Triple grinding mechanism of garbage disposer

A technology of garbage disposer and grinding mechanism, which is applied in grain processing, indoor sanitary plumbing installations, water supply installations, etc. It can solve the problems of affecting the service life, jamming and clogging of the cutter head, loosening of the crushing knife assembly, etc., and achieves improved fixity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

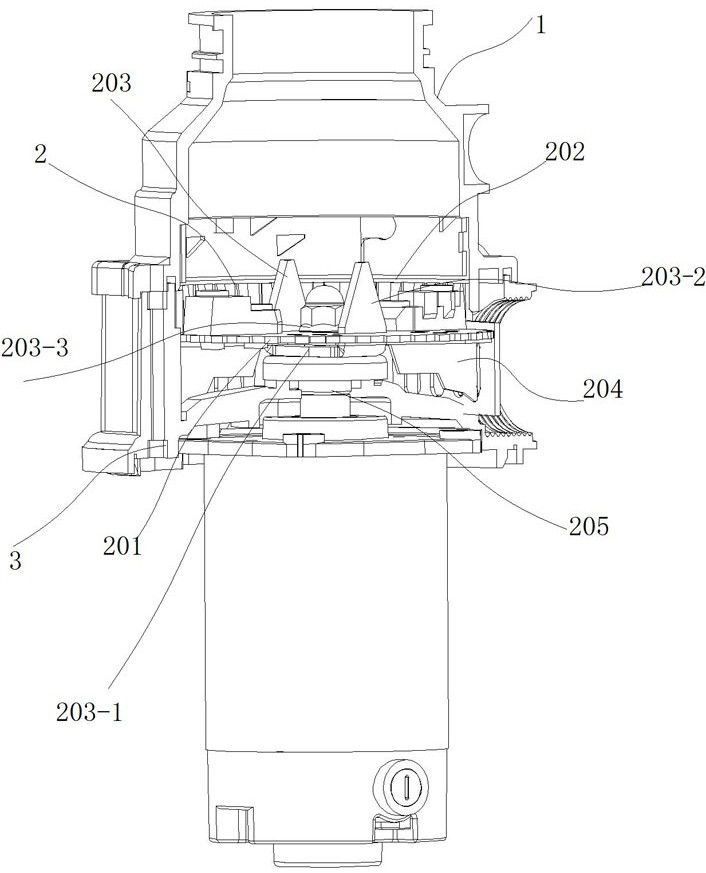

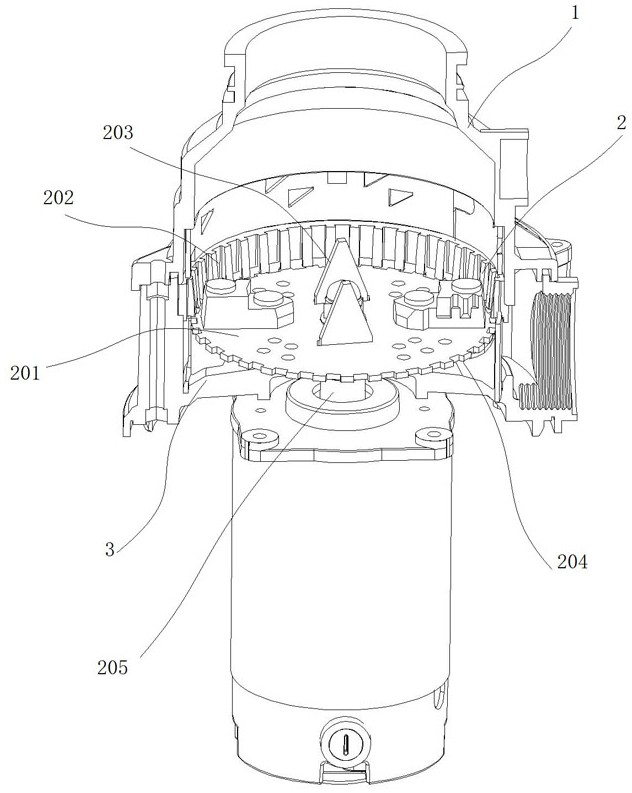

[0025] Example 1: A waste processor triple grinding mechanism comprising grinding the cavity 1, a grinding unit 2, and a ground cavity 3, and the ground cavity 1 is disposed on the upper end of the ground cavity 3 and passes through it. The bolt is fixed, and the grinding cutting unit 2 is sleeved in the inner end of the grinding cavity 1, and the abrasive cutting unit 2 is connected to the inner end of the grinding chamber 3; the abrasive cutting unit 2 includes triple grinding The cutter disc assembly 201, a triple grinding ring gear assembly 202, a broken strobe assembly 203, a cutting knife 204, and the triple grinding cutter disc assembly 201 is provided in the inner end of the triple grinding ring gear assembly 202, the broken knife assembly 203 rotation socket The motor drive shaft 205 is disposed on the upper end of the triple grinding blade assembly 201, the cutting knife 204 rotates the motor drive shaft 205 and is provided at the end end of the triple grinding tool disc...

Embodiment 2

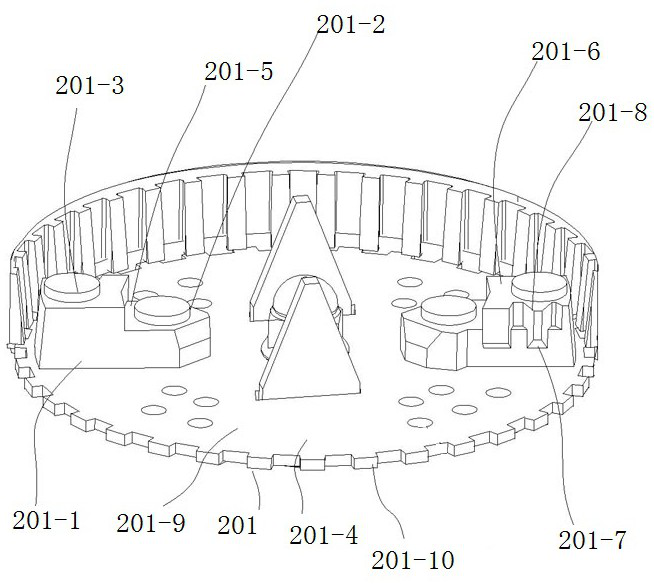

