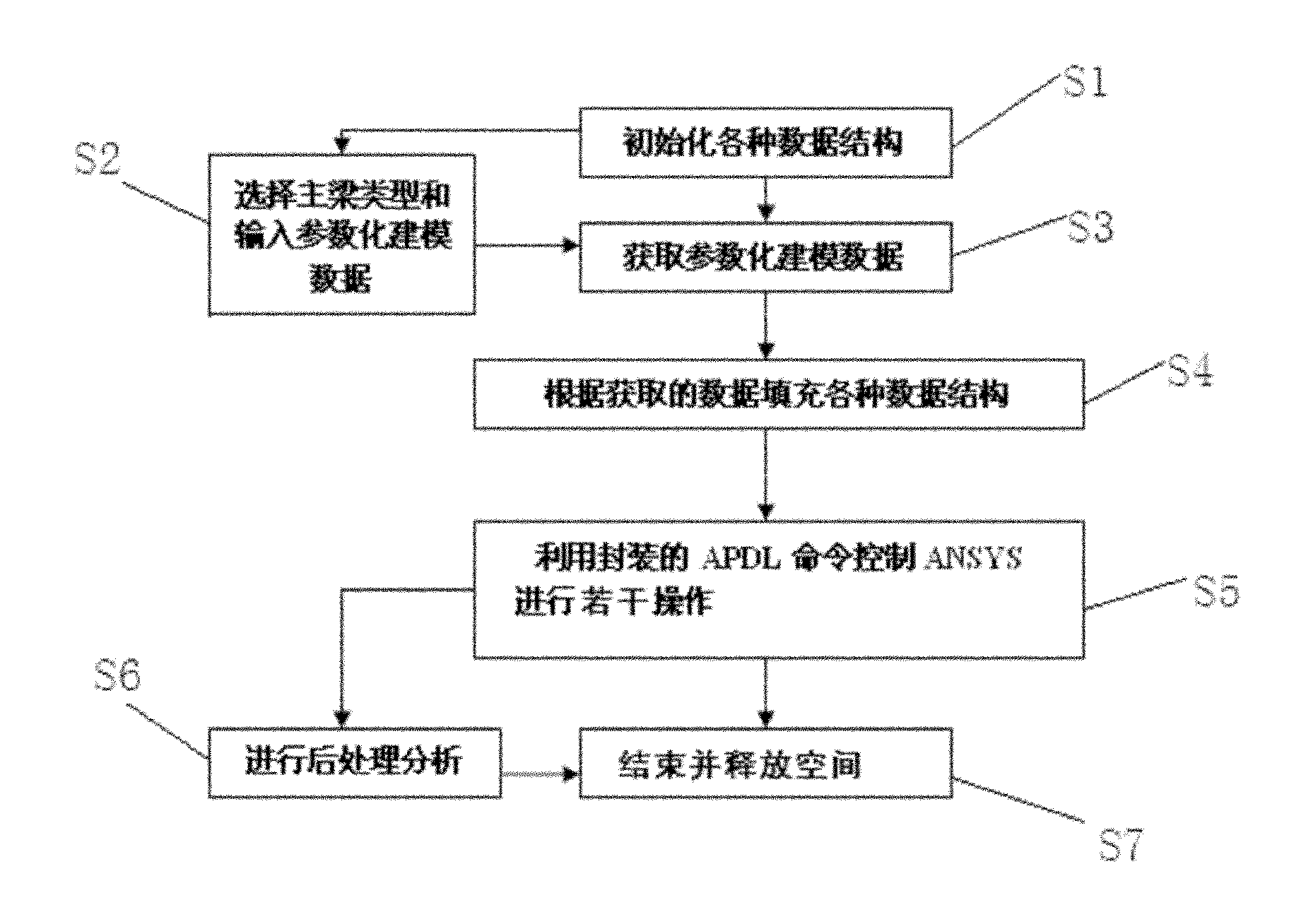

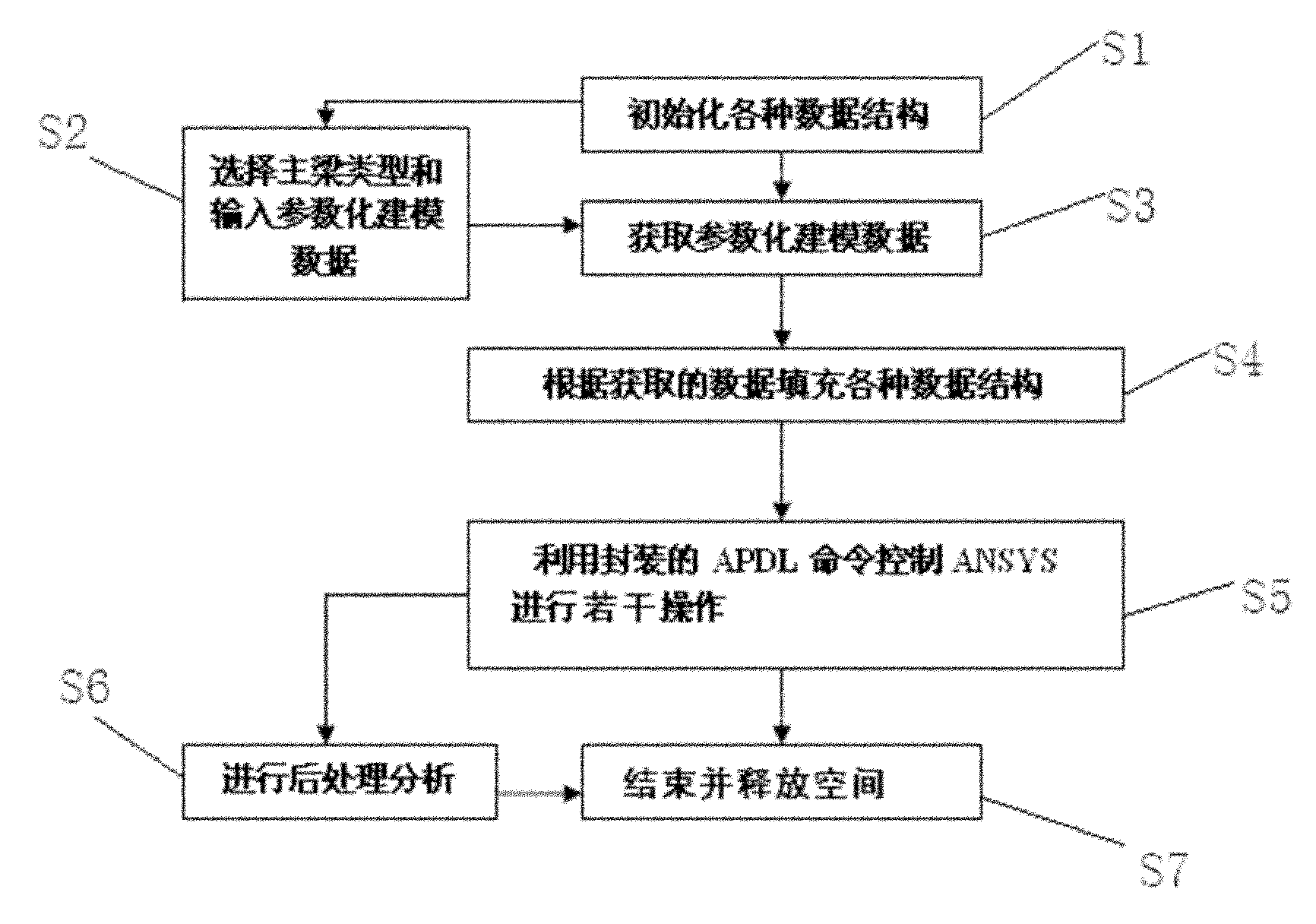

Parameterized computer modeling method for universal main girders of cranes

InactiveCN102375904APowerful parametric modeling capabilitiesPrevent Modeling Analysis FailuresSpecial data processing applicationsSimulationData filling

The invention discloses a parameterized computer modeling method for universal main girders of cranes, which comprises the following steps of: initializing various data structures; selecting the type of a main girder, and inputting parameterized modeling data; acquiring the parameterized modeling data; according to the acquired data, filling the various data structures; controlling a ANSYS to carry out a plurality of operations by using a packaged APDL (ANSYS parametric design language) command; carrying out post-processing analysis; and completing the modeling and releasing the space. The parameterized computer modeling method for universal main girders of cranes disclosed by the invention is a convenient, easy-to-use and reliable parameterized computer modeling method for main girders, which is re-developed on the basis of the current computer analysis system.

Owner:SHANGHAI ELECTRICGROUP CORP +1

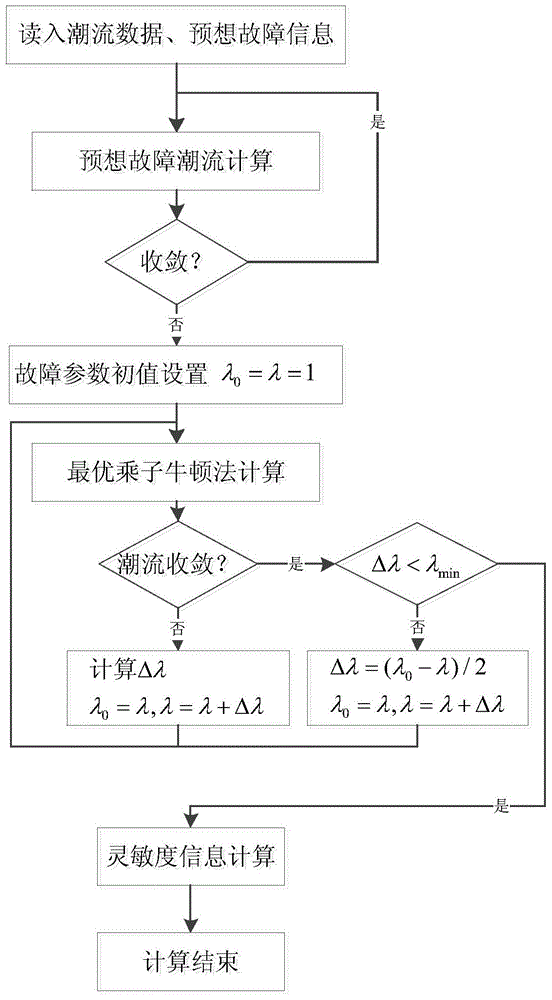

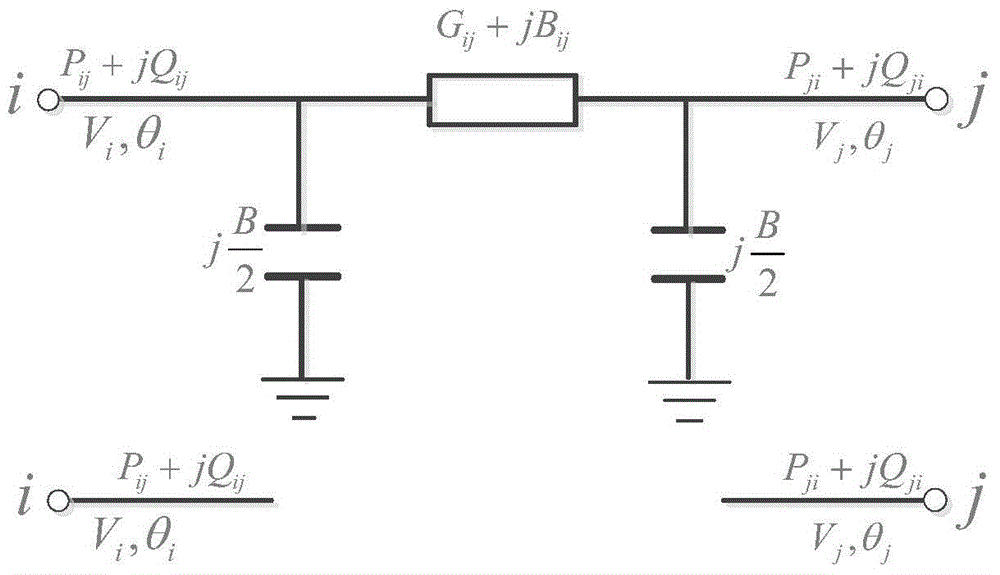

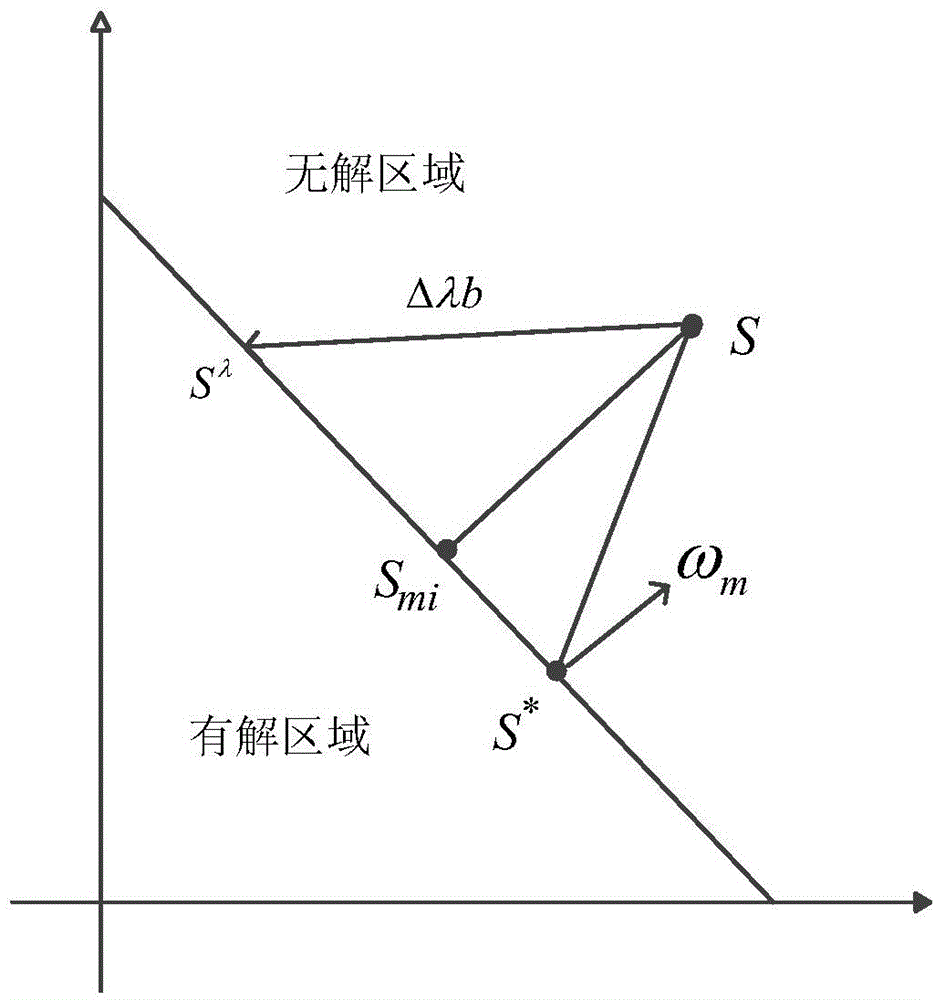

Method for using static security analysis to assess flow insolubility of anticipated faults

ActiveCN104617575AMake up for the lack of detailed analysis and calculationPerfect static security analysis functionSpecial data processing applicationsAc network circuit arrangementsSeverity levelEngineering

The invention discloses a method for using static security analysis to assess flow insolubility of anticipated faults. The method for using the static security analysis to assess the flow insolubility of the anticipated faults includes: simulating a fault parameterization calculation model when flow of N-k anticipated faults which include faults of a single device or breaking faults of device groups are unsolvable by establishing the static security analysis, and solving unsolvable fracture surfaces of the fault flow based on an optimal multiple factor Newton method base principle, and finally obtaining a fault parameter result which represents the severity level of the flow insolubility and can be an assessment basis of the static security analysis for the severity level of the flow insolubility of the anticipated faults . The method for using the static security analysis to assess the flow insolubility of the anticipated faults calculates characteristic vector according to critical point jacobian matrix information, can provide sensitivity information to prevention and control, and remedies the defect that the flow insolubility of the severe anticipated faults can not be thoroughly analyzed and calculated, caused by the static security analysis.

Owner:NARI TECH CO LTD +1

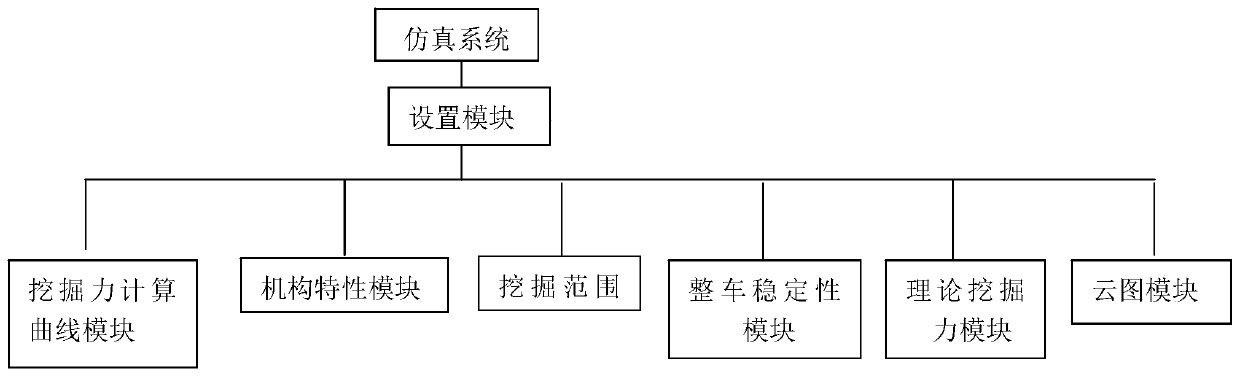

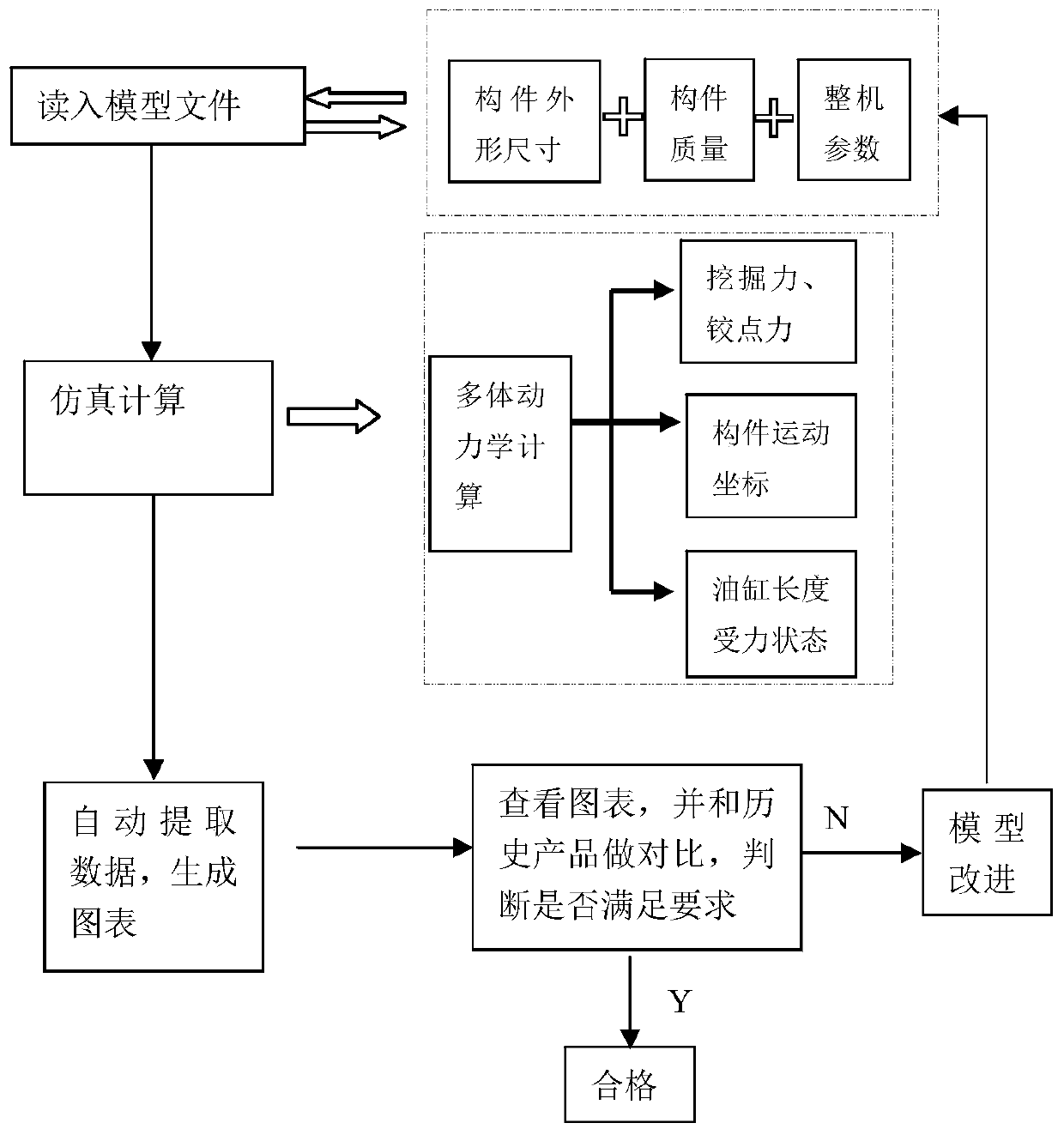

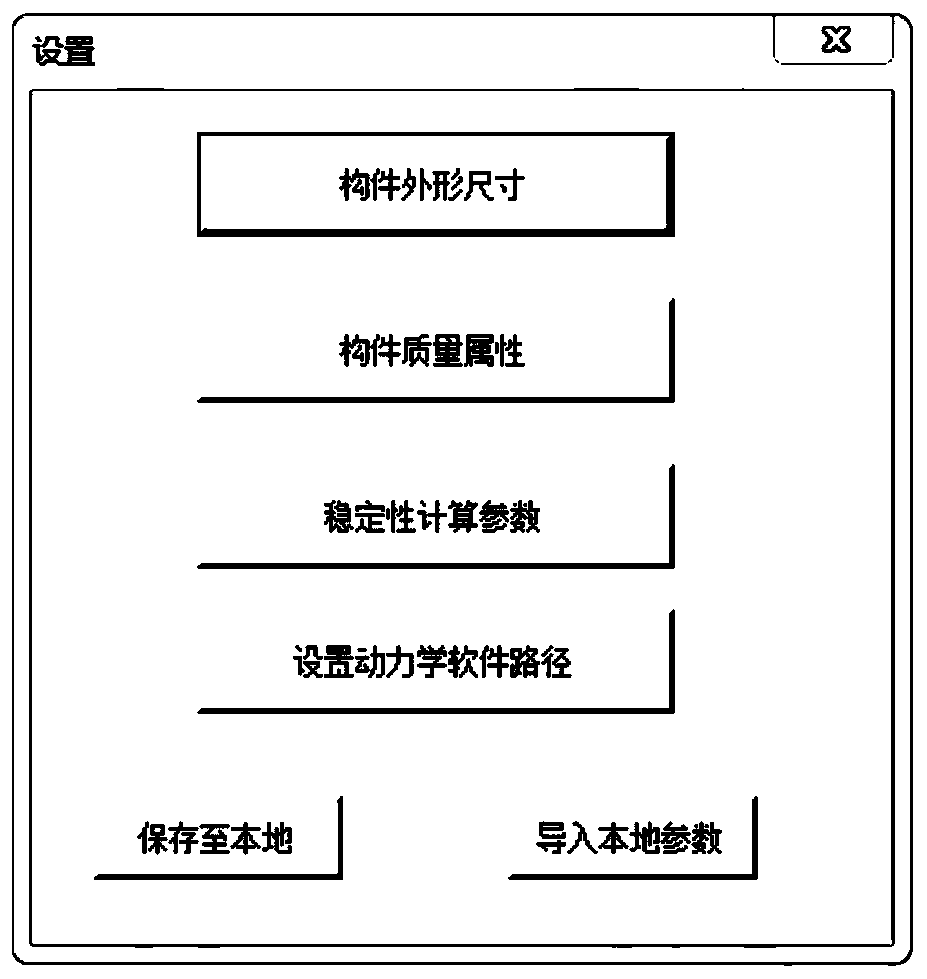

Excavator working device performance simulation calculation method based on VBA system

PendingCN111027153AImprove computing efficiencySave time and costGeometric CADSustainable transportationControl engineeringModularity

The invention provides an excavator working device performance simulation calculation method based on a VBA system. A simulation system based on VBA is included, the simulation system based on VBA isconnected with multi-body dynamics software, the simulation system based on VBA comprises a setting module, and the setting module is connected with an excavation force calculation curve module, a mechanism performance curve module, an excavation range module, a whole vehicle stability module, an oil cylinder theoretical excavation force module and a cloud picture module. According to the method,parameterization of the multi-body dynamic model of the working device, automation of the calculation and analysis process and modularization of basic performance calculation are achieved, the calculation efficiency is greatly improved, and the personnel and time cost is saved. Due to the fact that performance calculation of the working device is modularized and shares one input file, when one module is improved, only the input file needs to be changed, other modules do not need to be input again, other modules automatically update results, the simulation efficiency is improved in a modularized mode, and use is easy and fast.

