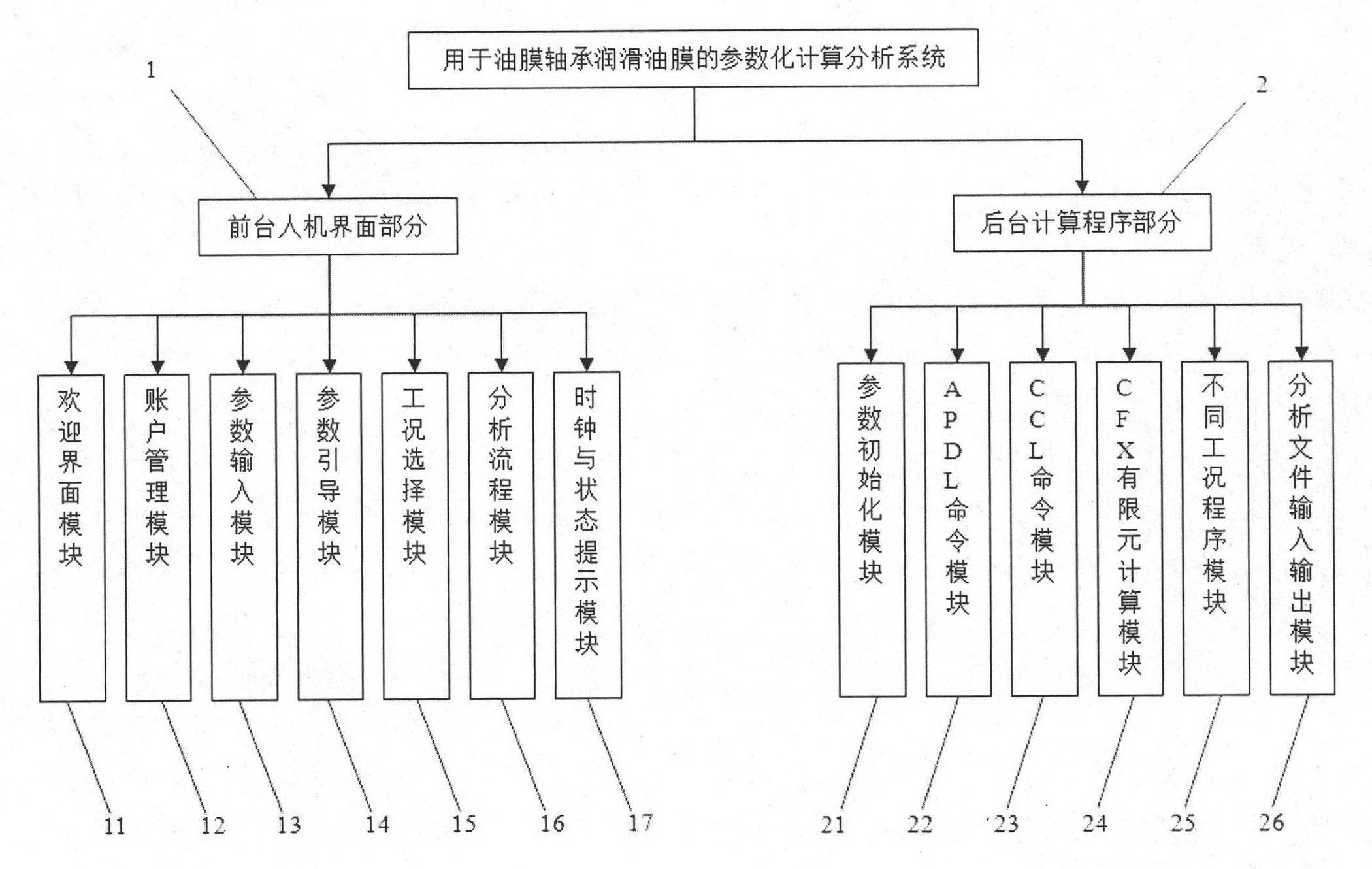

Parameterized computational analysis system for lubricating oil film of oil film bearing and operating method of parameterized computational analysis system

A technology of oil film bearing and analysis system, applied in the direction of calculation, electrical digital data processing, special data processing application, etc., can solve the problem of no oil film bearing, the lack of finite element calculation and analysis of oil film bearing, etc., to achieve good compatibility and strong parameterization Modeling and parametric analysis capabilities, the intuitive effect of finite element calculation and analysis of oil film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] According to the above analysis steps, the following finite element analysis of oil film can be carried out:

[0043] 1. Install ANSYS12.0 under the D disk, copy the system of the present invention to the F disk, and start the analysis.

