Method for filling carbon nano tube with magnetic nano metal iron particles

A technology of carbon nanotubes and magnetic nanometers, which is applied in the field of preparation of nanocomposite materials, can solve the problems of complex process and low filling rate of nano-metal iron, and achieve high controllability, facilitate mass production, and simple and easy-to-operate methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

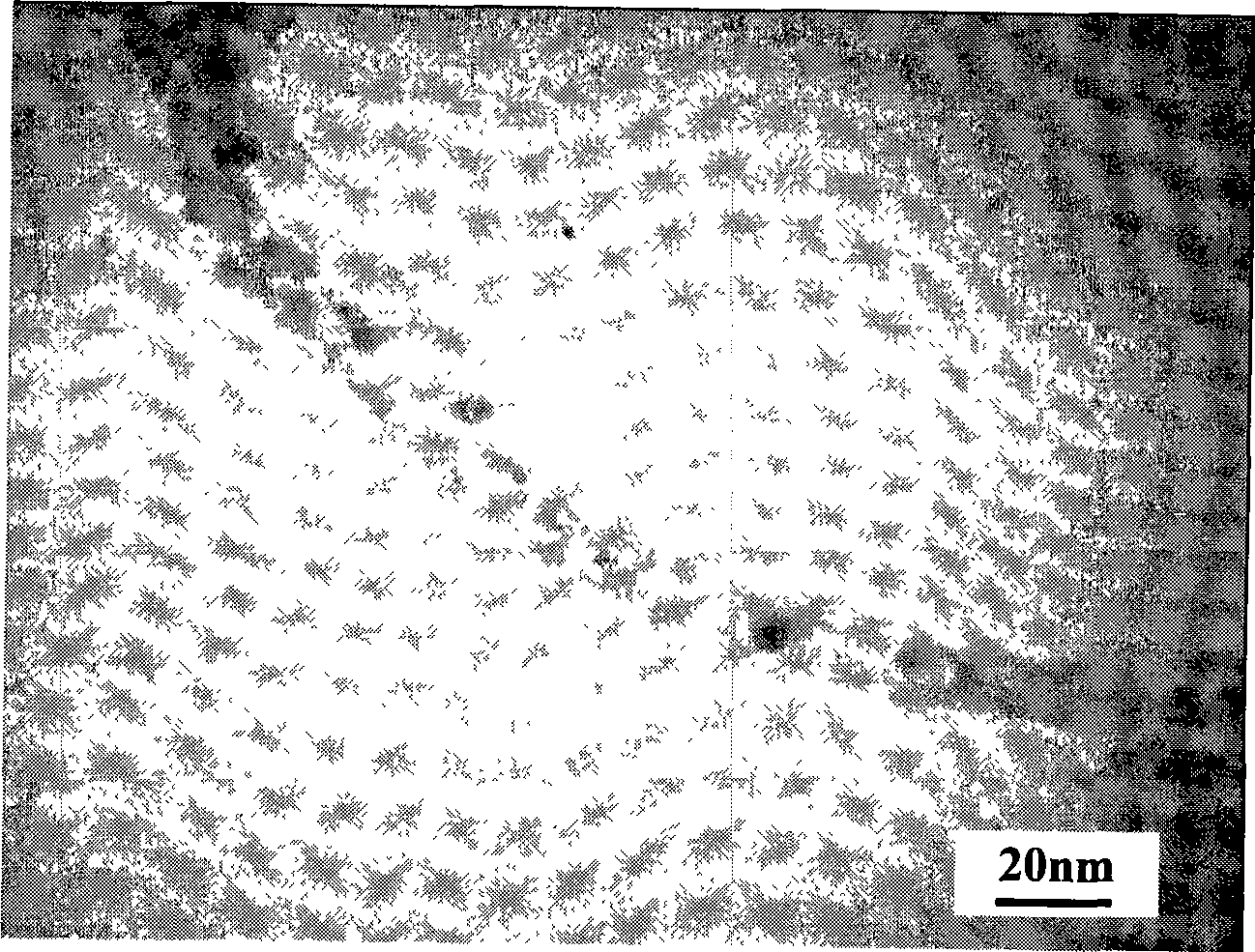

Embodiment 1

[0030] (1) At room temperature, add 5g of carbon nanotubes with a diameter of 10-20 nanometers to 250ml of concentrated nitric acid (68%), ultrasonically disperse for 30 minutes, reflux in an oil bath at 125°C for 24 hours, and then reflux The temperature of the reaction mixture was reduced to 23°C, filtered with a 0.85μm filter membrane, washed with deionized water and filtered to a pH of 6.8 to obtain carbon nanotubes with functional groups such as carbonyl, hydroxyl, and carboxyl groups introduced on the surface, and dried at 60°C in the air Dry for 24 hours;

[0031] (2) Prepare ferrous sulfate into an aqueous solution with a concentration of 20%, and put the carbon nanotubes with carbonyl, hydroxyl, carboxyl and other functional groups on the surface obtained in step (1) into the ferrous sulfate aqueous solution, ultrasonically disperse for 30 minutes, and electromagnetically stir After 24 hours, filter with a filter membrane and dry in the air at 60°C for 12 hours to obtain ...