Owner:QINGDAO LOVOL EXCAVATOR

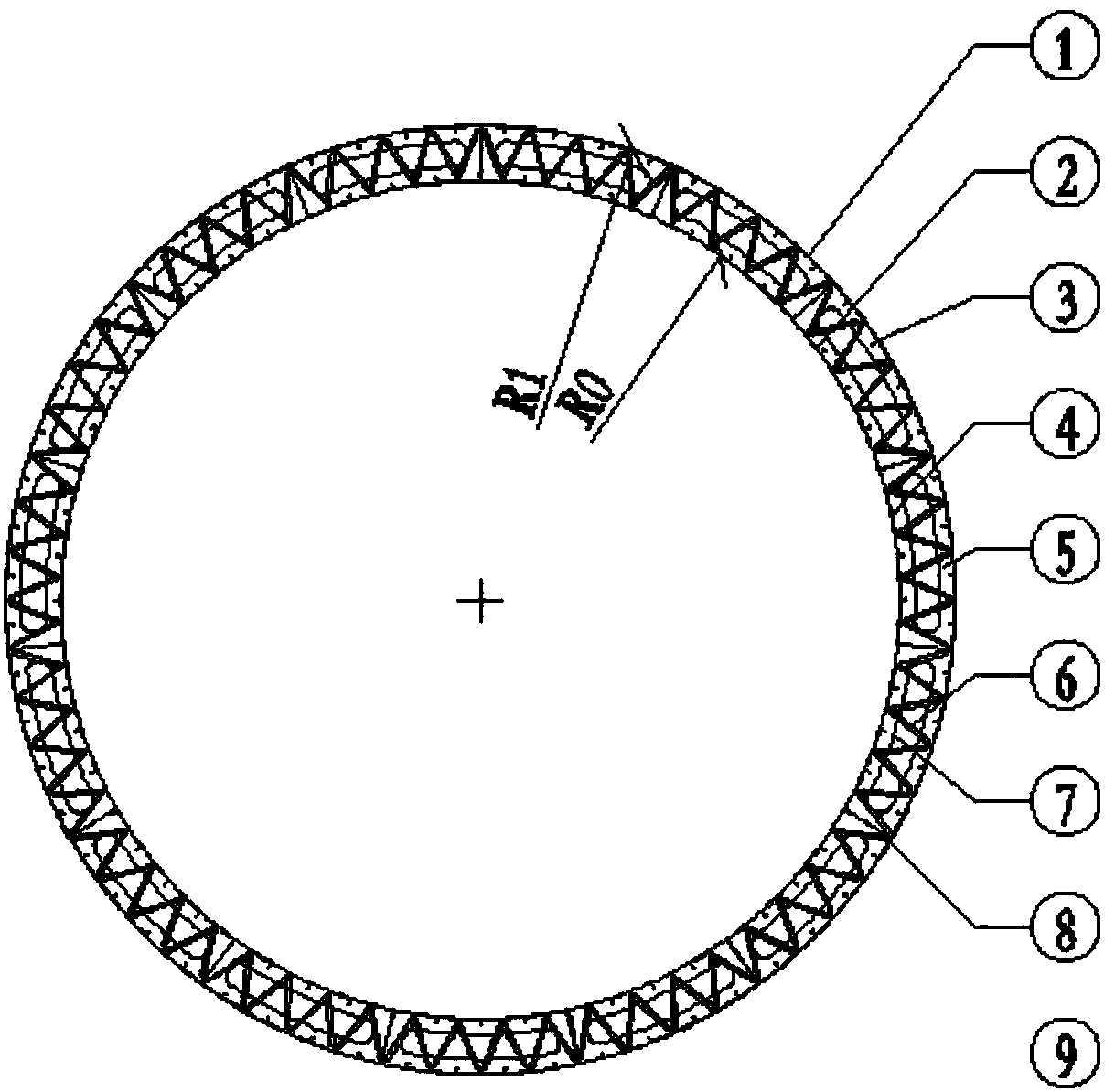

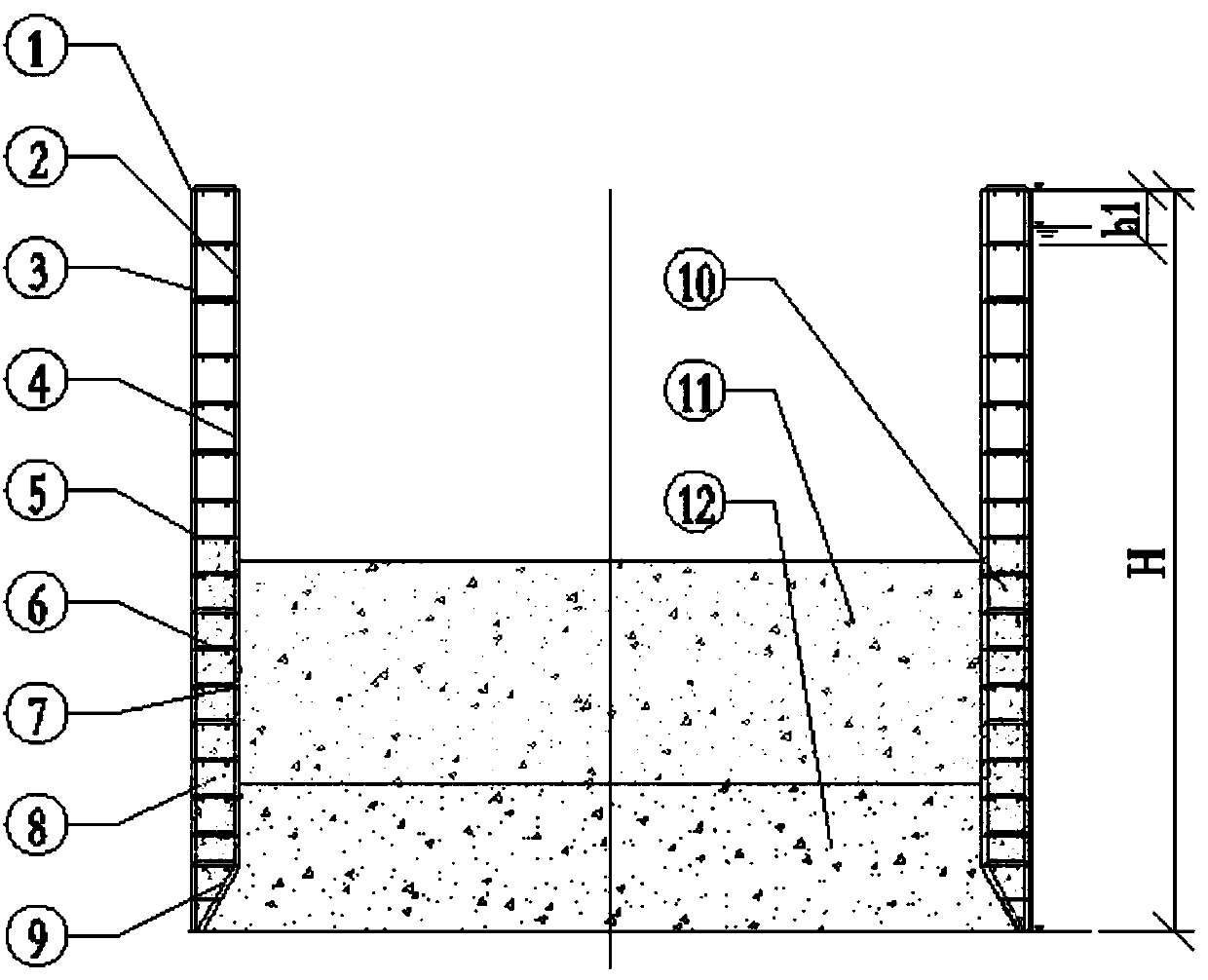

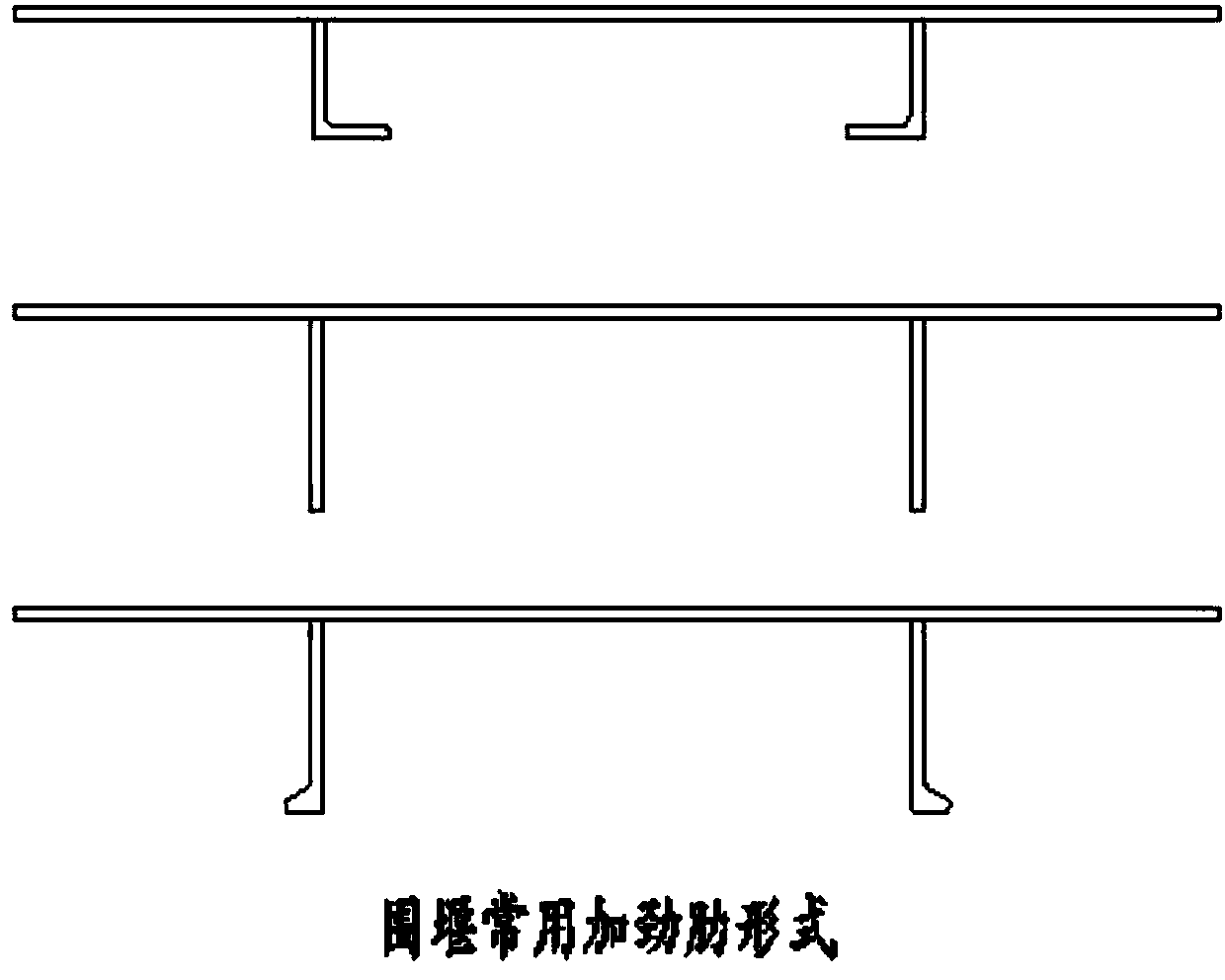

Parametrization design method for round double-wall steel cofferdam

ActiveCN106884434AReasonable and controllable forceGuaranteed economyFoundation engineeringCofferdamDouble wall

The invention relates to a parametrization design method for a round double-wall steel cofferdam. An existing design method is an empirical method, similar schemes of other projects are referred to in the protocolling process of related construction sizes, finite element trial is adopted, then, the related sizes are corrected, the main point of double-wall steel cofferdam design cannot be grasped integrally, and consequently the calculation process is complex, material waste is large, part of cofferdam structure stress is rather large, and the structural safety is low. It is necessary to tease the calculation process of the double-wall steel cofferdam design under the situation of considering the integrity, by means of a parametrization calculation manner, the reasonable structure of the cofferdam is considered in a unification manner, a reasonable structure and a related calculation formula for the round double-wall steel cofferdam design are given, and a cofferdam design person can primarily protocol the cofferdam structure sizes conveniently. Compared with double-wall steel cofferdams designed through the empirical methods of the other project, the round double-wall steel cofferdam designed in a parametrization manner has the beneficial effects that 20%-35% of material utilization amount is reduced, and great popularization significance is achieved.

