Novel structure three-dimensional woolen fabric and weaving method thereof

A technology of three-dimensional fabric and new structure, applied in the direction of fabric, knitting, weaving, etc., can solve the problem that a single fabric structure cannot meet the needs of use, and achieve the effect of realizing designability, ensuring continuity, and reliable fabric structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

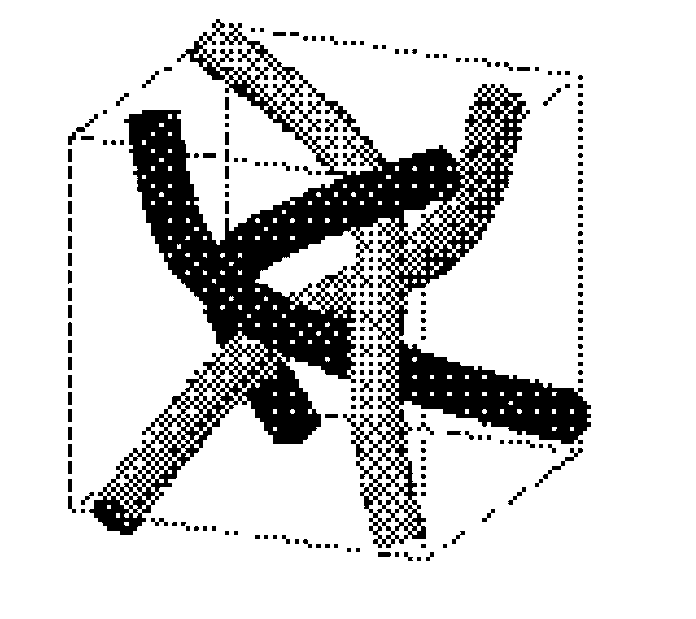

[0028] Example 1: The fabric adopts a new structure combining a three-dimensional four-way structure and a 2.5D shallow cross-bending structure.

