Online quality detecting parametric analysis method

A technology of quality inspection and parameter analysis, which is applied in the field of online quality inspection parameter analysis, can solve problems such as time-consuming, limited engineer ability, and increased production costs, so as to reduce human judgment errors, improve online production conditions, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

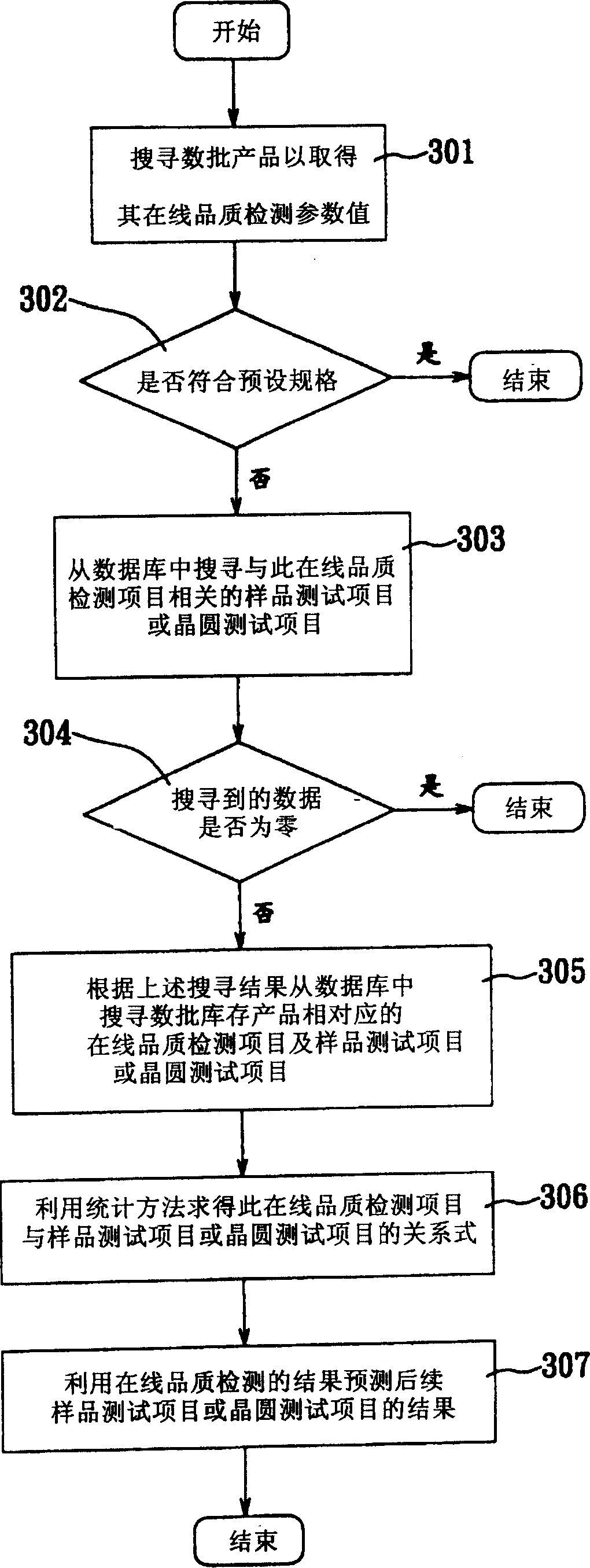

[0041] The method for analyzing online quality detection parameters according to a preferred embodiment of the present invention will be described below with reference to the accompanying drawings, wherein the same components will be denoted by the same reference symbols.

[0042] like image 3 As shown, first, in step 301, according to the online quality detection parameter analysis method of the preferred embodiment of the present invention, several batches of products that have passed the online quality detection and have not passed the sample test and wafer test are searched first, so as to obtain the parameters of these products Each online quality detection parameter value. In this embodiment, the search results in this step can be directly output to the engineer, so that the engineer can obtain relevant information, such as product batch numbers of these products, product manufacturing time, various online quality inspection parameter values, and the like.

[0043]Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com