Owner:湖北省路桥集团有限公司

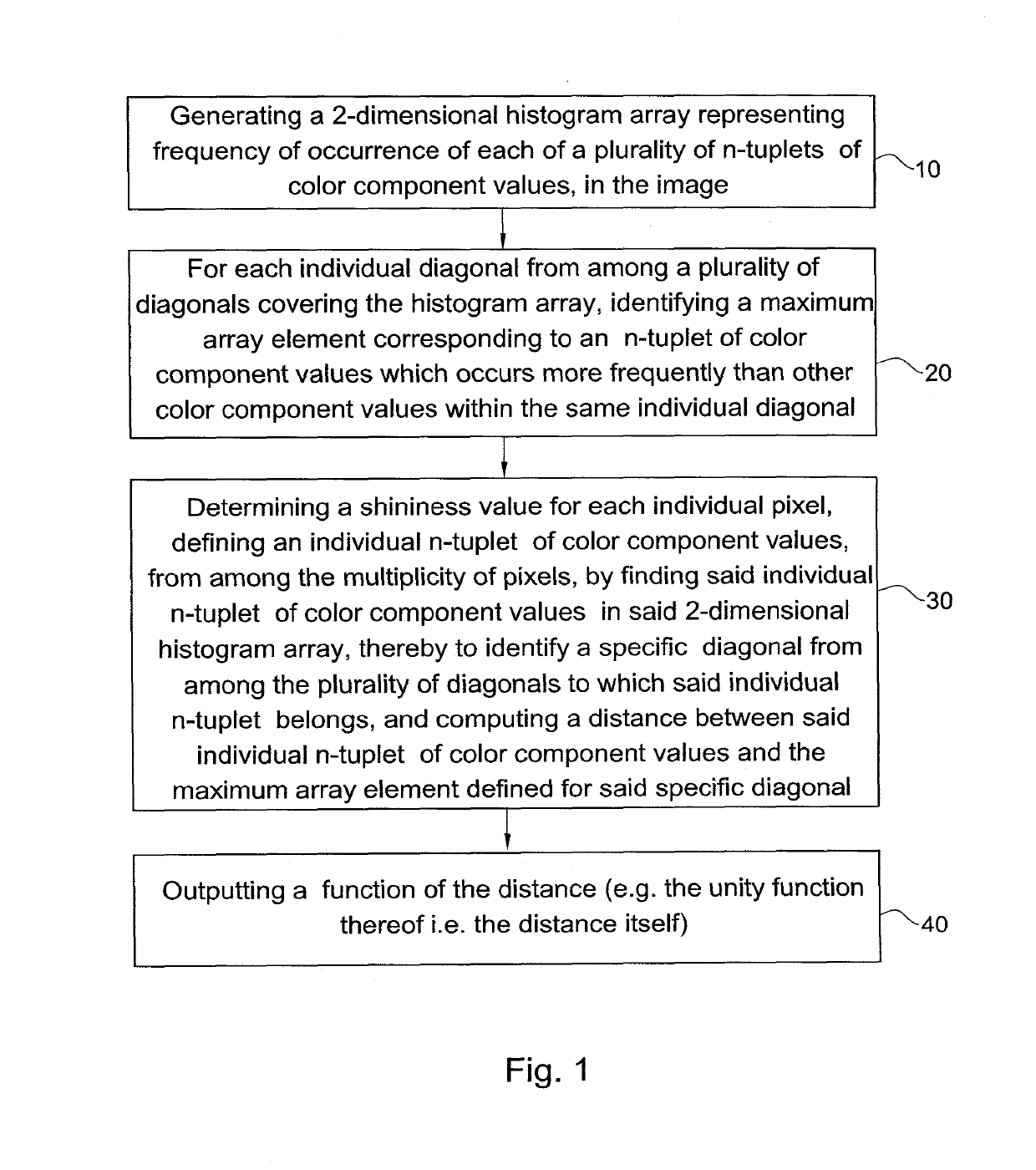

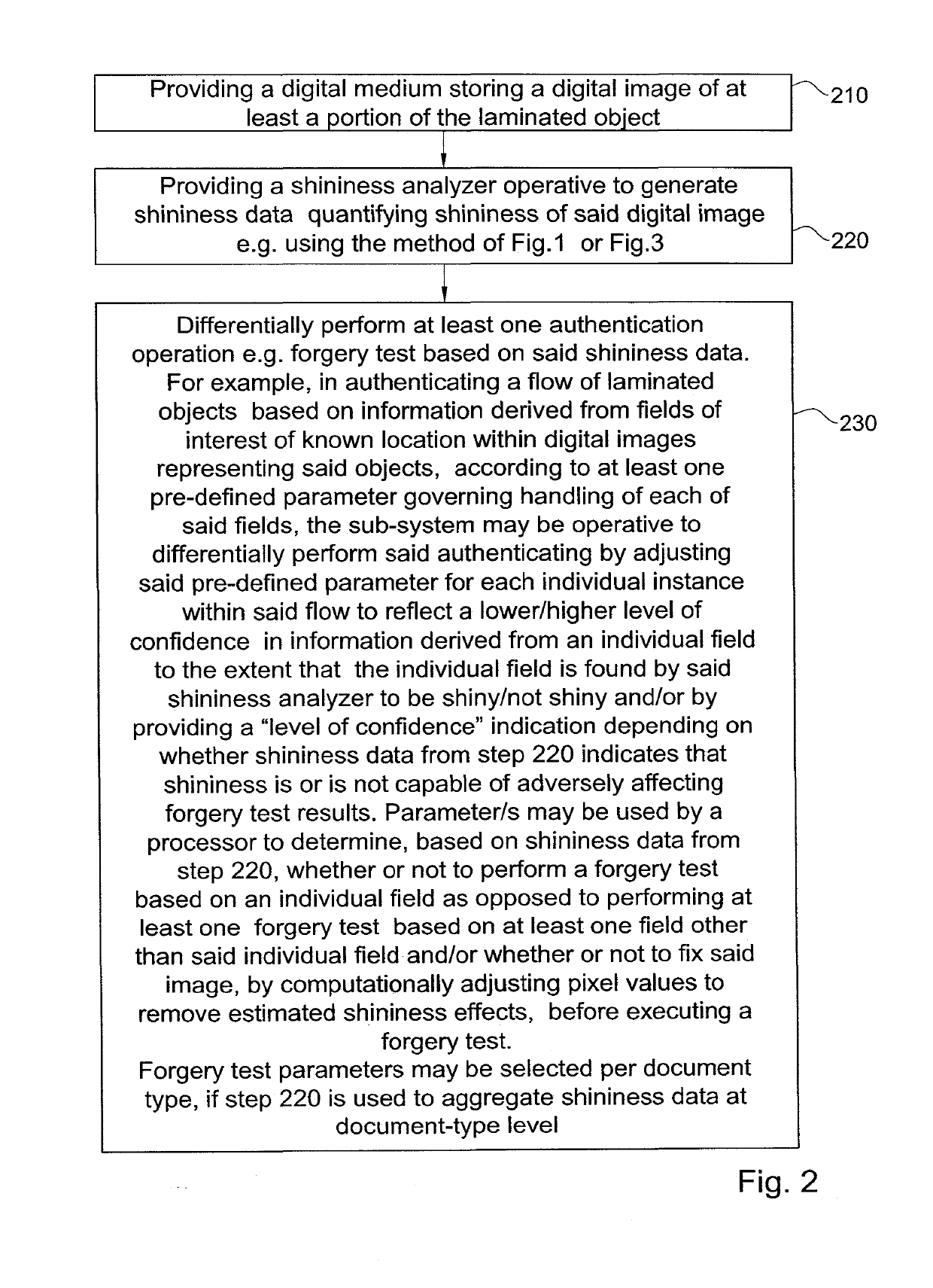

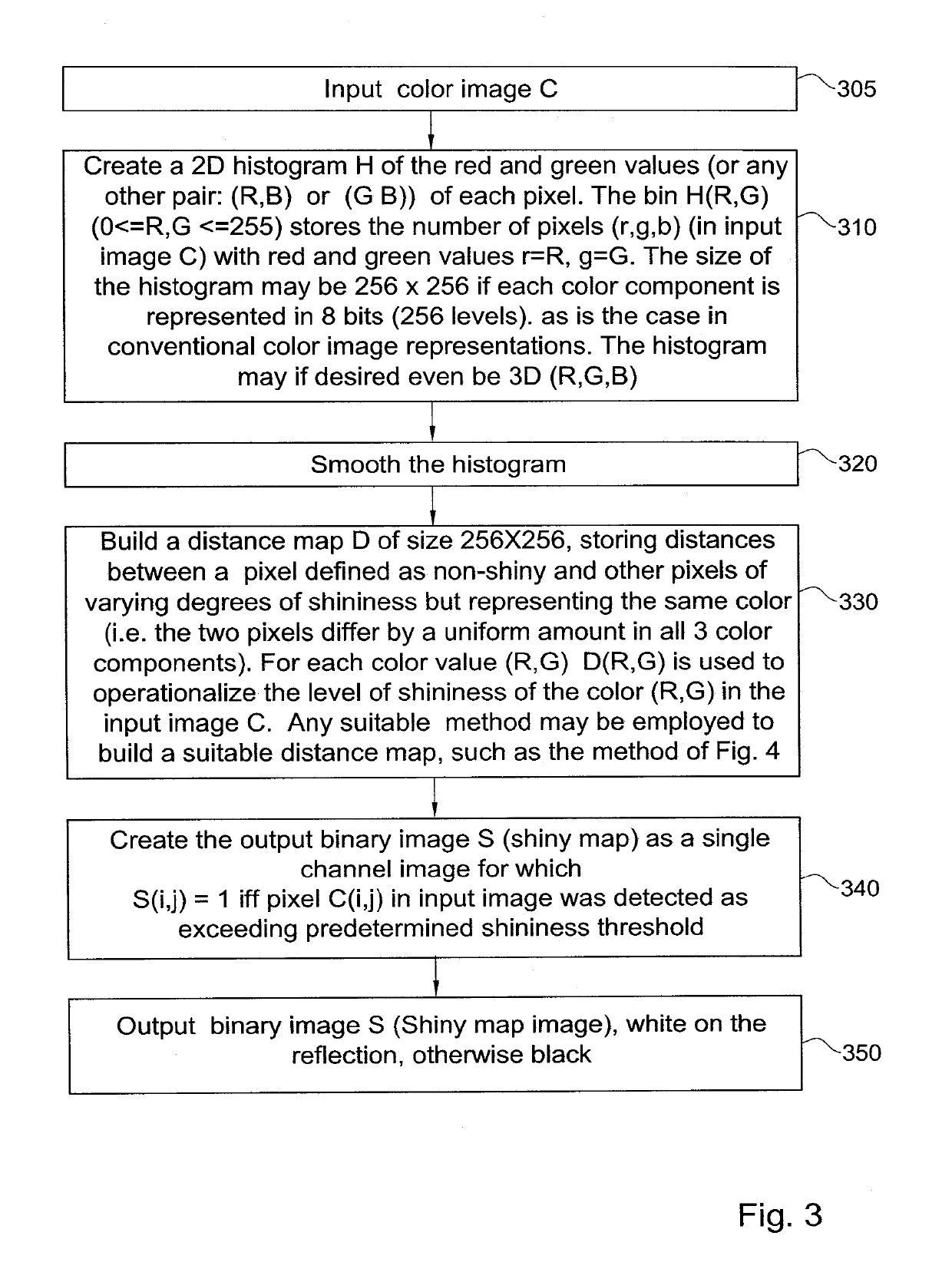

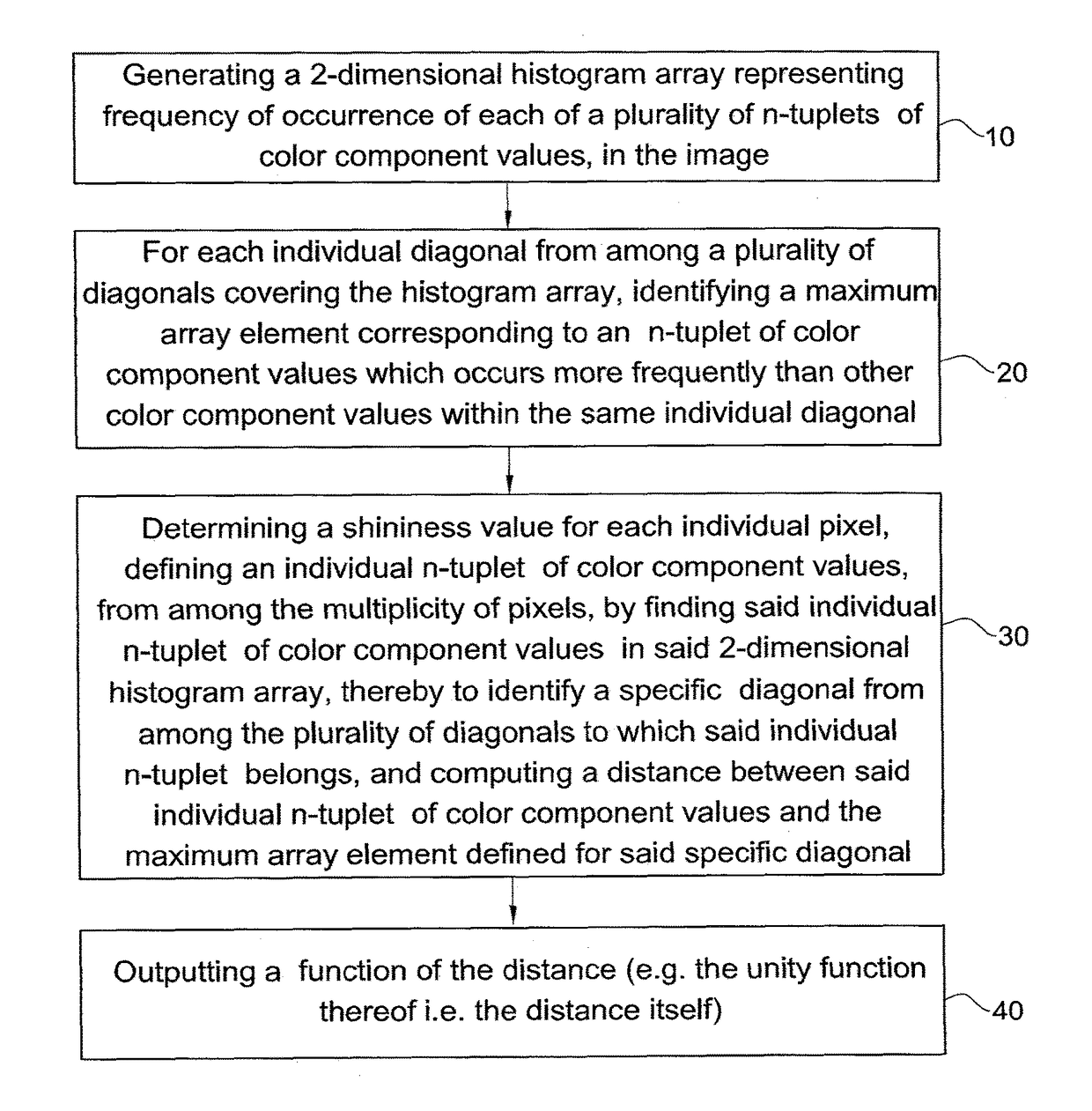

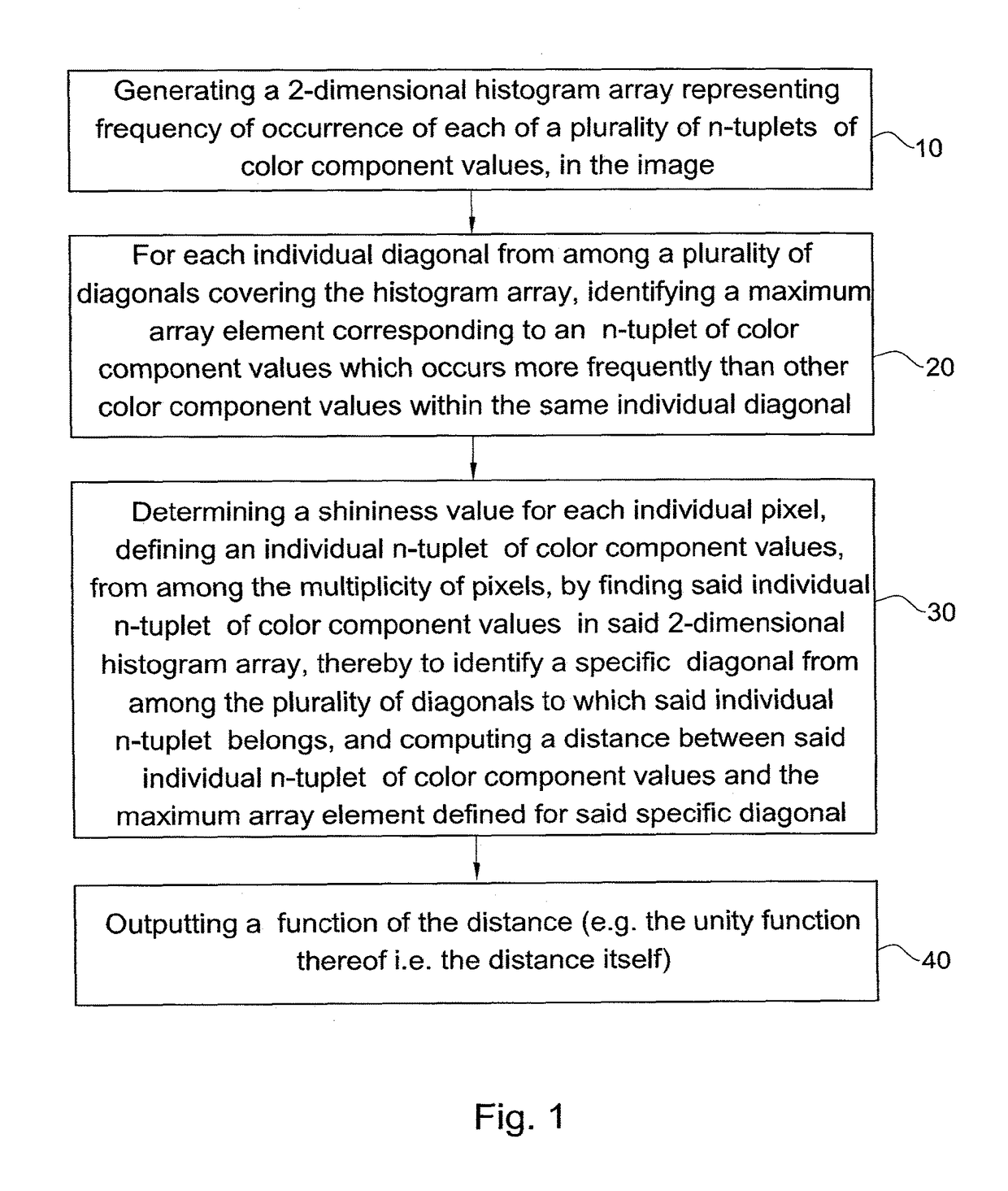

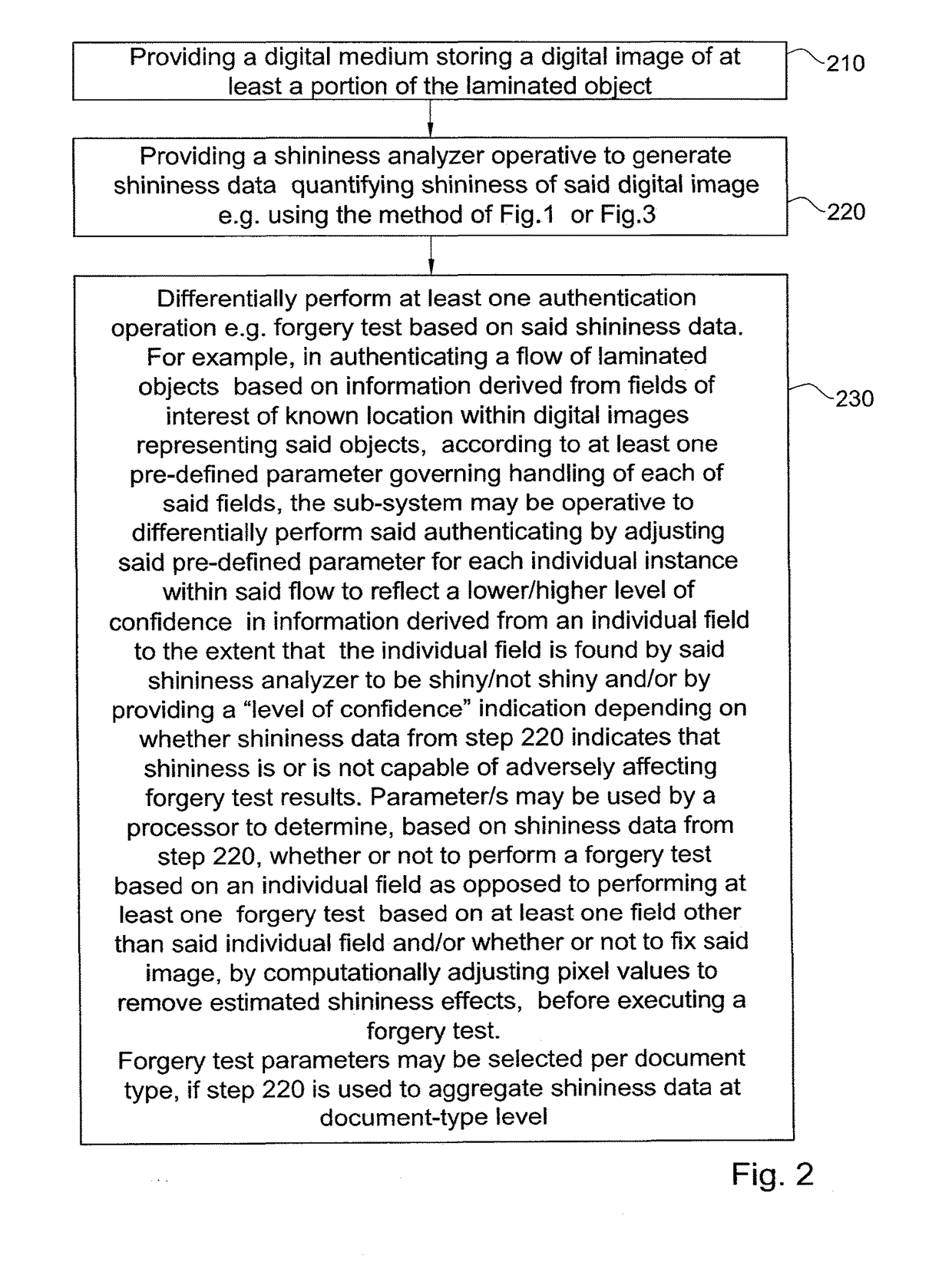

System and method for quantifying reflection e.g. when analyzing laminated documents

ActiveUS10255495B2Reduce error ratePaper-money testing devicesCharacter and pattern recognitionDigital imageAuthentication

A system for computerized authentication of a laminated object, the system comprising a digital medium storing a digital image of at least a portion of the laminated object in a computer-implemented memory; a shininess analyzer operative, using a processor, to generate shininess data quantifying shininess of the digital image; and a parameterized computerized authentication sub-system operative to differentially perform at least one laminated object authentication operation based on the shininess data.

