Filter part of vertical compressor and vertical compressor

A technology of filter components and compressors, which is applied in the field of compressors, can solve problems such as easy access and pump body jamming, and achieve the effects of reducing abnormal wear and noise, simple structure, and easy promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

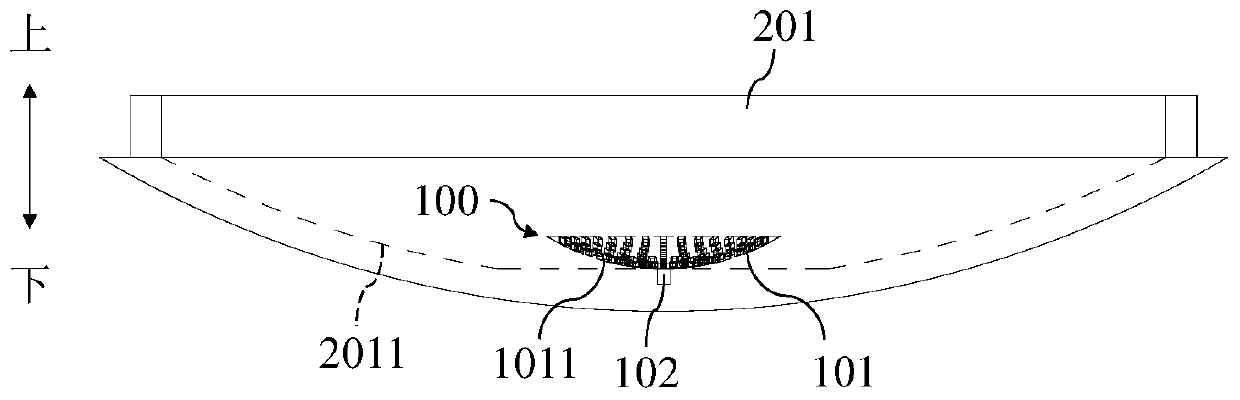

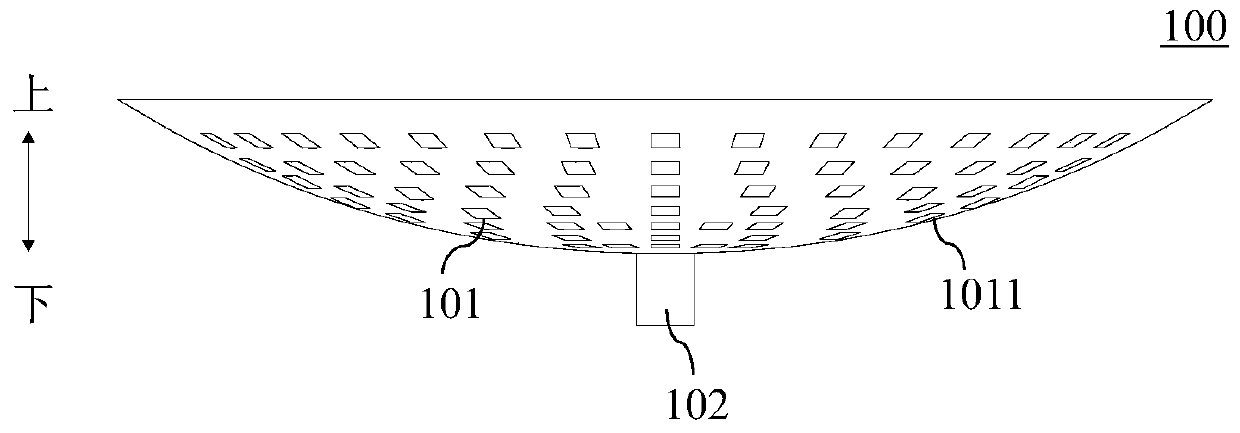

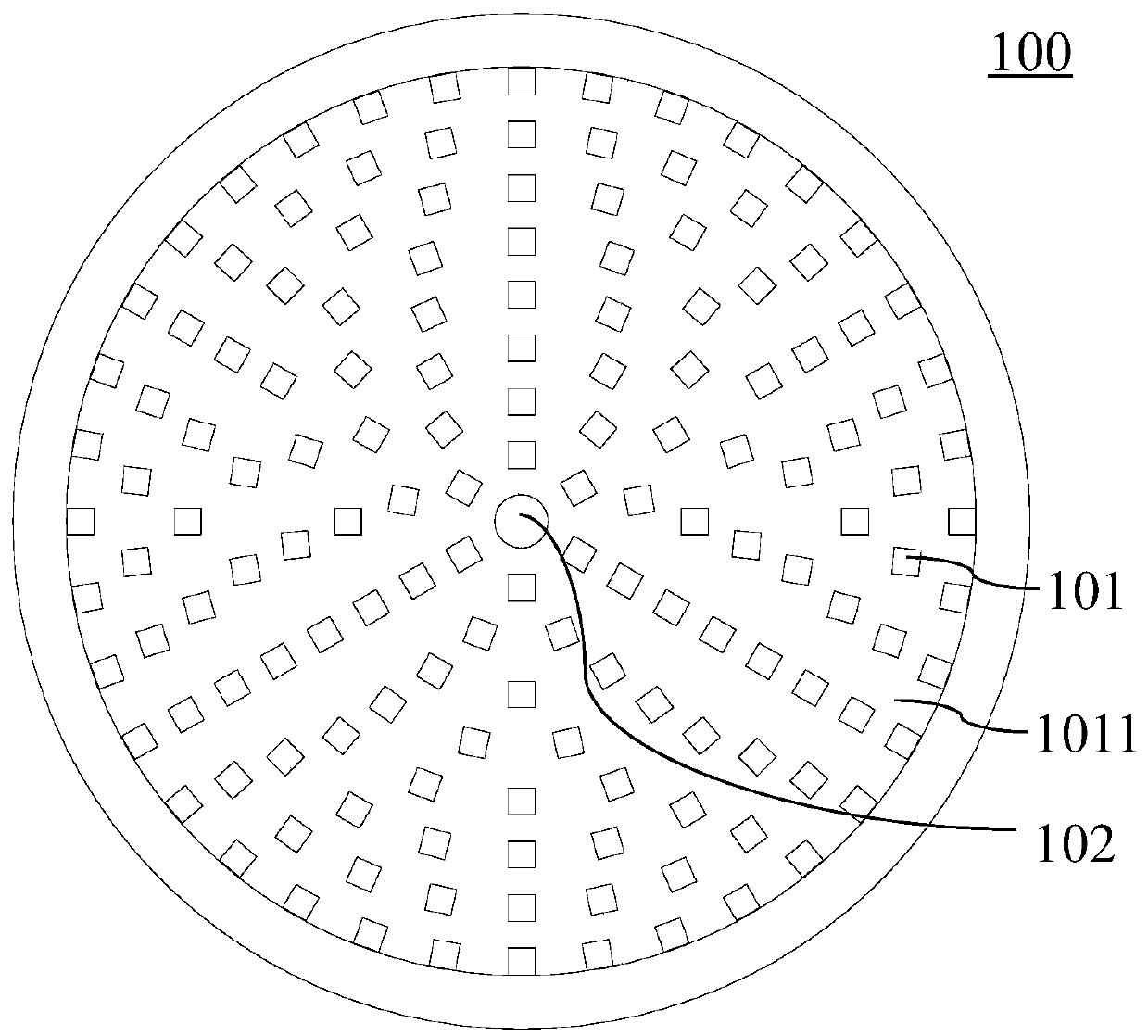

[0022] figure 1 Schematically shows the lower end cover of the vertical compressor and the filter component of the vertical compressor according to the embodiment of the present invention; figure 2 It is the front view of the filter part of the vertical compressor of the embodiment of the present invention; image 3 It is a top view of the filter component of the vertical compressor according to the embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, the filter component 100 of the vertical compressor includes a filter screen 101, the filter screen 101 is connected with the lower end cover 201 of the vertical compressor, and forms a space between it and the lower end cover 201, so that the filter screen 101 can be placed in the vertical The impurity in the flowing oil is intercepted in the compressor and forced to store in the space. Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com