Flower-like manganese dioxide electrode material for super-capacitor and preparation method thereof

A manganese dioxide electrode and supercapacitor technology, which is applied in capacitors, electrolytic capacitors, manganese oxide/manganese hydroxide, etc., can solve the problems of unsuitable supercapacitors, difficult to control the shape, long reaction time, etc., and achieve low cost, The method is simple and the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

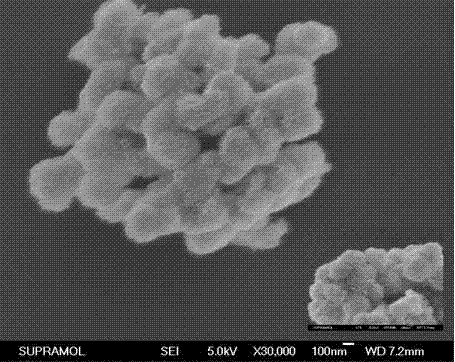

[0015] Weigh 1.5g of potassium permanganate and 0.5g of hydrated manganese sulfate, and then dissolve them in deionized water to obtain 15ml and 5ml of solutions; under strong stirring, add the manganese sulfate solution to the potassium permanganate solution drop by drop for 5 minutes. The addition is completed; transfer the mixed solution to a hydrothermal reaction kettle until the filling rate is 80%, and conduct a hydrothermal reaction at 120°C for 2 hours to obtain a brown-black precipitate; wash with deionized water and dry at 80°C for 12 hours to obtain nano-sized manganese dioxide .

Embodiment 2

[0017] Weigh 0.5g of potassium permanganate and 0.5g of hydrated manganese sulfate, and then dissolve them in deionized water to obtain 15ml and 5ml of the solutions; under strong stirring, add the manganese sulfate solution to the potassium permanganate solution drop by drop for 10 minutes The addition is completed; transfer the mixed solution to a hydrothermal reaction kettle until the filling rate is 90%, hydrothermally react at 100°C for 3 hours to obtain a brown-black precipitate; wash with deionized water and dry at 80°C for 24 hours to obtain nano-sized manganese dioxide .

Embodiment 3

[0019] Weigh 0.5g of potassium permanganate and 1.5g of manganese acetate, and then dissolve them in deionized water to obtain 15ml and 5ml of solutions respectively; under strong stirring, add the manganese sulfate solution to the potassium permanganate solution dropwise for 15min Complete; transfer the mixed solution to a hydrothermal reaction kettle until the filling rate is 80%, and conduct a hydrothermal reaction at 160°C for 2 hours to obtain a brown-black precipitate; wash with deionized water and dry at 100°C for 12 hours to obtain nano-sized manganese dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com