Owner:AU10TIX

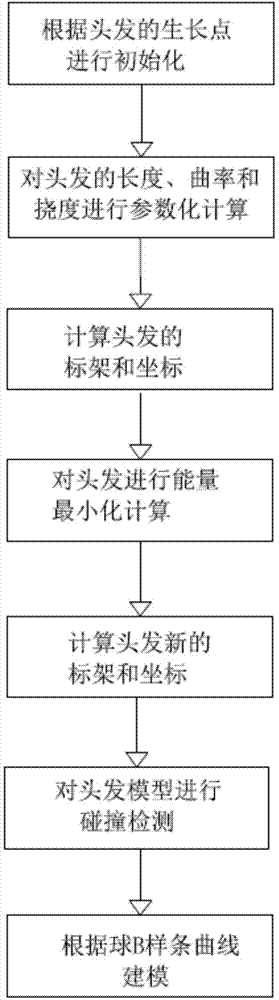

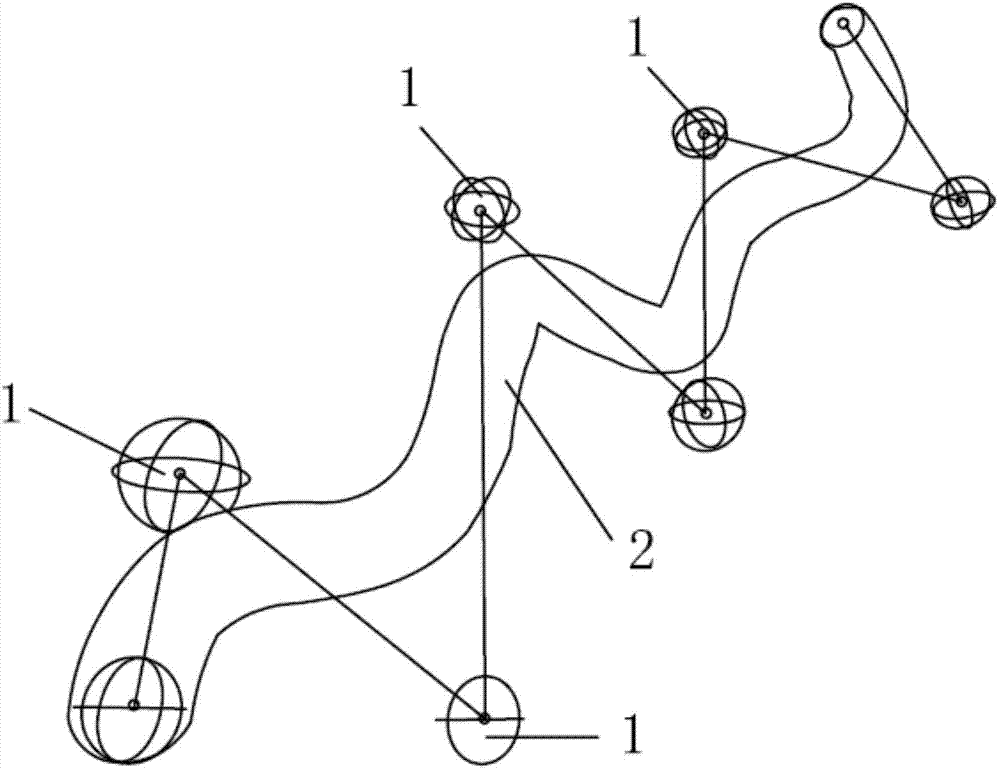

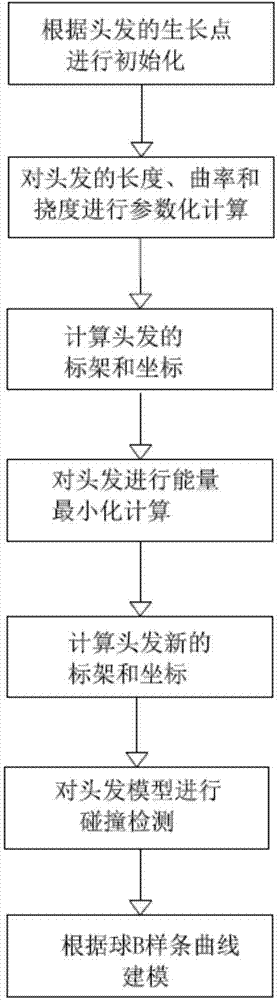

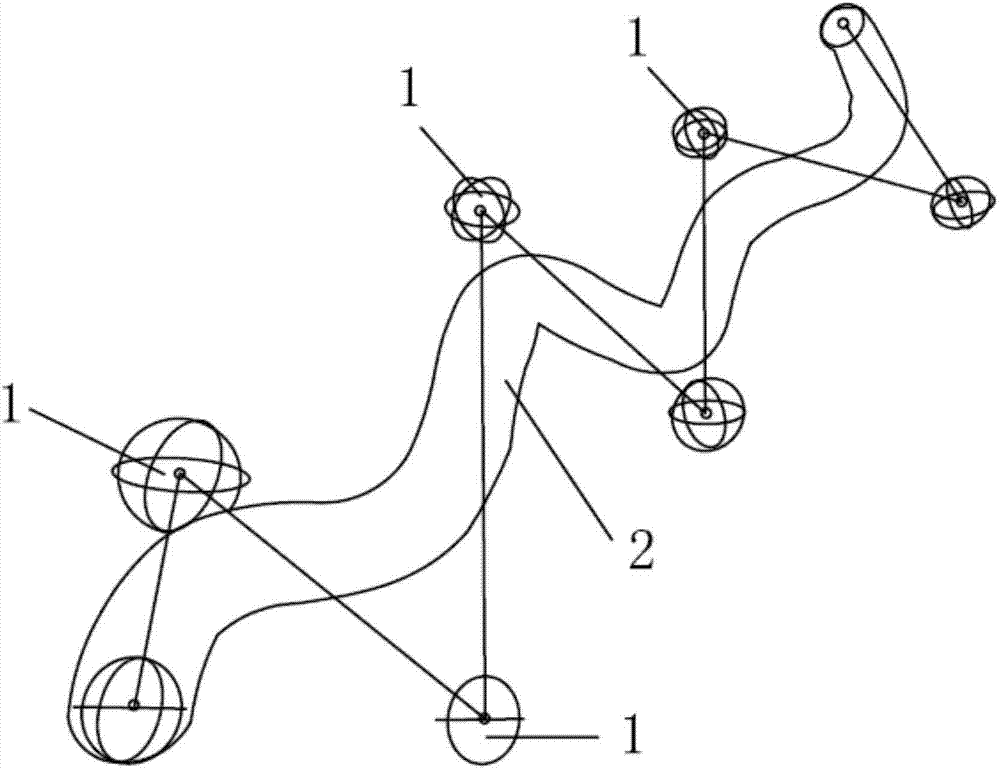

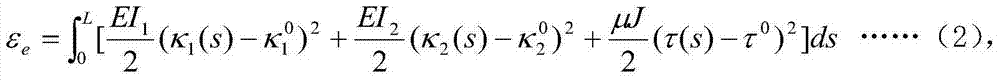

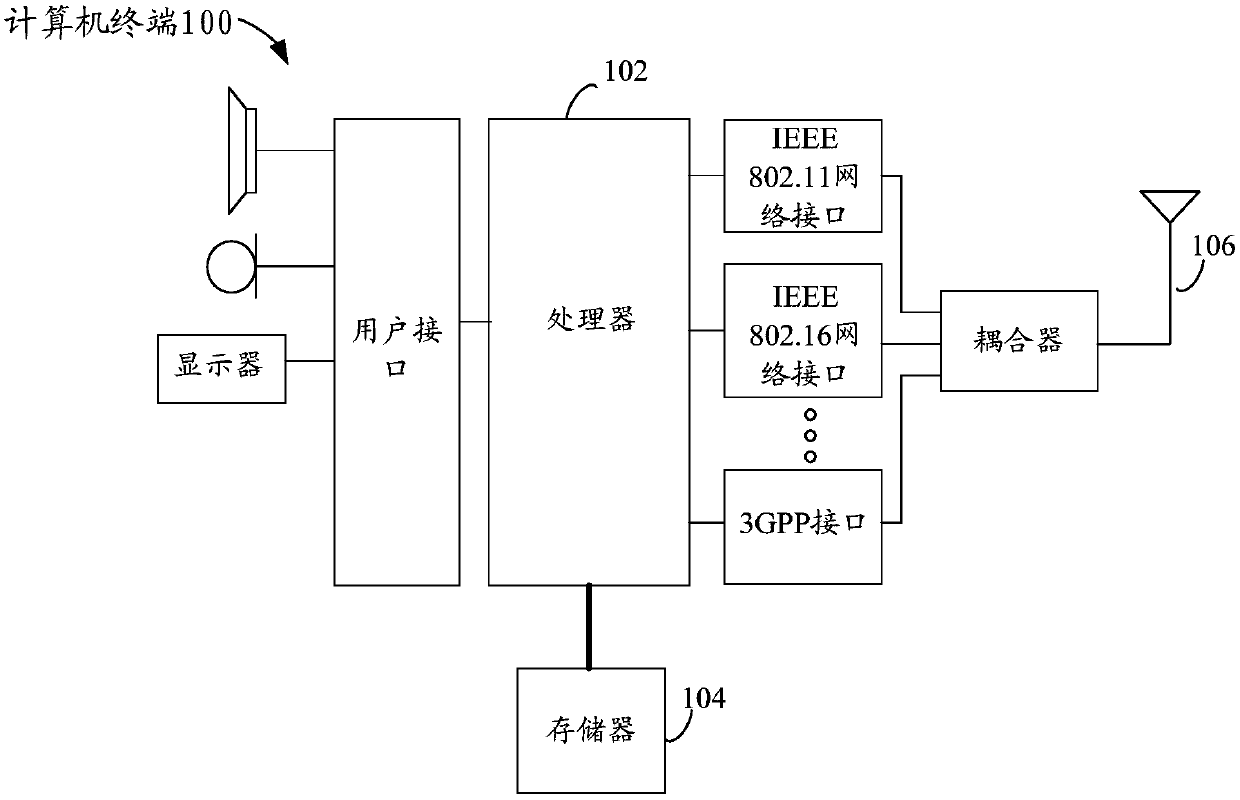

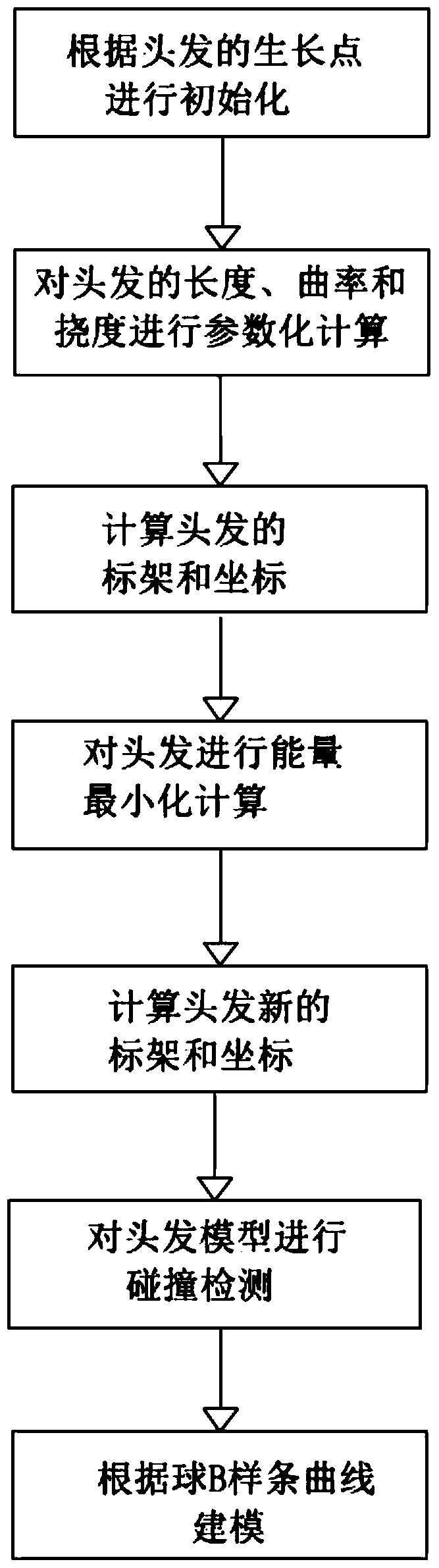

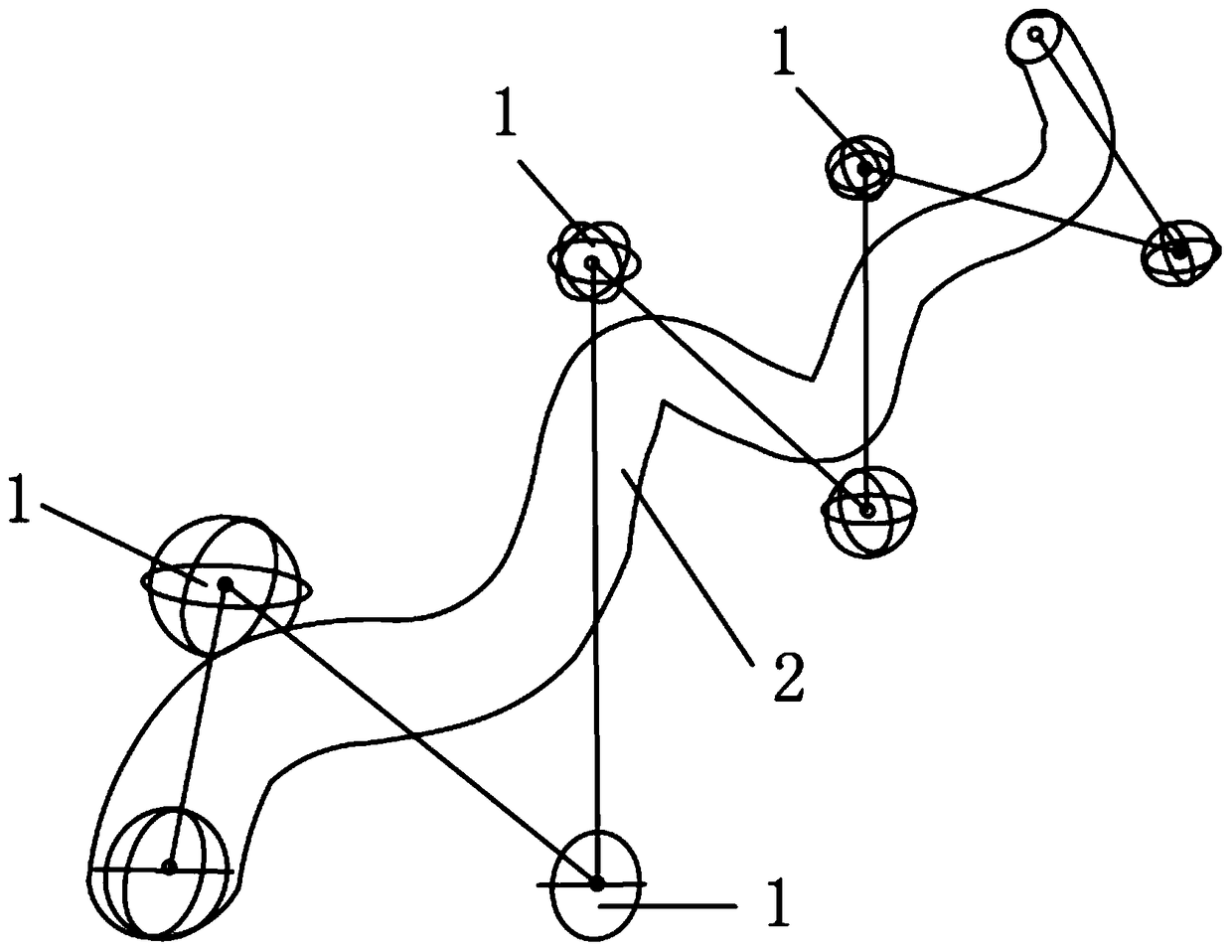

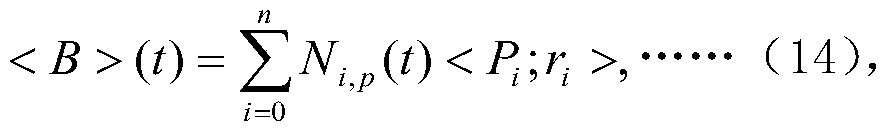

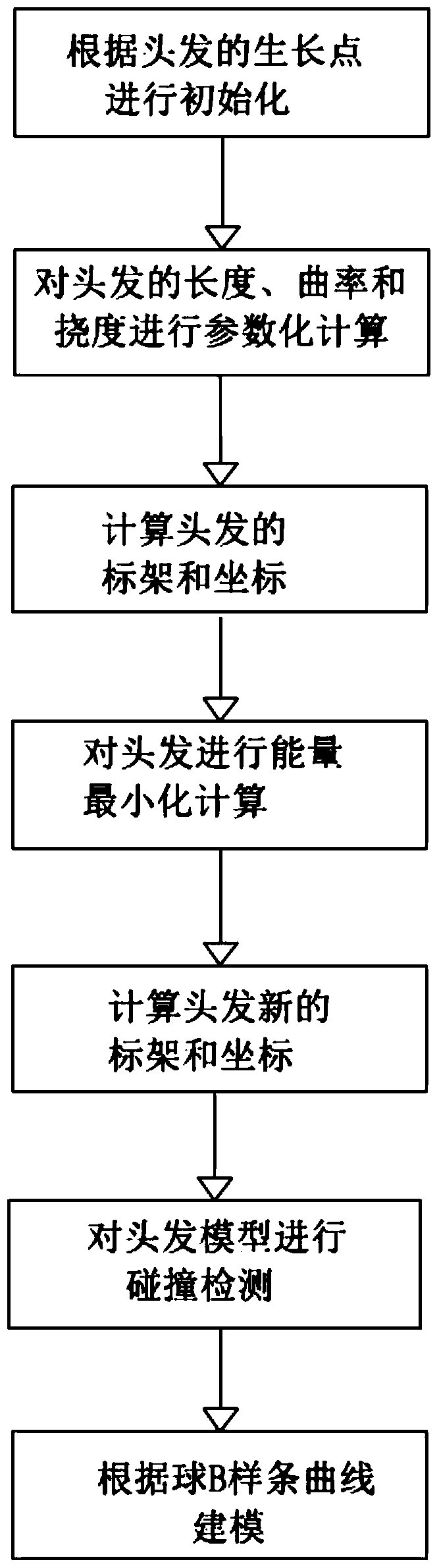

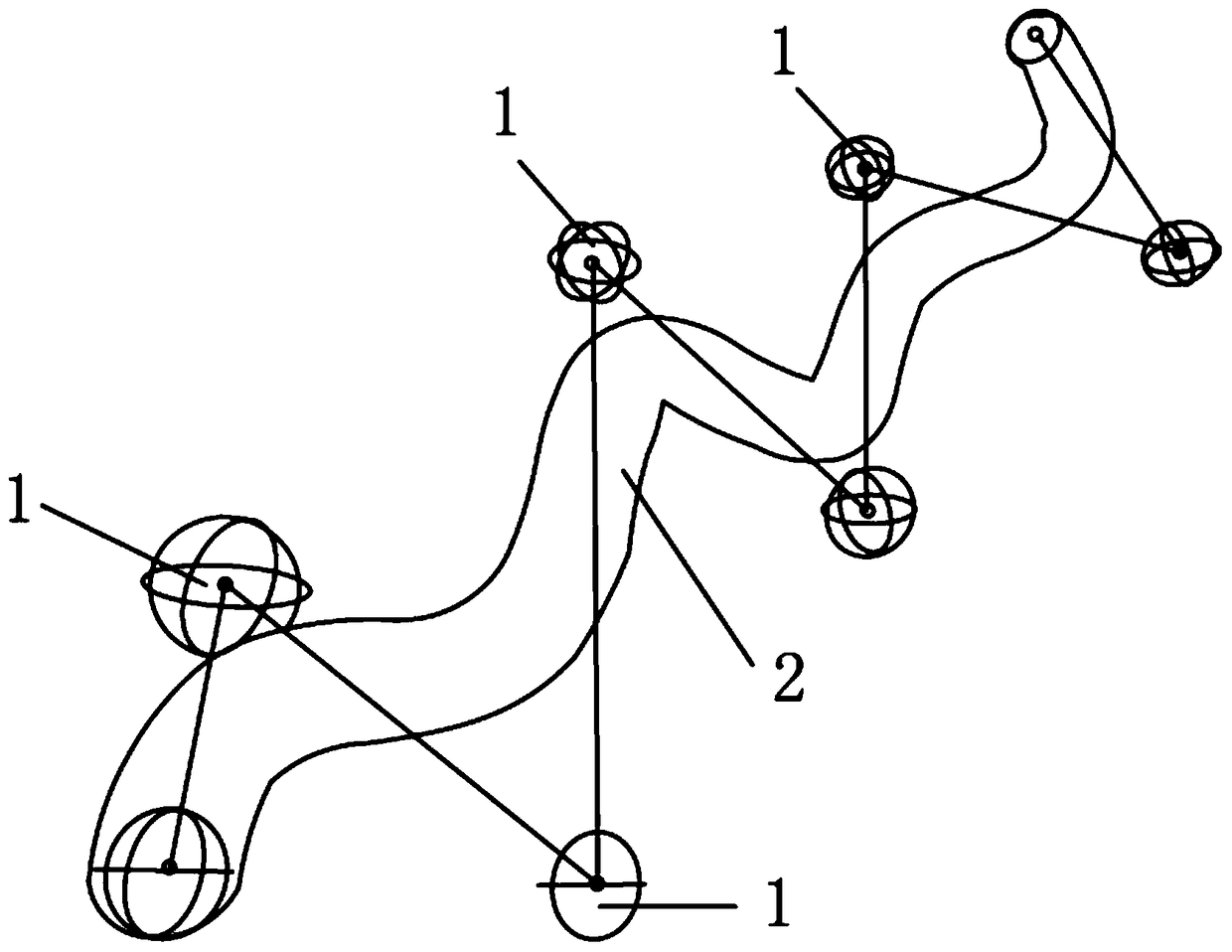

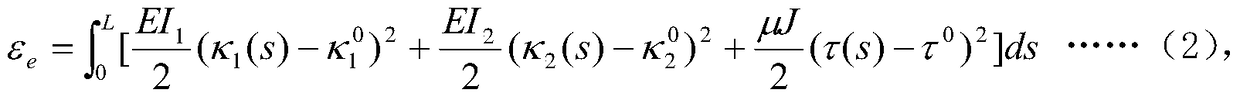

Hair modelling modeling method based on ball B-spline curve

The invention relates to the technical field of virtual human simulation, in particular to a hair modelling modeling method based on a ball B-spline curve. The hair modelling modeling method based on the ball B-spline curve includes the steps that growing points of hairs are initialized; parametric calculation is conducted on the hairs; a coordinate frame and coordinates of the hairs are computed; energy minimization calculation is conducted on the hairs; a new coordinate frame and coordinates of the hairs are computed; collision detection is conducted on the hairs; modeling is conducted on the hairs according to the ball B-spline curve. According to the hair modelling modeling method, hair strands can be constructed through ball B-splines, the hair modeling is optimized through energy minimization, and the obtained model can be used for various hair models of the virtual human.

Owner:BEIJING NORMAL UNIVERSITY

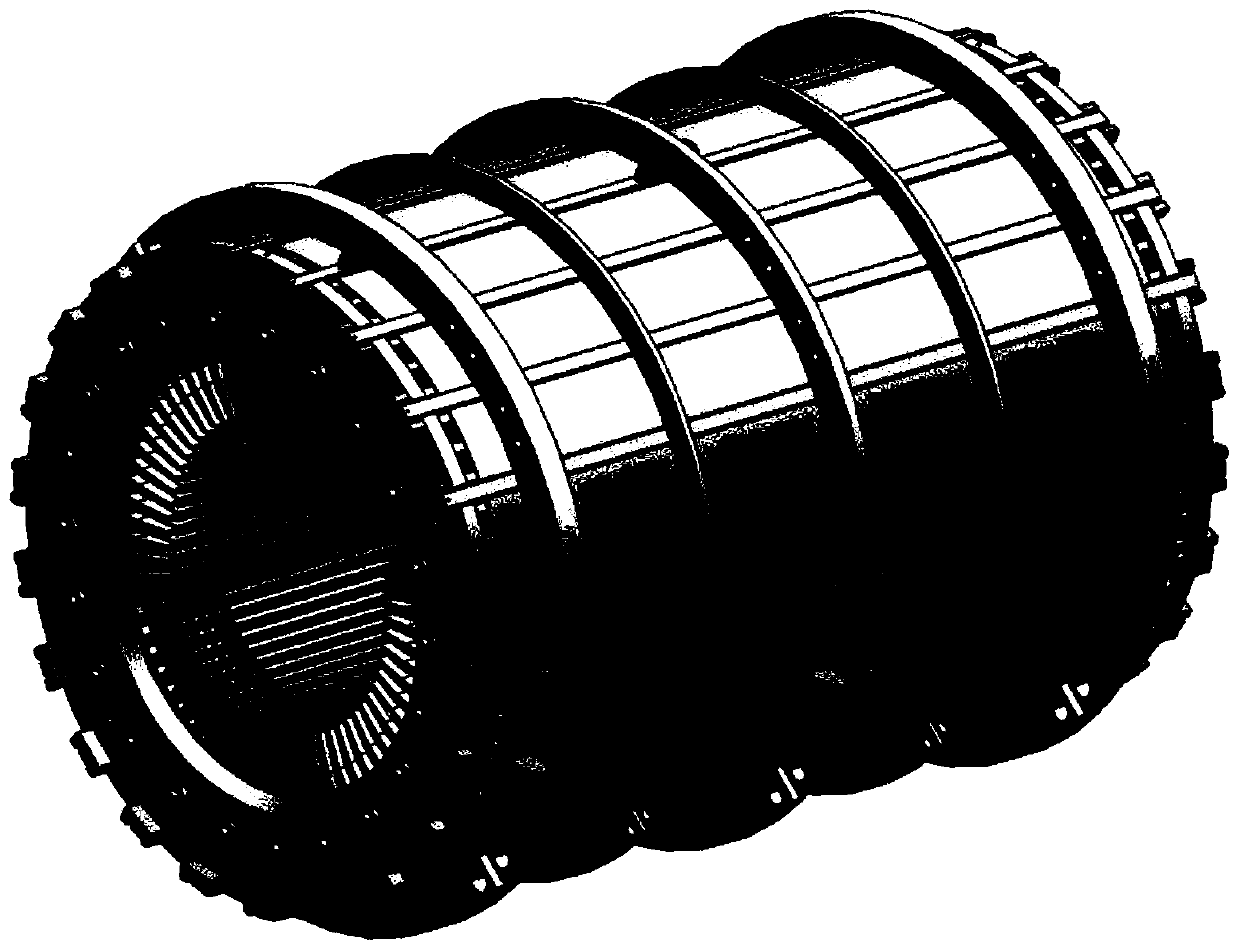

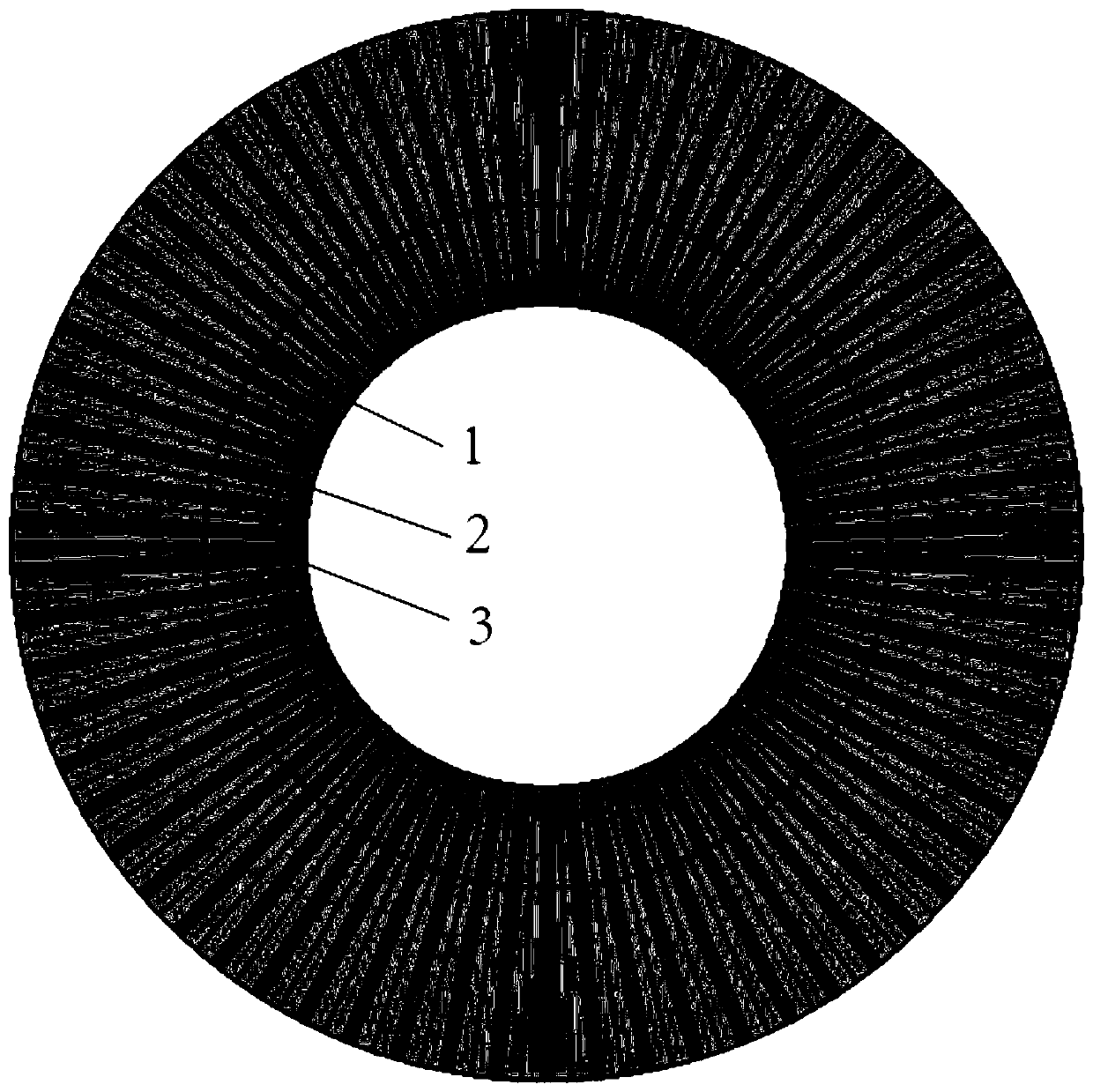

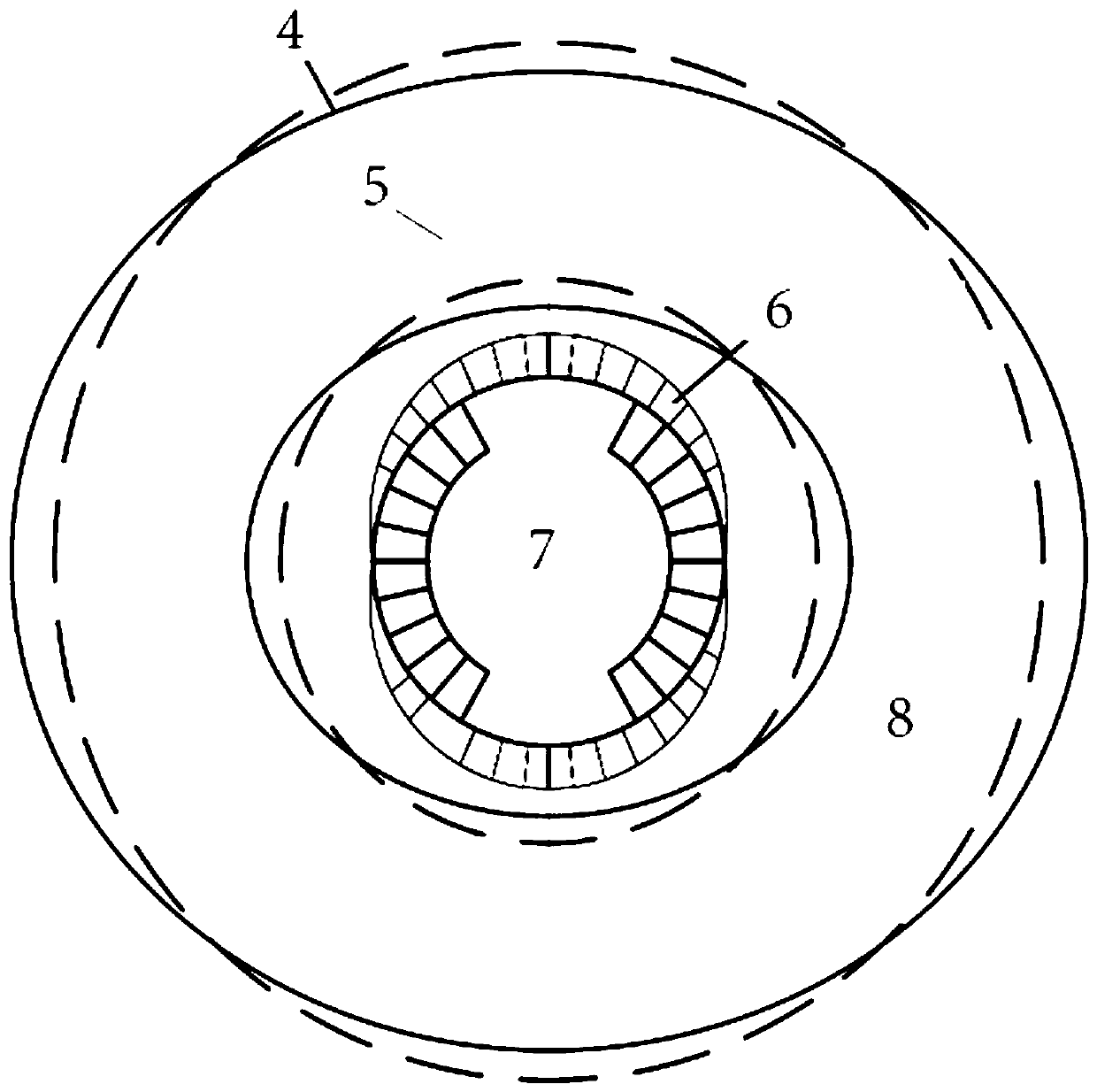

Parameterization calculation method for GVPI stator iron core mode

ActiveCN110837706AIncrease stiffnessHigh precisionGeometric CADSustainable transportationStructural engineeringProcess engineering

The invention discloses a parameterization calculation method for a GVPI stator iron core mode. A stator iron core is formed by stacking silicon steel sheets. When the stator iron core modal adoptingthe GVPI technology is calculated, the stator winding with actual mass and low elasticity modulus is established to simulate the improvement of the stator winding on the overall rigidity of the iron core after GVPI, so that the accuracy of the stator iron core modal calculation adopting the GVPI technology is improved. The method has the advantages that through secondary development, calculation of various GVPI iron core modes can be achieved, operation is easy, standardization of the calculation method and process is achieved, human factor errors caused by different analysts are avoided, thecalculation time is remarkably shortened, and the efficiency is improved.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Hair modelling modeling method based on static supercoiling model

The invention relates to the technical field of virtual human simulation, in particular to a hair modelling modeling method based on a static supercoiling model. The hair modelling modeling method based on the static supercoiling model includes the steps that growing points of hairs are initialized; parametric calculation is conducted on the hairs; a coordinate frame and coordinates of the hairs are computed; energy minimization calculation is conducted on the hairs; a new coordinate frame and coordinates of the hairs are computed; collision detection is conducted on the hairs; modeling is conducted on the hairs according to a ball B-spline curve. According to the hair modelling modeling method, hair strands can be constructed through ball B-splines, the hair modeling is optimized through energy minimization, and the obtained model can be used for various hair models of the virtual human.

