Multifunctional garbage processor and operation method thereof

A garbage disposer and multi-functional technology, applied in the field of kitchen appliances, can solve problems such as affecting the crushing effect, retaining impurities, reducing user experience, etc., and achieving the effect of avoiding jamming and burning, prolonging service life and improving crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

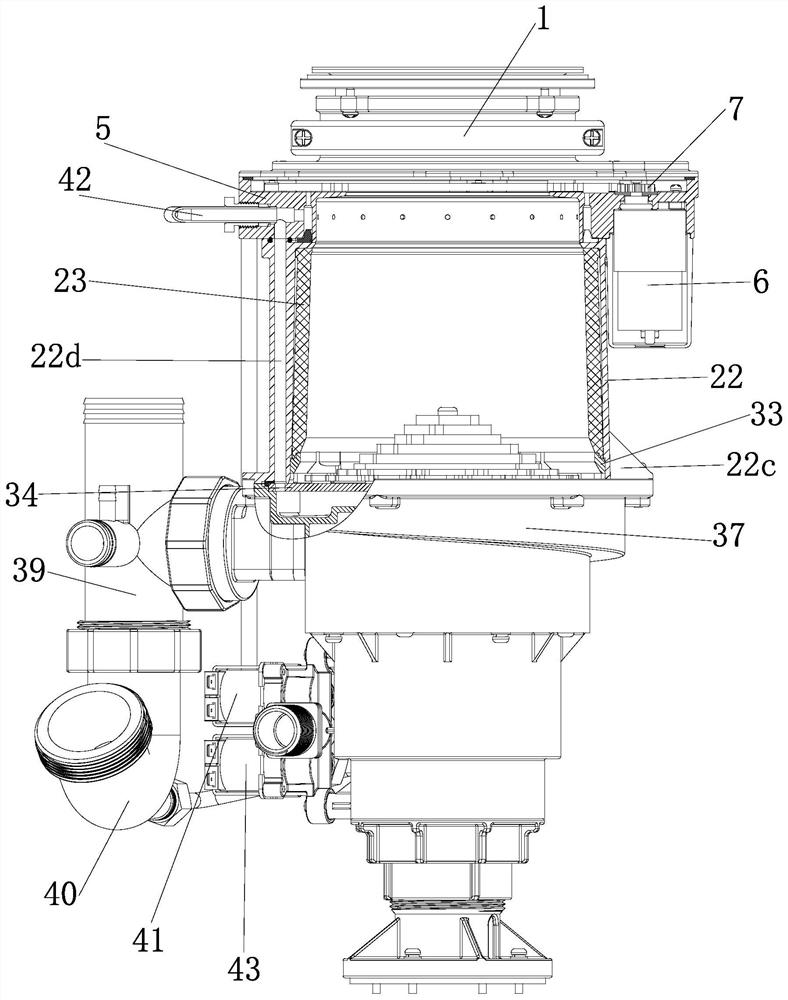

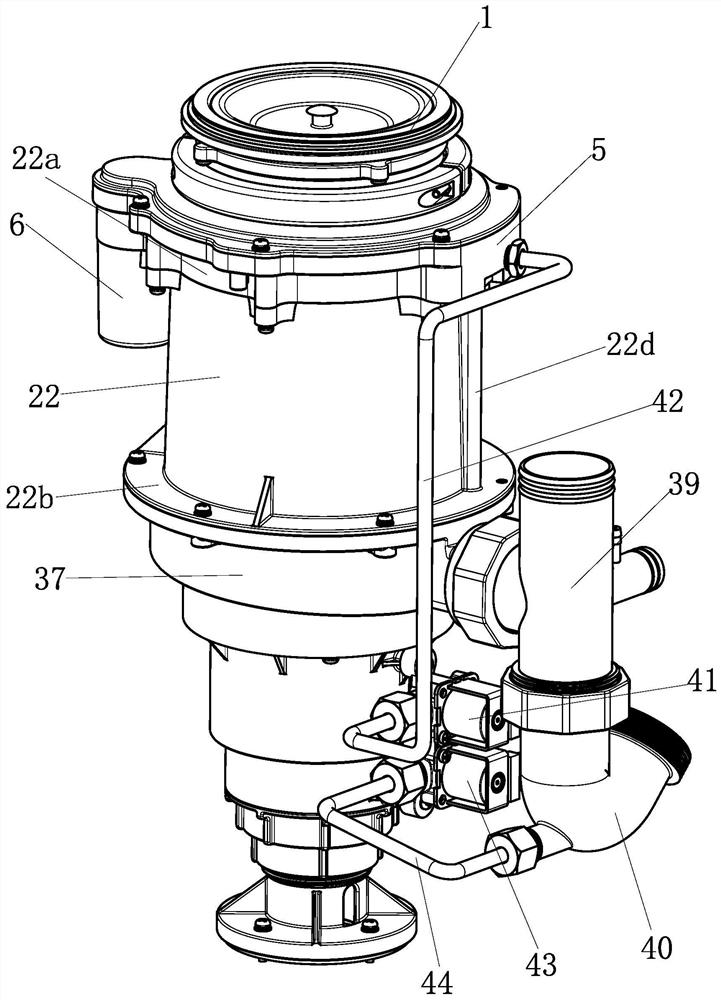

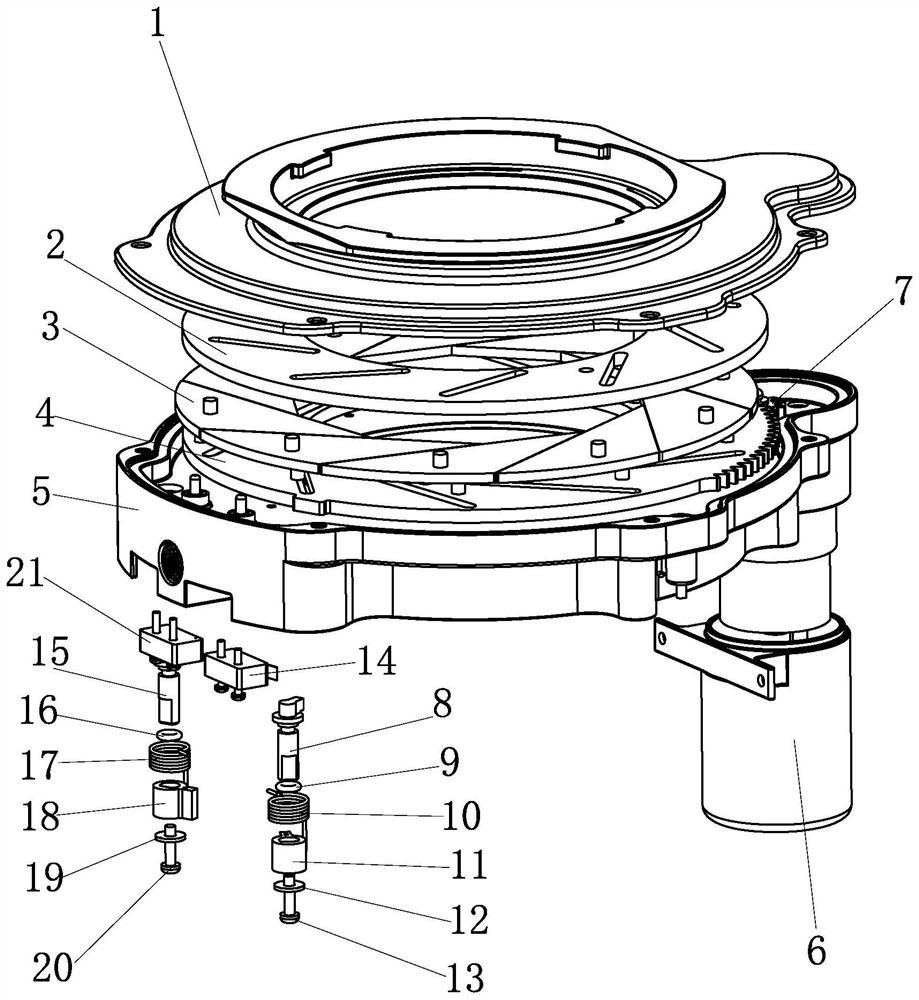

[0064] Such as Figure 1 to Figure 15 As shown, this multi-functional garbage disposer includes an opening and closing mechanism, a crushing cylinder 22 and a drainage cylinder 37 from top to bottom, and also includes a water inlet mechanism. A silent crushing mechanism is arranged in the crushing cylinder 22. An upper flange 22a is provided, and several mounting holes are provided on the upper flange 22a. A lower flange 22b is arranged on the lower periphery of the crushing cylinder 22, and several mounting holes are provided on the lower flange 22b. The lower flange 22b and the wall of the crushing cylinder 22 Several triangular reinforcing ribs 22c are fixedly connected between them. The upper flange 22a of the crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com