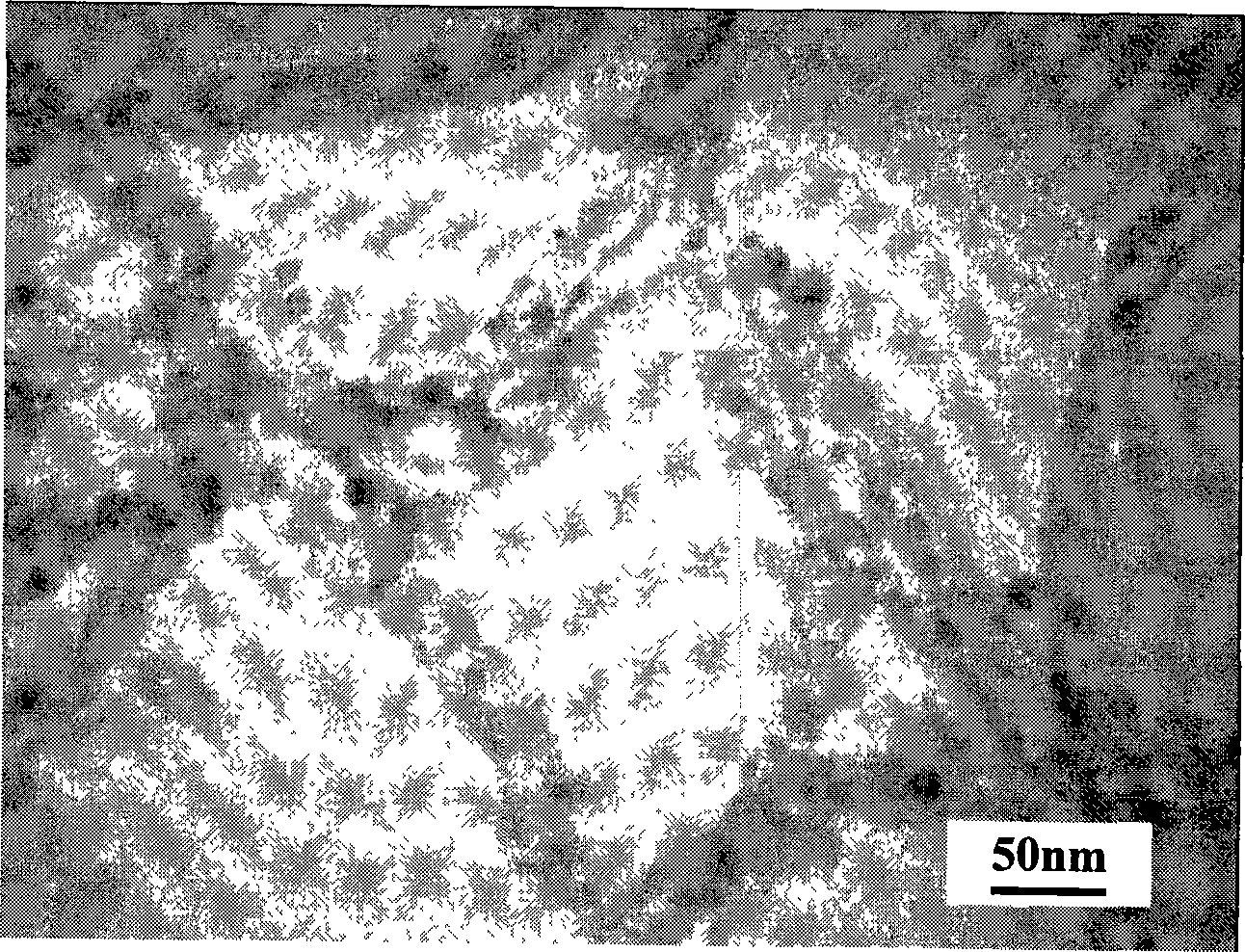

Embodiment 2

[0036] (1) At room temperature, add 4.5g of carbon nanotubes with a diameter of 20-40 nanometers to 200ml of concentrated nitric acid (68%), ultrasonically disperse for 30 minutes, reflux in an oil bath at 120°C for 20 hours, and then The temperature of the refluxing reaction mixture is lowered to 24℃, filtered with a 0.85μm filter membrane, washed with deionized water and filtered to a pH of 6.5 to obtain carbon nanotubes with carbonyl, hydroxyl, carboxyl and other functional groups introduced on the surface, in the air at 60℃ Dry for 24 hours;

[0037] (2) Prepare ferrous sulfate into an aqueous solution with a concentration of 25%, and put the carbon nanotubes with carbonyl, hydroxyl, carboxyl and other functional groups on the surface obtained in step (1) into the ferrous sulfate aqueous solution, ultrasonically disperse for 30 minutes, and electromagnetically stir After 24 hours, filter with a filter membrane and dry in the air at 60°C for 12 hours to obtain carbon nanotubes ...