Owner:BEIJING NORMAL UNIVERSITY

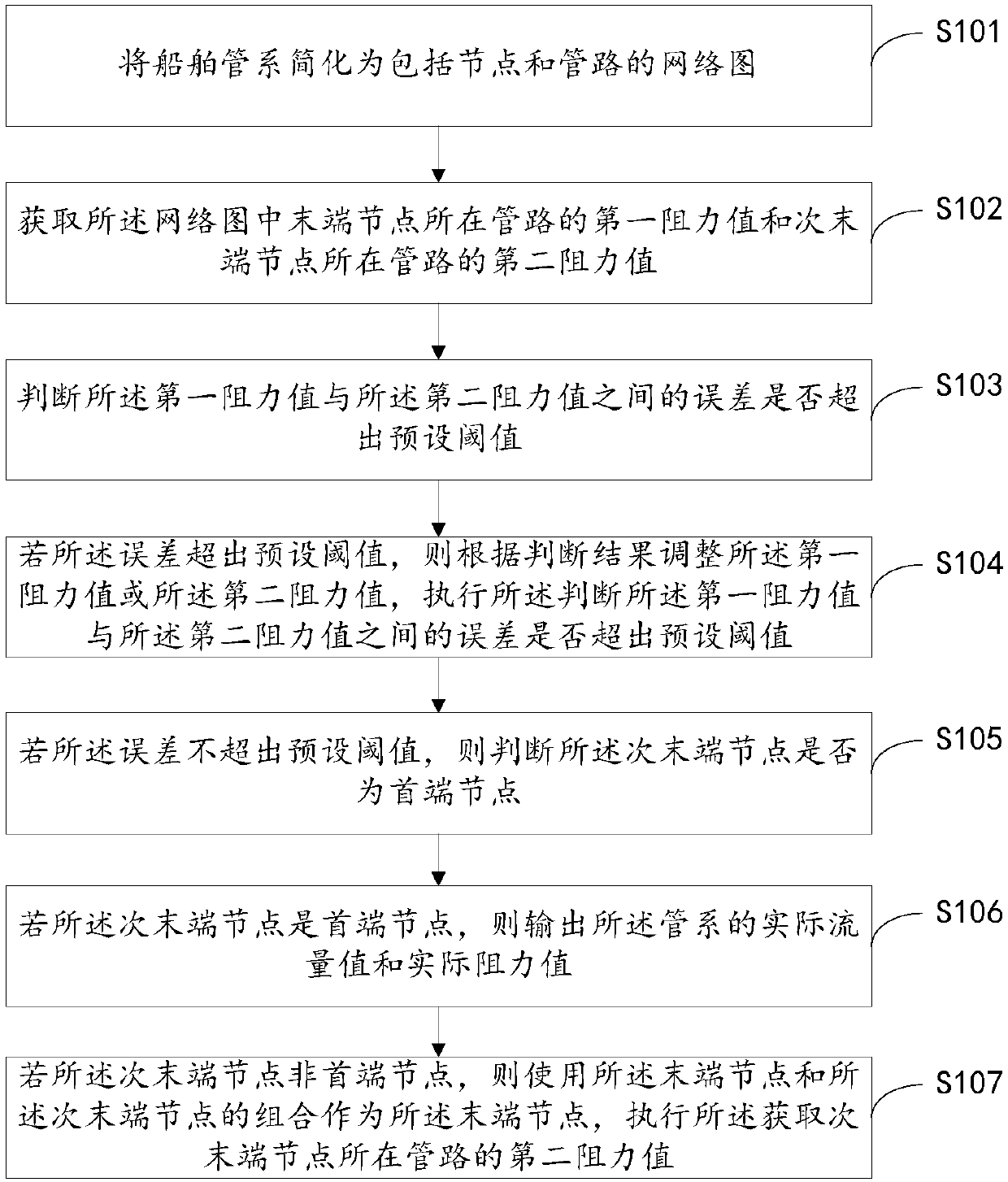

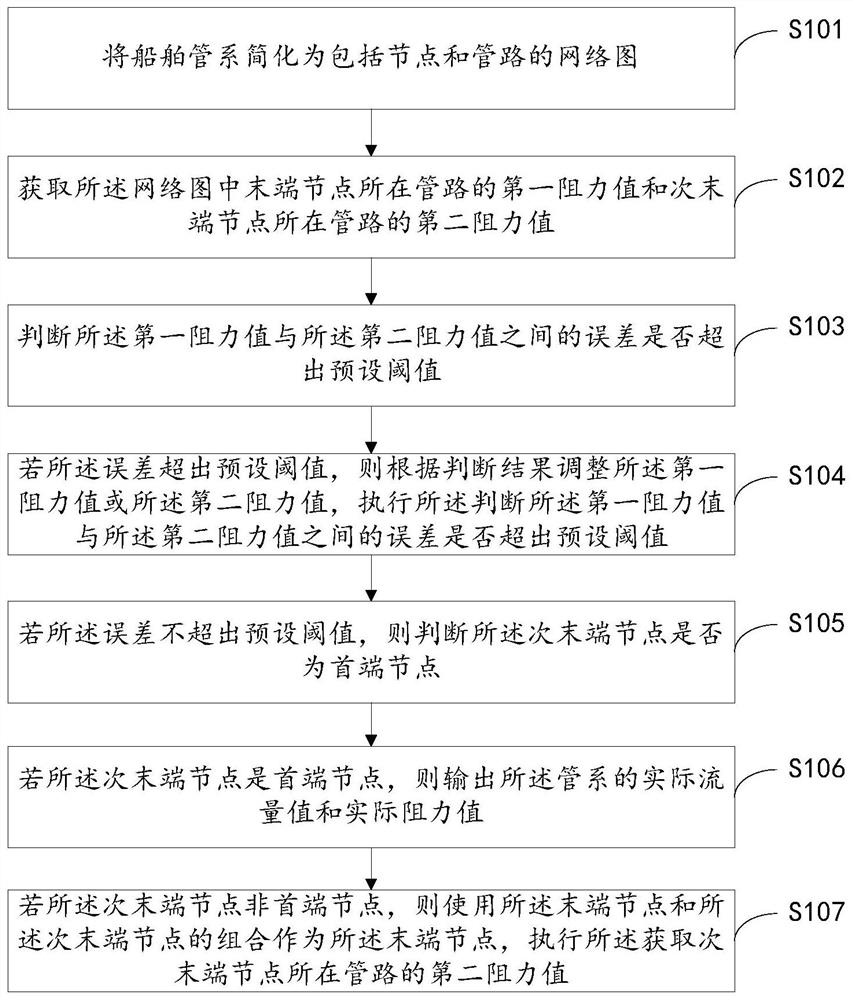

Ship piping system design scheme verification method and system

ActiveCN107818193AQuick calculationImprove verification efficiencyDesign optimisation/simulationSpecial data processing applicationsSystems designModel selection

The invention discloses a ship piping system design scheme verification method. The method includes the steps that a ship piping system is simplified into a network graph; a first resistance value anda second resistance value are acquired; whether or not the error between the first resistance value and the second resistance value exceeds a preset threshold value is judged; if yes, the first resistance value or the second resistance value is adjusted according to the judgment result, and the above-mentioned judgment step is executed again; if not, whether or not a penultimate tail end node isa head end node is judged; if yes, the actual flow value and the actual resistance value of the piping system are output; if not, the combination of a tail end node and the penultimate tail end node is used as a tail end node, and a new second resistance value is acquired. The invention further discloses a ship piping system design scheme verification system. By means of the method and system, parameterized calculation of the resistance and flow of the ship piping system is achieved, calculation is fast and accurate, and the calculation result can be used for assisting in piping system check and pump model selection.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

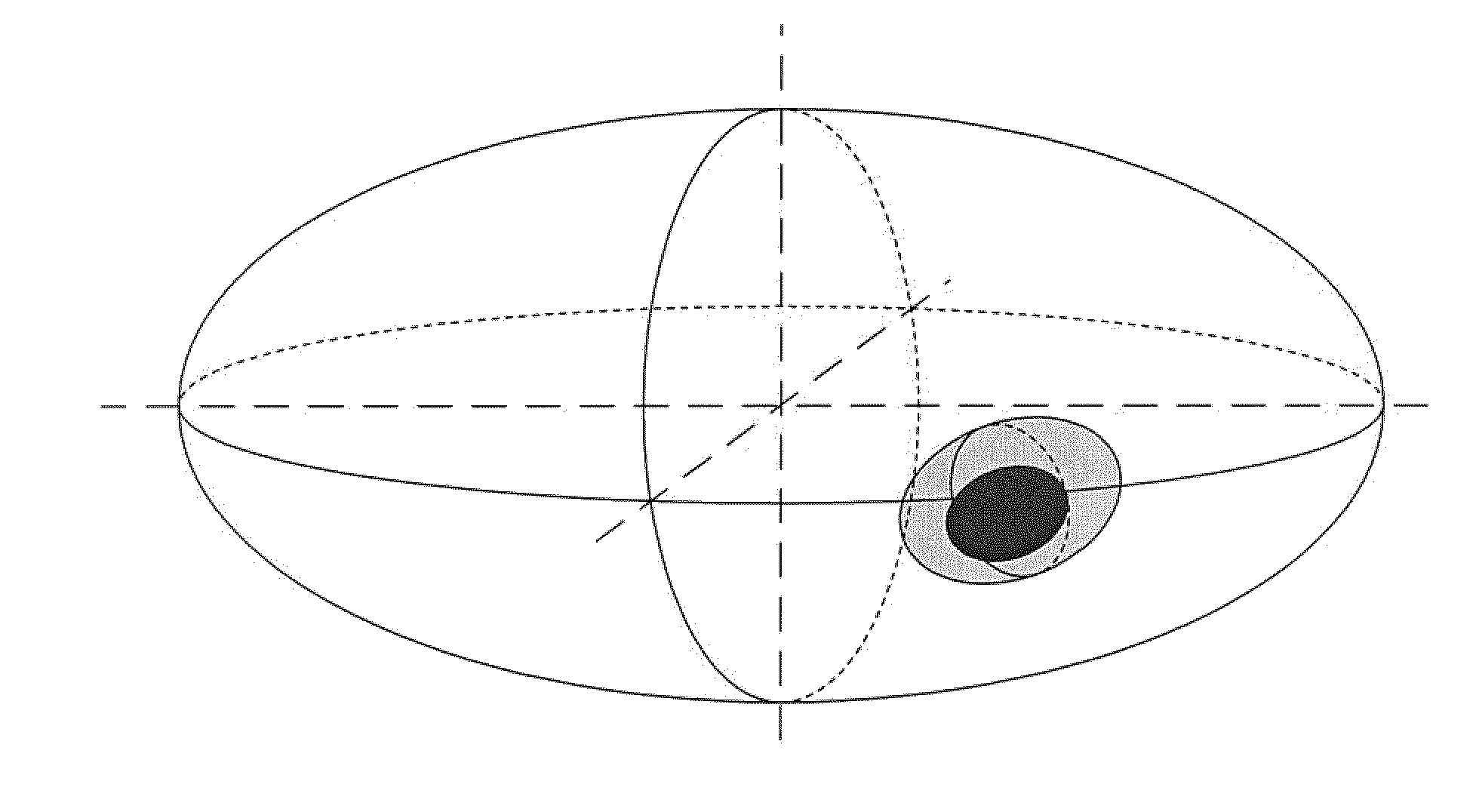

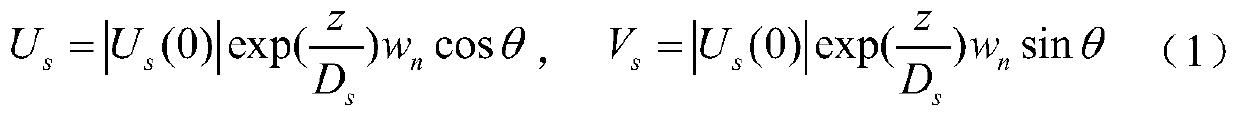

Method and system for characterizing tumors

ActiveUS20110208490A1Improve accuracyMedical simulationAnalogue computers for chemical processesComputational modelWilms' tumor

Embodiments of the present invention are directed to determining the spatial extent, aggressiveness, and other characteristics of various types of tumors, including glioma tumors that occur in brain tissue. Various embodiments of the present invention use parameterized computational models to characterize tumor growth and employ medical imaging technologies to generate images and other types of data from which values of parameters of the computational models are derived. Having obtained the parameters for a particular tumor, the extent of the tumor is estimated, with high accuracy, and other characteristics of the tumor are derived from the parameterized computational models.

Owner:SWANSON KRISTIN R +1

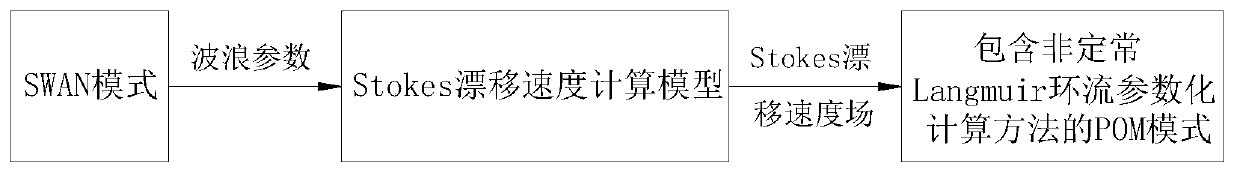

Dynamic simulation method for calculating unsteady Langmuir circulation

ActiveCN110096792APerfect physical processRealize Operational Ocean ForecastingDesign optimisation/simulationSpecial data processing applicationsOcean circulation modelOcean forecasting

The invention discloses a dynamic simulation method for calculating unsteady Langmuir circulation. The dynamic simulation method comprises the following steps: (1) calculating a wave field within a certain time range by adopting an offshore wave mode, and outputting wave parameters; (2) inputting the obtained wave parameters into a Stokes drift velocity calculation model, and calculating to obtaina stokes drift velocity; (3) improving the Prussian ocean mode, and enabling the Prussian ocean mode to comprise a parametric calculation method of unsteady Langmuir circulation; and (4) inputting the obtained stokes drifting speed into an improved Prussian ocean mode, and simulating an ocean dynamic process containing the unsteady Langmuir circulation in real time to obtain an ocean temperature,salinity and flow velocity field containing the influence of a physical process of the unsteady Langmuir circulation. According to the method, the effect of the unsteady Langmuir ring current is added into the turbulence energy parameterization calculation method of the ocean ring current model, the influence of the unsteady Langmuir ring current on ocean elements can be dynamically simulated, the physical process of an ocean numerical mode can be perfected, and a more accurate ocean forecasting model is obtained.

Owner:TIANJIN UNIV

Method and system for characterizing tumors

ActiveUS8571844B2Medical simulationAnalogue computers for chemical processesComputational modelComputer vision

Embodiments of the present invention are directed to determining the spatial extent, aggressiveness, and other characteristics of various types of tumors, including glioma tumors that occur in brain tissue. Various embodiments of the present invention use parameterized computational models to characterize tumor growth and employ medical imaging technologies to generate images and other types of data from which values of parameters of the computational models are derived. Having obtained the parameters for a particular tumor, the extent of the tumor is estimated, with high accuracy, and other characteristics of the tumor are derived from the parameterized computational models.

Owner:SWANSON KRISTIN R +1

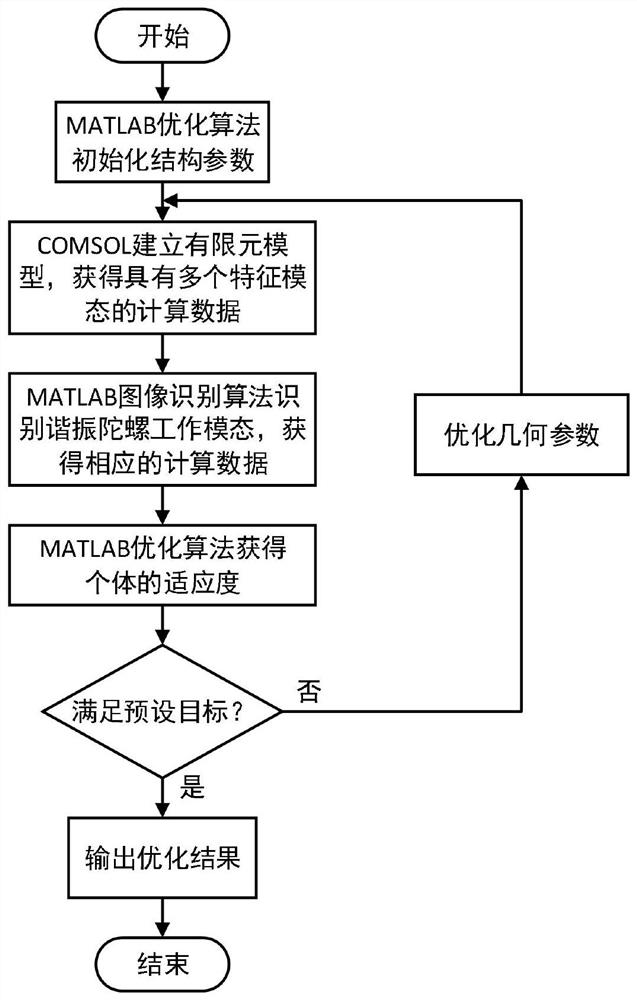

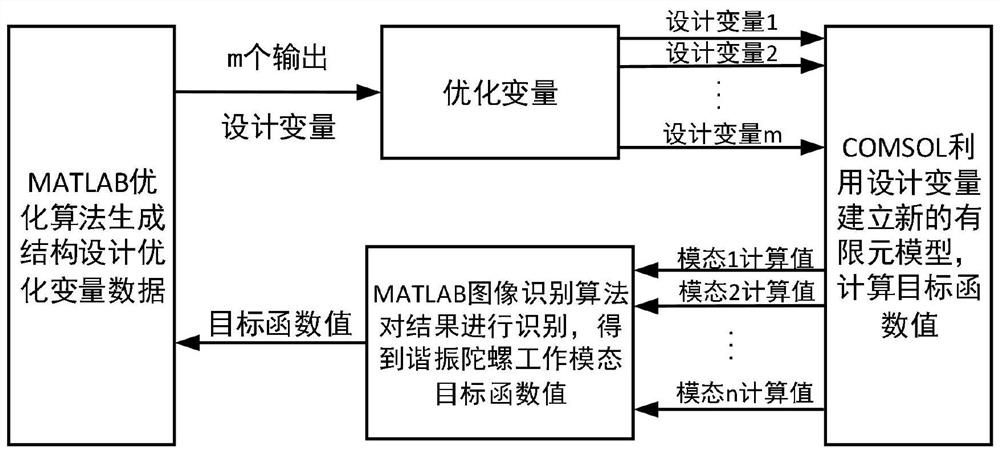

Resonant gyroscope optimization method and system based on joint simulation

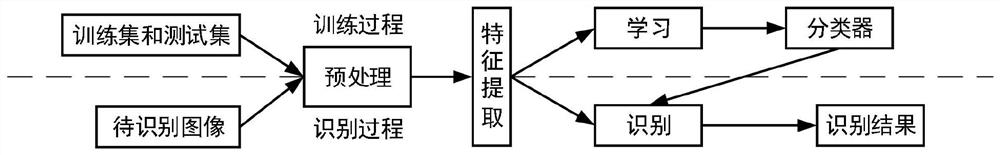

ActiveCN113297707ARealize automatic identificationImprove Simulation EfficiencyGeometric CADInternal combustion piston enginesElement modelGyroscope

The invention provides a resonant gyroscope optimization method and system based on joint simulation. The resonant gyroscope optimization method comprises the following steps: 1, writing an image recognition algorithm for resonant gyroscope characteristic modal recognition and an optimization algorithm for resonant gyroscope structure parameter optimization by utilizing MATLAB; 2, establishing a resonant gyroscope parameterization calculation model by using COMSOL, and outputting a finite element calculation result; and 3, establishing a channel for mutually transmitting data by utilizing data interfaces of the MATLAB and the COMSOL, calling the finite element model of the COMSOL by the MATLAB, and optimizing the structural parameters of the resonant gyroscope through an image recognition algorithm and an optimization algorithm. According to the method, automatic identification of the characteristic modal shape in finite element simulation of the resonant gyroscope is realized, synchronous and rapid optimization of multiple parameters of the resonant gyroscope structure is realized, the design accuracy of the resonant gyroscope can be effectively improved, and the design efficiency of the resonant gyroscope is improved.

