A Method for Optimizing the Parameters of Auger Drill Pipe

A technology of auger drill pipe and optimization method, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of increased difficulty in parametric design of auger drill pipe, complex force of coal particles, etc., and achieve the goal of improving coal delivery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

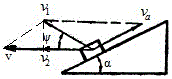

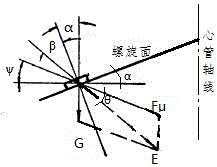

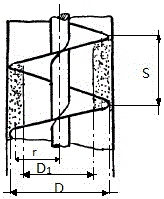

[0017] Embodiment 1 of the present invention: the principle of the present invention is: based on the single-particle motion algorithm, analyze the force situation of the soft coal seam during the drilling process of the auger drill rod, thereby deriving the factors that affect the rotation speed of the auger drill rod; further through The calculation and analysis of the coal particle mass delivery rate of the auger drill pipe during vertical drilling, the structural parameters affecting the delivery rate have been obtained, and the optimal structural parameters of the auger drill pipe have been reached. The specific algorithm is based on the single particle, and the single particle is separately Velocity analysis and force analysis, through the derivation of velocity equation and force equation, the absolute velocity relational expression of single particle is derived, and then the relational expression of auger pipe speed and single particle related parameters is deduced.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com