Hinged applicator for a cosmetic product and associated packaging and application assembly

A technology for applicators and cosmetics, applied in cosmetic powder containers, household packaging, packaging cosmetics, etc., can solve problems such as applicator gaps and reduced applicator service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

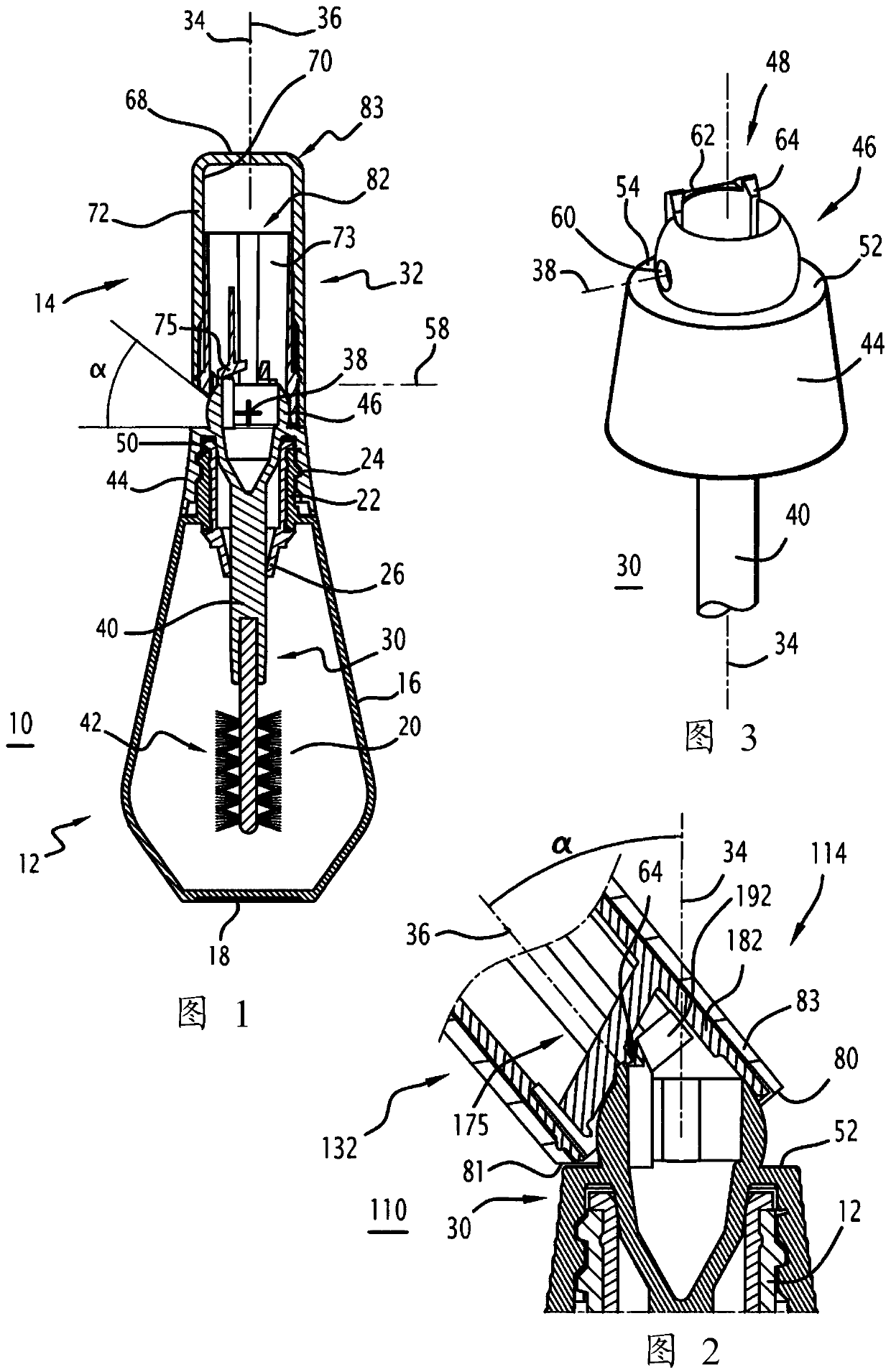

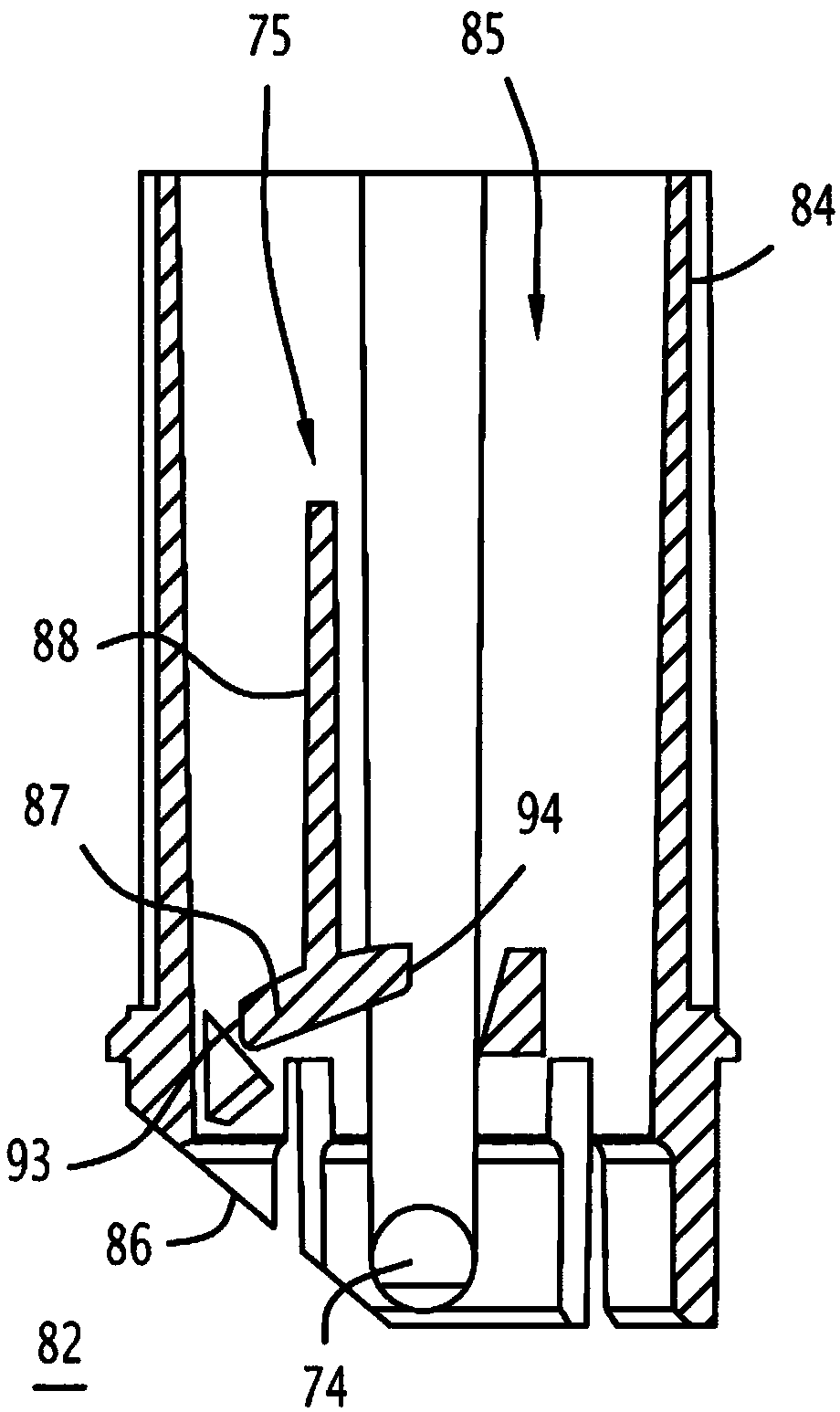

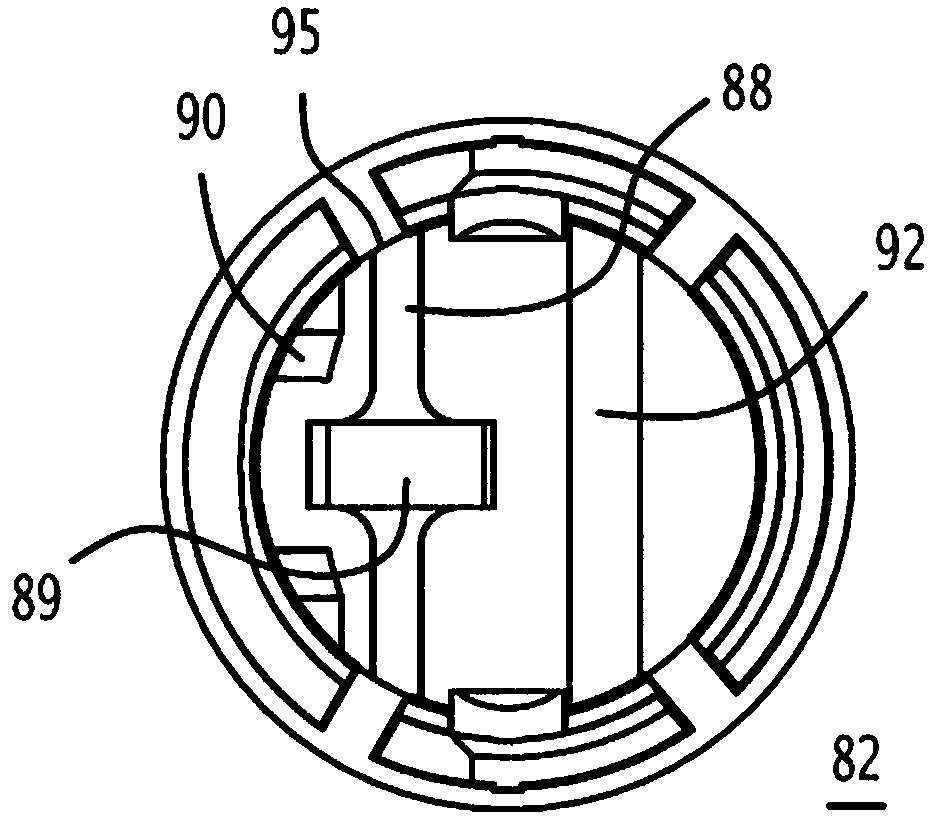

[0033] figure 1 A cosmetic packaging and applicator assembly 10 according to a first embodiment of the invention is shown. figure 2 A cosmetic packaging and applicator assembly 110 according to a second embodiment of the present invention is shown.

[0034] Except for the differences detailed below, assembly 10 and assembly 110 are substantially equivalent and will be described concurrently. Elements common to assembly 10 and assembly 110 are denoted by the same reference numerals.

[0035] Assembly 10, 110 is particularly useful for packaging and applying mascara. Assembly 10 , 110 includes, inter alia, container 12 and applicator 14 , 114 .

[0036] exist figure 1 visible in and in figure 2 The container 12 shown in the middle part notably comprises side walls 16 and a bottom 18 defining an internal volume 20 adapted to receive a cosmetic product, in particular a liquid mascara type composition.

[0037] The container 12 further comprises a tubular shaped neck 22 the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com