Owner:SHANGHAI JIAO TONG UNIV

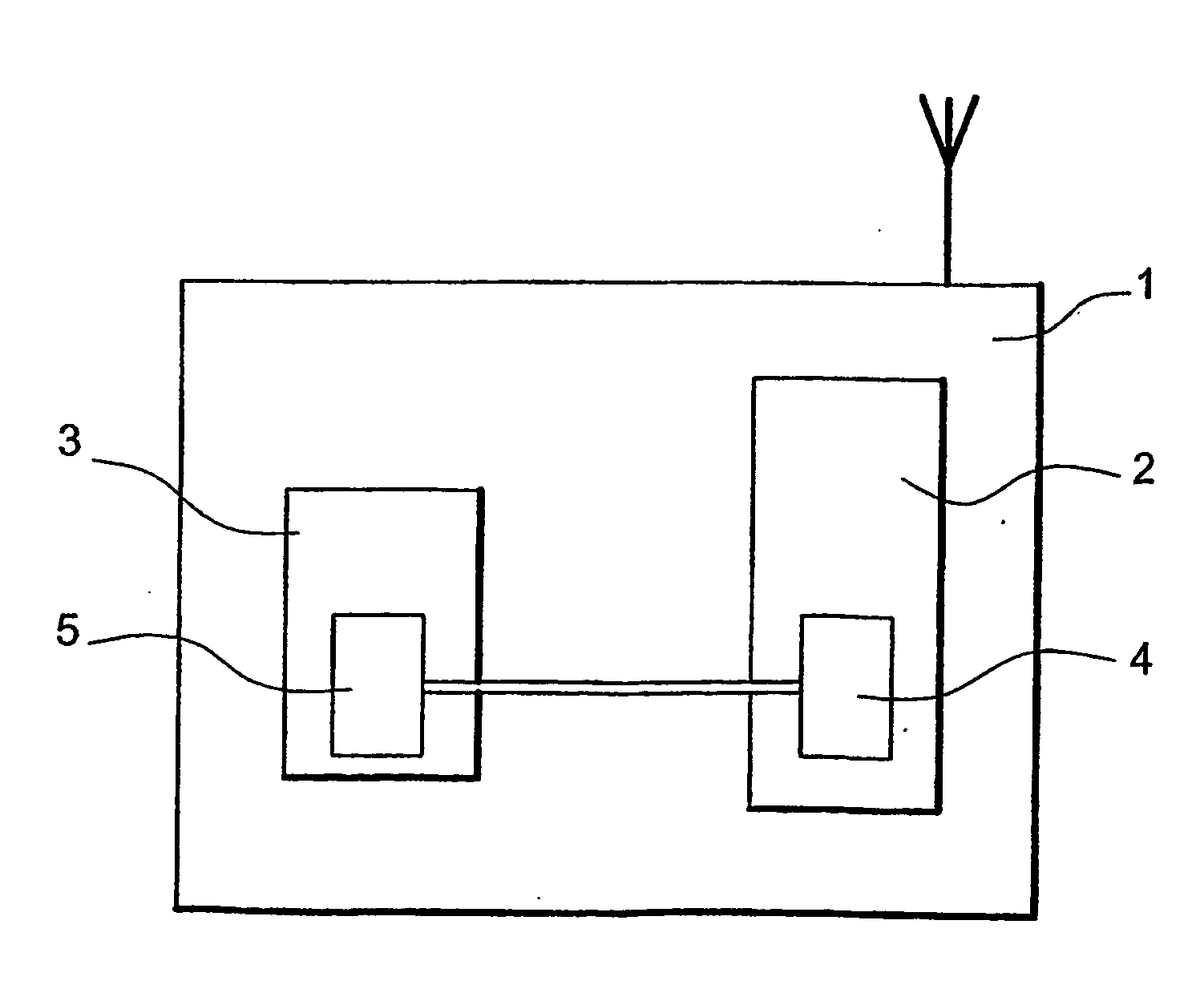

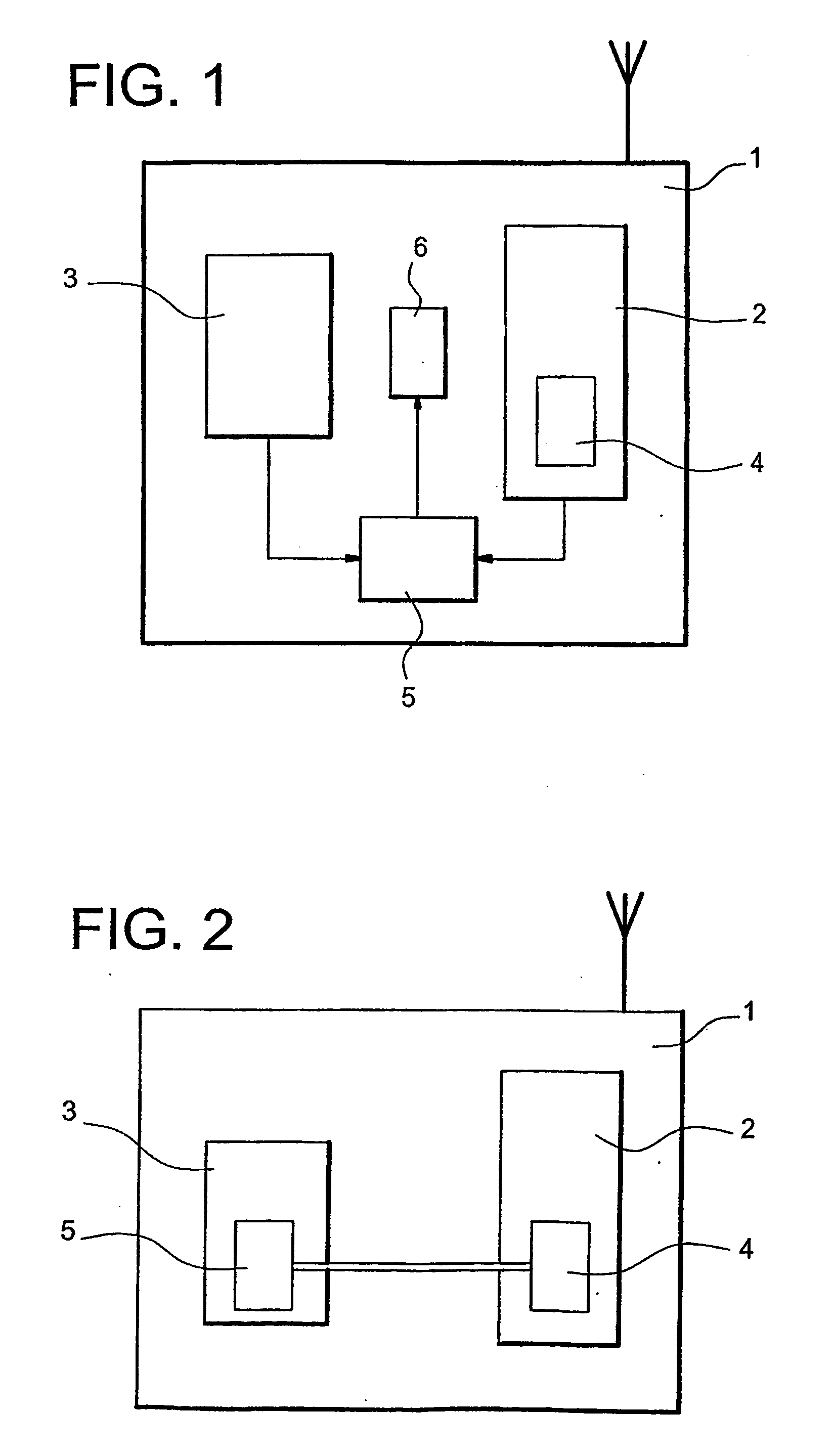

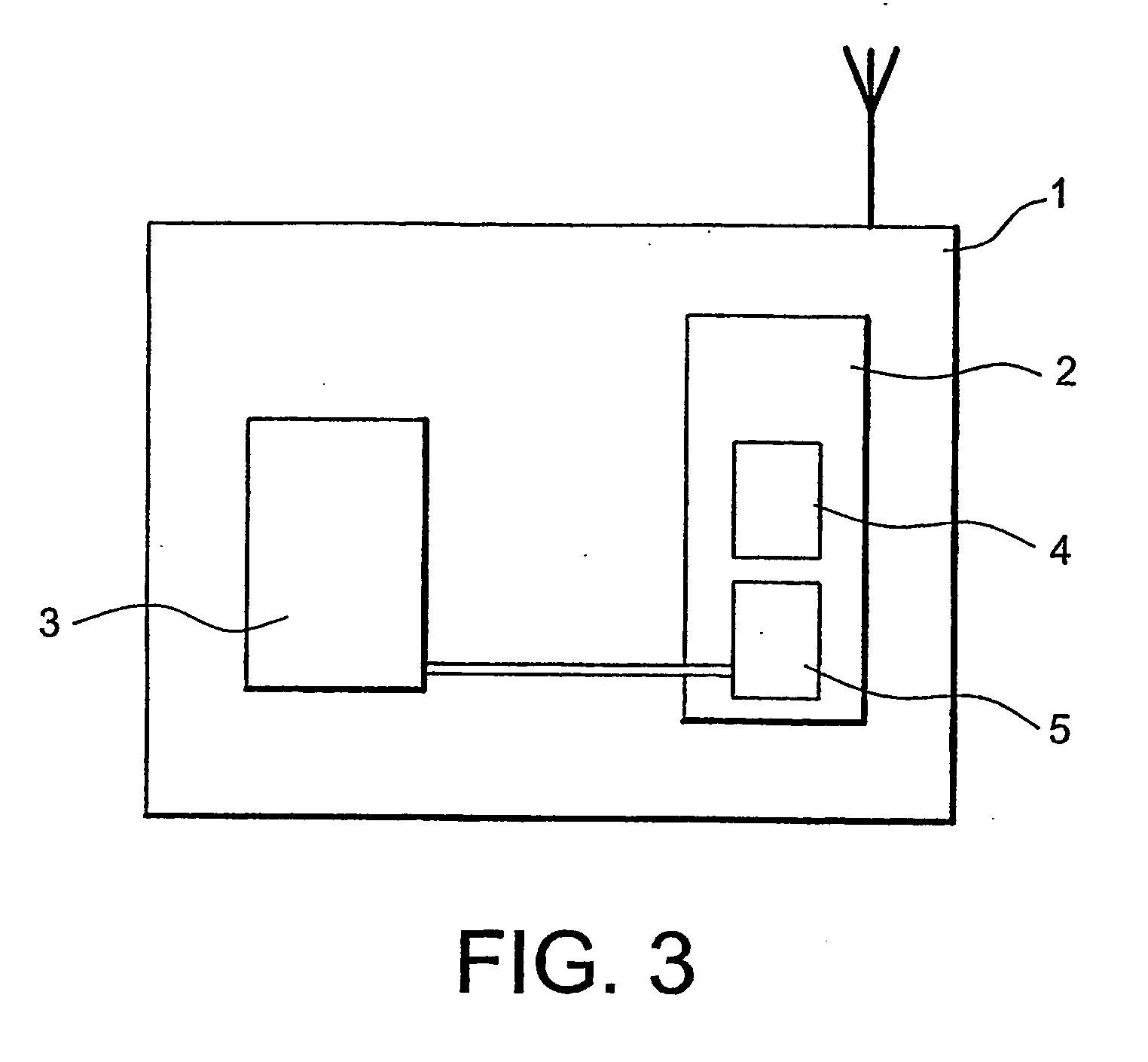

Method for verifying television receiver sets with access control and corresponding receiver set

InactiveUS20050044562A1Key distribution for secure communicationAnalogue secracy/subscription systemsTelevision receiversAccess control

The invention concerns a method for verifying television receiver sets with access control and a corresponding receiver set. The invention is characterized in that a broadcaster performs parametered calculations, for example through the subscriptions and the characteristics of the receiver sets. The results of said calculations are transmitted to the receiver set which store them. In order to verify a receiver, the broadcaster transmits thereto the parameter(s) used, the receiver performs the calculation and compares the result it obtains with that which it has stored. In case of non-conformity, the receiver set modifies its operating conditions. The invention is applicable to television with access control.

Owner:NAGRA FRANCE

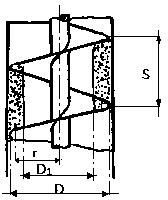

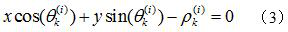

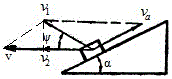

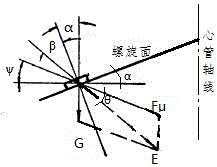

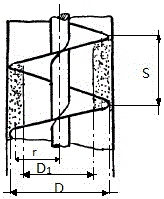

L800*76 efficient transmission spiral drill rod and parameter optimizing method

ActiveCN103967432AAvoid the impact of parametric calculationsIncrease coal delivery rateDrilling rodsDrilling casingsFilling rateEngineering

The invention discloses an L800*76 efficient transmission spiral drill rod and a parameter optimizing method. On the basis of a single-particle motion algorithm, the stress situation of a loose and soft coal seam in the spiral drill rod advancing process is analyzed, and accordingly a factor of rotation speed of the spiral drill rod is derived; further, a structural parameter influencing the conveying rate is obtained through computation and analysis on the coal particle quality conveying rate of the spiral drill rod during vertical drilling, and an optimum structural parameter of the spiral drill rod is obtained. The influence of secondary coal particle breakage on the parameterized computation is avoided through the single-particle motion analysis of the coal seam in the conveying process, an optimum drill rod parameter method is obtained, the filling rate, a drill rod blade helix angle and the mandrel diameter of the L800*76 spiral drill rod are design variables, meanwhile the influence of float coal quantity and lump coal rate on the coal seam density and friction factors is considered, a corresponding parameterized model is established, accordingly the coal conveying rate is improved, and the structural parameter of the spiral drill rod meets the working requirement.

Owner:田东昊润新材料科技有限公司

System and method for quantifying reflection e.g. when analyzing laminated documents

ActiveUS20170140217A1Reduce error ratePaper-money testing devicesCharacter and pattern recognitionDigital imageAuthentication

A system for computerized authentication of a laminated object, the system comprising a digital medium storing a digital image of at least a portion of the laminated object in a computer-implemented memory; a shininess analyzer operative, using a processor, to generate shininess data quantifying shininess of the digital image; and a parameterized computerized authentication sub-system operative to differentially perform at least one laminated object authentication operation based on the shininess data.