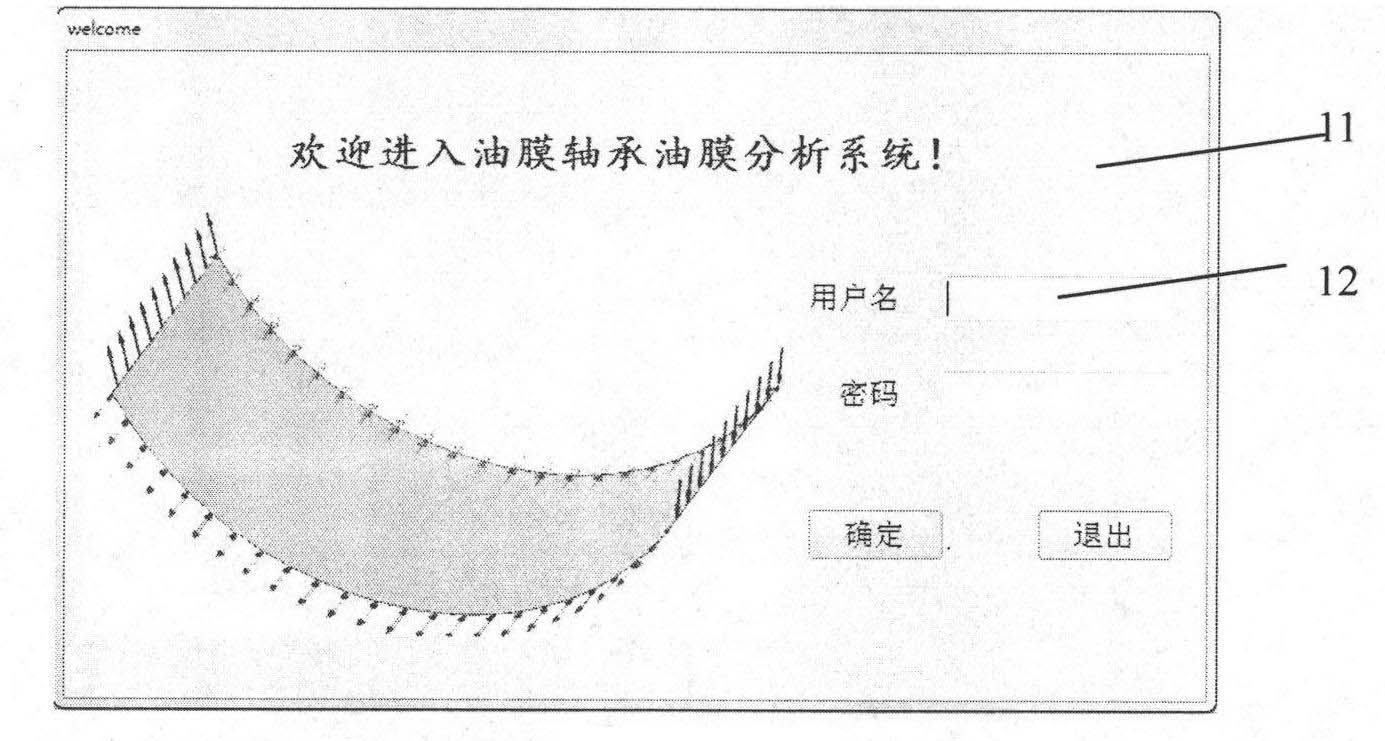

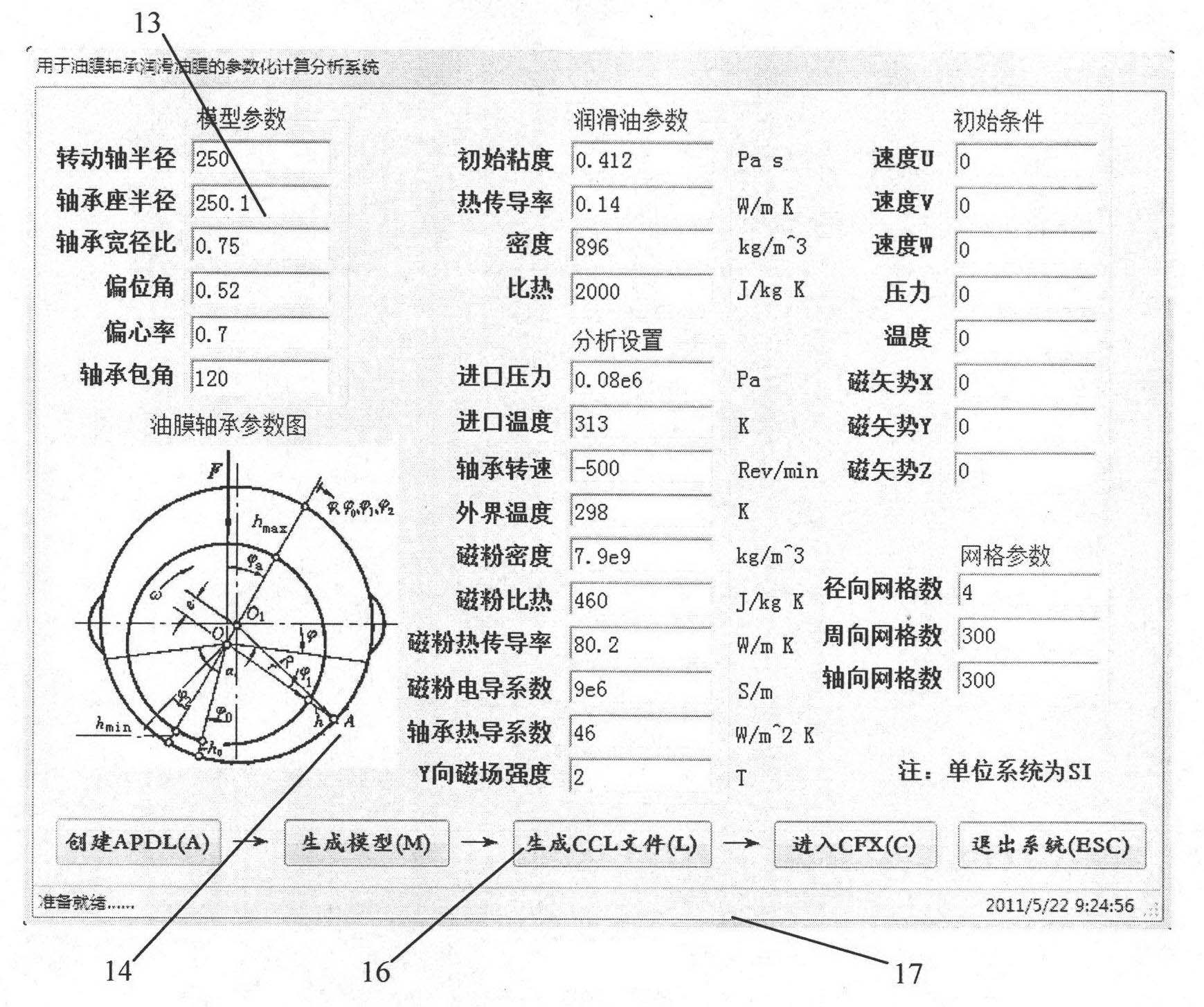

[0044] 2. Run the oilfilm.exe application program to display the welcome interface ( figure 2 ), enter the user name and password, and click the "OK" button to enter the main interface of the analysis system ( image 3 )

[0045] 3. Set the bearing speed to -100rev / min.

[0046] 4. Click the "Create APDL(A)" button to generate the input.dat file in the current directory.

[0047] 5. Click the "Generate Model (M)" button to run ANSYS in the background and pop up the modeling information output window ( Figure 6 ), display the modeling process, and generate the oilfilm.cdb file in the current directory.

[0048] 6. Click the "Generate CCL File (L)" button, select the traditional lubrication analysis, and generate the oilfilm_unmag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com