[0026] Example 2: The triple grinding cutter disc assembly 201 includes a pulverizer head member 201-1, a mounting hole 201-2, a fixing member 201-3, and a cutting hole 201-4, and a fixed hole 201-2 Components 201-3, the cutting tool head member 201-1 is fixedly connected by the fixing member 201-3; the pulverizer head member 201-1 is provided with two parts, including the grinding step 201- 5 and Grinding Parts 201-6, the grinding tooth portion 201-6 is provided in the positioning groove 201-7 of the polishing step portion 201-5, and the corner of the grinding step 201-5 is protruding Prismatic structure, the grinding gear portion 201-6 is provided with a grinding projection 201-8, the cutter disk member 201-4 includes a cutter disk 201-9 and a grinding projection 201-10, the cutter disk The outer edge is provided with grinding projections 201-10, and the remaining technical solutions are identical to the examples.

Embodiment 3

[0027]Example 3: The triple grinding ring gear assembly 202 includes a grinding ring gear body 202-1, a triple abrasive assembly 202-2, and the inner wall fixing is provided with a triple abrasive assembly 202-2, and the triple grinding. Components 202-2 include four parts, and one end is provided with a rectangular positioning unit 202-3, and the rectangular positioning portion 202-3 is provided with the grinding ring gear body 202-1, the rectangular positioning portion 202-3 At least one of the grinding projections 202-4 are provided in parallel, the grinding projection 202-4 is provided with a trapezoid abrasive portion 202-5, and the grinding bumps 202-4 and trapezoidal grinding. The portion 202-5 is provided in parallel, and the grinding projection 202-4 and the trapezoidal abrasive portion 202-5 are provided with a polishing cavity groove 202-6, and the remaining technical schemes and examples are provided. One or two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com