Owner:AU10TIX

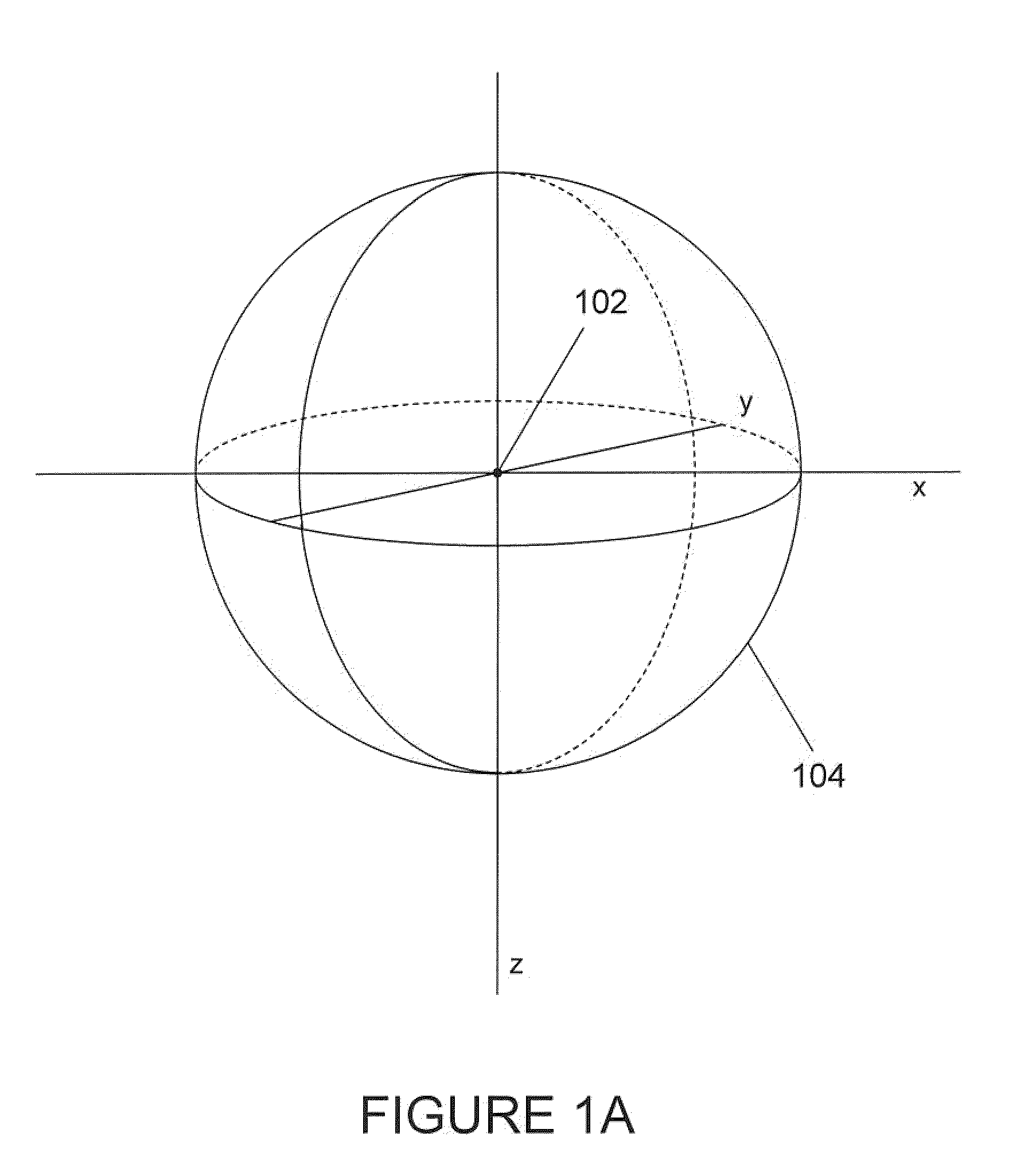

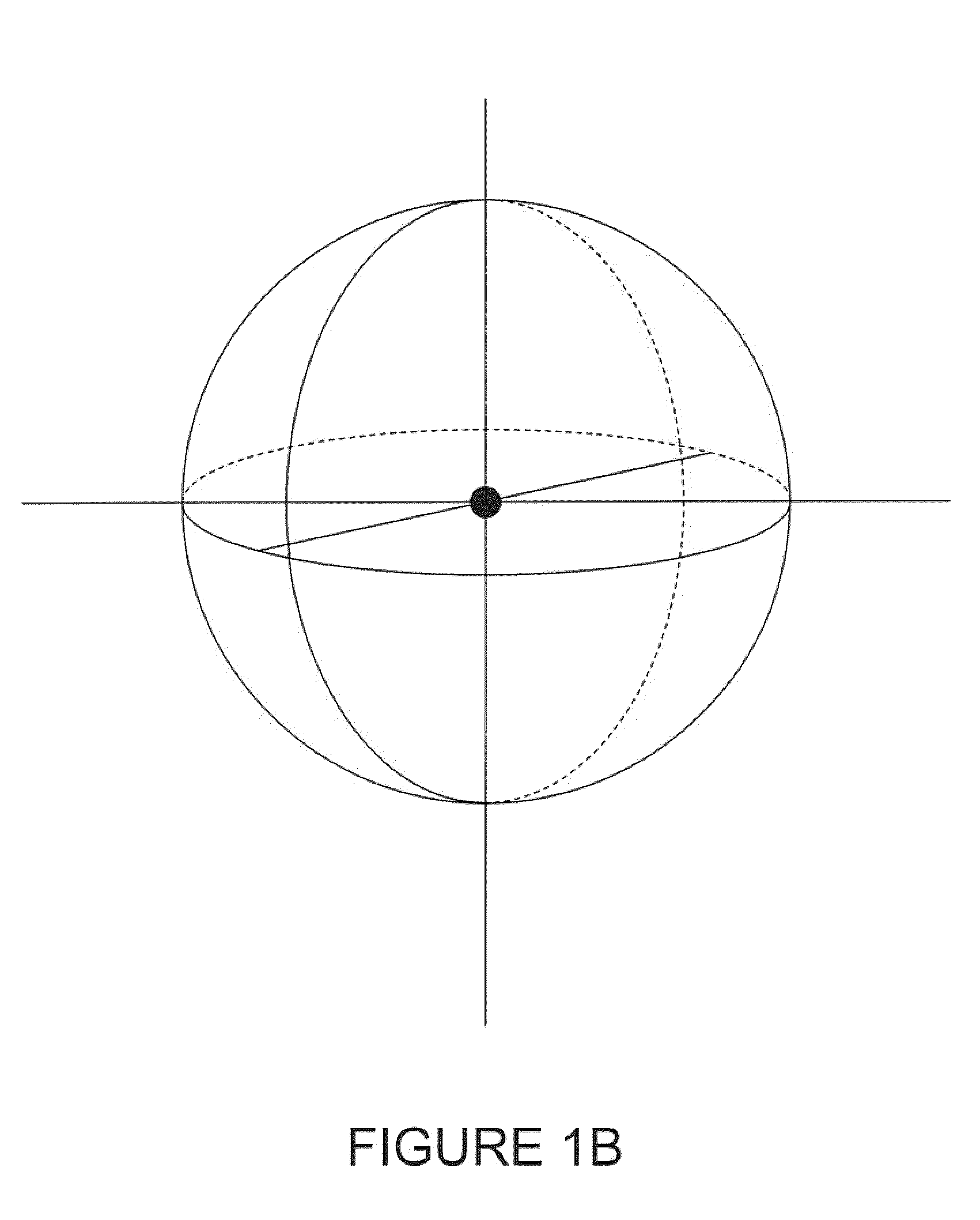

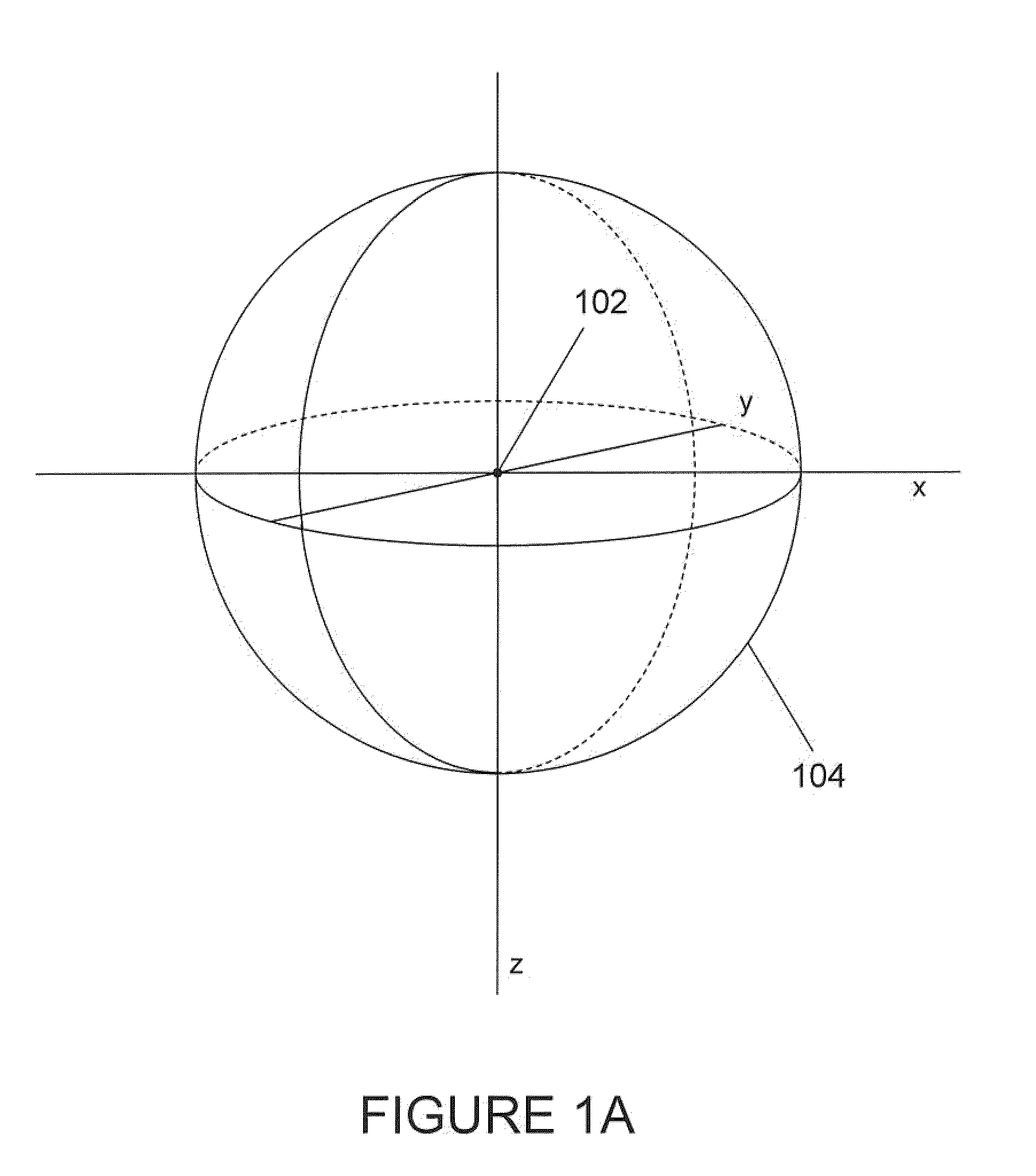

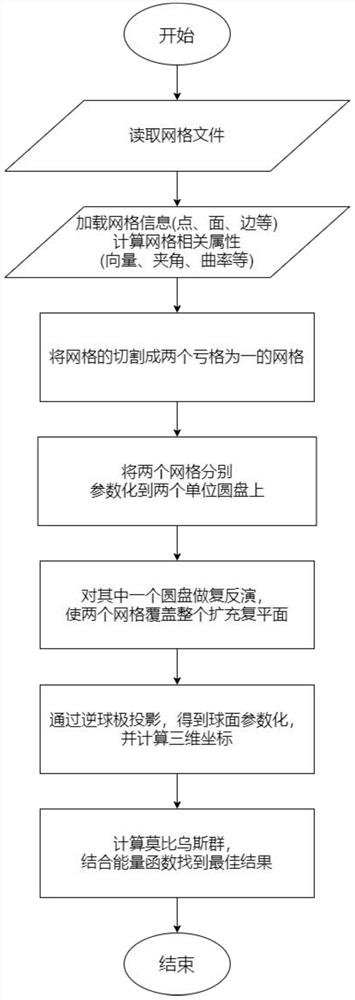

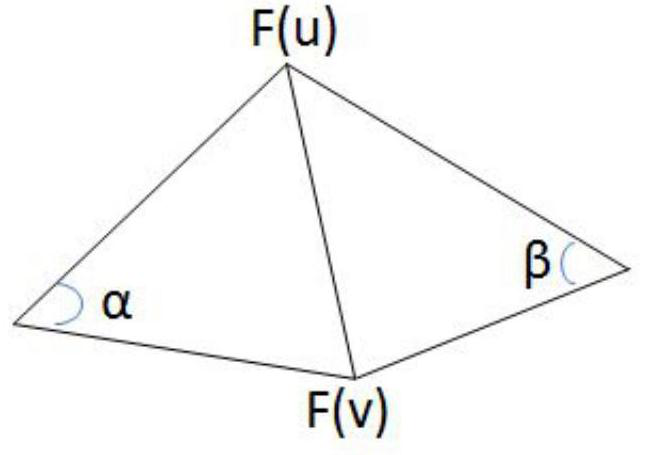

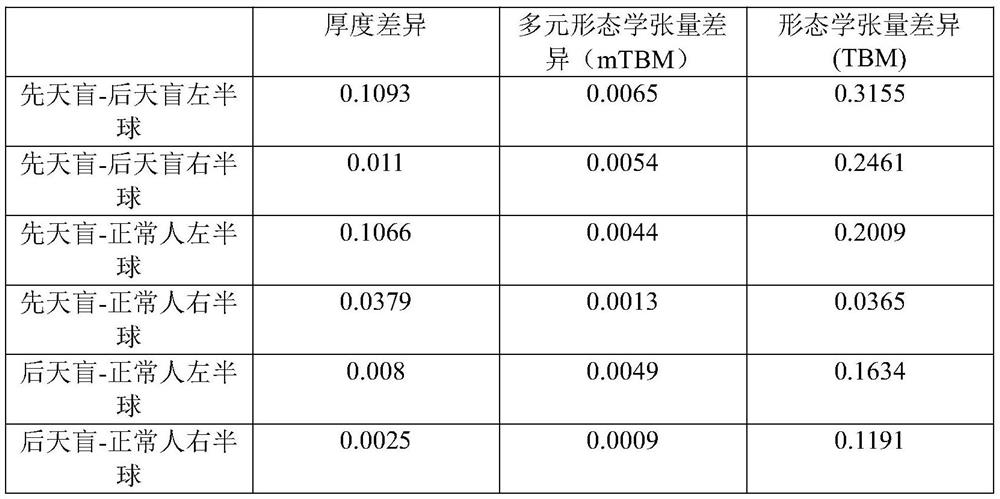

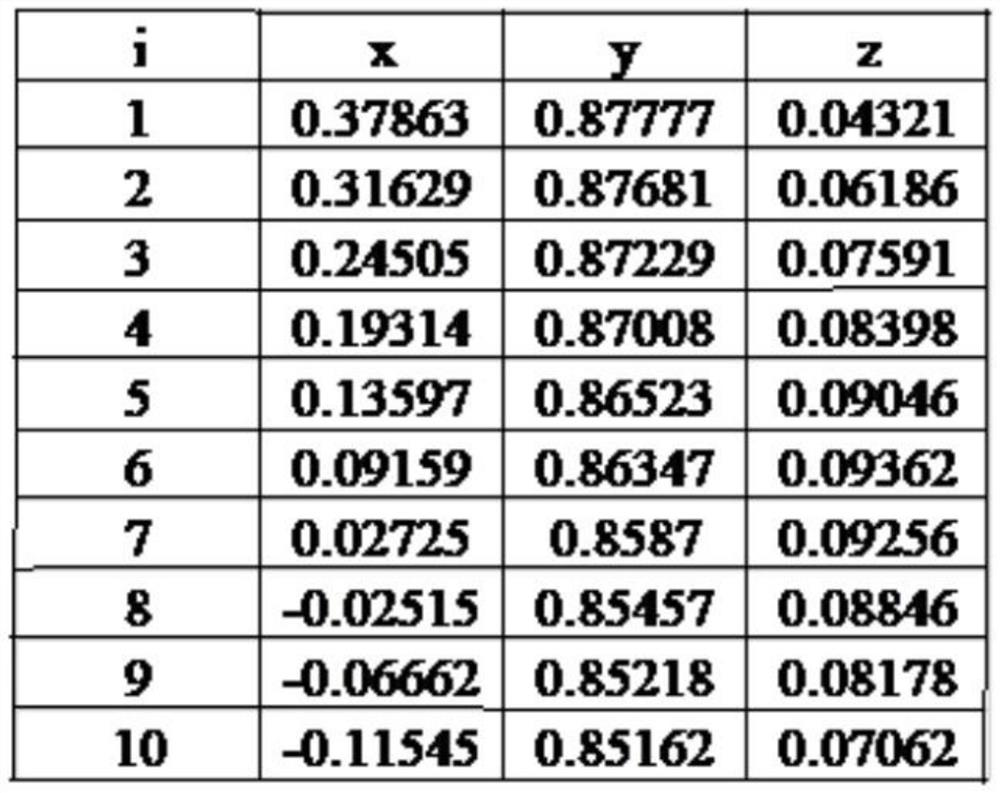

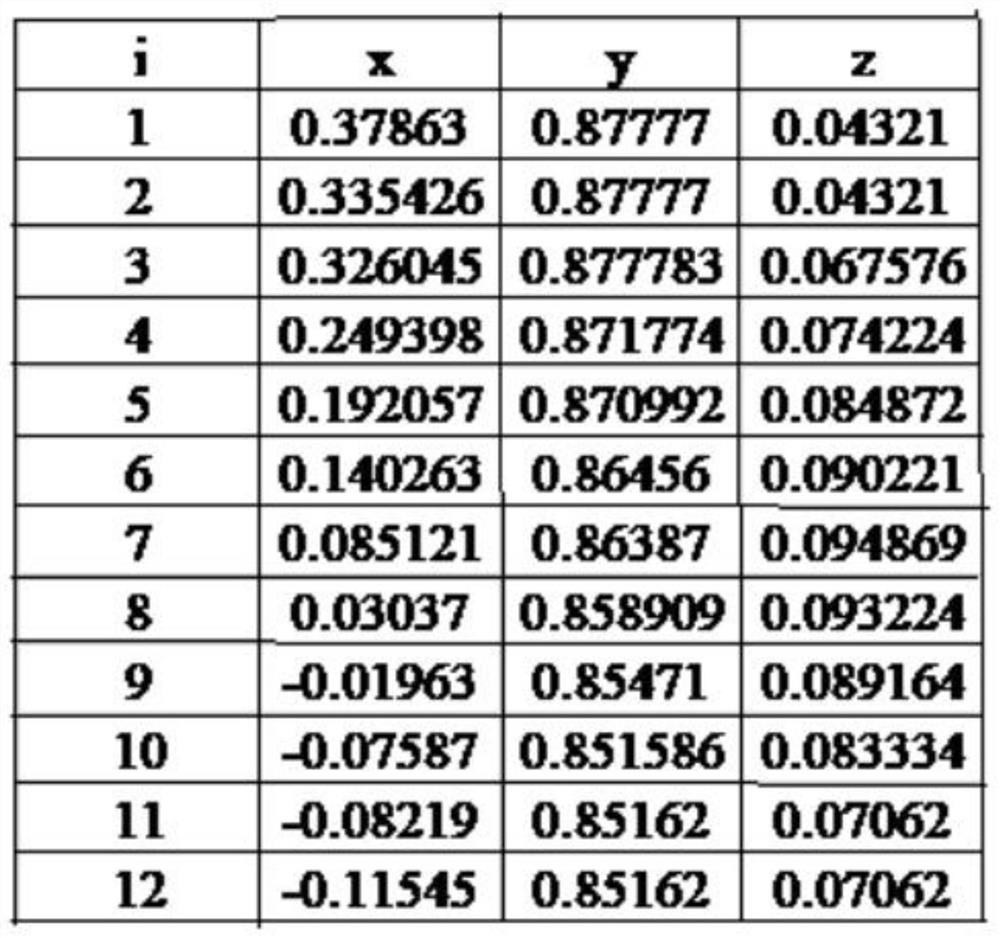

Grid spherical surface conformal parameterization method based on inverse spherical pole projection and application thereof

The invention discloses a grid spherical surface conformal parameterization method based on inverse spherical pole projection and application thereof, and belongs to the field of computer image analysis. The method mainly aims at the current situation that the zero-deficit grid spherical surface conformal parameterization calculation amount is large, a grid is cut into a grid with two deficits as one; secondly, plane parameterization is carried out on the two grids, parameterization is harmonic mapping with the fixed boundary as a unit circle, kerfs are evenly mapped to the unit circle, and therefore the two grid curved surfaces with one deficit are parameterized to two unit discs in a conformal mode; complex inversion is performed on one disc to enable the two discs to cover the whole expansion complex plane; then inverse transformation of spherical pole projection is carried out, so that points on the expansion complex plane are mapped to a Riemannian spherical surface; and finally, Mobius transformation which enables harmonic energy to be minimum and meets 0 centroid constraint is found from a Mobius group, so that original grid characteristics of the parameterized grid are kept as far as possible. The method is applied to brain geometric vector analysis, the state of disease progress is known on the premise that no surgical operation is adopted, and the pain of a patient is relieved.

Owner:LIAONING UNIVERSITY

A hair modeling method based on spherical b-spline curve

The invention relates to the technical field of virtual human simulation, in particular to a hair modelling modeling method based on a ball B-spline curve. The hair modelling modeling method based on the ball B-spline curve includes the steps that growing points of hairs are initialized; parametric calculation is conducted on the hairs; a coordinate frame and coordinates of the hairs are computed; energy minimization calculation is conducted on the hairs; a new coordinate frame and coordinates of the hairs are computed; collision detection is conducted on the hairs; modeling is conducted on the hairs according to the ball B-spline curve. According to the hair modelling modeling method, hair strands can be constructed through ball B-splines, the hair modeling is optimized through energy minimization, and the obtained model can be used for various hair models of the virtual human.

Owner:BEIJING NORMAL UNIVERSITY

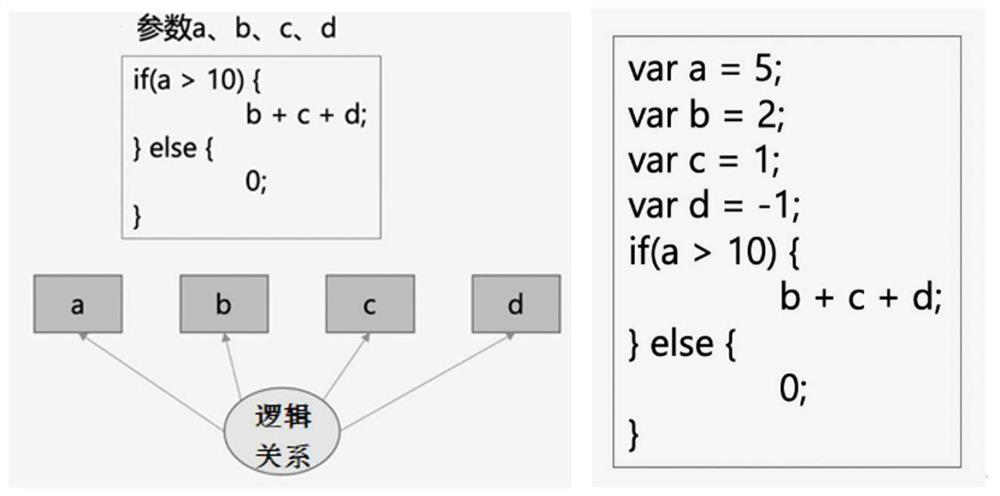

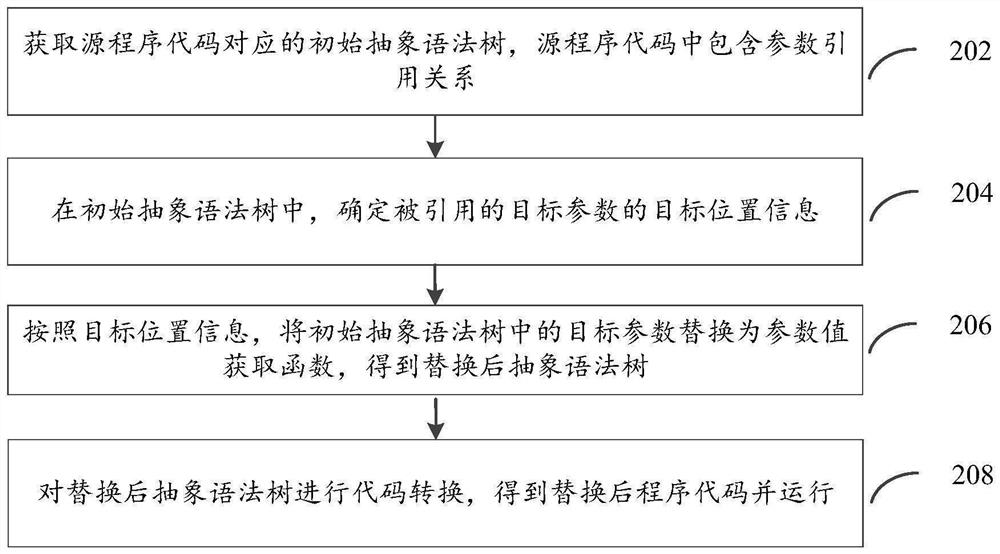

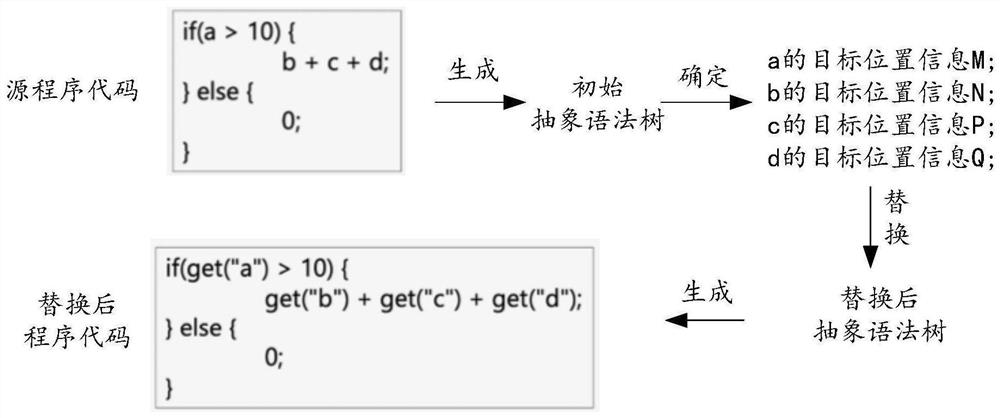

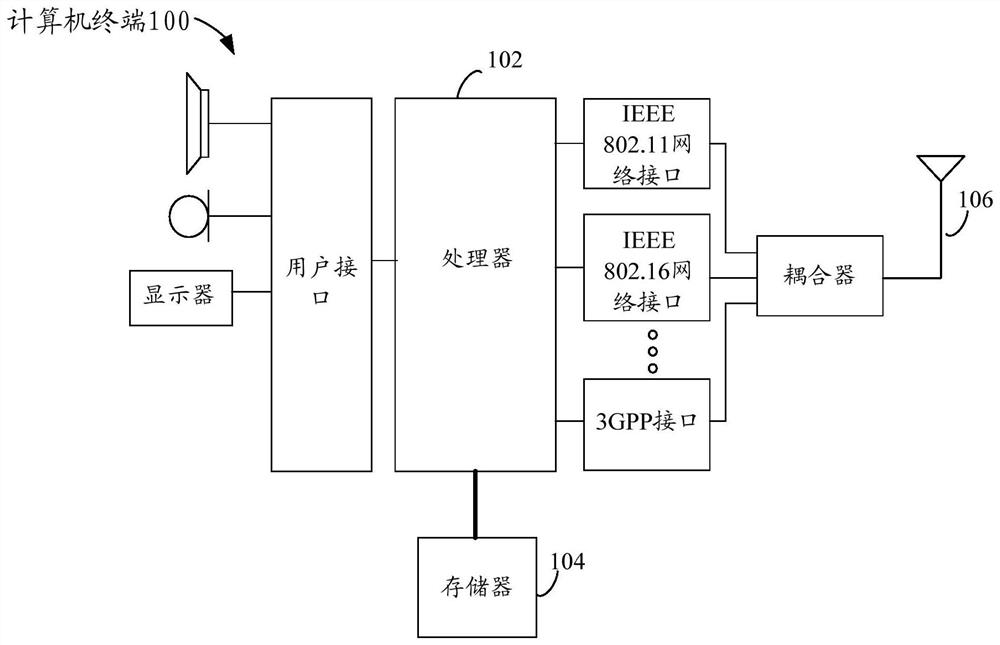

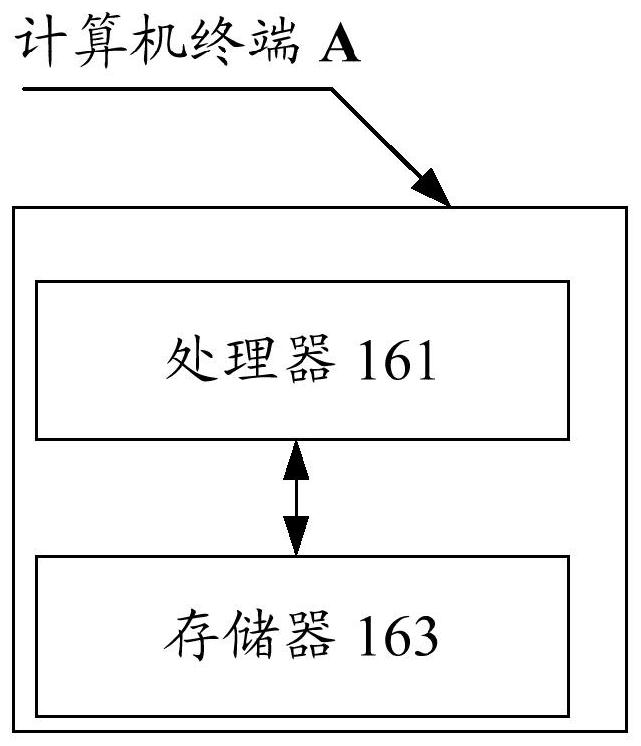

Data processing method and device, equipment and storage medium

PendingCN114741085AImprove the efficiency of parameterized calculationsCode compilationAlgorithmAbstract syntax tree

The embodiment of the invention provides a data processing method and device, equipment and a storage medium. The data processing method comprises the steps of obtaining an initial abstract syntax tree corresponding to a source program code; the source program code comprises a parameter reference relationship; in the initial abstract syntax tree, determining target position information of a referenced target parameter; according to the target position information, replacing a target parameter in the initial abstract syntax tree with a parameter value acquisition function to obtain a replaced abstract syntax tree; wherein when the parameter value obtaining function is called, the parameter value obtaining function is used for running a target program code corresponding to the target parameter so as to obtain a parameter value of the target parameter; and performing code conversion on the replaced abstract syntax tree to obtain a replaced program code, and running the replaced program code. According to the embodiment of the invention, the parameterization calculation efficiency can be improved.