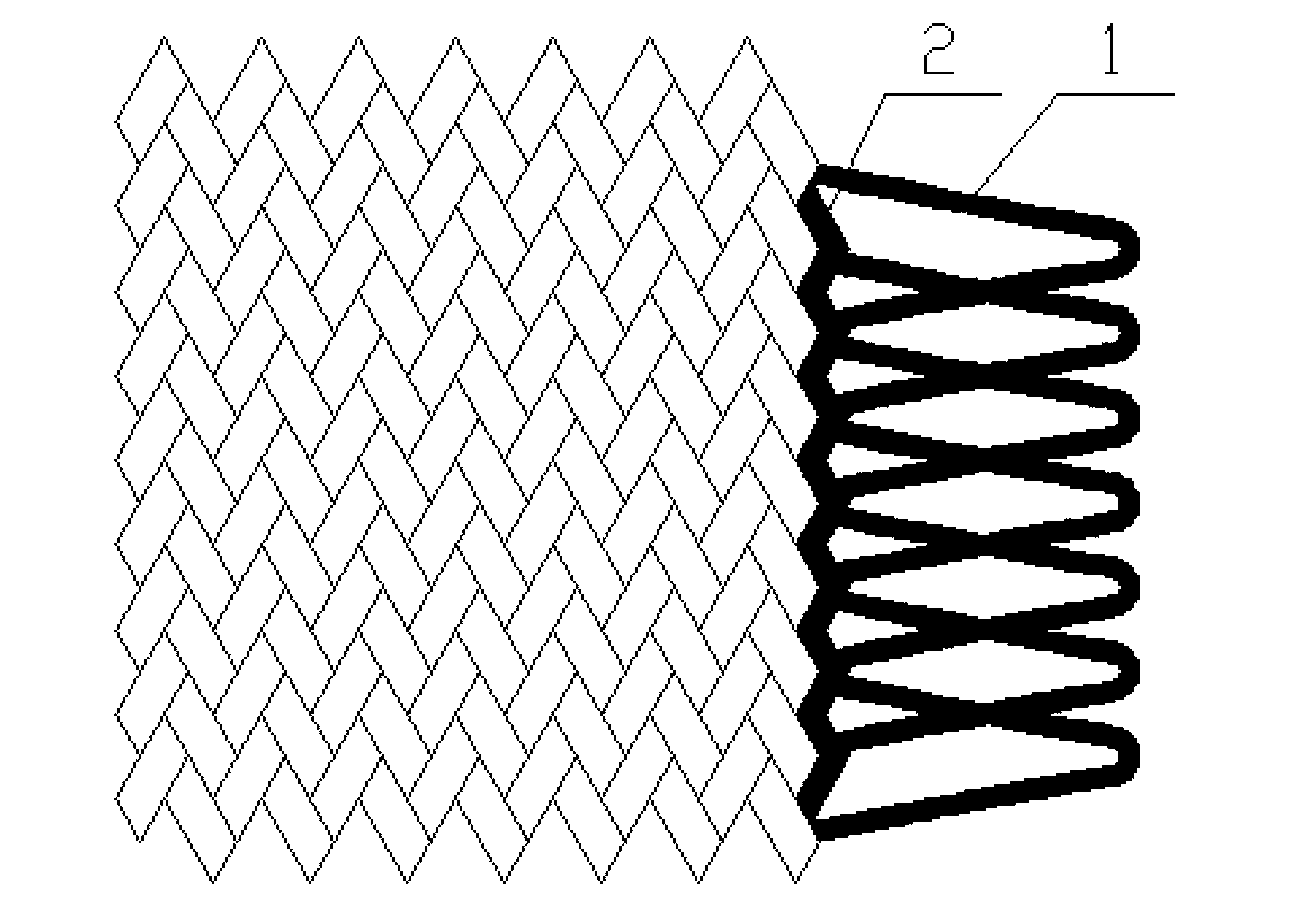

[0029] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the three-dimensional fabric of the new structure of the present invention takes 3K fiber as a raw material, weaves 100mm * 100mm * 20mm flat fabric as an example, first adopts four-step three-dimensional weaving process, first weaves a section of 100mm * 50mm * 20mm fabric, according to 2.5D shallow The warp length of cross-bending structure requires fiber reserve weaving. When the fiber moves to the right side of the fabric (set as the reserved fiber side), the length of the reserved fiber is greater than 60mm, the number of strands is one, and the number of strands is 250, and then they are woven into the fabric to reach the designed fabric size. Weave another piece of fabric to complete the three-dimensional and four-way structure part of the new stru...

Embodiment 2

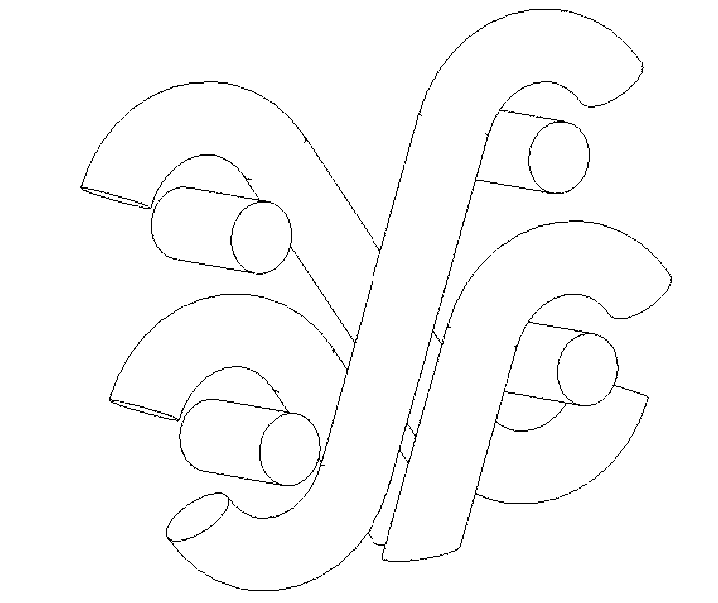

[0031] Example 2: The fabric adopts a new structure combining a 2.5D shallow cross-bending structure and a three-dimensional five-directional structure.

[0032] refer to figure 2 , Figure 6 , Figure 7 , the new structure of the present invention three-dimensional fabric 3K fiber one fiber as a raw material, weaving 100mm * 100mm * 20mm flat fabric as an example, first according to the 2.5D shallow cross-bending structure forming process to complete the weaving of 2.5D shallow cross-bending structure in the fabric, weaving Fabric size 100mm×50mm×20mm, reserve warp yarn, one fiber, 90mm long, 250 pieces.

[0033] According to the design requirements, the formed 2.5D shallow cross-bending structure fabric is fixed, and then the reserved fiber in the 2.5D shallow cross-bending structure is used as the weaving yarn, and part of the weaving yarn is added or directly woven according to the volume density of the fabric. For example, if the volume content is 45%, it is necessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com