Drilling machine-free self-balancing rotary vibration coupling rock crushing drilling system

A self-balancing, rig-less technology, used in vibration drilling, in-hole drilling driving devices, drill pipes, etc., can solve the problems of low transmission efficiency of strong and weak currents, reduce the risk of being stuck, control the Ease of effect, improved reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

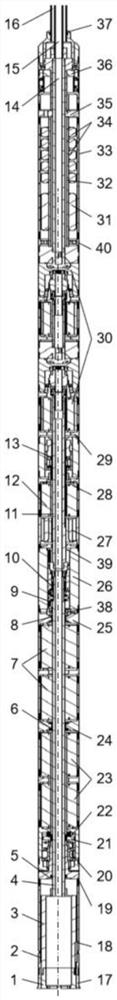

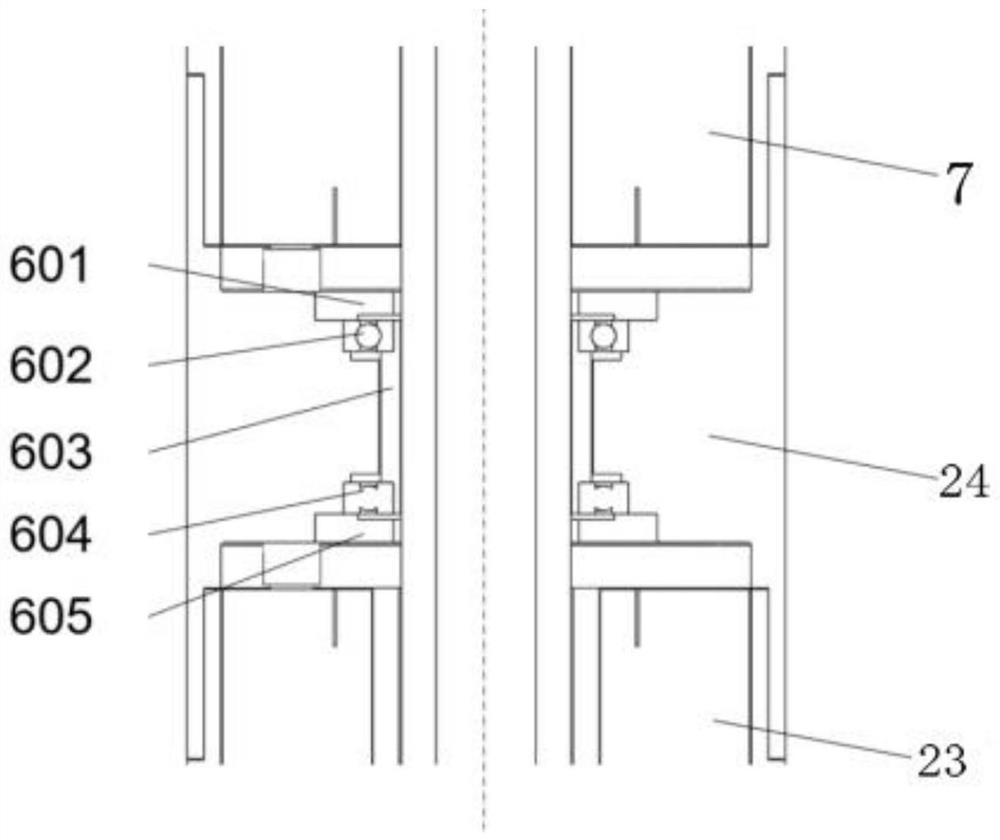

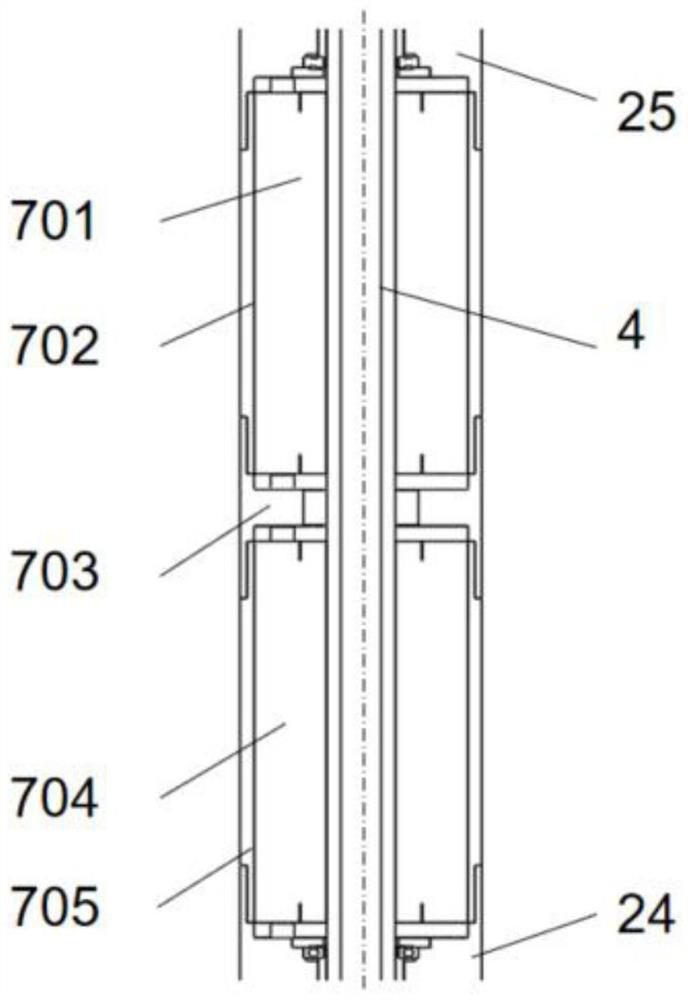

[0040] see Figure 1 to Figure 11 As shown in the figure, the self-balancing rotary vibration coupling rock-breaking drilling system without drilling rig, the drilling system includes inner and outer drill bit centering oil-free bearings 2, inner drill bit rotary lower seal 5, inner drill bit lower guide mechanism 6, inner drill bit upper guide Mechanism 8, high frequency vibrator of inner drill bit 9, pressure transmission and torsion isolating mechanism of inner drill bit 10, inner drill bit shaft 11, drilling fluid transition shaft 14, cable drilling fluid tube 15, cable tube outer tube 16, outer drill bit pressure transmission insulation Torsion mechanism 20, high frequency vibrator of outer drill bit 21, joints of inner and outer drill bit motor unit 24, upper joint of rotary motor unit of inner drill bit 25, pressure transmission and torsion isolation mechanism of inner drill bit and high frequency vibrator cavity 26, WOB distribution circumferential limit Position compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com