Owner:ALIBABA (CHINA) CO LTD

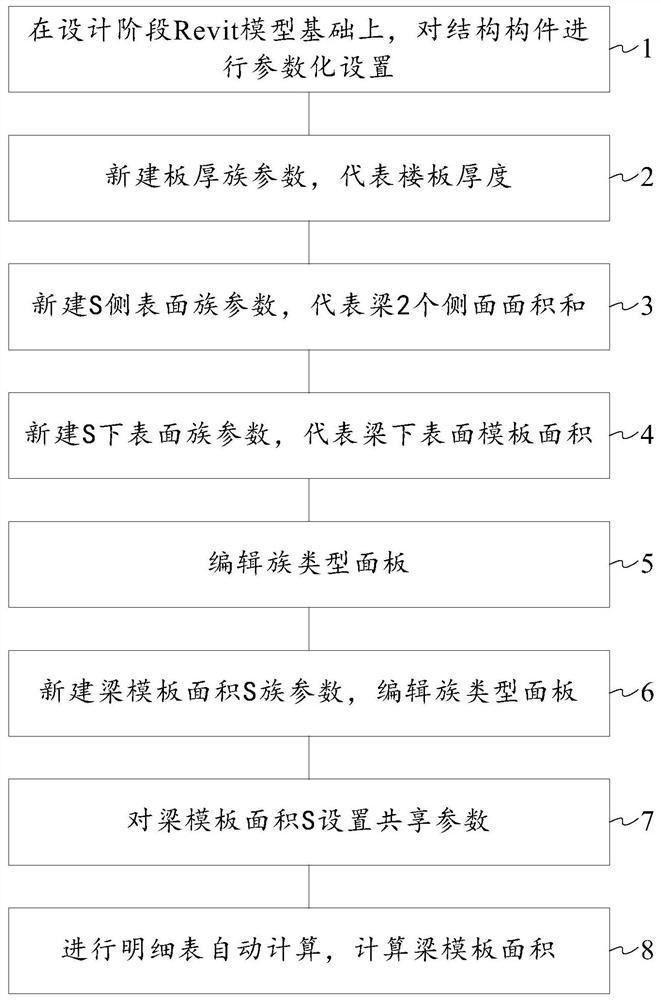

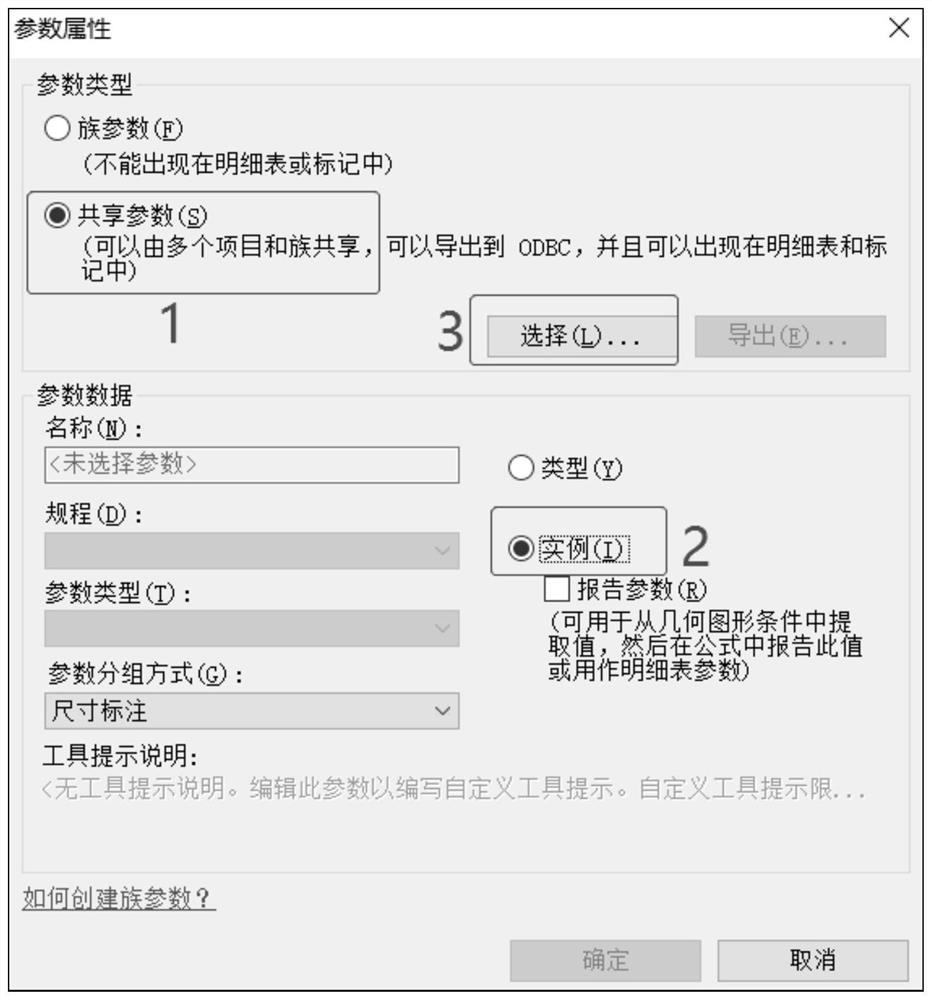

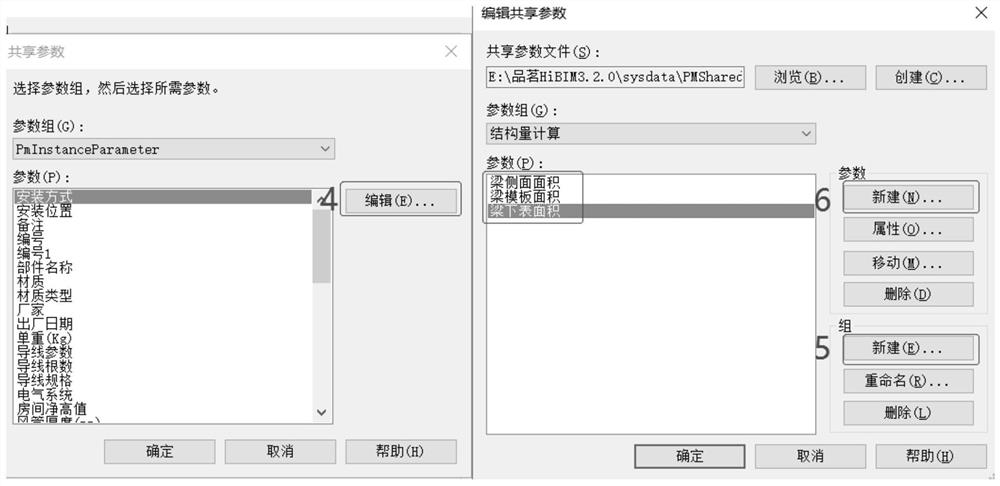

BIM (Building Information Modeling)-based refined template quantity calculation method in bidding and tendering stage

PendingCN112948940ASolve template calculation workCalculation results are intuitiveGeometric CADBuying/selling/leasing transactionsInformatizationProcess engineering

The invention discloses a BIM (Building Information Modeling)-based refined template quantity calculation method in a bidding and tendering stage, which is characterized in that on the basis of a BIM model in a design stage, a revit component is subjected to parameterization setting, a parameterization calculation structure is associated with a detailed statement, and a template engineering quantity is quickly calculated, so that the problem of template quantity calculation work in the bidding and tendering stage is greatly solved, and the calculation result is based on the evidence and is more visualized and informationized, and the calculation result of the template quantity is more transparent.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

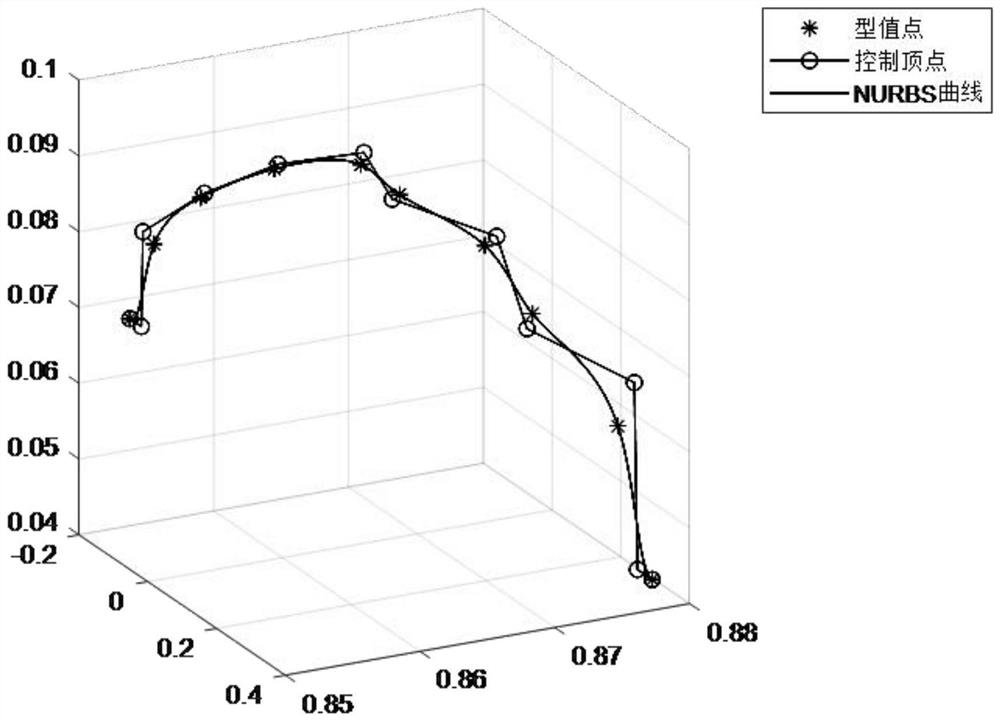

NURBS (Non-Uniform Rational B-Spline) curve velocity interpolation method based on parameter encryption

PendingCN113290558AImprove smoothnessAvoid second-order derivative operationsProgramme-controlled manipulatorClassical mechanicsEngineering

The invention discloses an NURBS (Non-Uniform Rational B-Spline) curve velocity interpolation method based on parameter encryption, and belongs to the technical field of robot motion control. The NURBS curve velocity interpolation method comprises the steps of: calculating a node vector in an accumulated chord length parameterization manner, inversely calculating a control vertex through a type value point, positively calculating a parameter track through a control vertex, establishing a relation between a curve track parameter and an arc length parameter through a least square method, and performing track point selection in combination with a parameterization model and a T-shaped velocity interpolation model to realize T-shaped acceleration and deceleration variable motion control. The NURBS curve velocity interpolation method is scientific and reasonable. The parameterization model is used in parameter encryption of the NURBS curve, direct second-order derivation operation on the NURBS spline function is avoided, a complex numerical calculation method is avoided, and only basic arithmetic operation is used. The algorithm is simple and convenient, and the operation efficiency is high. The T-shaped velocity interpolation model with self-defined acceleration and deceleration is used, variable-speed motion control over the tail end of a mechanical arm on a cubic NURBS curve is achieved, the velocity is continuously controllable, and vibration generated by an industrial robot is greatly reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

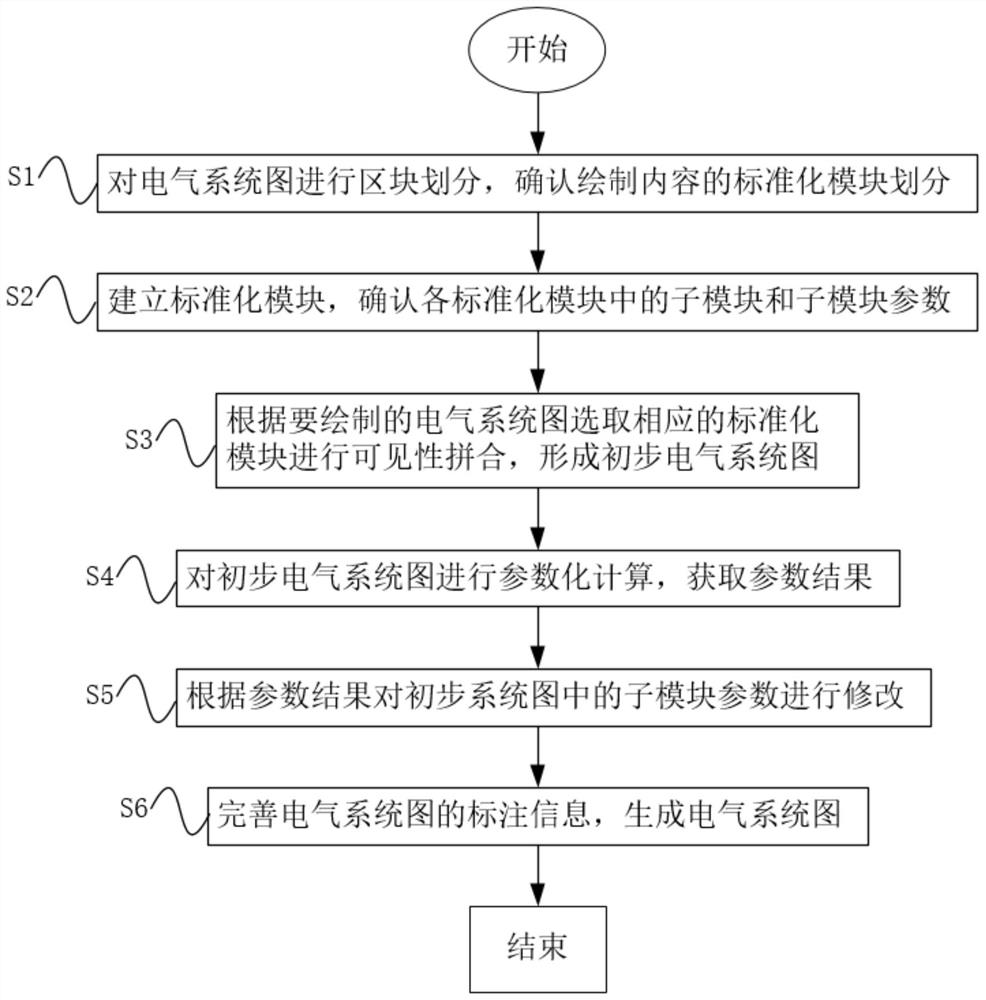

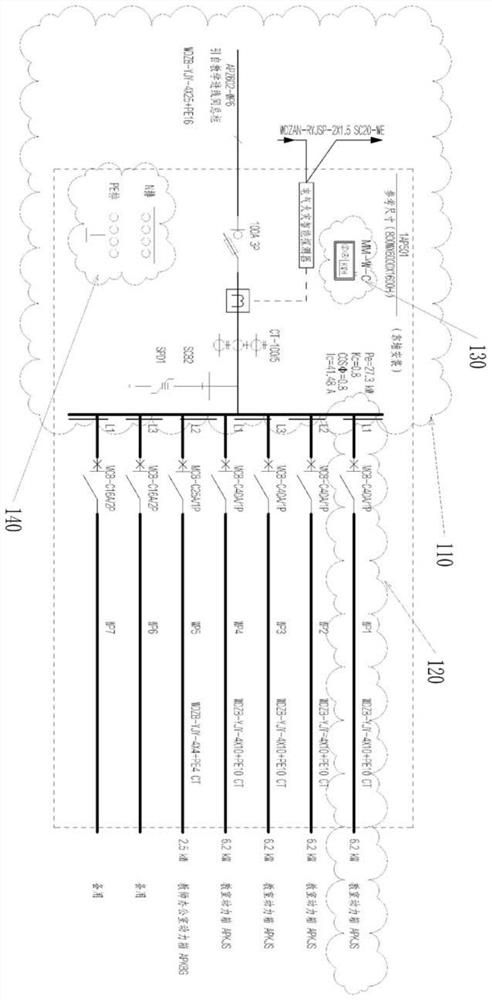

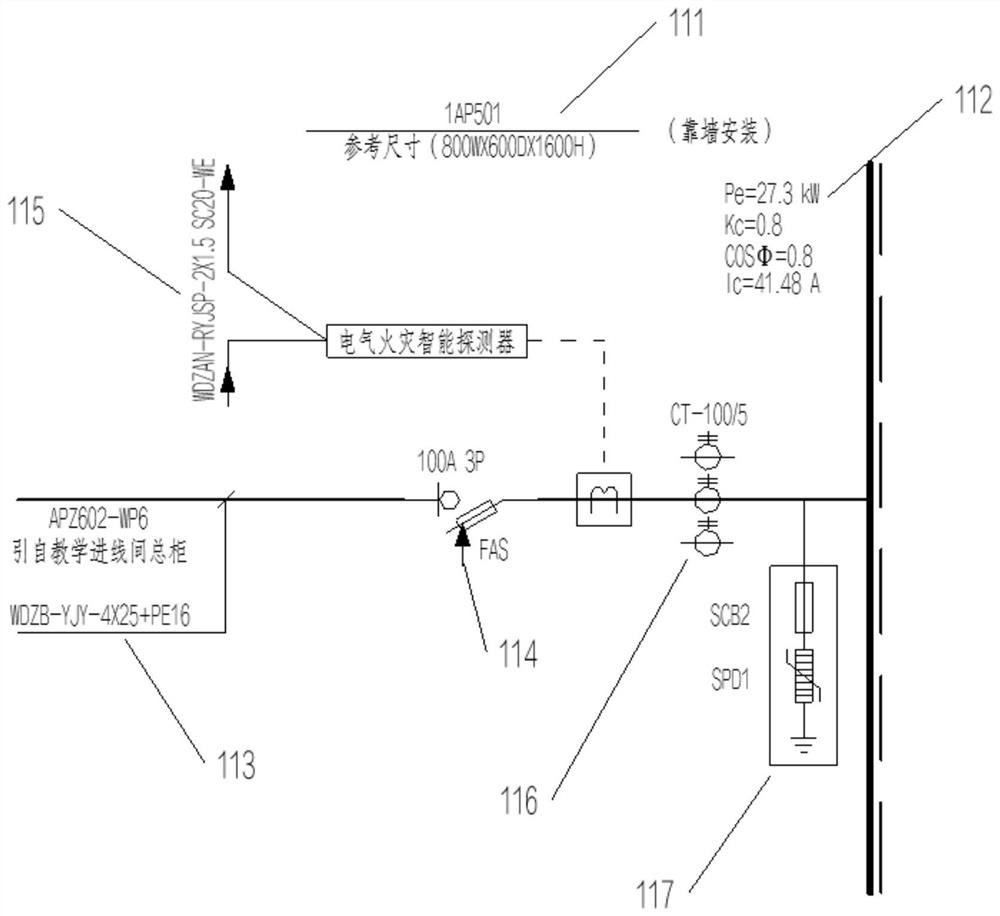

Revit-based electrical system diagram generation method

PendingCN112784517AImprove drawing efficiencyMeet the needs of standardized drawingCAD circuit designSpecial data processing applicationsSoftware engineeringMechanical engineering

The invention relates to a Revit-based electrical system diagram generation method, and the method comprises: S1, carrying out the block division of an electrical system diagram, and confirming the standardized module division of drawing content; S2, establishing standardized modules, and confirming sub-modules and sub-module parameters in each standardized module; S3, selecting corresponding standardized modules according to the electrical system diagram to be drawn to carry out visible splicing so as to form a preliminary electrical system diagram; S4, performing parameterization calculation on the initial electrical system diagram to obtain a parameter result; S5, modifying sub-module parameters in the preliminary system diagram according to a parameter result; and S6, completing the labeling information of the electrical system diagram, and generating the electrical system diagram. Compared with the prior art, the method is advantageous in that, on the basis of establishment, splicing, calculation and adjustment of the standardized modules, the electrical system can be generated in a standardized, modularized and normalized mode, the application range is wide, the drawing efficiency is high, and the requirement for standardized drawing is met.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Method and system for verification of ship piping system design scheme

ActiveCN107818193BQuick calculationImprove verification efficiencyDesign optimisation/simulationSpecial data processing applicationsSystems designAlgorithm

The invention discloses a ship piping system design scheme verification method. The method includes the steps that a ship piping system is simplified into a network graph; a first resistance value anda second resistance value are acquired; whether or not the error between the first resistance value and the second resistance value exceeds a preset threshold value is judged; if yes, the first resistance value or the second resistance value is adjusted according to the judgment result, and the above-mentioned judgment step is executed again; if not, whether or not a penultimate tail end node isa head end node is judged; if yes, the actual flow value and the actual resistance value of the piping system are output; if not, the combination of a tail end node and the penultimate tail end node is used as a tail end node, and a new second resistance value is acquired. The invention further discloses a ship piping system design scheme verification system. By means of the method and system, parameterized calculation of the resistance and flow of the ship piping system is achieved, calculation is fast and accurate, and the calculation result can be used for assisting in piping system check and pump model selection.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

A Hair Styling Modeling Method Based on Static Superhelix Model

The invention relates to the technical field of virtual human simulation, in particular to a hair modelling modeling method based on a static supercoiling model. The hair modelling modeling method based on the static supercoiling model includes the steps that growing points of hairs are initialized; parametric calculation is conducted on the hairs; a coordinate frame and coordinates of the hairs are computed; energy minimization calculation is conducted on the hairs; a new coordinate frame and coordinates of the hairs are computed; collision detection is conducted on the hairs; modeling is conducted on the hairs according to a ball B-spline curve. According to the hair modelling modeling method, hair strands can be constructed through ball B-splines, the hair modeling is optimized through energy minimization, and the obtained model can be used for various hair models of the virtual human.

Owner:BEIJING NORMAL UNIVERSITY

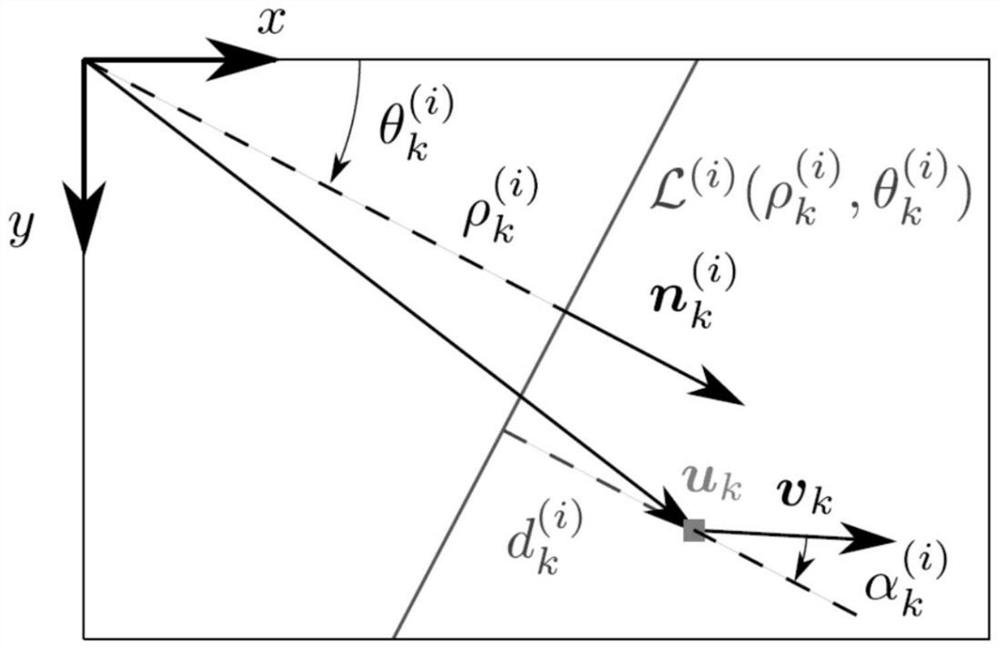

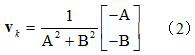

Conversion event linear detection method based on pulse type image sensor

ActiveCN112446236AImprove adaptabilityCharacter and pattern recognitionComplex mathematical operationsImage detectionEngineering

The invention discloses a conversion event linear detection method based on a pulse type image sensor. The method comprises the steps: converting a high-speed pulse into an event signal with a direction, achieving the linear parameterization through employing a least square method, calculating the activity, and judging whether an event belongs to a straight line or not. According to the method, each incoming event is fitted to a straight line by using an iterative weighted least square method, and the past event weight is attenuated exponentially, so that the algorithm can be kept effective ina violent change scene. The detection algorithm is suitable for parallelism, can be applied in real time and achieves image detection, recognition and tracking accurate to pixel points.

Owner:TIANJIN UNIV MARINE TECH RES INST

A Method for Optimizing the Parameters of Auger Drill Pipe

ActiveCN103967432BAvoid the impact of parametric calculationsIncrease coal delivery rateDrilling rodsDrilling casingsFilling rateEngineering

The invention discloses an L800*76 efficient transmission spiral drill rod and a parameter optimizing method. On the basis of a single-particle motion algorithm, the stress situation of a loose and soft coal seam in the spiral drill rod advancing process is analyzed, and accordingly a factor of rotation speed of the spiral drill rod is derived; further, a structural parameter influencing the conveying rate is obtained through computation and analysis on the coal particle quality conveying rate of the spiral drill rod during vertical drilling, and an optimum structural parameter of the spiral drill rod is obtained. The influence of secondary coal particle breakage on the parameterized computation is avoided through the single-particle motion analysis of the coal seam in the conveying process, an optimum drill rod parameter method is obtained, the filling rate, a drill rod blade helix angle and the mandrel diameter of the L800*76 spiral drill rod are design variables, meanwhile the influence of float coal quantity and lump coal rate on the coal seam density and friction factors is considered, a corresponding parameterized model is established, accordingly the coal conveying rate is improved, and the structural parameter of the spiral drill rod meets the working requirement.

Owner:田东昊润新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com