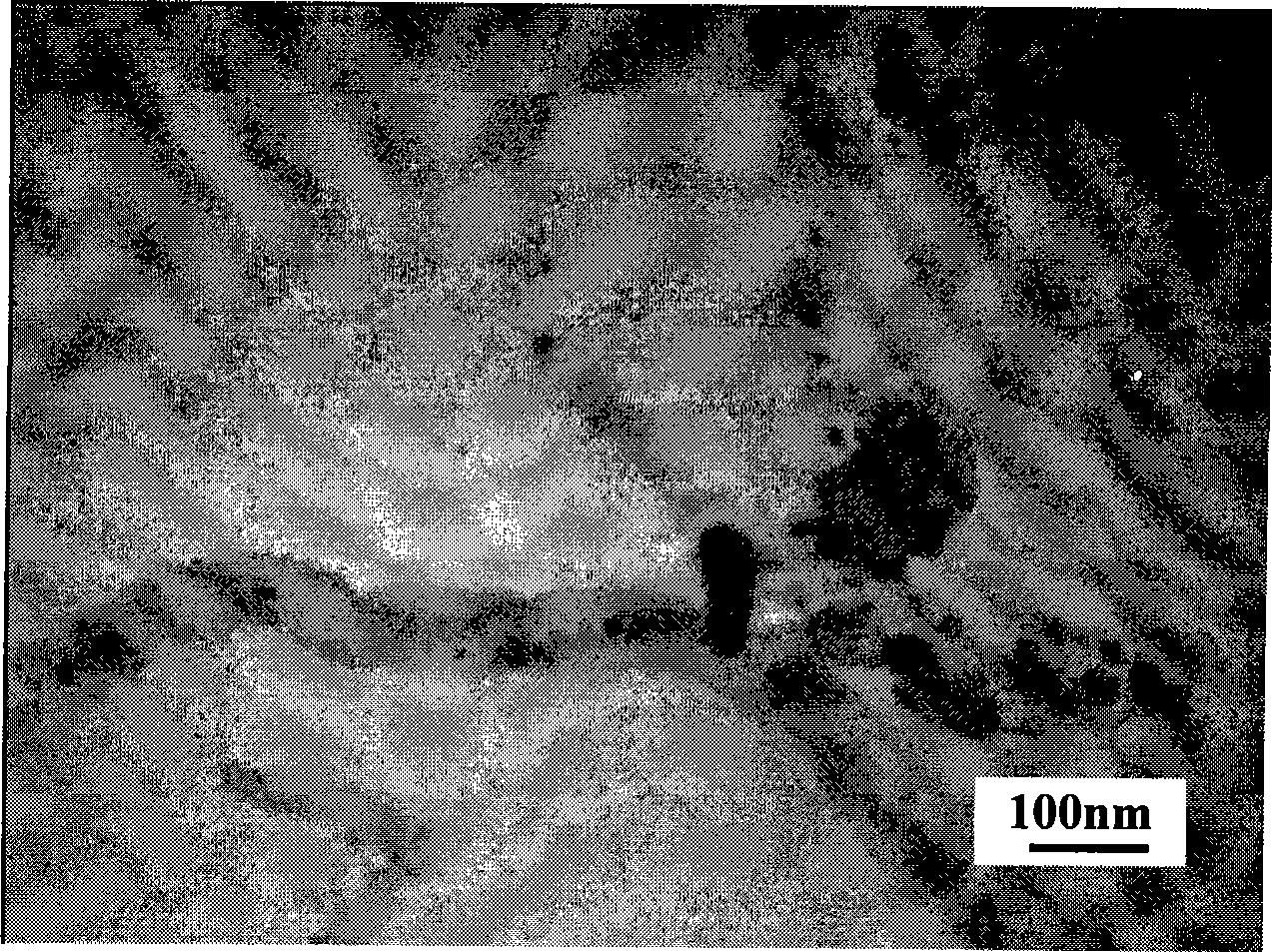

Embodiment 3

[0042] (1) At room temperature, add 6g of carbon nanotubes with a diameter of 40-60 nanometers to 300ml of concentrated nitric acid (68%), ultrasonically disperse for 30 minutes, reflux in an oil bath at 130°C for 22 hours, and then reflux The temperature of the reaction mixture was reduced to 25℃, filtered with a 0.85μm filter membrane, washed with deionized water and filtered to a pH of 7, to obtain carbon nanotubes with carbonyl, hydroxyl, carboxyl and other functional groups introduced on the surface, and dried at 60℃ in the air Dry for 24 hours;

[0043] (2) Prepare ferrous sulfate into an aqueous solution with a concentration of 30%, and put the carbon nanotubes with carbonyl, hydroxyl, carboxyl and other functional groups on the surface obtained in step (1) into the ferrous sulfate aqueous solution, ultrasonically disperse for 30 minutes, and electromagnetically stir After 24 hours, filter with a filter membrane and dry in the air at 60°C for 12 hours to obtain carbon nanot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com